Patents

Literature

60results about How to "High degree of engagement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

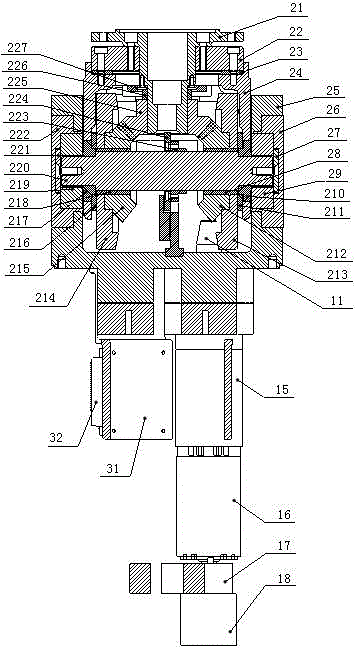

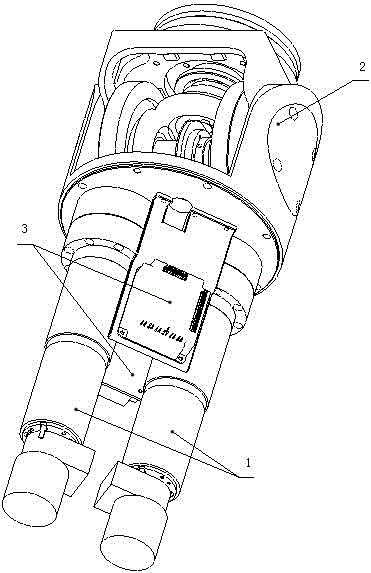

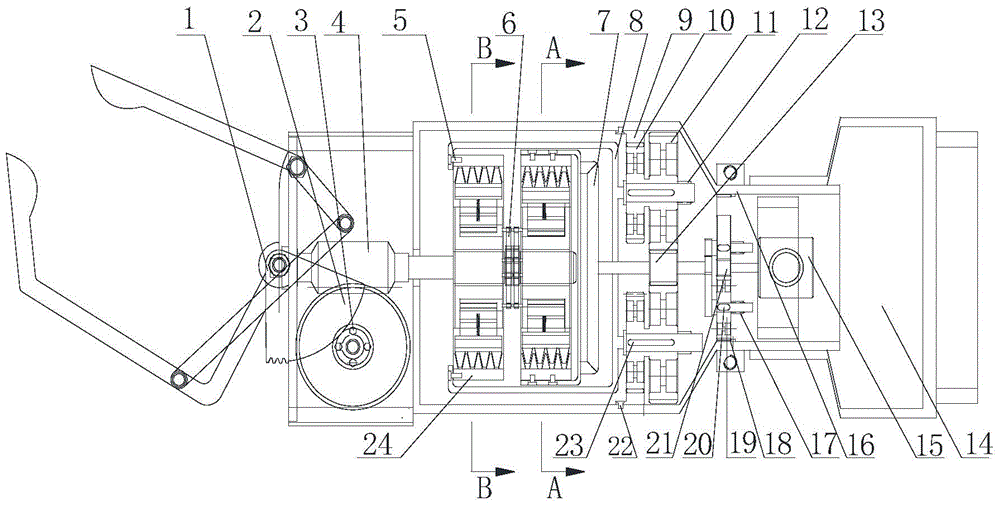

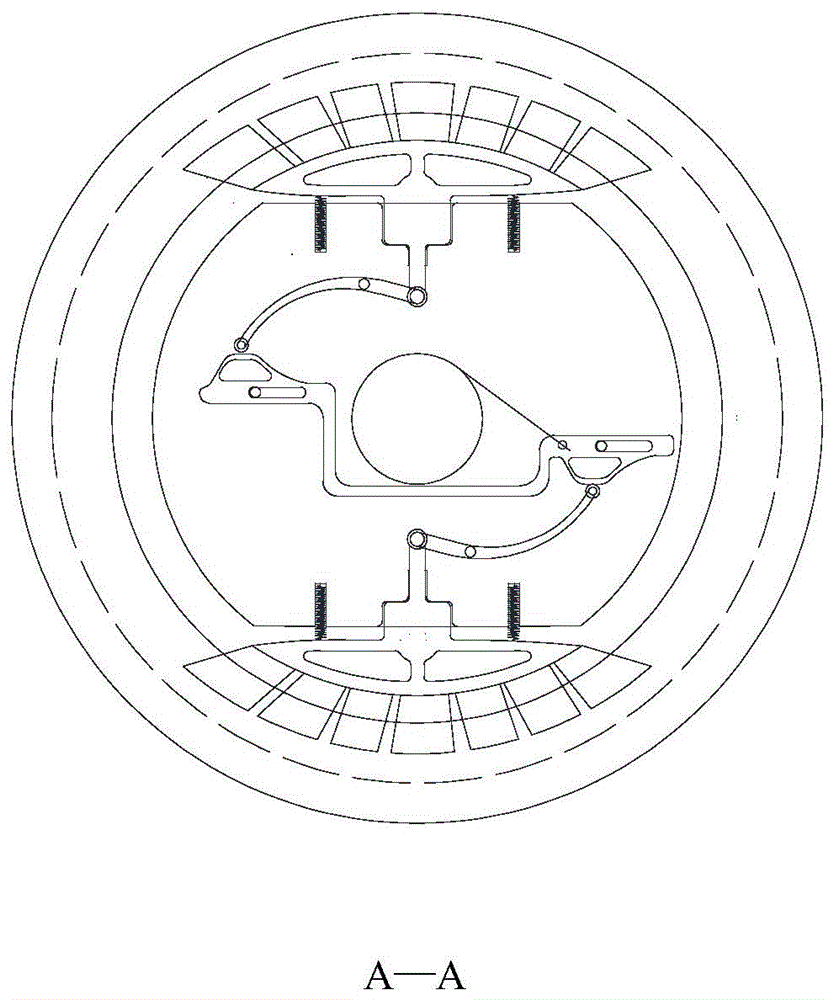

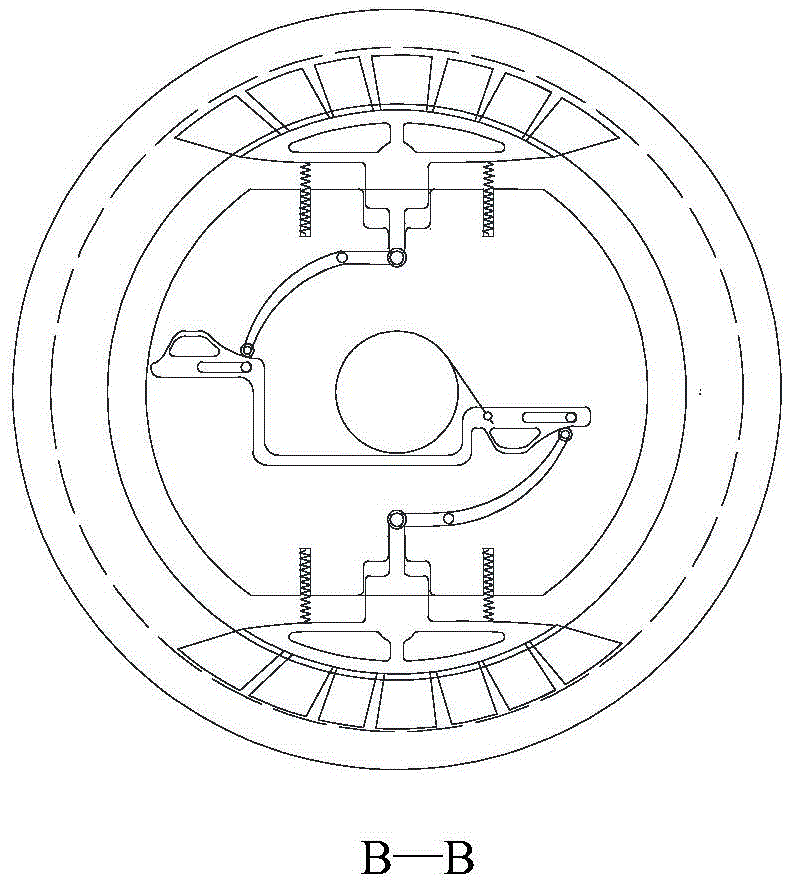

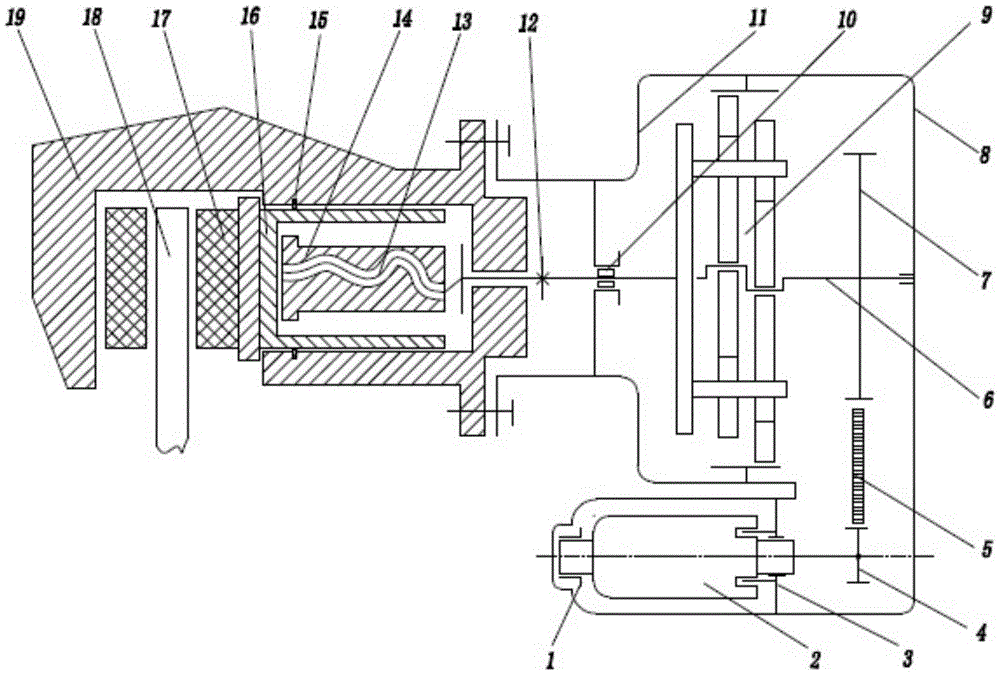

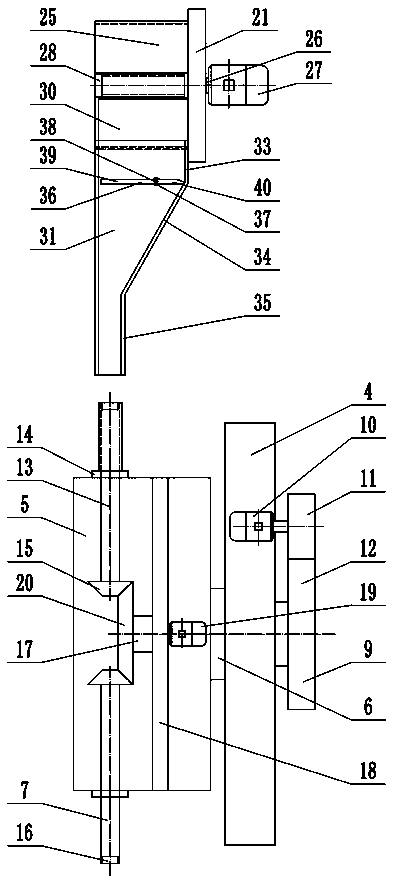

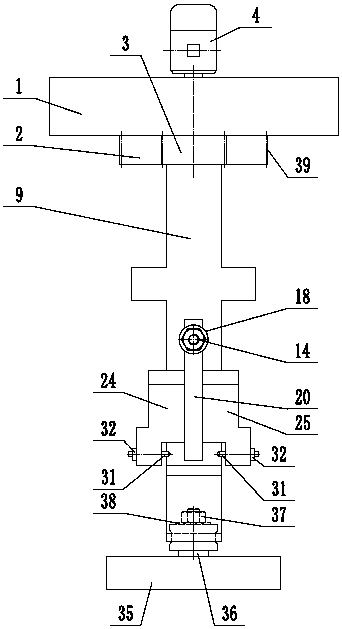

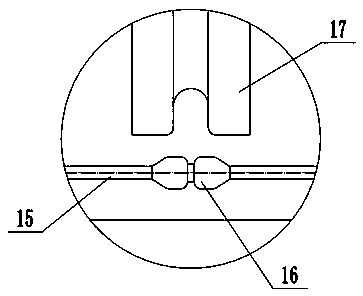

Two-degree-of-freedom joint of space robot

The invention discloses a two-degree-of-freedom joint of a space robot. The two-degree-of-freedom joint comprises two joint driving assemblies and a joint transmission assembly. Two-degree-of-freedom movement of the joint can be achieved. Three movement modes of pitching, rotating and combining of pitching and rotating can be achieved by adjusting the rotating speeds and the rotating angles of two motors. The joint transmission assembly is a differential movement mechanism formed by two input bevel gears and an output bevel gear. The two input bevel gears are fixedly connected with corresponding hypoid gears respectively, and an output flange is fixedly connected with the output bevel gear. First-stage speed reduction is carried out on the torque of the motors through planetary reducers connected with the motors, then second-stage speed reduction is carried out through the hypoid gears, and finally the torque is transmitted to the output end through the bevel gear differential mechanism. As the reduction ratios of two stages of speed reduction are large, the output torque of the mechanism is large, and the high load capacity is achieved.

Owner:SHANGHAI AEROSPACE SYST ENG INST

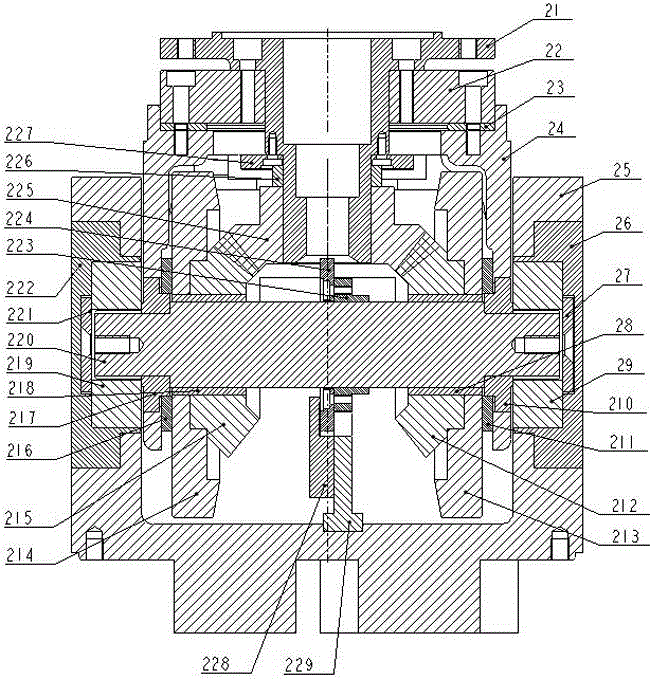

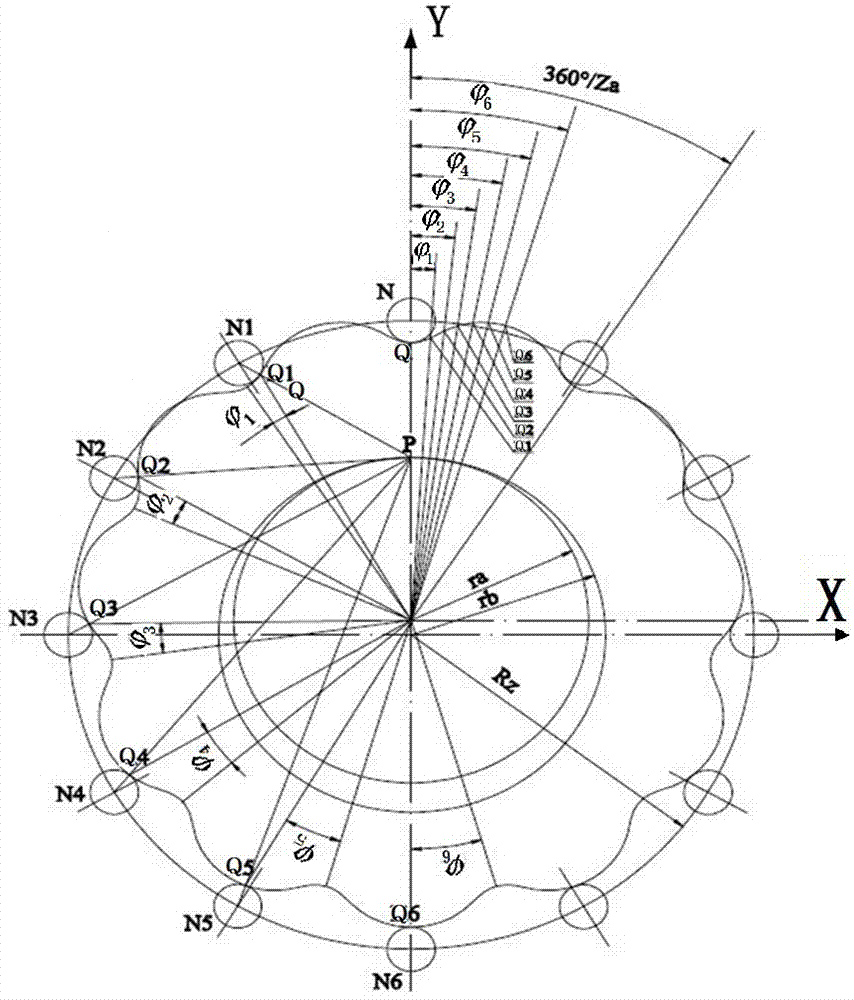

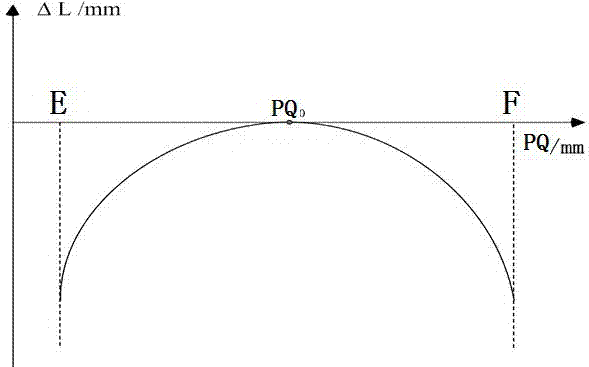

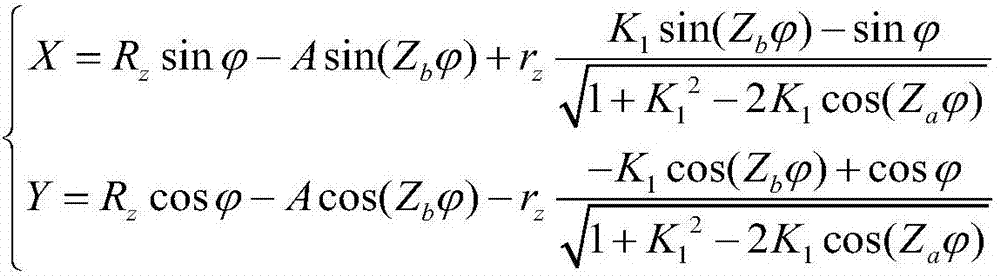

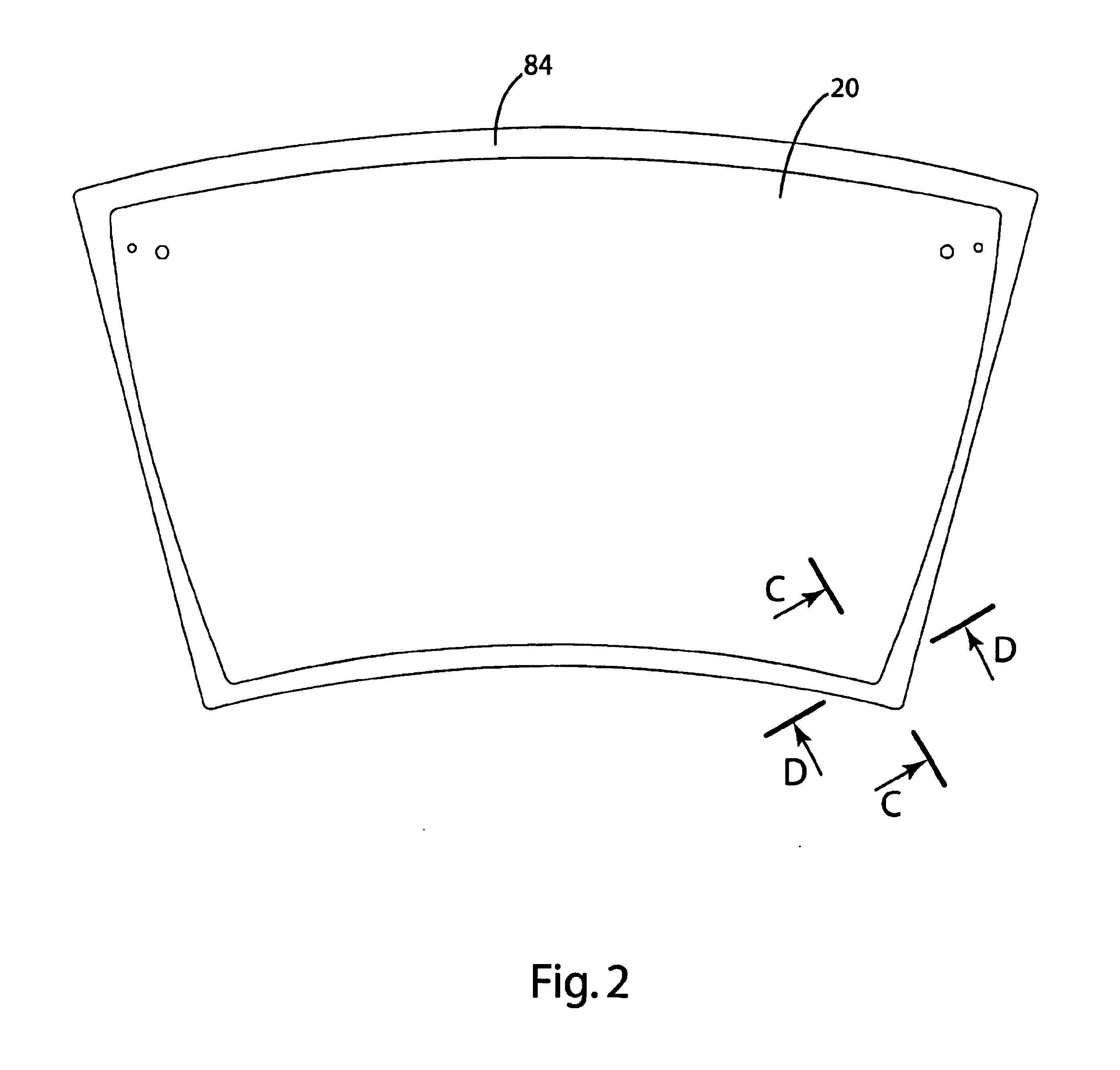

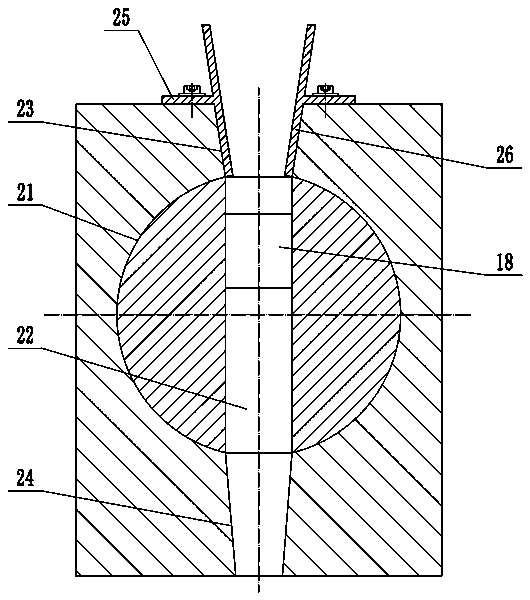

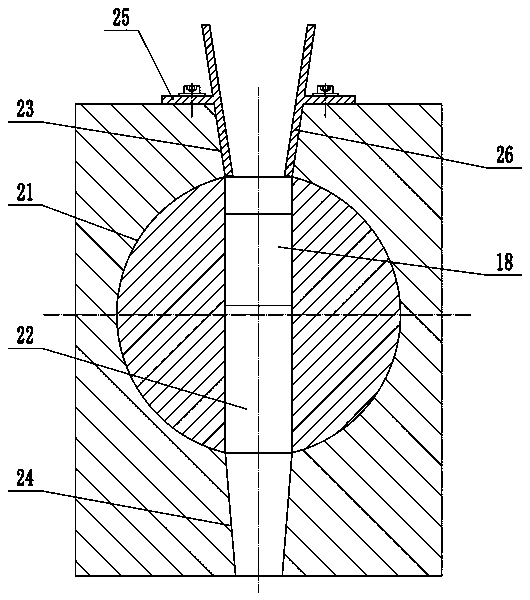

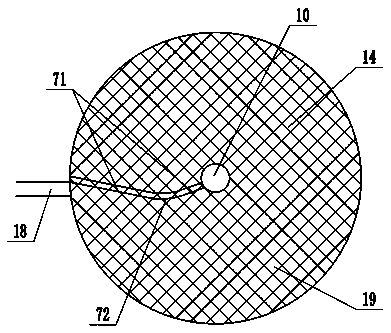

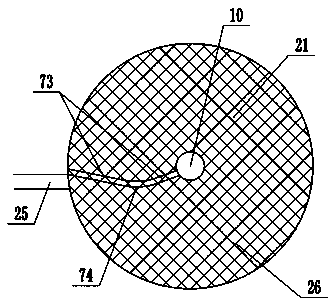

Cycloidal gear tooth profile correction method, cycloidal gear and RV (rotary vector) reducer

InactiveCN107229836ASmall amount of modificationHigh degree of engagementInformaticsSpecial data processing applicationsReducerGear tooth

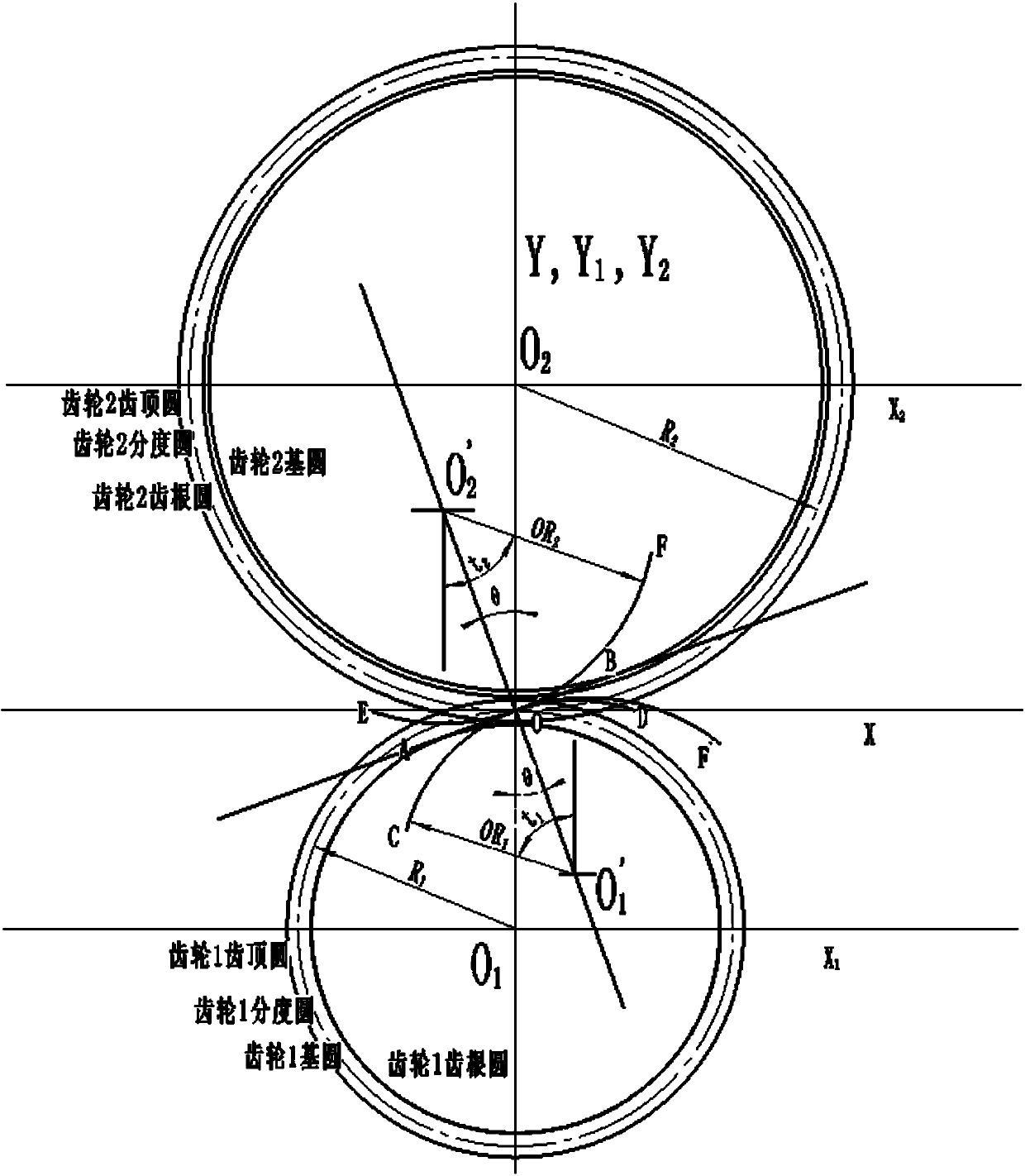

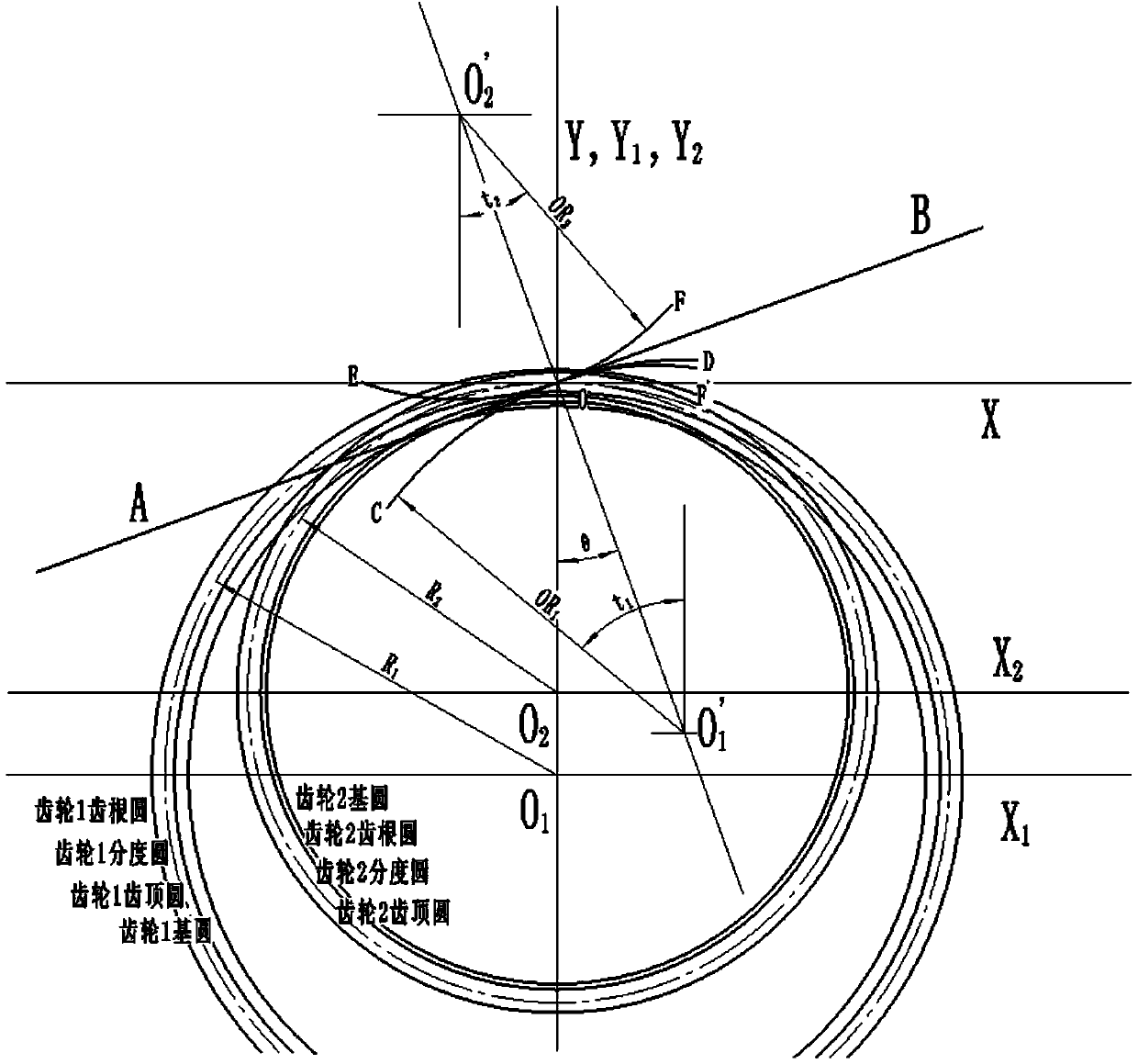

The invention relates to the field of processing of cycloidal gears, in particular to a cycloidal gear tooth profile correction method, a cycloidal gear and an RV (rotary vector) reducer; a main operating area of each tooth of the cycloidal gear is located mainly between the root and crest of the tooth close to its middle, and the root and crest are non-principal operating areas. The method of the invention imparts a second-order or higher-order parabolic relationship the correction amount of the tooth profile and a normal distance from a standard cycloidal gear node to a meshing point of a standard cycloidal gear and pin wheel, the correction amount decreases gradually from the crest and root to the middle main operating area, a certain meshing clearance is generated in the non-principal operating areas and forms a lubricating clearance, and the main operating area has small correction amount so that it is ensured that the main operating area attaches to the standard cycloidal gear tooth profile to the maximum extent; during transmission in no-load state, only one pair of teeth are involved in meshing transmission; after loading, the cycloidal gear and the pin wheel deform slightly under stress, multiple pairs of teeth are involved in meshing, meshing contact ratio is increased, and the transmission is more stable.

Owner:HENAN UNIV OF SCI & TECH

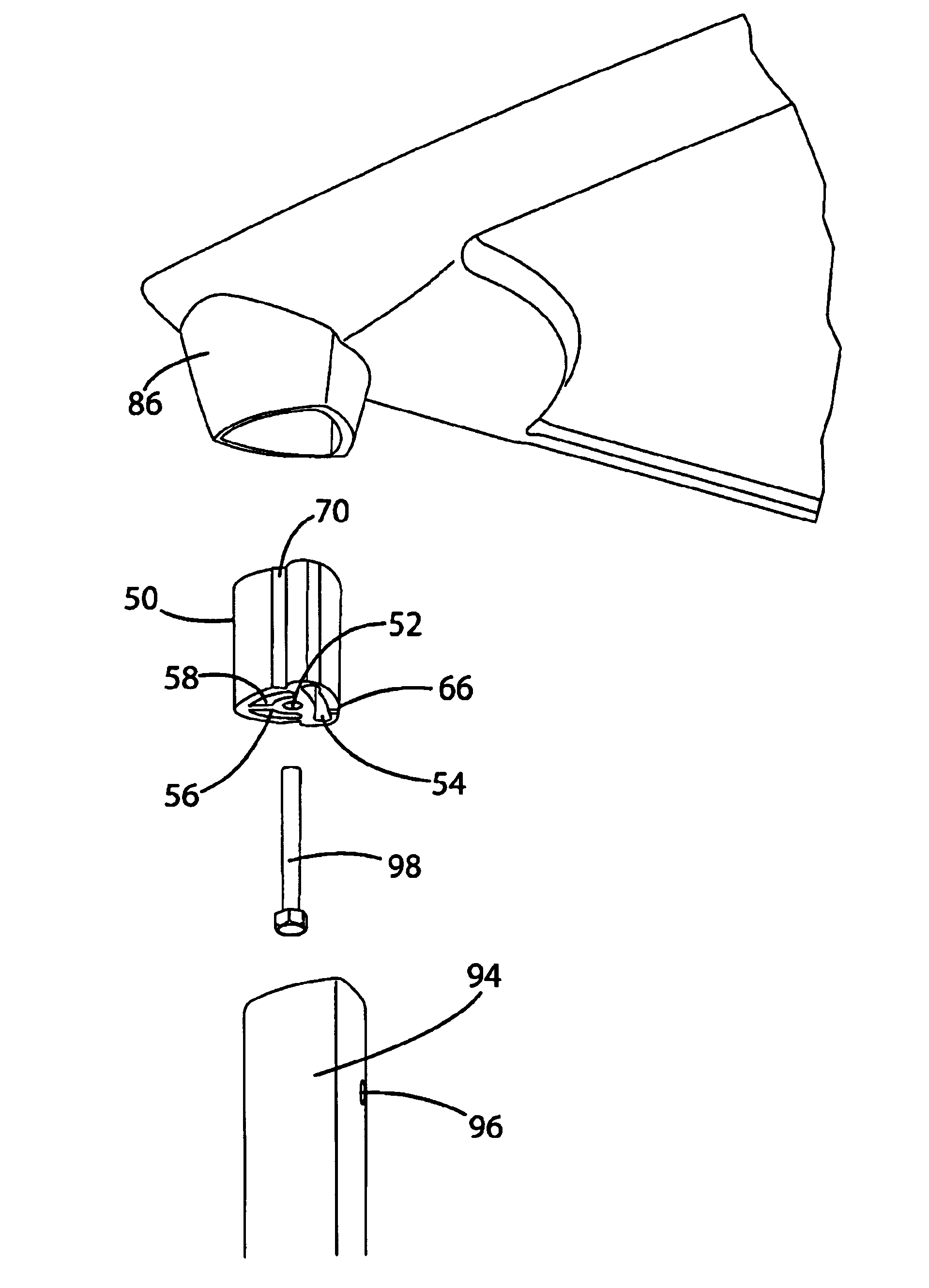

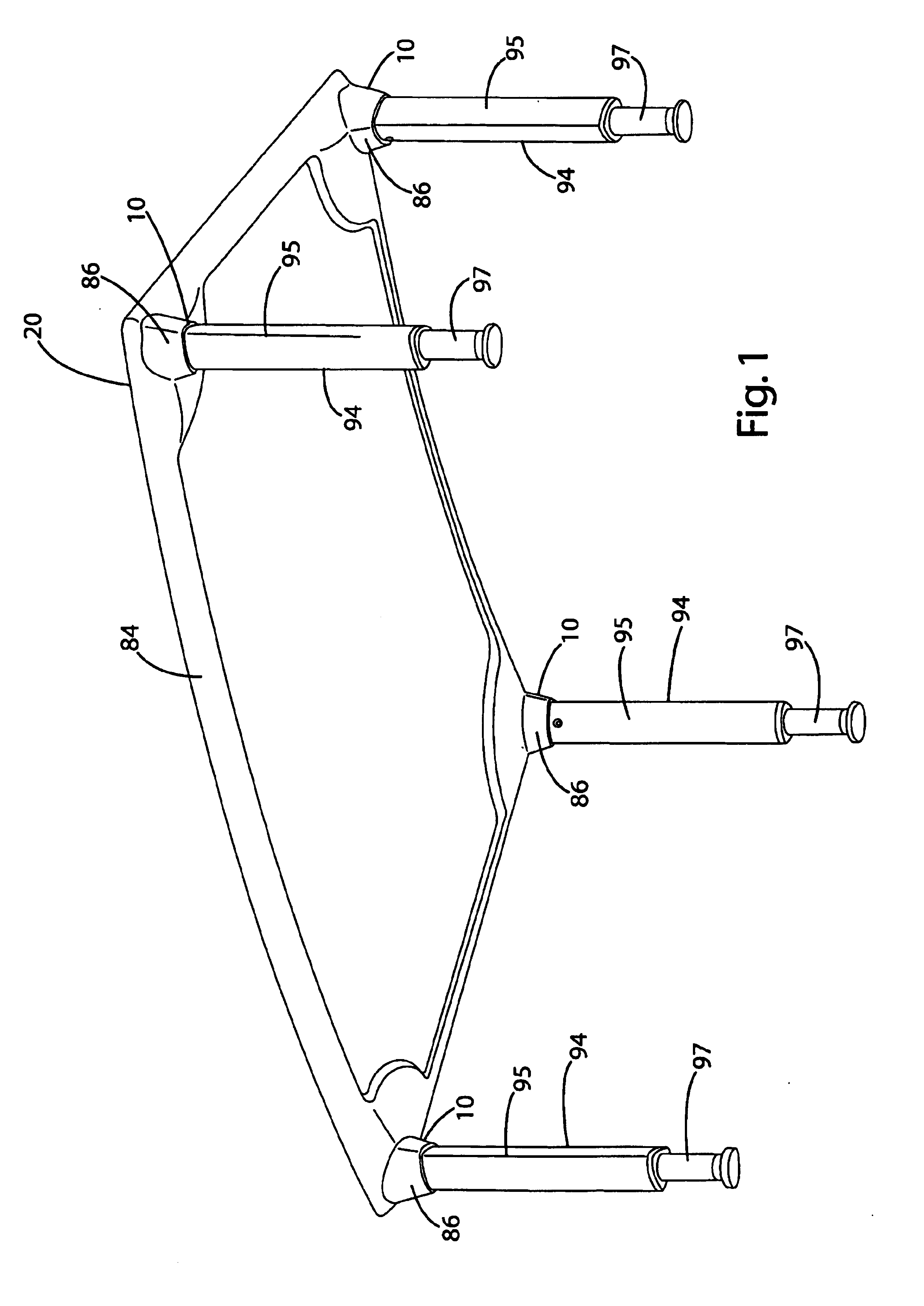

Leg attachment and method for manufacturing same

InactiveUS6925945B2High degree of engagementReduce effectFoldable tablesStands/trestlesEngineeringSet screw

A leg attachment mechanism and a method of manufacture for an article of furniture including a bracket attached to the article of furniture and an expandable post attached to the bracket. The leg includes a receptacle of sufficient dimension to receive the post. The leg is attached to the post by fitting the receptacle over the post and then expanding the post to forcefully engage the walls of the leg defining the receptacle. The post preferably includes a flexible wall that is movable outwardly by rotation of a threaded element, such as a set screw. A foam overmold is preferably formed over the edge of the article of furniture and the bracket. The overmold preferably includes an undercut boot that closely receives upper end of the leg.

Owner:JSJ FURNITURE CORP

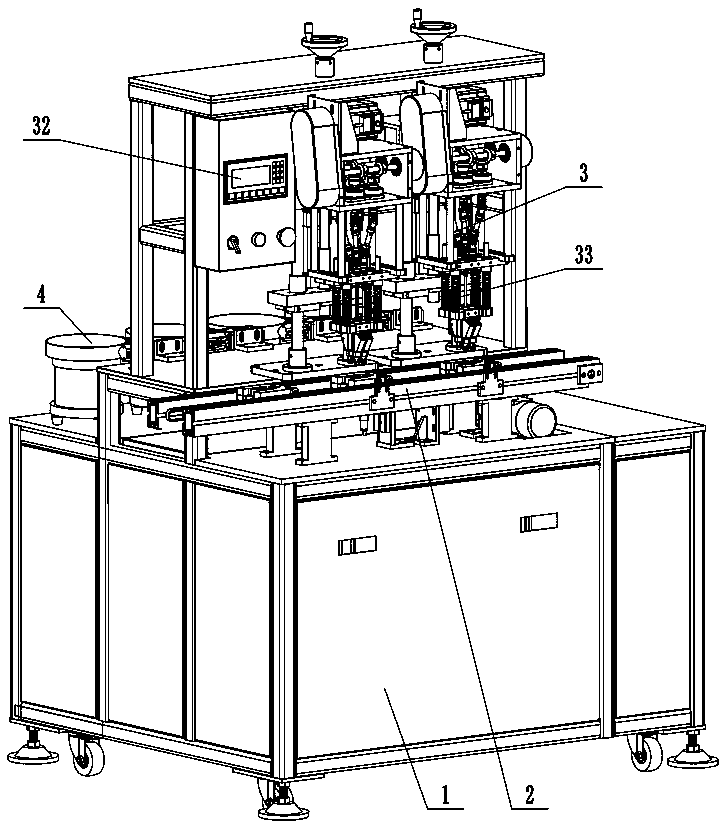

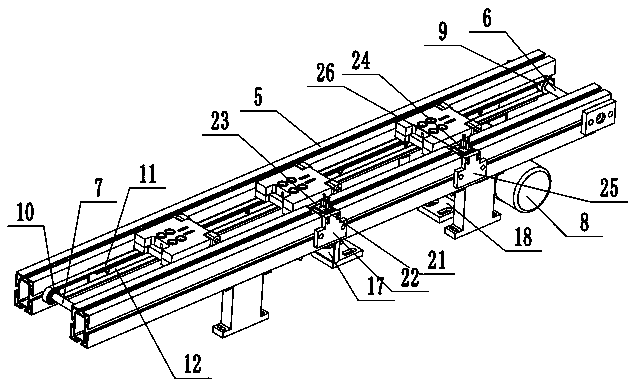

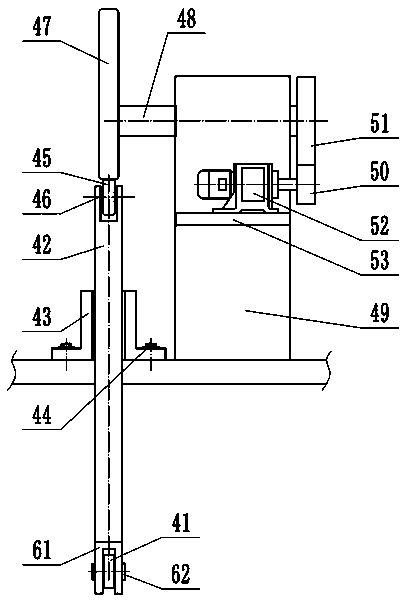

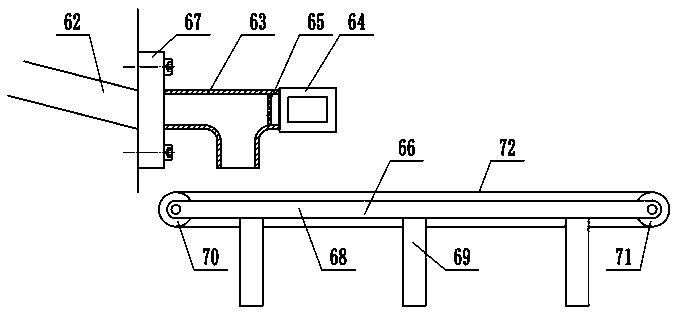

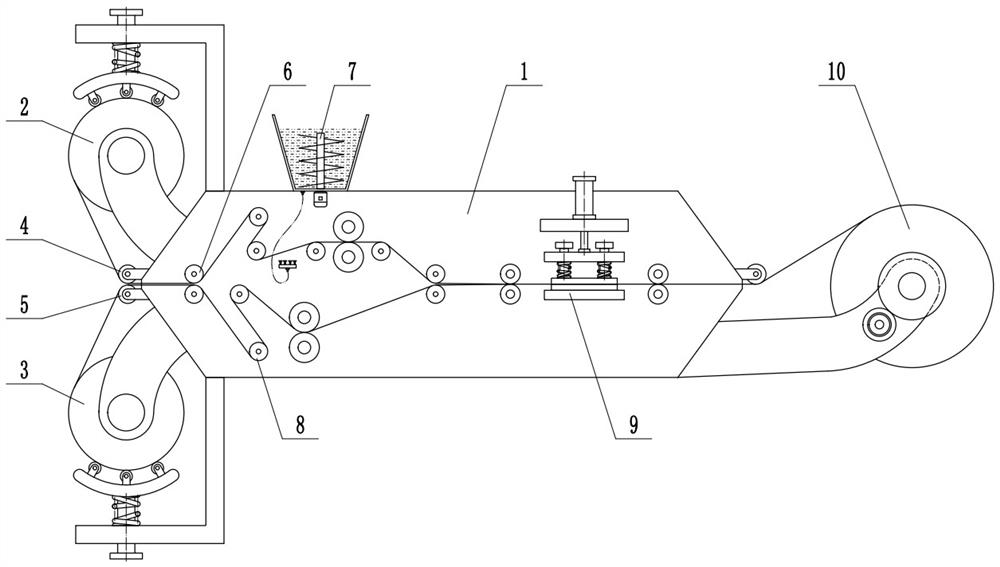

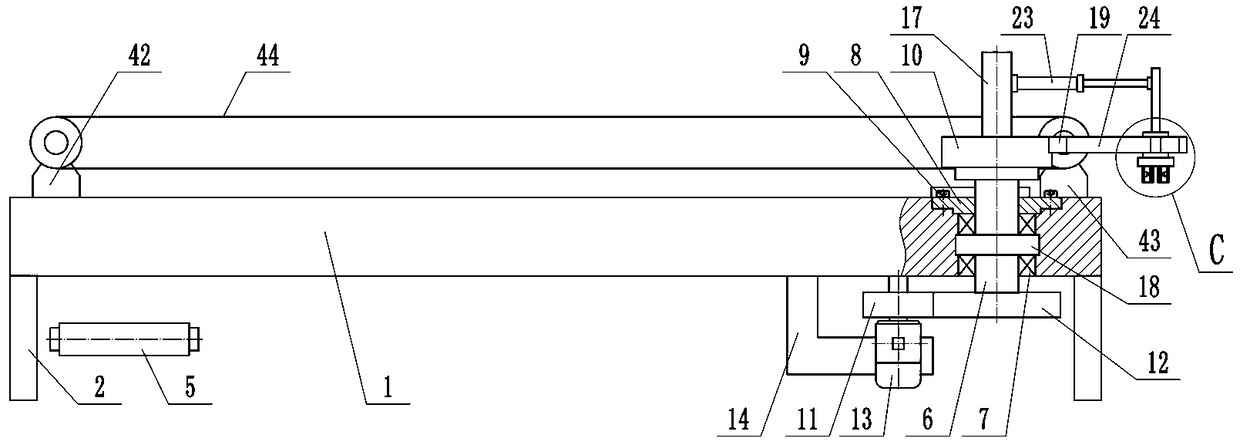

Multi-end screwing device

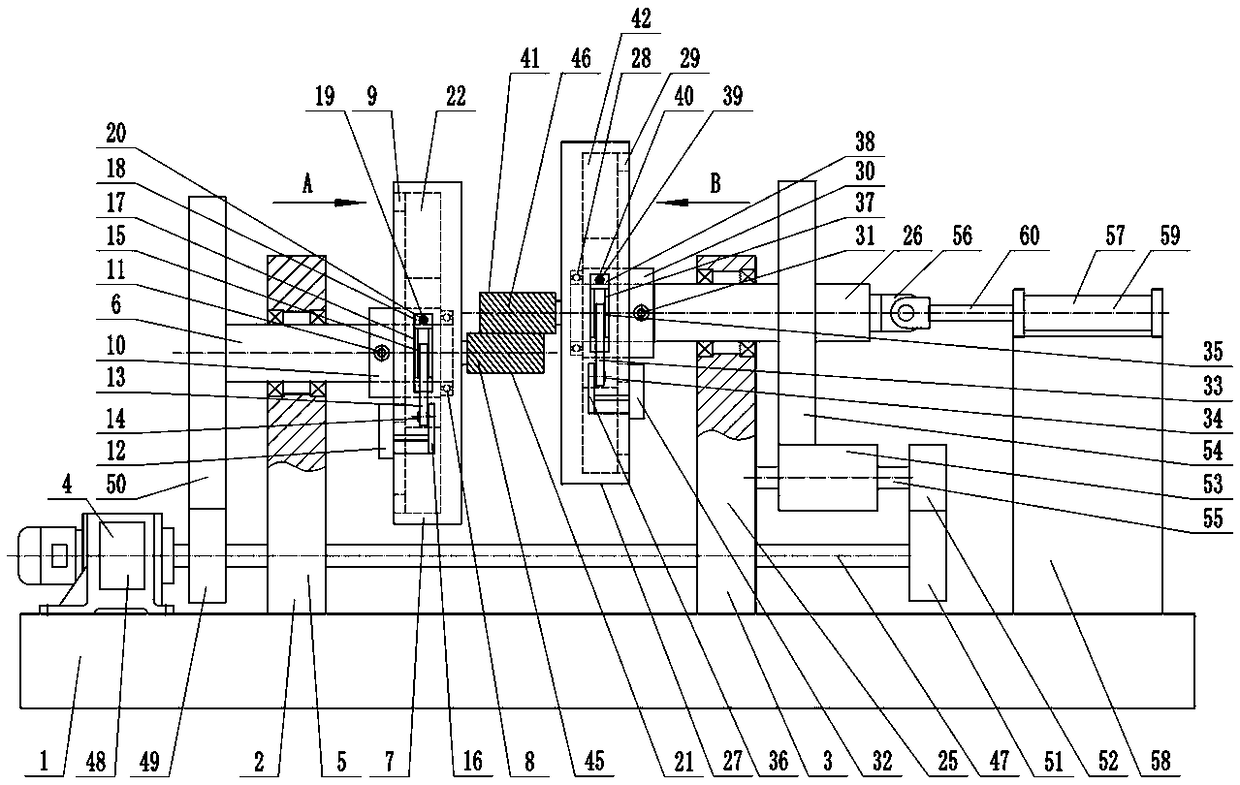

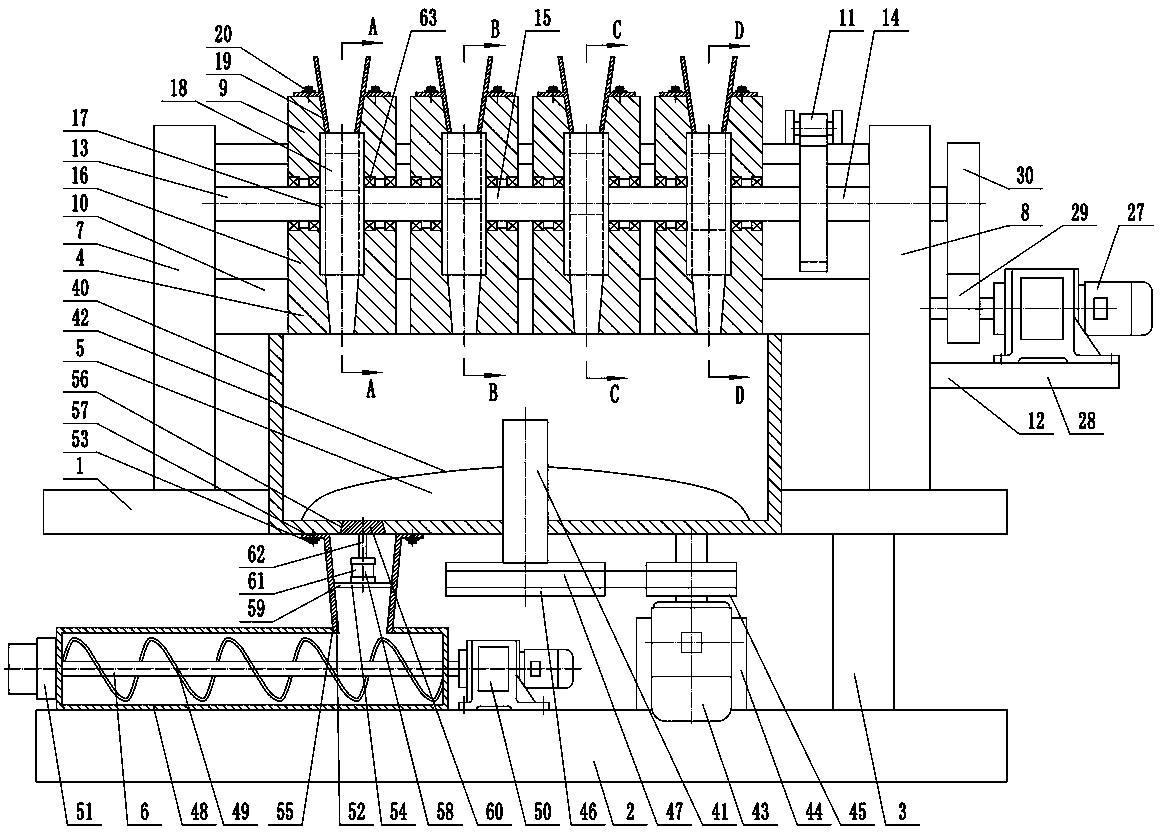

InactiveCN108637652AHigh degree of engagementReduce noiseMetal working apparatusEngineeringTransfer mechanism

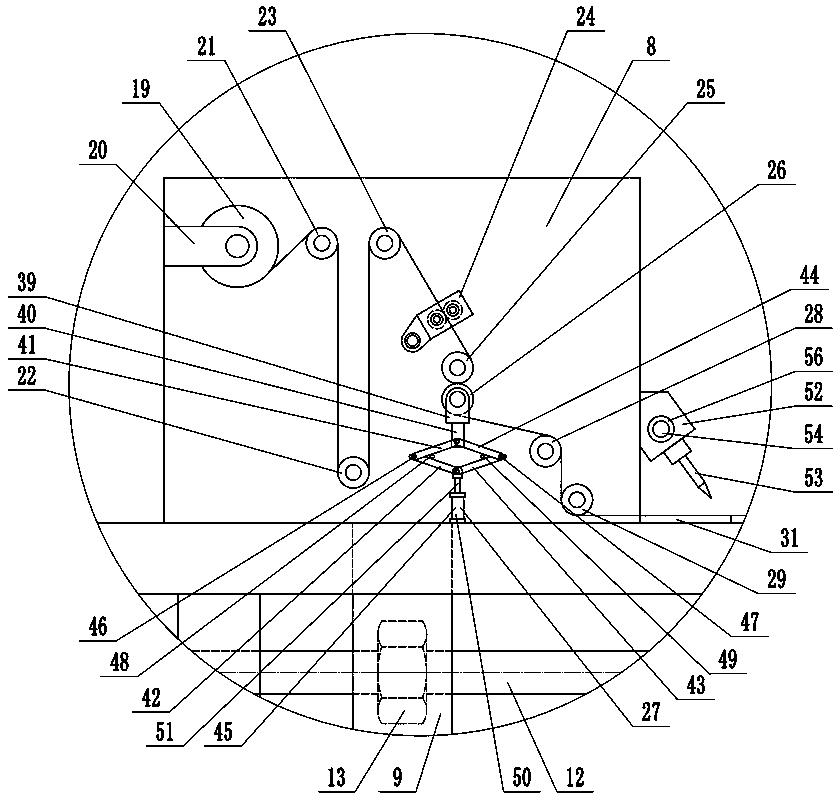

The invention provides a multi-end screwing device and belongs to the technical field of machining equipment. The multi-end screwing device comprises a bearing transferring mechanism, a screwing mechanism and a screw supply mechanism; each transferring supporting belt of the bearing transferring mechanism is arranged on a corresponding first transferring bearing wheel and a corresponding second transferring bearing wheel in a surrounding mode; L-shaped transferring supporting belt brackets achieve bearing for the transferring bearing belts; the screwing mechanism comprises a screwing supporting base, a control cabinet and two sets of multi-end screwing assemblies, and the multi-end screwing assemblies are arranged on the screwing supporting base side by side; and the screw supply mechanismis arranged on one side of the screwing mechanism and comprises four screw supply assemblies, and the four screw supply assemblies are arranged on a screwing rack side by side. By means of the multi-end screwing device, multi-end can be synchronously screwed and installed, and the screws can be fed and discharged automatically, so that the degree of automation of the multi-end screwing device isincreased and the production efficiency is improved.

Owner:全红英

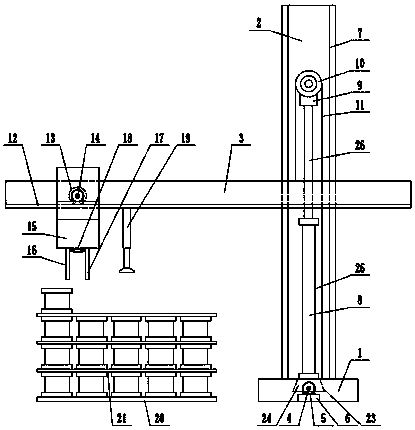

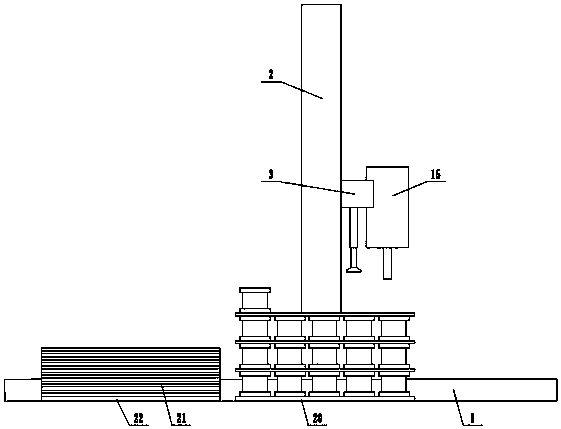

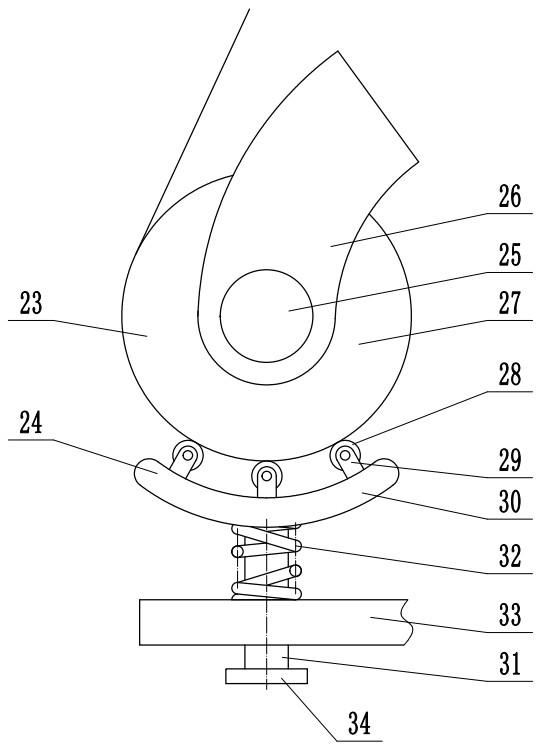

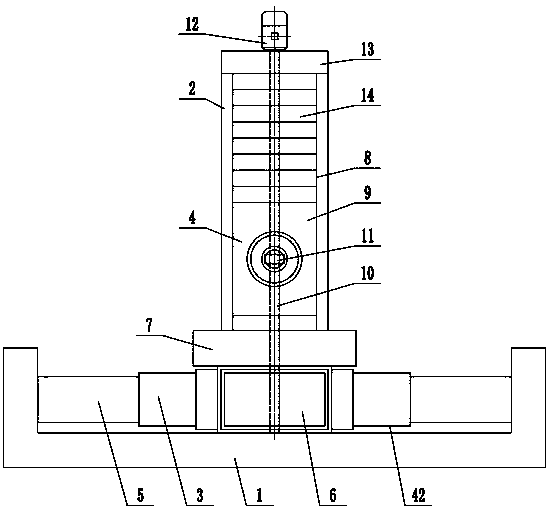

Chemical fiber cone yarn stacking device

The invention provides a chemical fiber cone yarn stacking device and belongs to the technical field of chemical fiber processing. The chemical fiber cone yarn stacking device comprises a vertical beam frame, a horizontal beam frame and a clamping jaw support; the vertical beam frame is slidably arranged on a dovetail-shaped sliding chute of a base through a slider; a screw has threaded connectionwith the slider positioned at the lower end of the vertical beam frame; the horizontal beam frame is arranged on a vertical guide rail of the vertical beam frame in a manner of sliding up and down; the lower end of a lifting cylinder body is fixed to the vertical beam frame; the upper end of a lifting piston rod is connected with a chain wheel support; a chain wheel is rotationally arranged on the chain wheel support; a chain is arranged on the chain wheel in a surrounding manner; one end of the chain is connected with the horizontal beam frame; the other end of the chain is connected with the base; the clamping jaw support is slidably arranged on the horizontal beam frame; a gear is meshed with a gear rack; a first clamping jaw and a second clamping jaw are slidably arranged on the clamping jaw support; the two ends of a clamping jaw cylinder are separately connected with the first clamping jaw and the second clamping jaw; and a lift type sucking disc is installed at the lower side of the horizontal beam frame. The chemical fiber cone yarn stacking device provided by the invention can be used for quickly implementing stacking of chemical fiber cone yarns and is high in automationdegree.

Owner:浙江银汇高纤材料股份有限公司

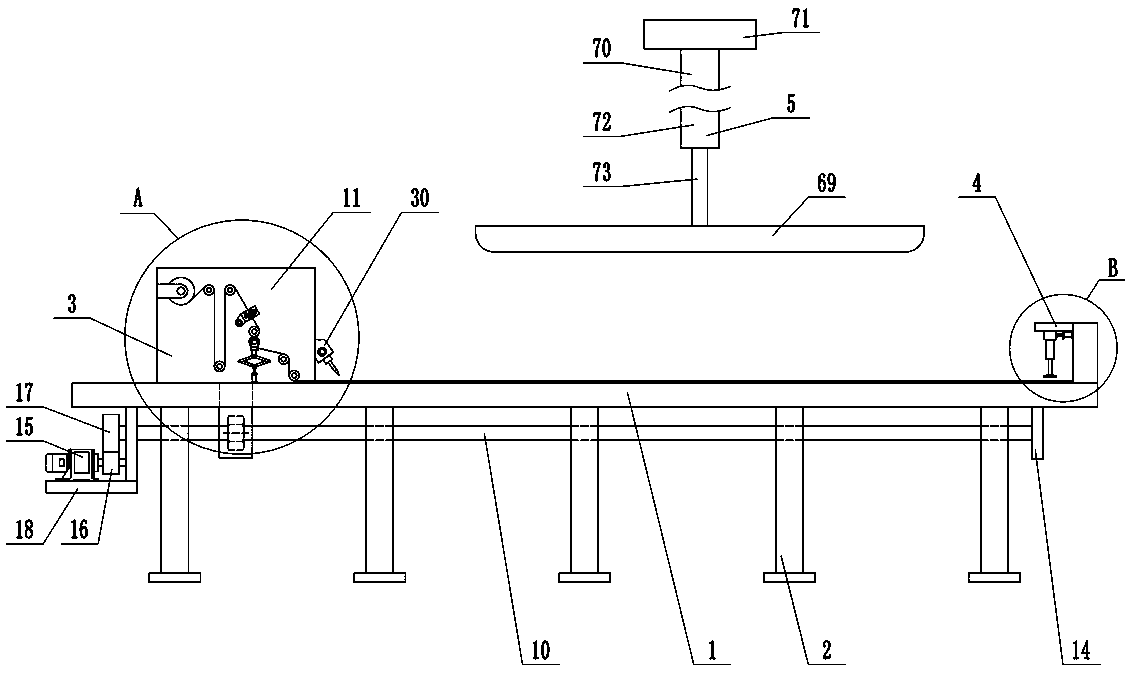

Fabric cutting equipment

The invention provides fabric cutting equipment, and belongs to the technical field of garment processing. The fabric cutting equipment comprises a cutting device, a fabric pressing device and a discharging device; the cutting device comprises a cutting support base driving mechanism and a cutting mechanism, a cutting support base sliding block is slidably arranged in a guide sliding groove, and acutting support base driving lead screw and a cutting support base driving lead screw nut of the cutting support base driving mechanism are in threaded connection with each other; the cutting devicecomprises a fabric roll, a fabric roll support base, a first guide roller, a second guide roller, a third guide roller, an edge suction device assembly, a fourth guide roller, a fifth guide roller, afifth guide roller driving assembly, a sixth guide roller, a seventh guide roller, a cutting blade assembly and a cutting support pad; a telescopic suction cup of the fabric pressing device is installed at the lower end of a cloth pressing translation sliding block, and a discharging pressing strip of the discharging device is located over a U-shaped discharging groove of a cutting rack platform.The fabric cutting equipment can automatically and quickly cut fabric, the cutting size is adjustable, and the applicability is high.

Owner:亘美集团有限公司

Double-eccentricity cycloid cylindrical gear

ActiveCN103671825AHigh degree of engagementImprove transmission stabilityPortable liftingGearing elementsStress conditionsEngineering

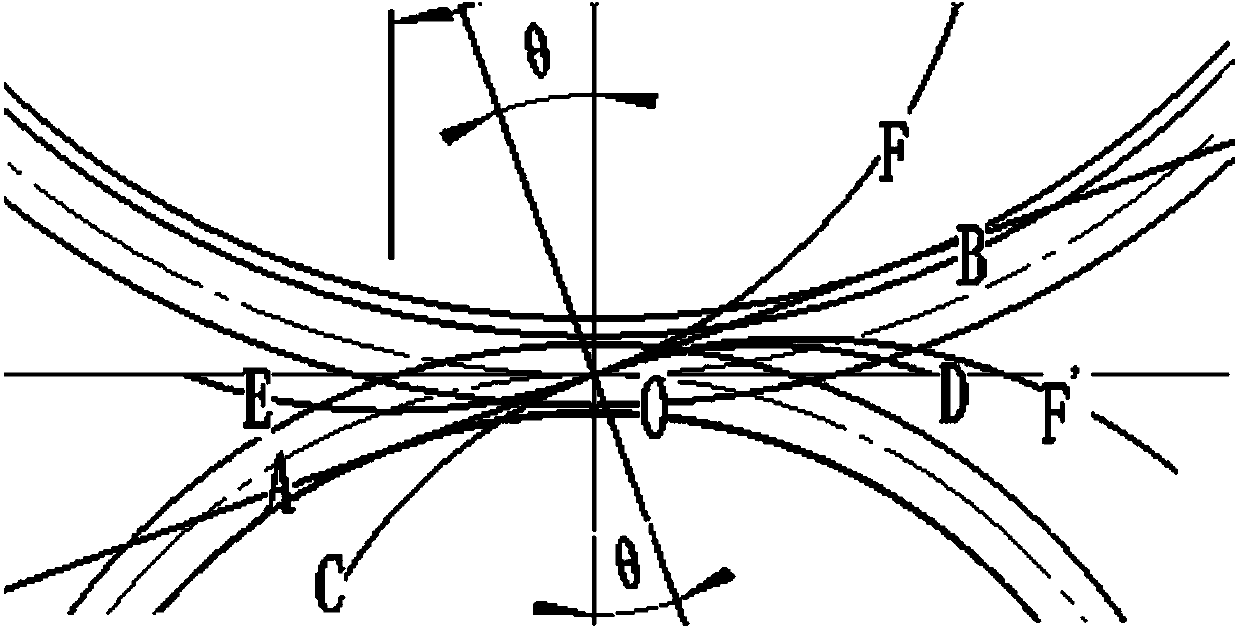

The invention provides a double-eccentricity cycloid cylindrical gear applicable to a transmission mechanism. The meshing line of the gear is formed by two sections of eccentric arcs CO-OF, EO-OD or CO-OF'. The gear contour calculated according to the meshing line is formed by two sections eccentric cycloids. By the arrangement, the length of the meshing line of the gear is increased, the stress condition of a gear root is improved, and gear meshing contact ratio, transmission stability and load capacity of the gear are increased. In addition, the gear is especially applicable to power transmission devices in environments such as a heavy-load environment and a highly-stable environment.

Owner:陕西法士特沃克齿轮有限公司

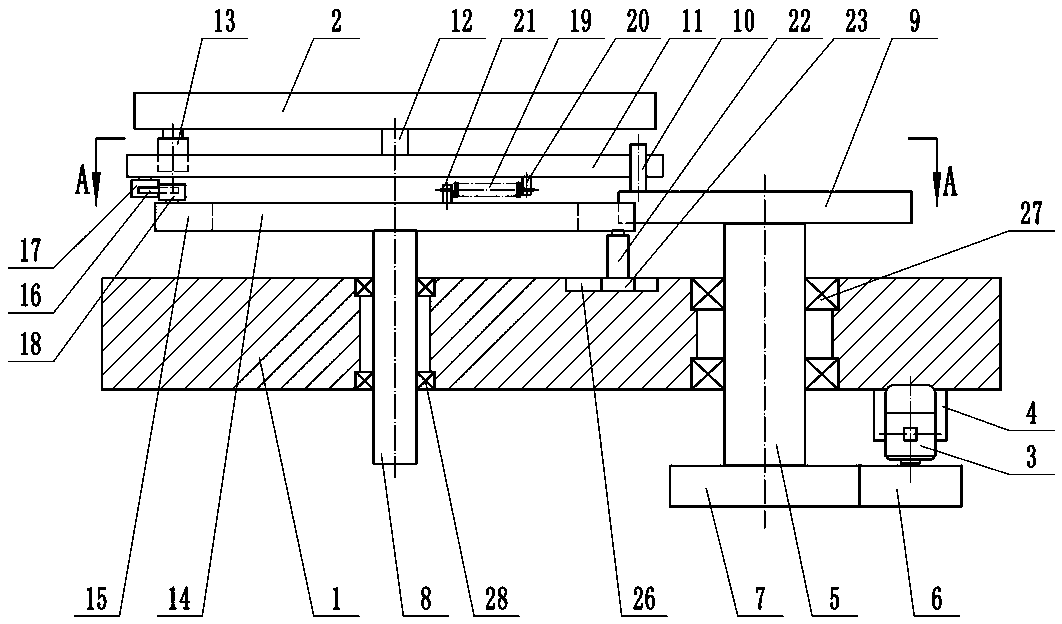

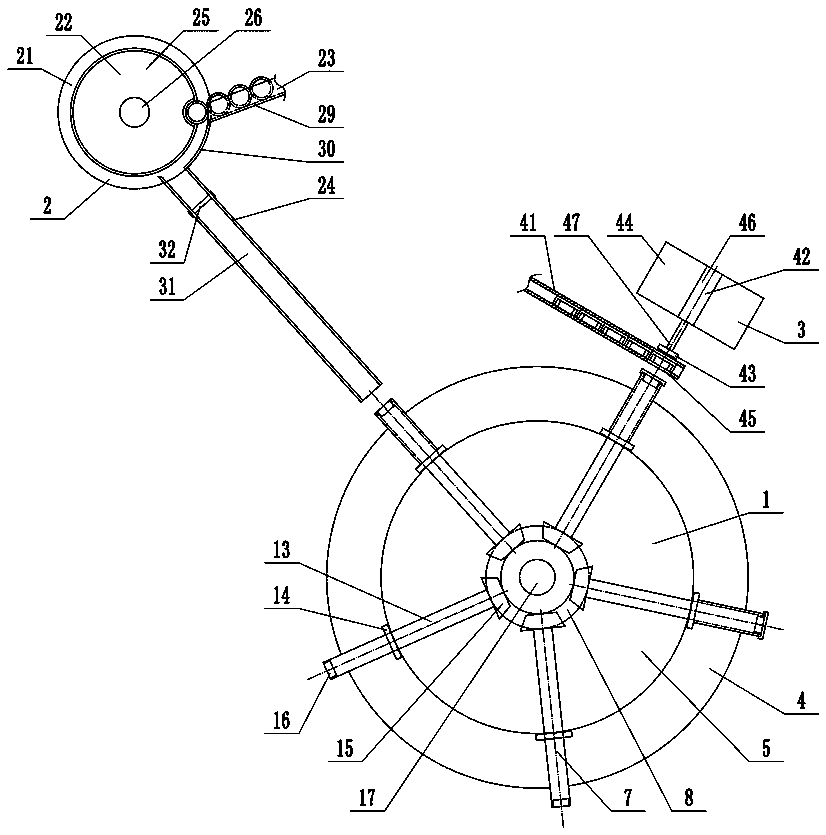

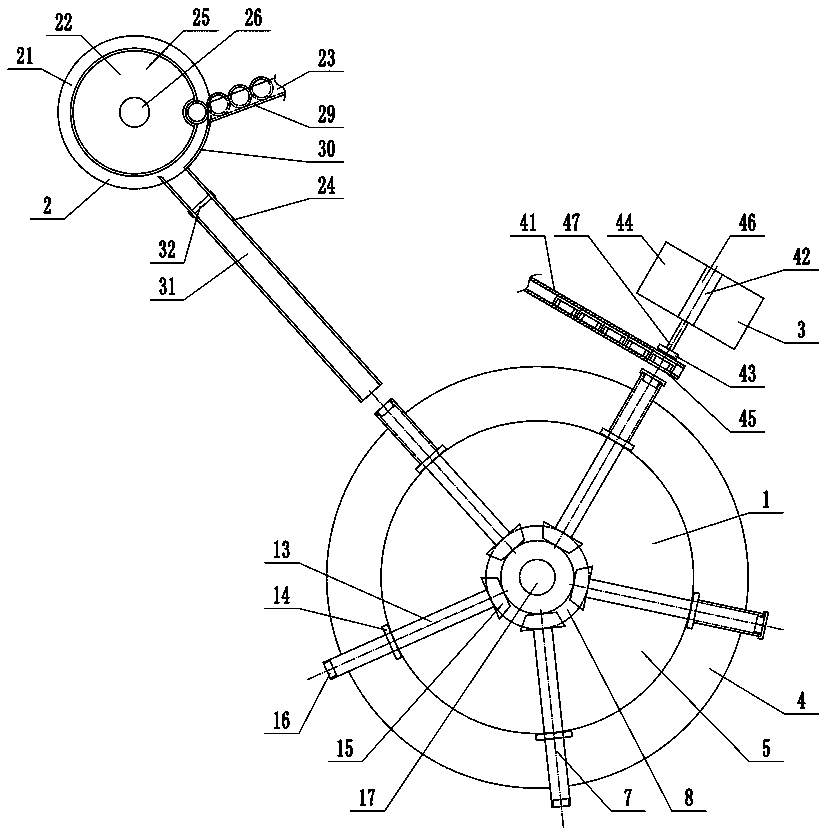

Intermittent rotation drive device

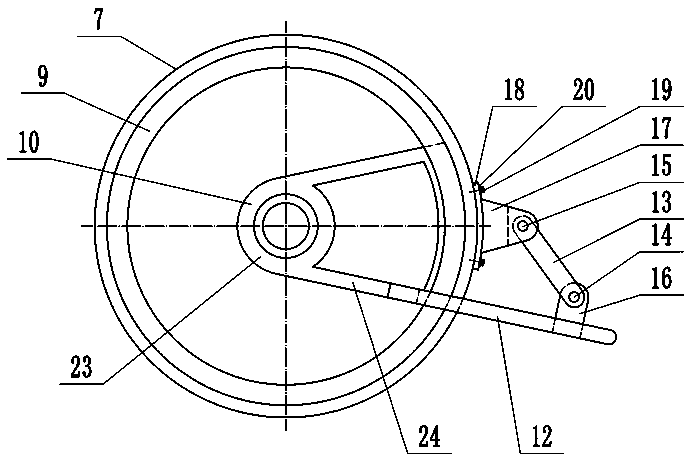

The invention provides an intermittent rotation drive device and belongs to the technical field of textile machinery. The intermittent rotation drive device comprises a plate wheel, a drive pin, a lever, a planet gear, a drive tooth claw and a connection rod. The plate wheel is coaxially arranged at the upper end of a drive main shaft, the drive pin is installed on the plate wheel, and the middleend of the lever is installed on an upper bearing seat in a swing manner through a lever supporting shaft. The planet gear is coaxially installed on an output shaft, and star teeth are uniformly distributed on the planet gear. One end of the connection rod is hinged to the left end of the lever through a first connection rod pin shaft, and the other end of the connection rod is hinged to the leftend of the drive tooth claw through a second connection rod pin shaft. The middle of the drive tooth claw is provided with a drive tooth, a guide pin is installed at the right end of the drive tooth claw, a guide clamp wheel is coaxially and rotatably arranged at the lower end of the guide pin, and the guide clamp wheel is clamped into a U-shaped guide groove of a rack. The two ends of a reset tension spring are connected with the first connection rod pin shaft and the second connection rod pin shaft correspondingly. By means of the intermittent rotation drive device, intermittent small-anglerotation of the output shaft can be realized, and the rotation angle is precise.

Owner:王燕飞

Fabric punching device

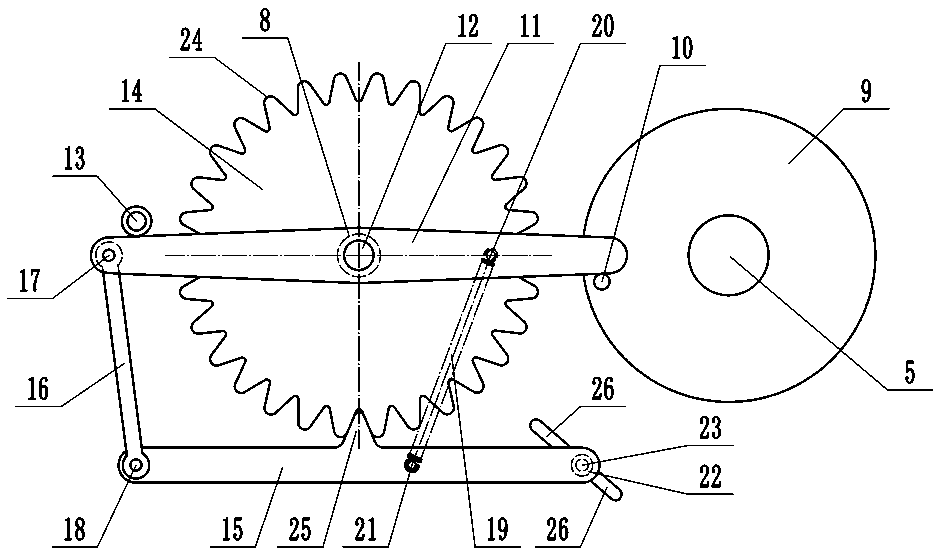

InactiveCN109159207ARealize intermittent accurate feedingReduce tensionMetal working apparatusPunchingDrive shaft

The invention provides a fabric punching device, and belongs to the technical field of fabric processing. The fabric punching device comprises a punching mechanism and a fabric supply mechanism; the fabric supply mechanism comprises an unreeling guide assembly, a reeling guide assembly, a supply drive assembly, and an unreeling pressing roller assembly; a fabric unreeling roller is rotatably arranged on the rear side of a supply rack, a fabric reeling roller is rotatably arranged on the front side of the supply rack, a rotating disc of the punching mechanism is rotatably arranged on an upper bearing ring of an upper disc base and a lower bearing ring of a lower disc base, a lever is clamped in a lever mounting groove of the rotating disc, a left pin shaft at the left end of the lever is inserted into a lower U groove in the lower end of a bearing frame of a punching lower supporting plate, punching nails are evenly distributed at the upper end of the punching lower supporting plate, adrive rod is arranged on a drive rod guide base in an up and down sliding manner, the lower pin shaft is inserted into a right U groove in the right end of the lever, and a drive cam is arranged at one end of a drive shaft. Punching machining of fabric can be efficiently achieved, punching efficiency is high, and reliability is good.

Owner:桐乡市宏力纺织股份有限公司

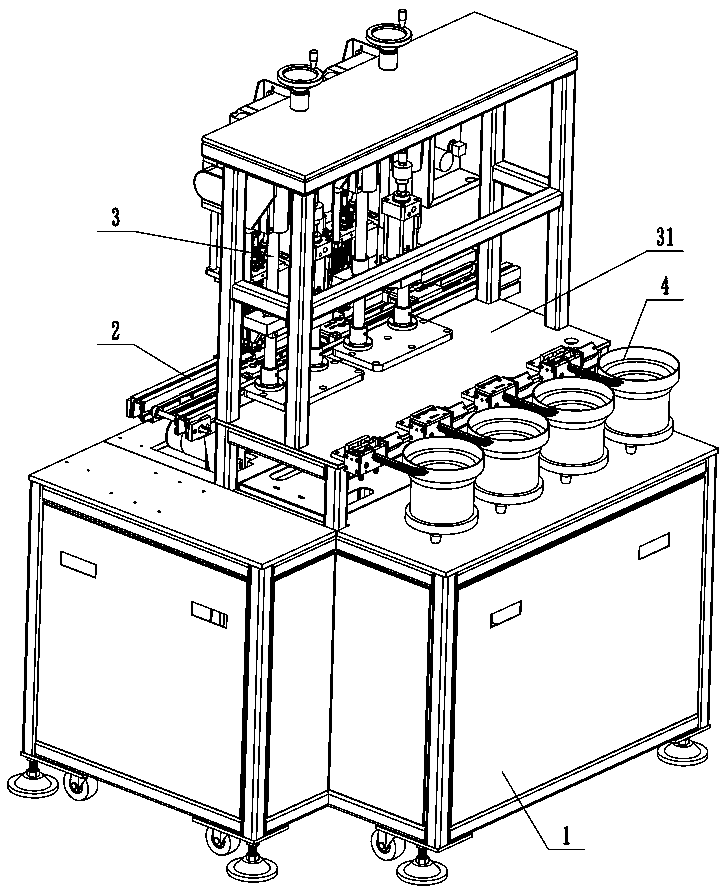

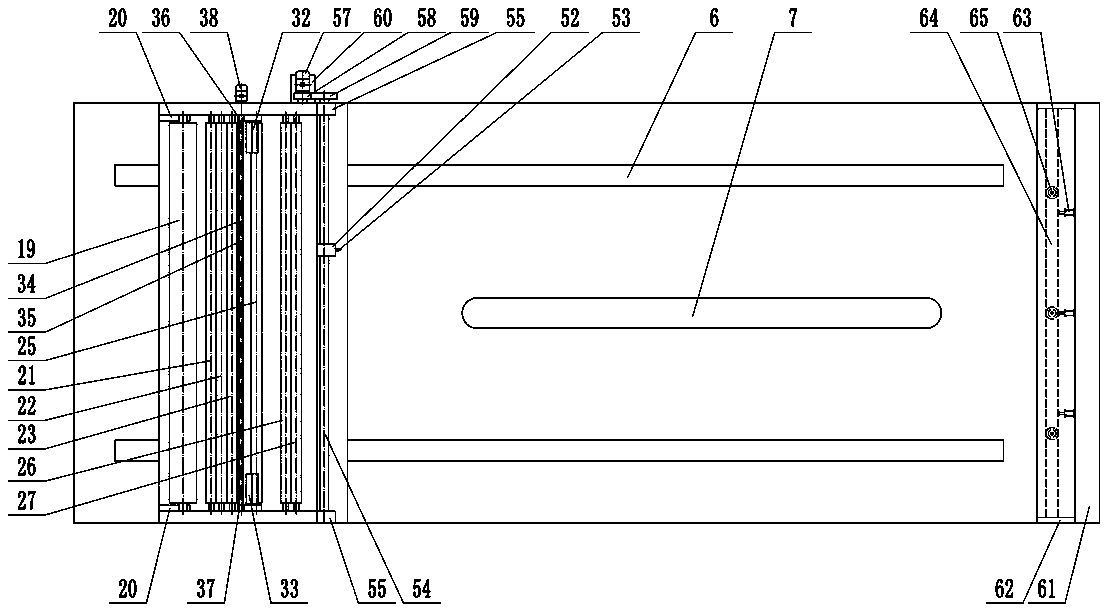

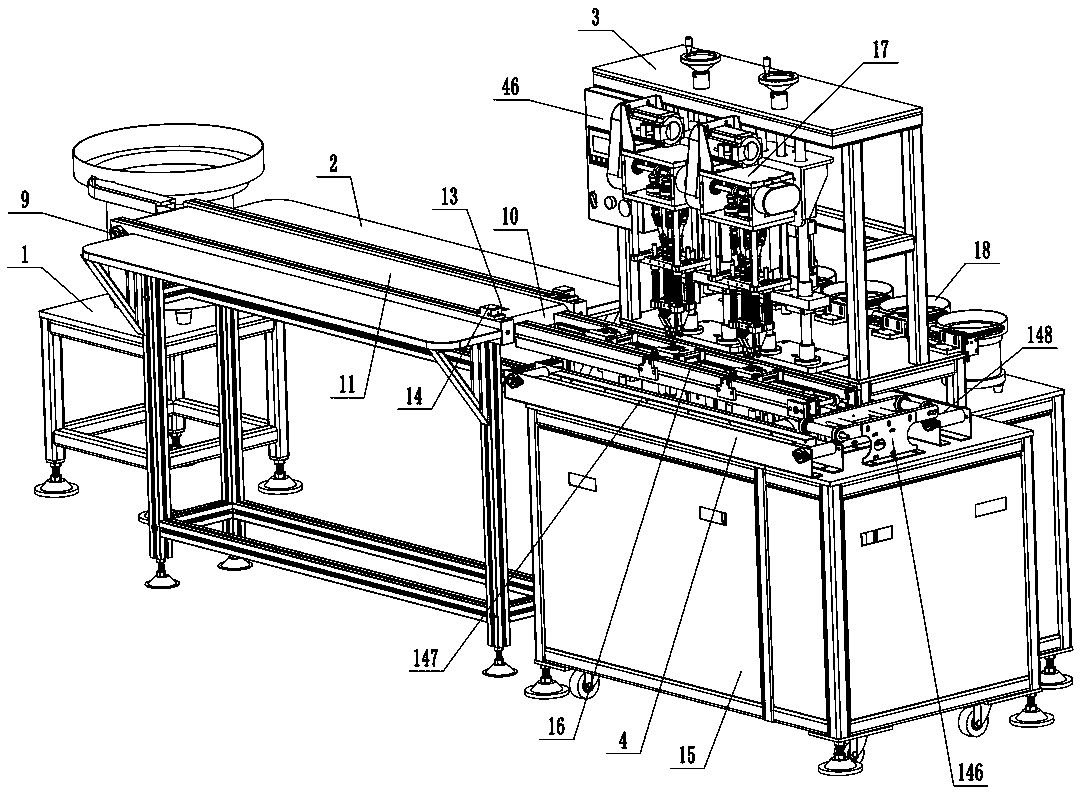

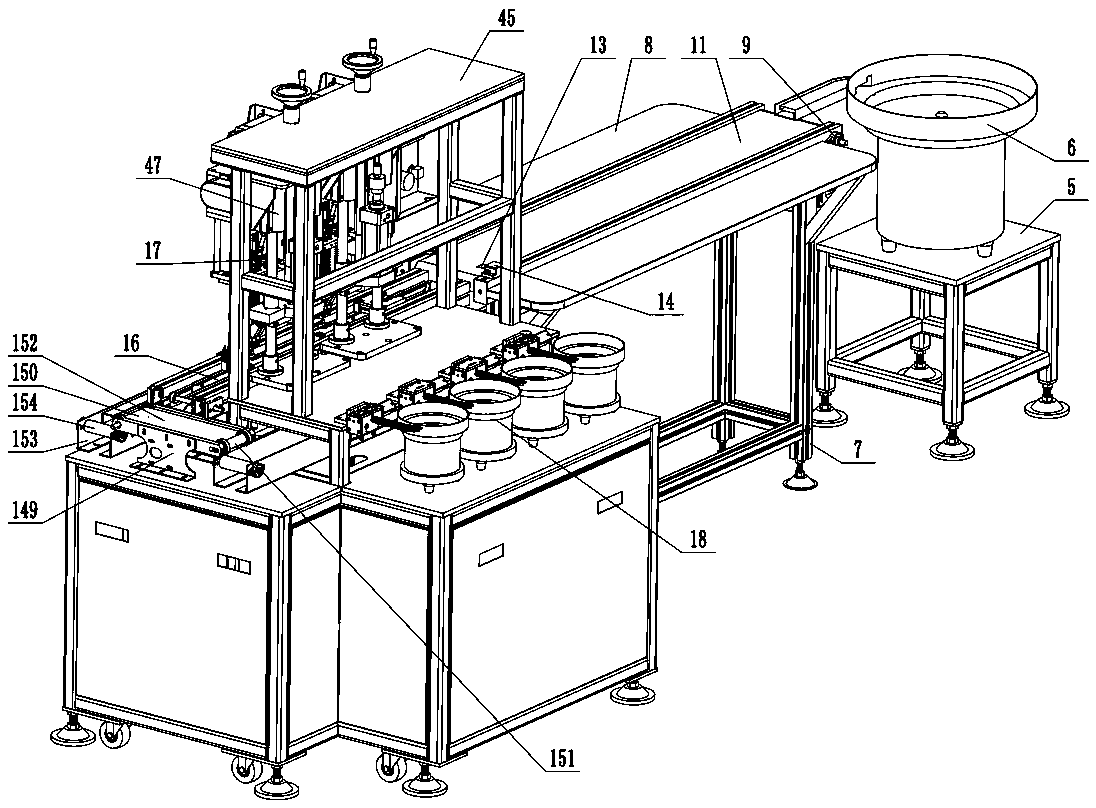

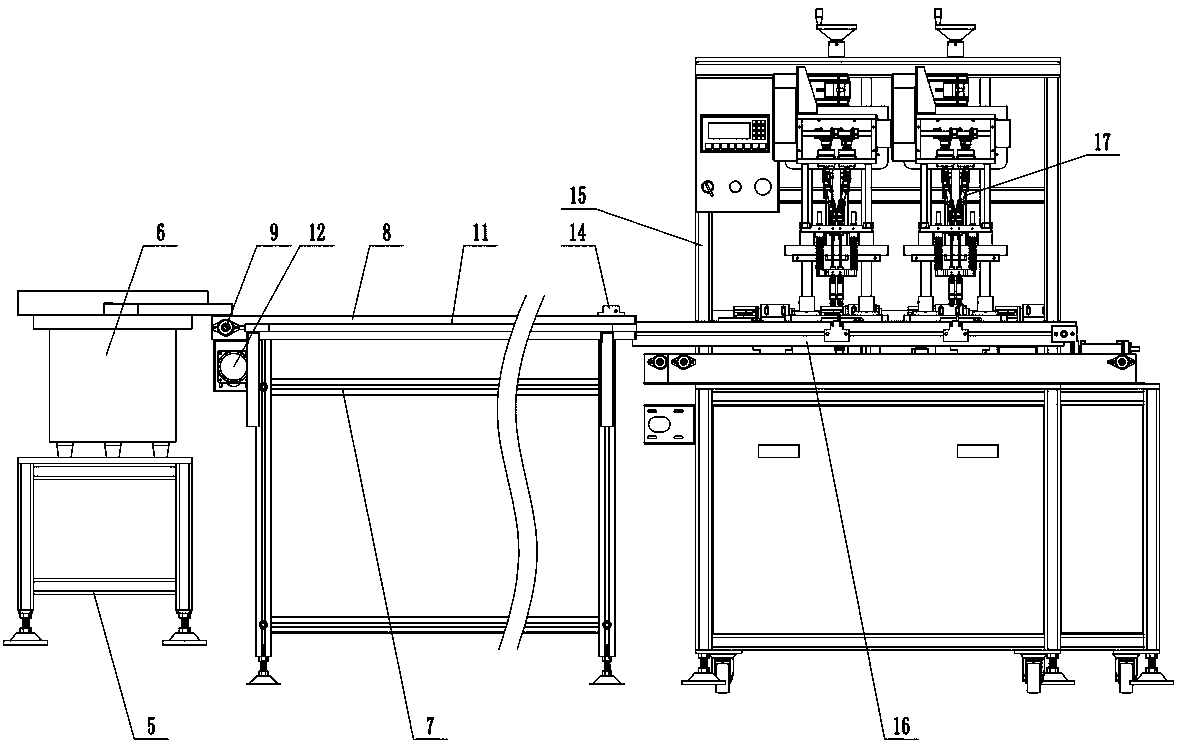

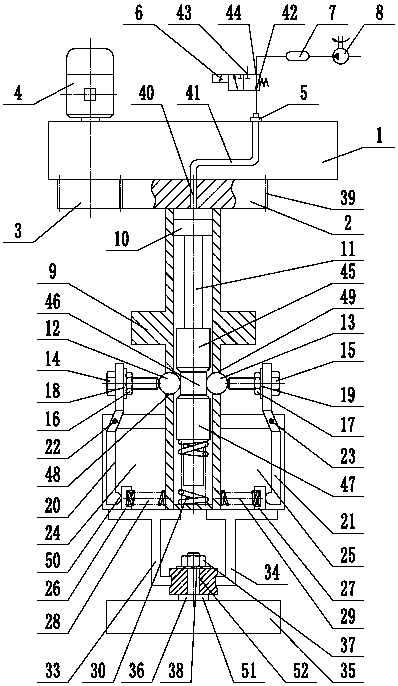

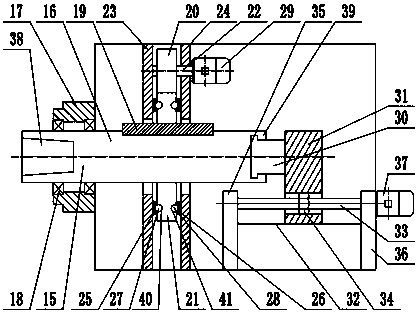

Multi-head screw locking machine for jig

InactiveCN108637653ACount achievedHigh degree of engagementMetal working apparatusLocking mechanismEngineering

The invention provides a multi-head screw locking machine for a jig and belongs to the technical field of machining equipment. The multi-head screw locking machine for the jig comprises a jig feedingdevice, a jig conveying device, a multi-head screw locking device and a jig backflow device. The jig backflow device comprises a jig feeding rack and a vibration type jig feeder. A jig conveying chainof the jig conveying device is wound on a first conveying roller and a second conveying roller. The multi-head screw locking device comprises a screw locking rack, a jig bearing circulating mechanism, a screw locking mechanism and a screw feeding mechanism. The jig backflow device comprises a shunt mechanism, a first backflow mechanism and a second backflow mechanism. By means of the multi-head screw locking machine for the jig, synchronous screwing and installing of multi-head screws can be achieved, automatic feeding of the screws can also be achieved, the structure is reasonable, and the automation degree is high.

Owner:全红英

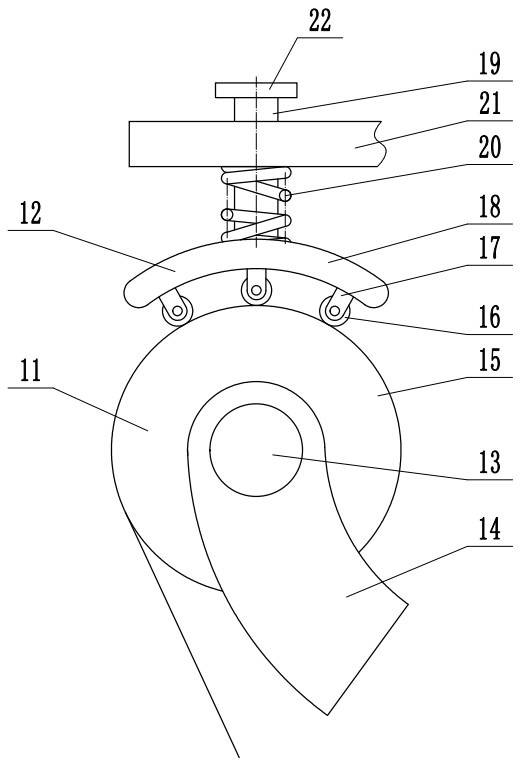

Double-roller-type yarn twisting device

InactiveCN108796696AQuality improvementSmooth turningContinuous wound-up machinesYarnReciprocating motion

The invention provides a double-roller-type yarn twisting device, and belongs to the technical field of textile machines. The device comprises a left twisting assembly, a right twisting assembly and atwisting driving assembly; a left twisting main shaft of the left twisting assembly is rotatably arranged on a left twisting supporting base, one end of a left connecting rod is hinged to a first left connecting rod supporting base, and the other end of the left connecting rod is hinged to a second left connecting rod supporting base; a left twisting roller is coaxially and fixedly connected to the right side of a left rotation bearing disc, a right twisting main shaft of the right twisting assembly is rotatably arranged on the left twisting supporting base and can slide axially, one end of aright connecting rod is hinged to a first right connecting rod supporting base, the other end of the right connecting rod is hinged to a second right connecting rod supporting base, and a right twisting roller is coaxially and fixedly connected to the left side of a right rotation bearing disc. By means of the device, two parallel twisting rollers with speed difference are utilized for rotating,and twisting of yarn is also achieved through axial and reciprocating movement between the two twisting rollers.

Owner:赵凯

Anti-corrosion concrete special for building and production system thereof

ActiveCN112358253AImprove fusion effectImprove compactnessSolid waste managementMixing operation control apparatusArchitectural engineeringStructural engineering

The invention provides an anti-corrosion concrete special for a building, and belongs to the technical field of concrete. The anti-corrosion concrete is prepared by stirring the following components in parts by weight: 95-105 parts of an anti-corrosion concrete gel base material, 375-412 parts of an anti-corrosion concrete base material, 10-17 parts of an anti-corrosion concrete filling base material and 40-45 parts of water. A production system of the anti-corrosion concrete special for a building comprises a production rack device, an anti-corrosion concrete gel base material production device, an anti-corrosion concrete base material production device, an anti-corrosion concrete filling base material production device and a mixing and stirring device. The corrosion resistance of the concrete is greatly improved, the service life of a building is greatly prolonged, the production system is reasonable in structure, continuous processing of the anti-corrosion concrete special for a building is facilitated, and the automation degree is high.

Owner:桐乡市钟大建材有限公司

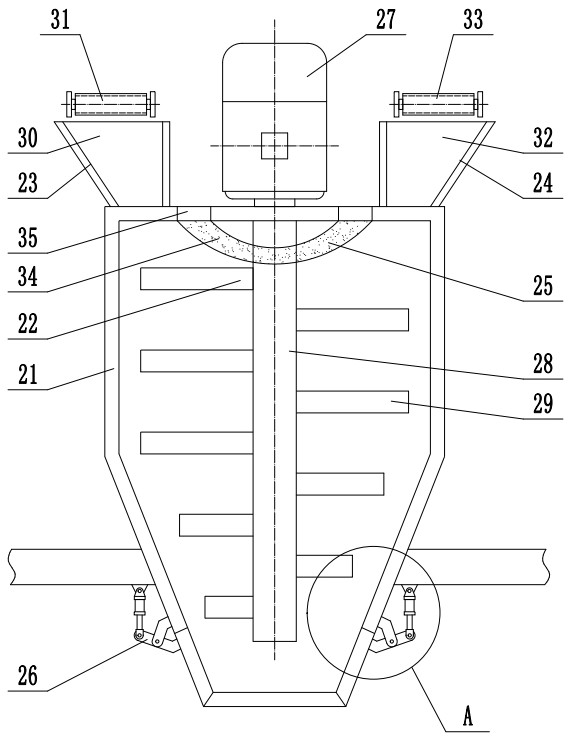

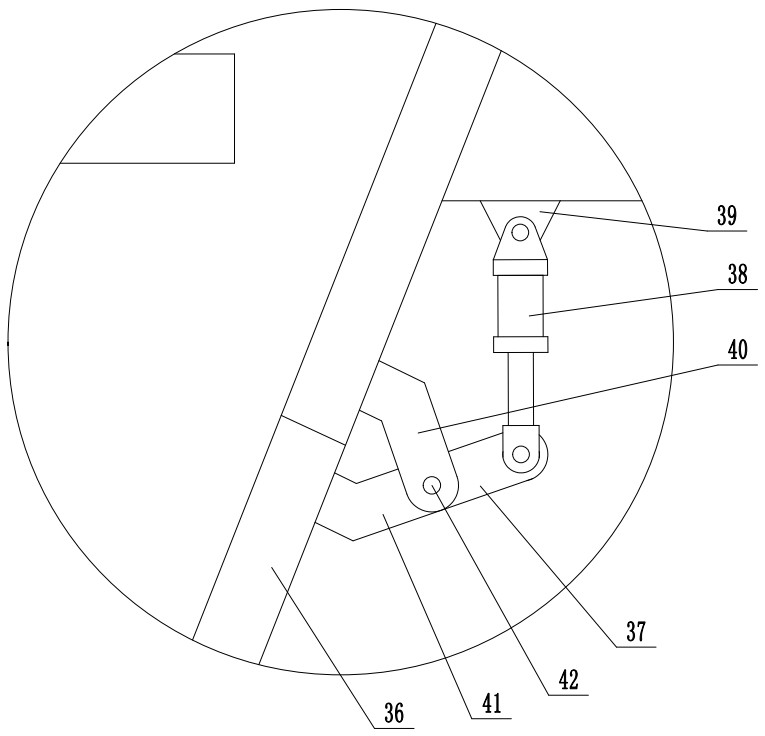

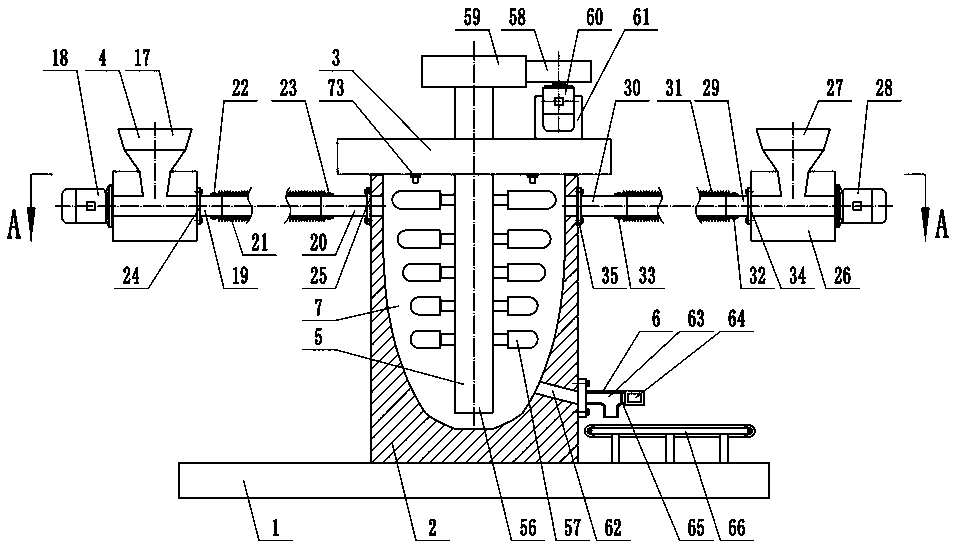

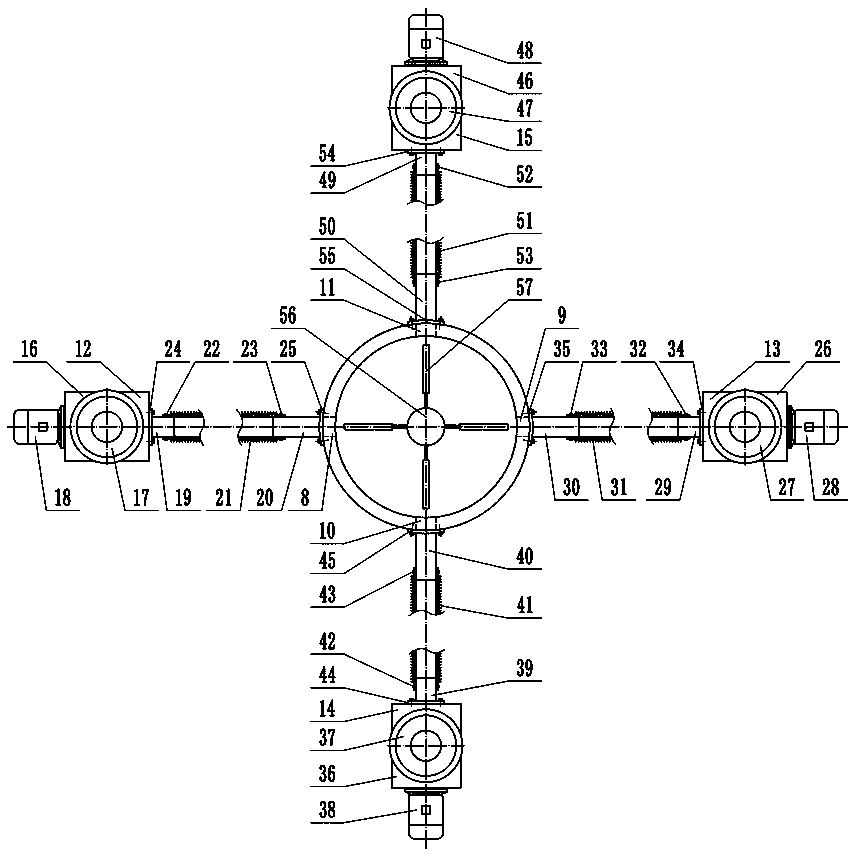

Wool feeding and blending mechanism

The invention provides a wool feeding and blending mechanism, and belongs to the technical field of wool spinning and processing equipment. The wool feeding and blending mechanism comprises a wool blending barrel, a feeding component, a wool blending component and a discharge component. The feeding component comprises a left feeding group, a right feeding group and a rear feeding group. A wool blending spindle of the wool blending component is arranged on a wool blending cover plate rotationally. Mixing and stirring plates are arranged on the wool blending spindle evenly. The left end of a discharge three-way pipe of the discharge component is mounted on the wool blending barrel through a discharge connection ring. The left end of the discharge three-way pipe is communicated with a discharge hole. A discharge air suction pump is connected to the right end of the discharge three-way pipe. A separation net is mounted on the right side of a three-way pipe junction of the discharge three-way pipe. A discharge conveying group is arranged on the lower side of the discharge three-way pipe. The wool feeding and blending mechanism has the advantages that different wools and fibers are fed through different feeding components, feeding quantity and time can be adjusted and controlled, and blending of the wools and the fibers in different types and proportions is realized.

Owner:桐乡市建泰纺织有限公司

Novel artificial hand flexible transmission control mechanism

ActiveCN104565215AReduce frictionReduce weightProgramme-controlled manipulatorToothed gearingsOverlap ratioArtificial hand

Owner:NORTHWESTERN POLYTECHNICAL UNIV

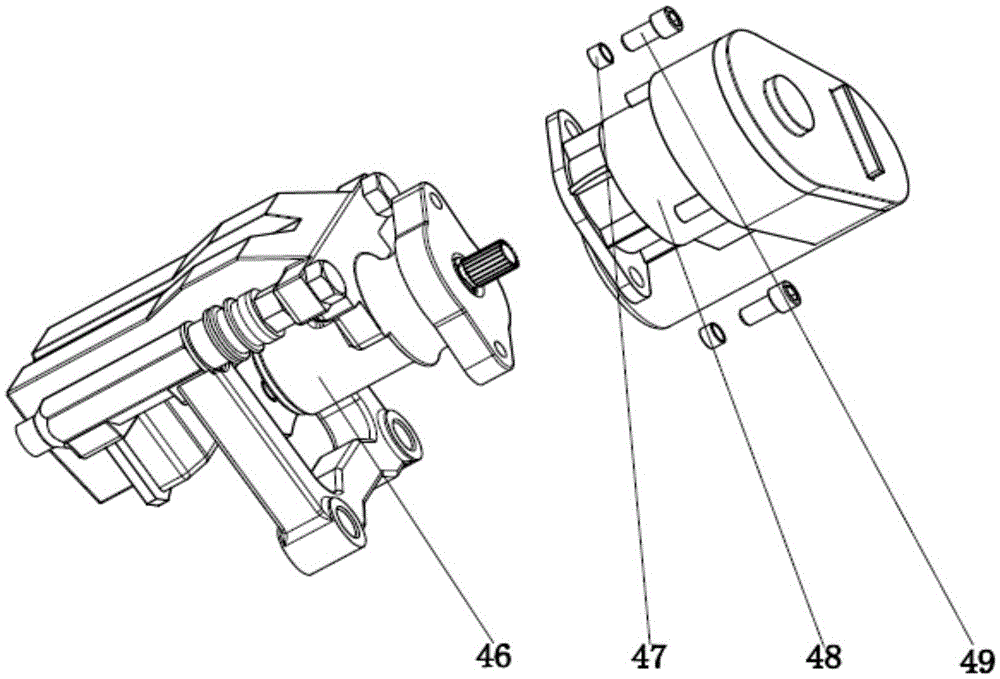

Cycloidal electronic parking brake

InactiveCN103925315BSave spaceReduce labor intensityAxially engaging brakesBrake actuating mechanismsEngineeringCalipers

The invention discloses a cycloidal-pin wheel type electrical parking brake which overcomes the defects that starting operation on a slope is complex, and gap self-adjustment is difficult to achieve. The cycloidal-pin wheel type electrical parking brake comprises an actuating device (48) and a brake caliper assembly (46). The actuating device (48) comprises an output shaft (20) and a front shell (11). An internal spline hole is machined in the left end of the output shaft (20). The output shaft (20) is installed in the front shell (11) and extends out of the left end of the front shell (11). The brake caliper assembly (46) comprises a screw (13) and a brake caliper body (19). The screw (13) is installed in the brake caliper body (19) and extends out of the right end of the brake caliper body (19). The output shaft (20) of the actuating device (48) is connected with a spline pair of the screw (13) of the brake caliper assembly (46). Meanwhile, the front shell (11) of the actuating device (48) makes contact with the brake caliper body (19) of the brake caliper assembly (46) and connected with a connecting screw (49) through an embedded sleeve (47).

Owner:JILIN UNIV

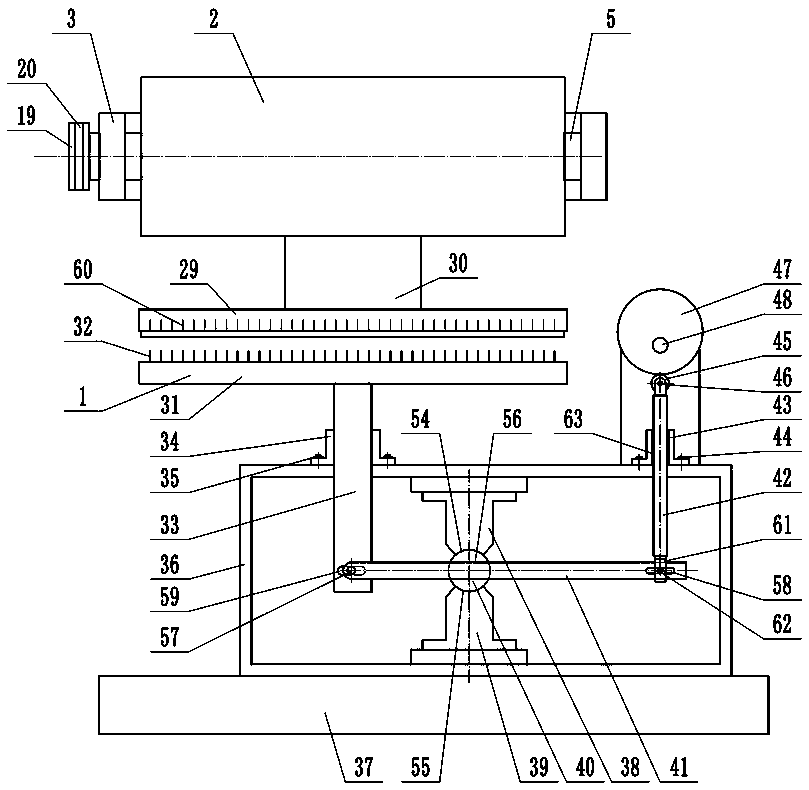

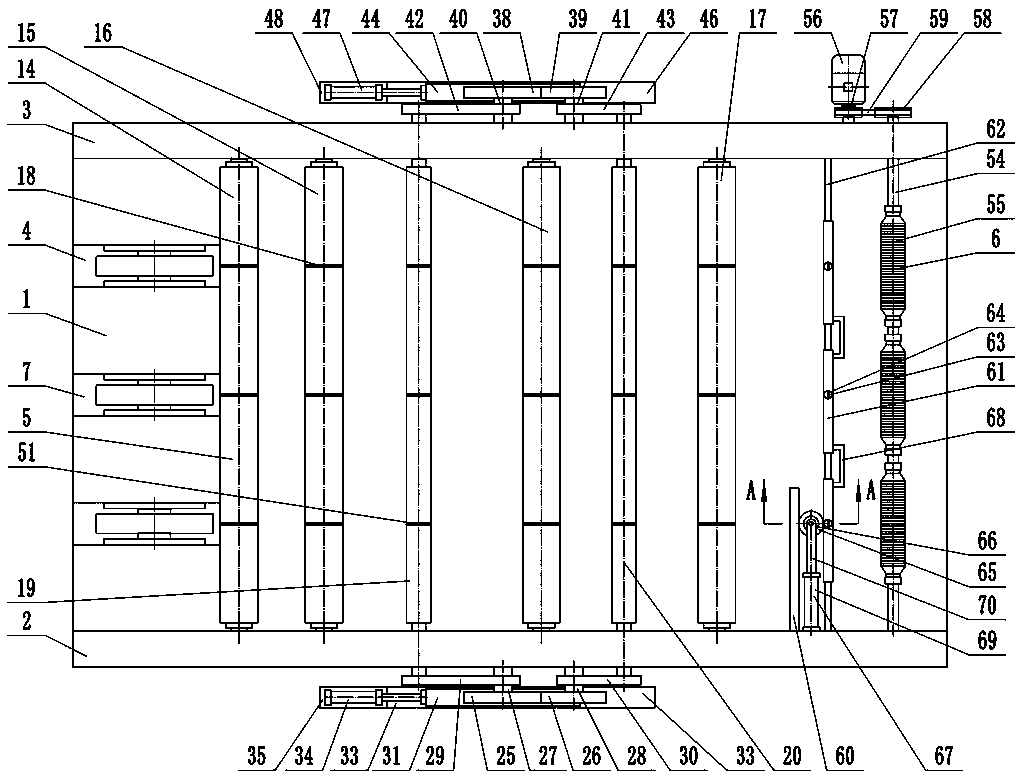

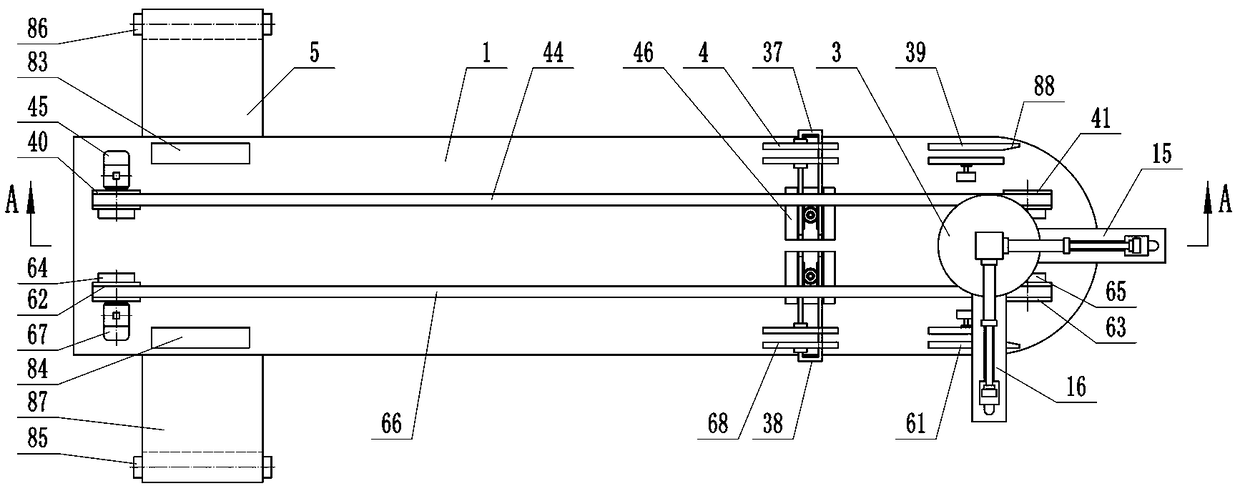

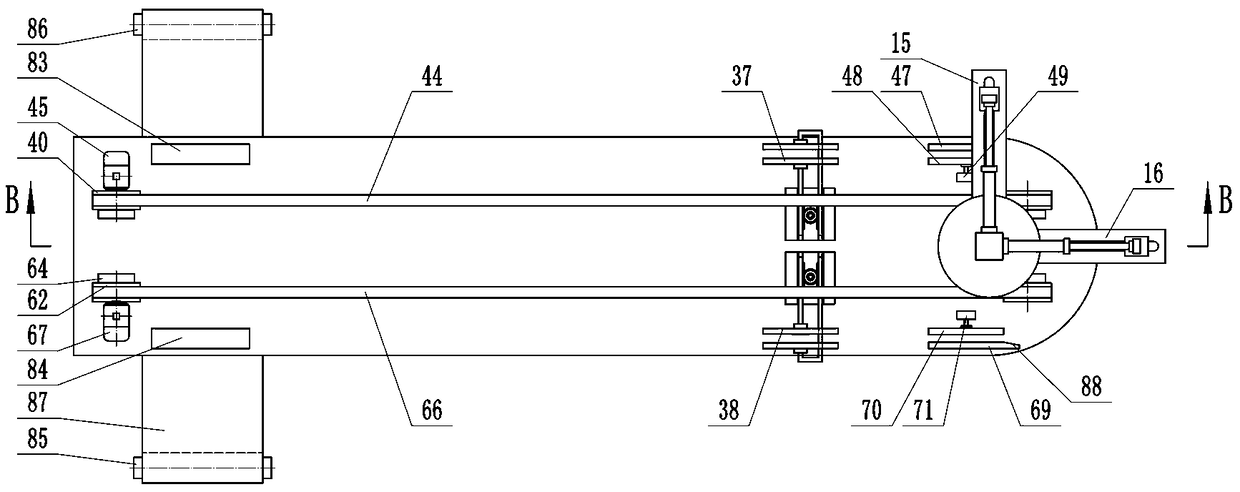

Full-automatic bobbin sleeving equipment

ActiveCN111153281AHigh degree of engagementImprove transmission stabilityFilament handlingYarnEngineering

The invention provides full-automatic bobbin sleeving equipment, and belongs to the technical field of textile machinery. The full-automatic bobbin sleeving equipment comprises a rotary disc type yarncollecting device, a bobbin turning supplying device and a bobbin plug sleeve plug pressing device; the rotary disc type yarn collecting device comprises yarn collecting assemblies, a yarn collectingdriving assembly and a yarn collecting rotary disc driving assembly, the yarn collecting assemblies are evenly arranged on a yarn collecting rotary disc rack, and a yarn collecting driving bevel gearand yarn collecting driven bevel gears of the yarn collecting driving assembly mesh with each other; the bobbin turning supplying device comprises a supplying rotary disc assembly, a bobbin supplyingassembly and a turning sleeving assembly, a supplying rotary disc of the supplying rotary disc assembly is evenly provided with bobbin receiving grooves, a bobbin supplying channel of the bobbin supplying assembly is obliquely arranged on one side of the supplying rotary disc, and a turning plate of a bobbin turning device of the turning sleeving assembly is arranged in a sleeving falling hopperin a swinging mode through a turning plate support shaft; and a plug pressing pushing plate of the bobbin plug sleeve plug pressing device is installed on a plug pressing piston rod. According to thefull-automatic bobbin sleeving equipment, bobbin sleeving can be automatically achieved, and the automation degree is high.

Owner:浙江银汇高纤材料股份有限公司

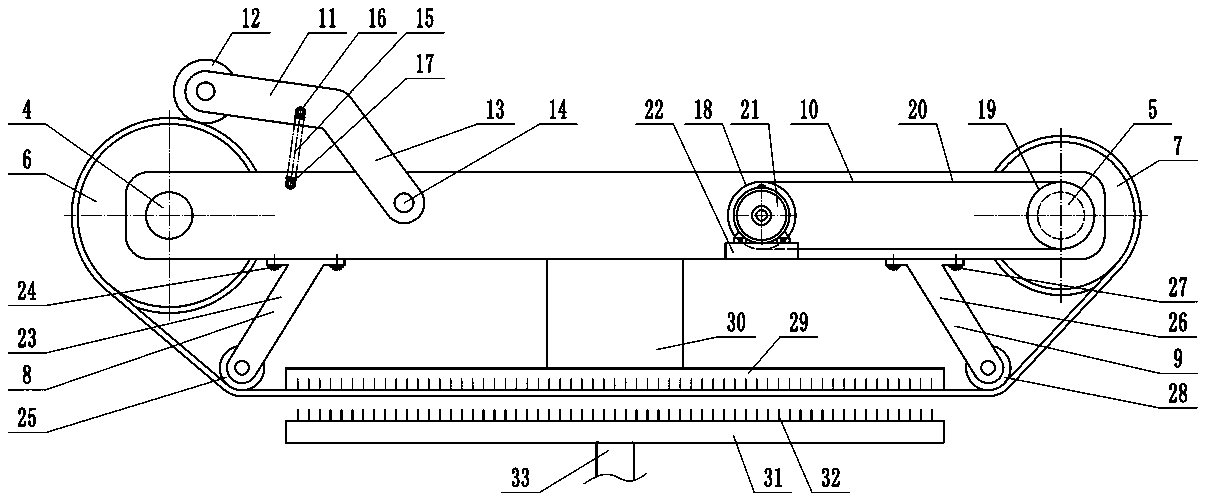

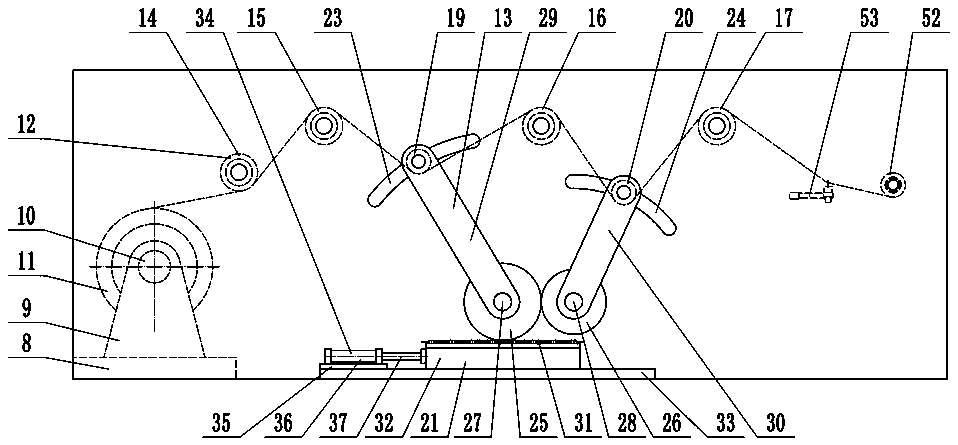

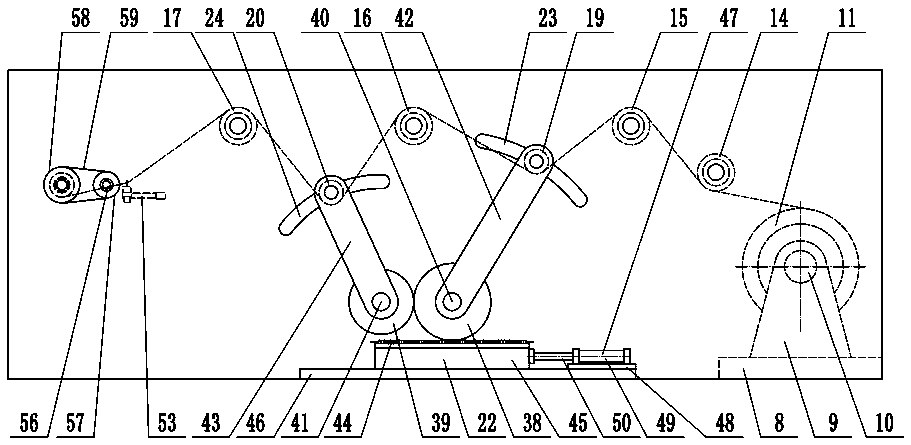

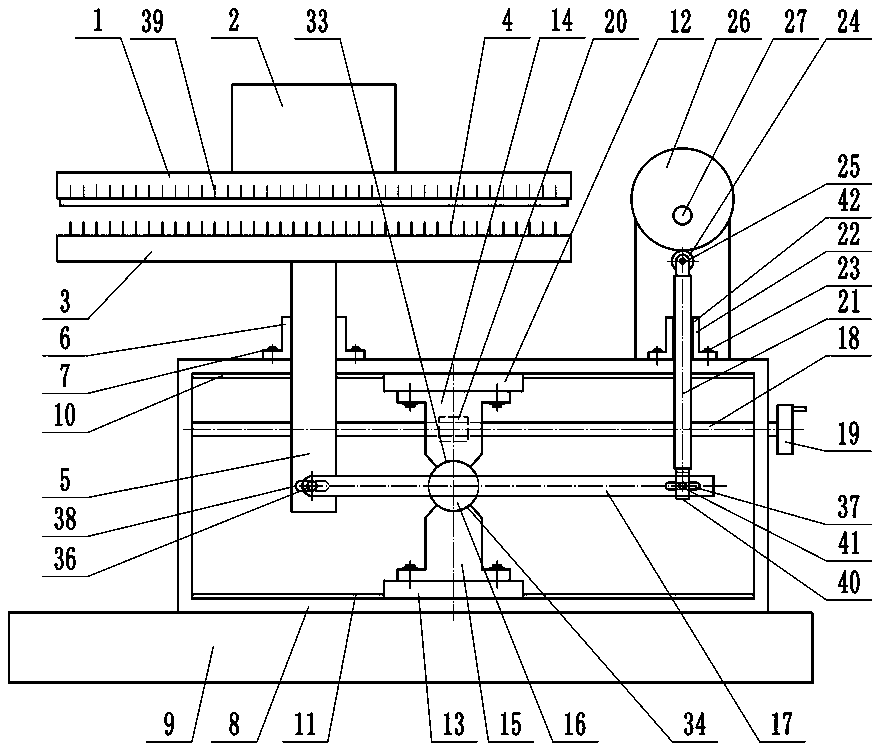

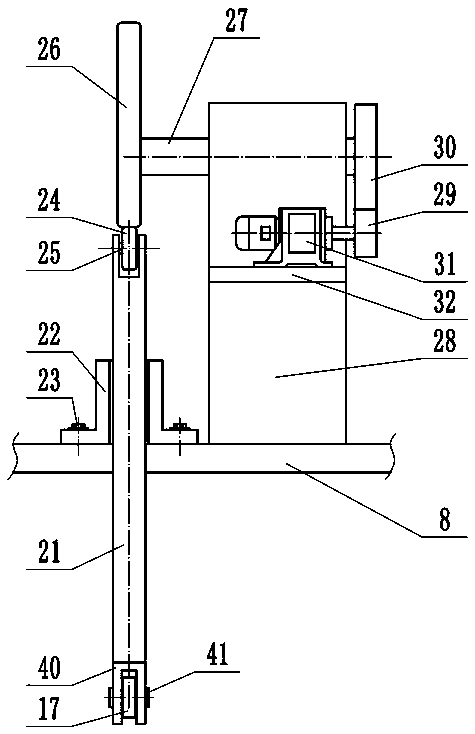

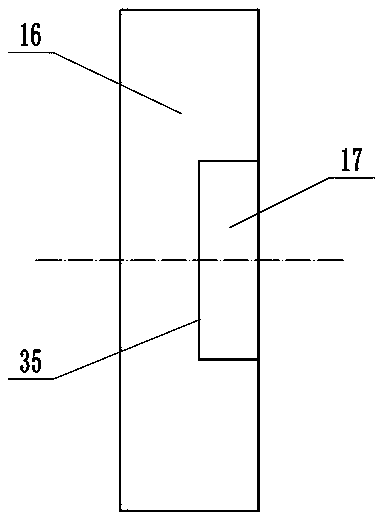

Yarn collecting device for core spun yarns in different types

PendingCN108532070APrevent tamperingRealize back and forth reciprocating actionYarnTextile disintegration and recoveryYarnEngineering

The invention belongs to the technical field of core spun yarns and provides a yarn collecting device for core spun yarns in different types. The yarn collecting device comprises a yarn unwinding mechanism, a yarn guide mechanism and a yarn collecting mechanism. The yarn unwinding mechanism comprises more than two yarn unwinding components, the lower end of a first front swing rod of a front tension adjustment driving portion of the yarn guide mechanism is fixed to a first front gear, the lower end of a second front swing rod is fixed to a second front gear, the lower end of a first rear swingrod of a rear tension adjustment driving portion is fixed to a first rear gear, and the lower end of a second rear swing rod is fixed to a second rear gear. A first tension adjustment roller is rotationally arranged at upper ends of the first front swing rod and the first rear swing rod, and a second tension adjustment roller is rotationally arranged at upper ends of the second front swing rod and the second rear swing rod. A driving gear of a yarn collecting guide component of the yarn collecting mechanism is rotationally arranged on a gear supporting seat and meshed with a fixed rack and amoving rack. The yarn collecting device is adjustable in yarn collecting force and applicable to collecting of the core spun yarns in different types.

Owner:桐乡市建泰纺织有限公司

Adjustable fabric punching device

The invention provides an adjustable fabric punching device and belongs to the technical field of fabric processing. The adjustable fabric punching device comprises a turntable, a lever and an adjusting screw rod. The turntable is rotationally arranged on an upper supporting ring of an upper disc seat and a lower supporting ring of a lower disc seat. The lever is clamped into a lever mounting groove of the turntable. The adjusting screw rod is in threaded connection with an adjusting screw rod nut. A left pin shaft at the left end of the lever is inserted into a lower U-shaped groove in the lower end of a punching lower supporting plate supporting frame. A punching lower supporting plate is horizontally arranged at the upper end of the punching lower supporting plate supporting frame. Punching nails are uniformly arranged at the upper end of the punching lower supporting plate. Punching grooves are uniformly formed in a punching upper supporting plate. A driving rod is arranged on a driving rod guide seat in the form of sliding up and down. A lower pin shaft at the lower end of the driving rod is inserted into a right U-shaped groove in the right end of the lever. A driving rod roller is rotationally arranged at the upper end of the driving rod through a driving rod roller supporting shaft. A driving cam is arranged at one end of a driving shaft. According to the adjustable fabric punching device, the stroke of the punching lower supporting plate is adjustable, and the punching processing of fabrics with different thicknesses can be realized.

Owner:桐乡市宏力纺织股份有限公司

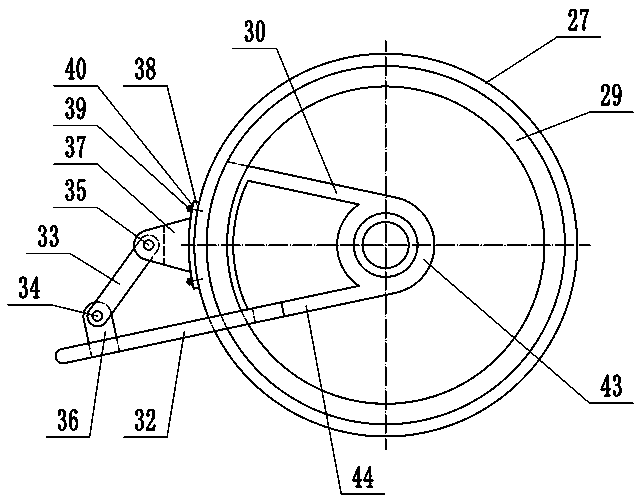

Supply device for glass fiber production

InactiveCN108905726AExtended service lifeHigh degree of engagementRotary stirring mixersTransportation and packagingGlass fiberPiston rod

The invention provides a supply device for glass fiber production and belongs to the technical field of glass fibers. The supply device comprises a proportional supply mechanism, a mixing mechanism and an auger supply mechanism; proportional supply assemblies of the proportional supply mechanism are equidistantly arranged; supply turnplates of the proportional supply assemblies are rotatably arranged in a turnplate supporting ring in a proportional supply seat; through supply holes which are connected in a diameter direction are formed in the supply turnplates; floating blocks are slidably arranged in the through supply holes in the supply turnplates; two rotation stopping flanges on rotation stopping wheels of a 180-DEG rotation stopping assembly are spaced for 180 DEG; mixing and stirring blades of the mixing mechanism are uniformly distributed and mounted on a mixing fulcrum shaft; a feeding auger of the auger supply mechanism is rotatably arranged in an auger supporting pipe; and the upper end of a discharging and unsealing piston rod of a mixing turnplate discharging and unsealing assembly is connected with a discharging and unsealing conical disk. By using the supply device,not only can the proportional mixing and supplying of various raw materials be rapidly realized, but also the various raw materials are precisely proportioned.

Owner:桐乡市安港新材料有限公司

Rotary grooving device for rubber ring

InactiveCN108015838ARealize groovingHigh degree of engagementMetal working apparatusRubber ringGear wheel

The invention provides a rotary grooving device for a rubber ring and belongs to the technical field of rubber ring processing. The rotary grooving device comprises a bearing sleeve, a left steel balland a right steel ball. An outer gear is arranged on the outer side of a rotary disc. A drive gear is engaged with the outer gear. The upper end of a drive shaft is coaxially fixed to the lower end of a piston. The middle end of a left swing rod is hinged to a left support through a left swing rod pin shaft. The middle end of a right swing rod is hinged to a right support through a right swing rod pin shaft. A left grooving seat is arranged on the left support through a guide pin in a left-right sliding manner. A right grooving seat is arranged on the right support through a guide pin in a left-right sliding manner. A left bearing bolt is attached to the left steel ball under the effect of a left return spring, and a right bearing bolt is attached to the right steel ball under the effectof a right return spring. The rubber ring is mounted on a centering rod and is locked through a locking nut. By the adoption of the rotary grooving device for the rubber ring, the rubber ring can be clamped stably, rotary grooving of the rubber ring can be achieved as well, the grooving speed is high, and efficiency is high.

Owner:TONGXIANG GREENCITY FLOCKING

Adhesive interlining device with anti-skid function

PendingCN111976258AGuaranteed stabilityAchieve fitLamination ancillary operationsBiochemical fibre treatmentEngineeringMechanical engineering

The invention provides an adhesive interlining device with an anti-skid function, and belongs to the technical field of garment processing. The adhesive interlining device comprises an adhesive interlining unwinding mechanism, a fabric unwinding mechanism, an adhesive interlining guiding mechanism, a fabric guiding mechanism, an adhesive interlining flattening mechanism, an adhesive interlining spraying and coating mechanism, a fabric flattening and shaping mechanism, a pressing mechanism and a winding mechanism, wherein the adhesive interlining spraying and coating mechanism comprises an adhesive interlining spraying assembly and an adhesive interlining coating assembly; an adhesive interlining upper coating roller and an adhesive interlining lower coating roller of the adhesive interlining coating assembly are rotationally arranged on a rack body; and the adhesive interlining spraying assembly is arranged between a second adhesive interlining flattening supporting roller and a firstadhesive interlining coating supporting roller. According to the adhesive interlining device, the adhesive interlining processing of the fabric and the adhesive interlining can be automatically completed, the relative sliding of the shell fabric and the adhesive interlining in the bonding process can be effectively avoided, the smoothness of the adhesive interlining is greatly improved, and the antibacterial property and stiffness of the molded adhesive interlining are greatly improved.

Owner:亘美集团有限公司

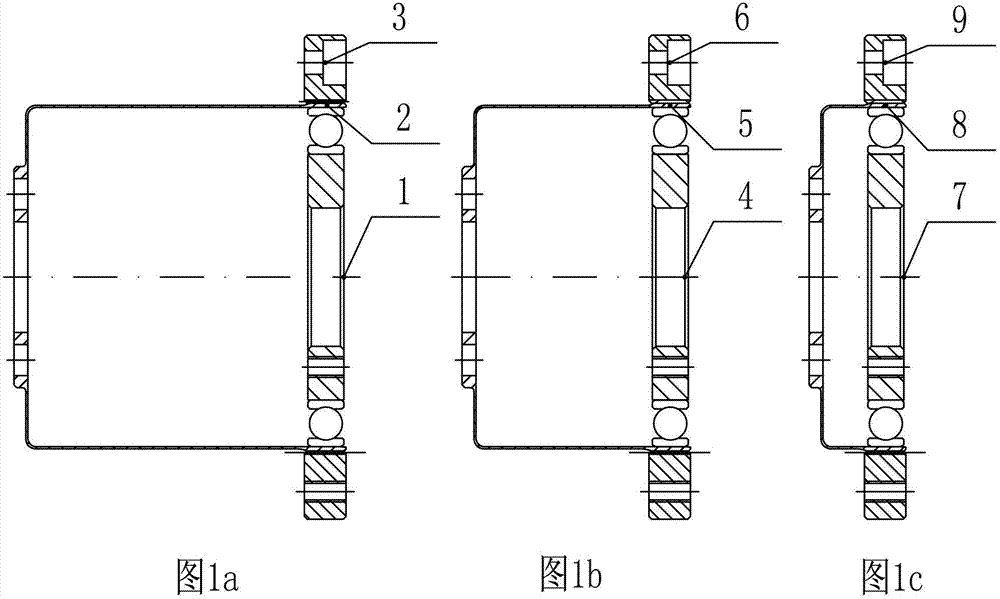

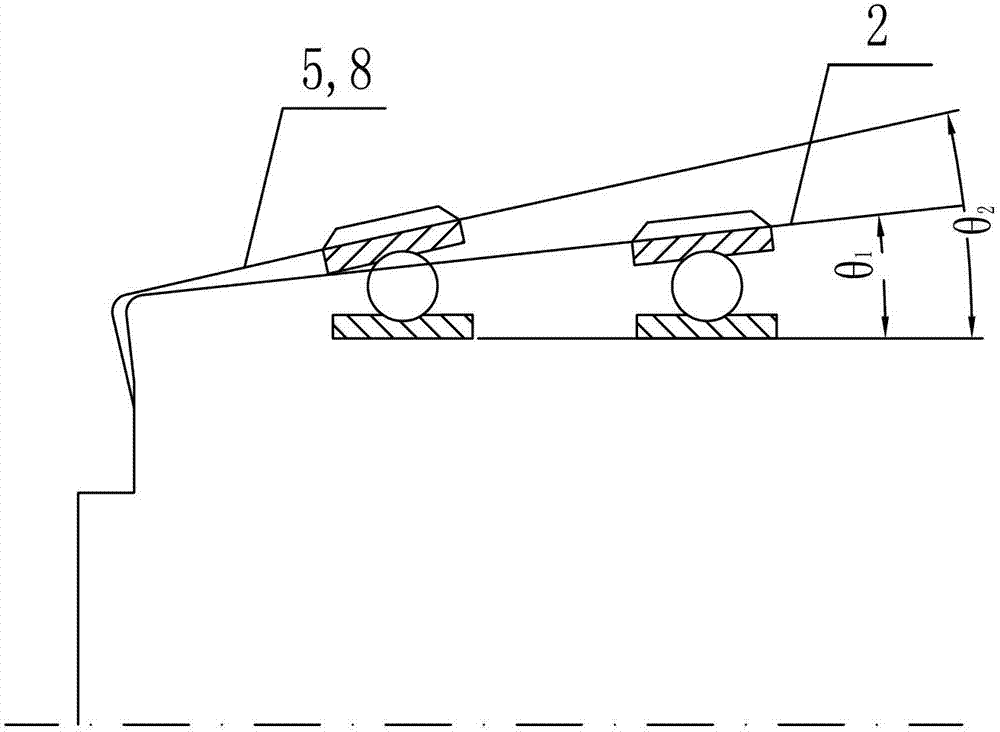

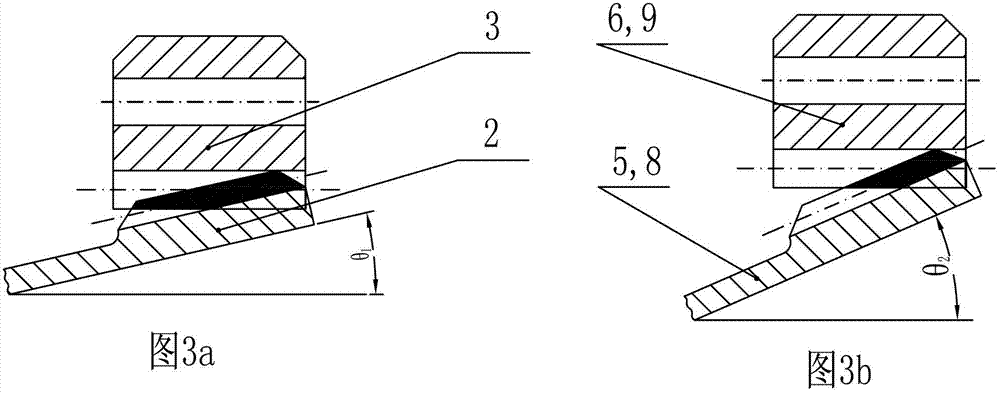

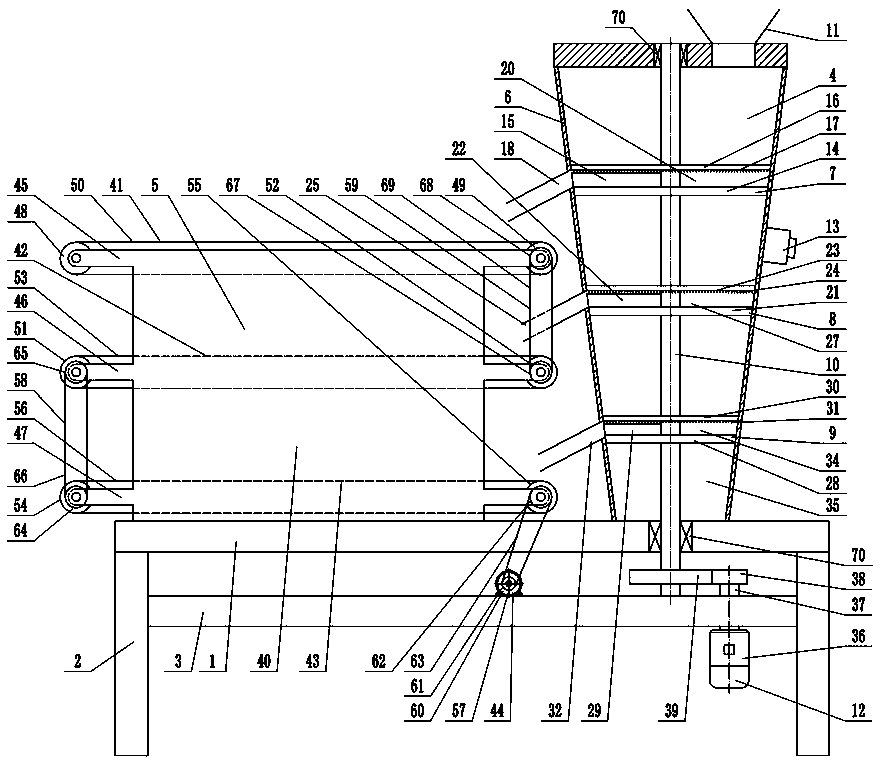

Rigid gear and flexible gear which are used for short-tube flexible-gear harmonic speed reducer and machining process thereof

Provided are a rigid gear and flexible gear which are used for short-tube flexible-gear harmonic speed reducer and a machining process thereof. Inner teeth of the rigid gear are gear teeth with an inclination angle alpha, the inclination direction of the inclination angle alpha is consistent with the field angle theta2 at the position of a long shaft of the flexible gear, and the inclination angle alpha is 0.1 degree to 2 degrees. Top ends of two tooth profile curve line sections of the outer tooth profile of the flexible gear are connected through a tooth top straight line section. Each tooth profile curve line section is formed by connecting upper circular radius and lower circular radius in smooth transition mode. The harmonic speed reducer comprises the rigid gear, the flexible gear and a wave generator. The ratio of the length and the inner diameter of the flexible gear is smaller than 1. The flexible gear and the rigid gear in the short-tube flexible-wheel harmonic speed reducer are both machined through a slow-feeding wire cutting off machine. The gear teeth of the flexible gear and the gear teeth of the rigid gear are meshed in the certain inclination angle. The total contact area of the meshing teeth pair is increased by 15% compared with the condition where no inclination angle exists. Overlapping ratio of the harmonic gears is improved, and harmonic transmission rigidity is improved.

Owner:DONGGUAN RICHTEK ELECTRONICS CO LTD

Cocoon stripper with screening function

PendingCN109881263AReduce wearHigh degree of engagementSilk cocoons cleaning/classifyingEngineeringControl theory

The invention provides a cocoon stripper with a screening function and belongs to the technical field of cocoon processing equipment. The cocoon stripper comprises a screening and cocoon stripping device and a screening and conveying device, wherein a first screening and cocoon stripping mechanism, a second screening and cocoon stripping mechanism and a third screening and cocoon stripping mechanism of the screening and cocoon stripping device are sequentially arranged in a cocoon feeding hopper from top to bottom; a first screening and cocoon stripping cavity is formed between a first cross-shaped cocoon stripping frame and a first screening disc of the first screening and cocoon stripping mechanism, a second screening and cocoon stripping cavity is formed between a second cross-shaped cocoon stripping frame and a first screening disc of the first screening and cocoon stripping mechanism, and a third screening and cocoon stripping cavity is formed between a third cross-shaped cocoon stripping frame and a third screening disc of the third screening and cocoon stripping mechanism, a collecting cavity is formed below the third screening disc, and the screening and conveying device comprises a first screening and conveying mechanism, a second screening and conveying mechanism, a third screening and conveying mechanism and a screening and conveying driving mechanism. The cocoon stripper not only can screen silkworm cocoons, but also can strip cocoon coats on the silkworm cocoons.

Owner:桐乡市腾飞家纺股份有限公司

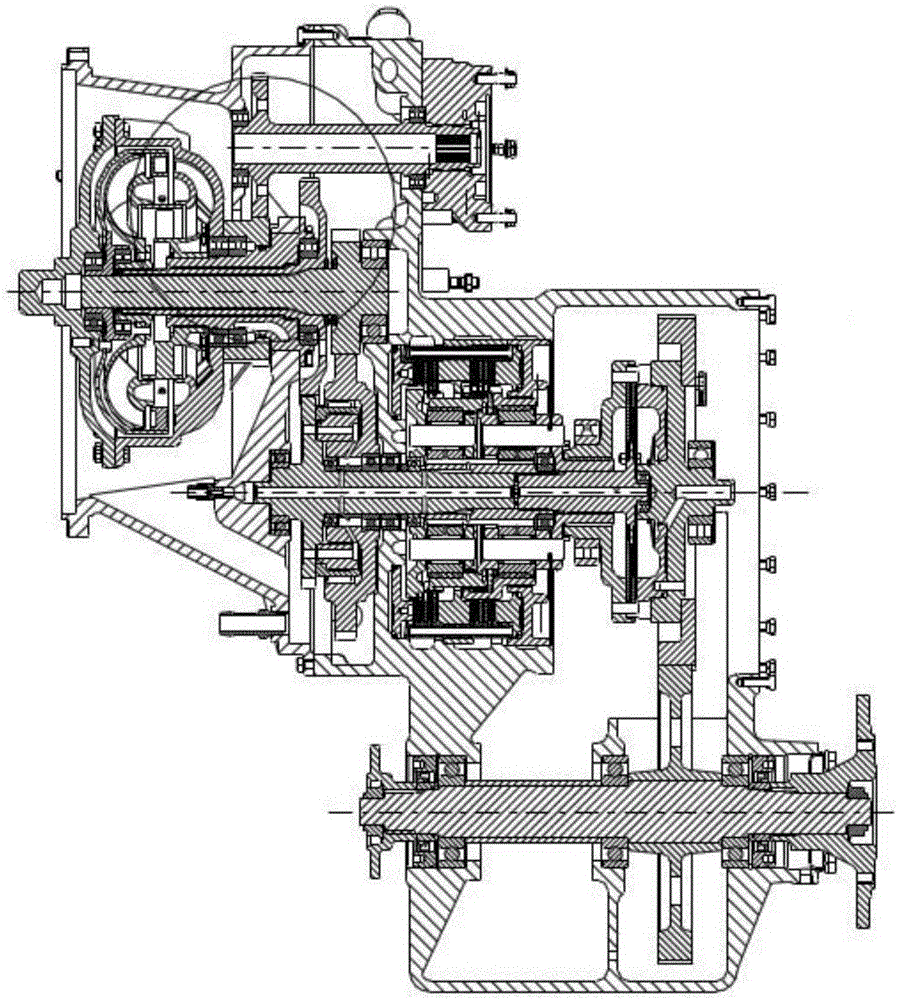

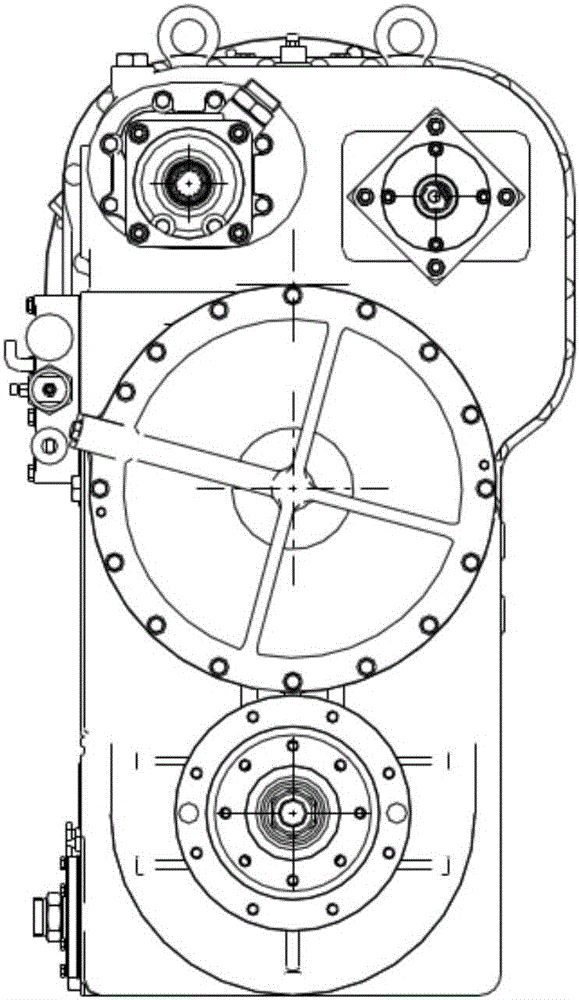

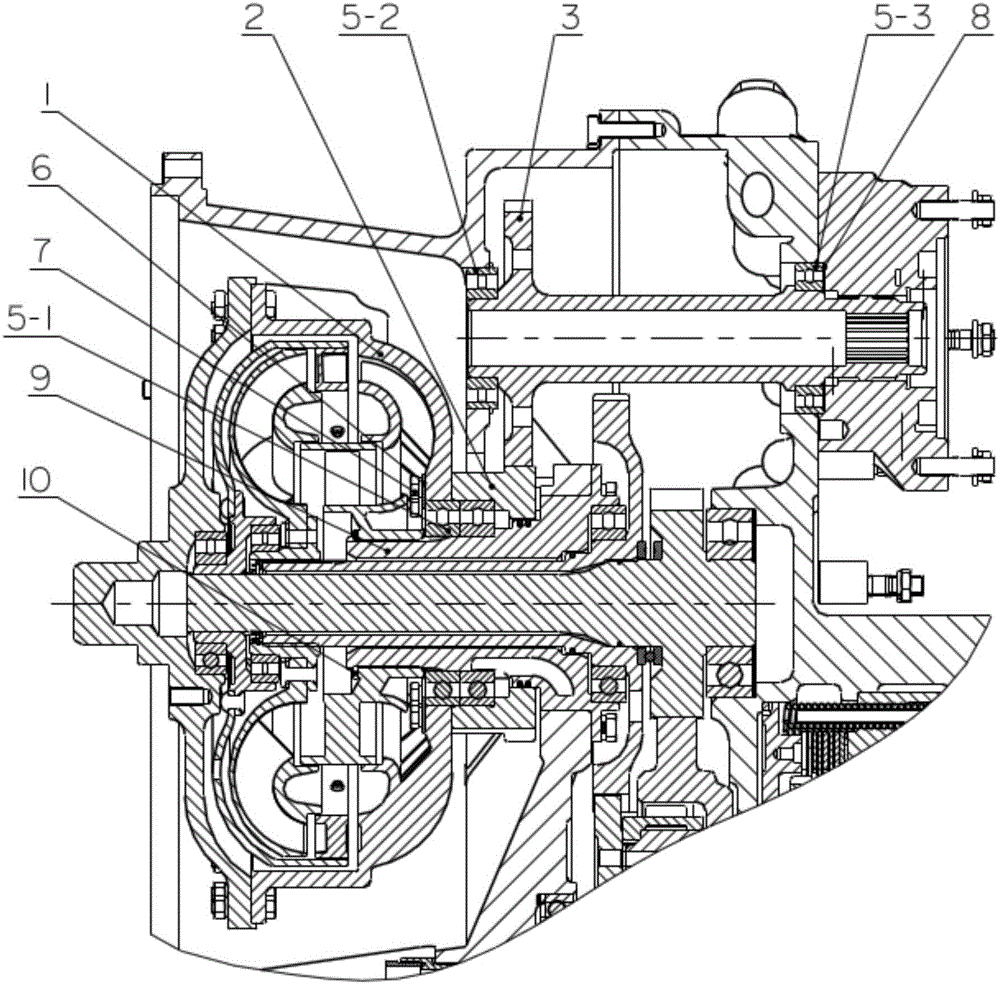

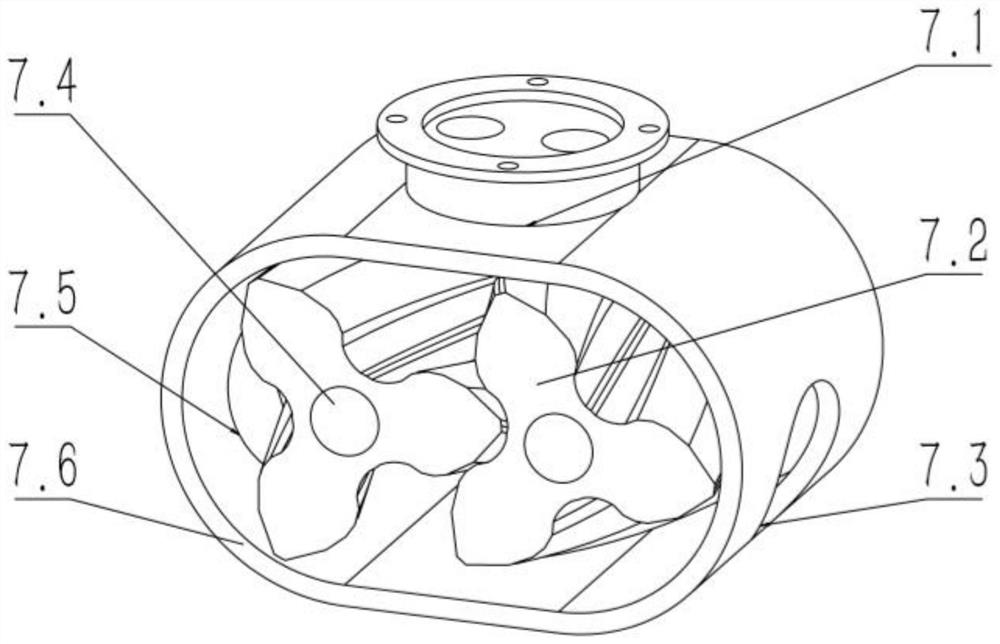

Gearbox

InactiveCN105805277ASolve the noiseHigh degree of engagementFluid gearingsGearing detailsImpellerTakeoff

The invention relates to gearboxes, aims to solve the problem that the noise of a conventional gearbox is high, and provides a gear box. The gearbox comprises a box body, wherein a double-turbine torque converter and a power take-off are arranged inside the box body; the power take-off comprises a transfer gear and at least one power takeoff shaft gear; the two ends of a rotating shaft of each power takeoff shaft gear are mounted on the box body through bearings; the transfer gear is fixedly connected with a pump impeller of the double-turbine torque converter; and the transfer gear and the power takeoff shaft gear are in meshing transmission through a helical cylinder gear. In the gearbox, the axial force generated by meshing of a helical gear pair between the transfer gear and the power takeoff shaft gear is easily absorbed by axially mounted parts such as the bearings and a locked spacer, and a power takeoff helical gear is steady in transmission and meshing, and low in noise.

Owner:GUANGXI LIUGONG MASCH CO LTD

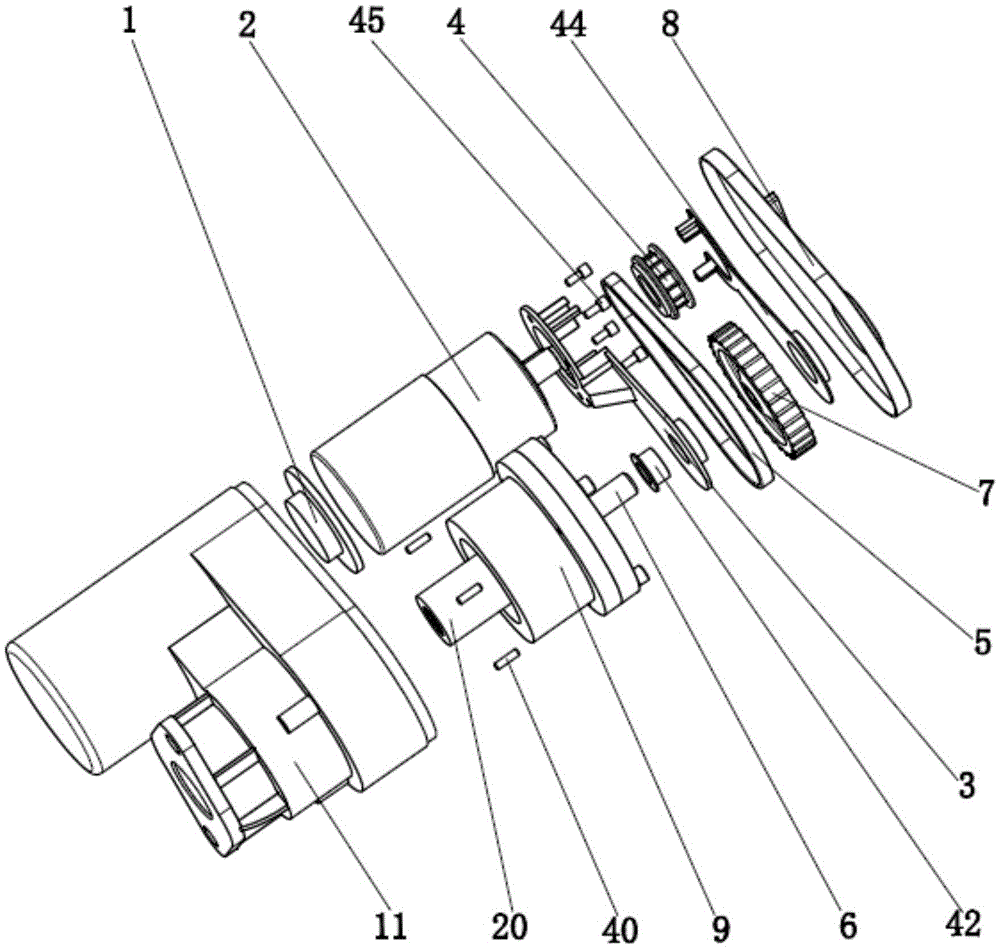

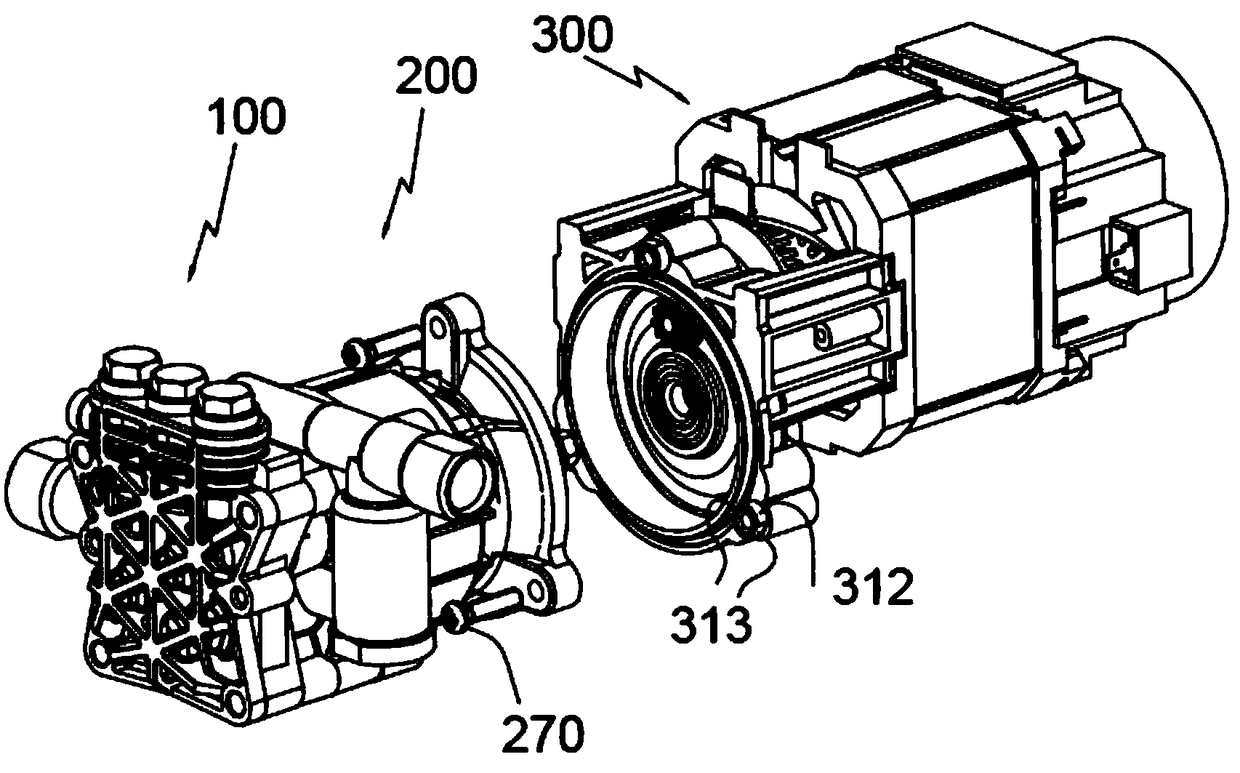

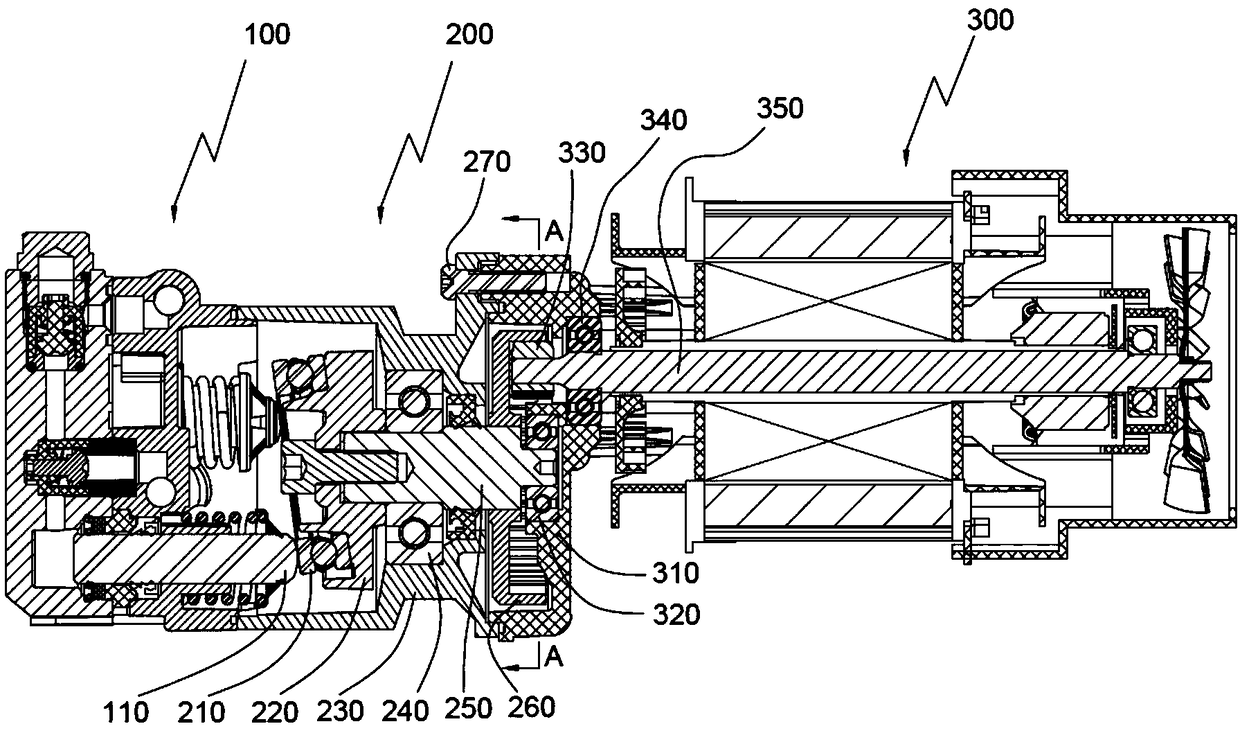

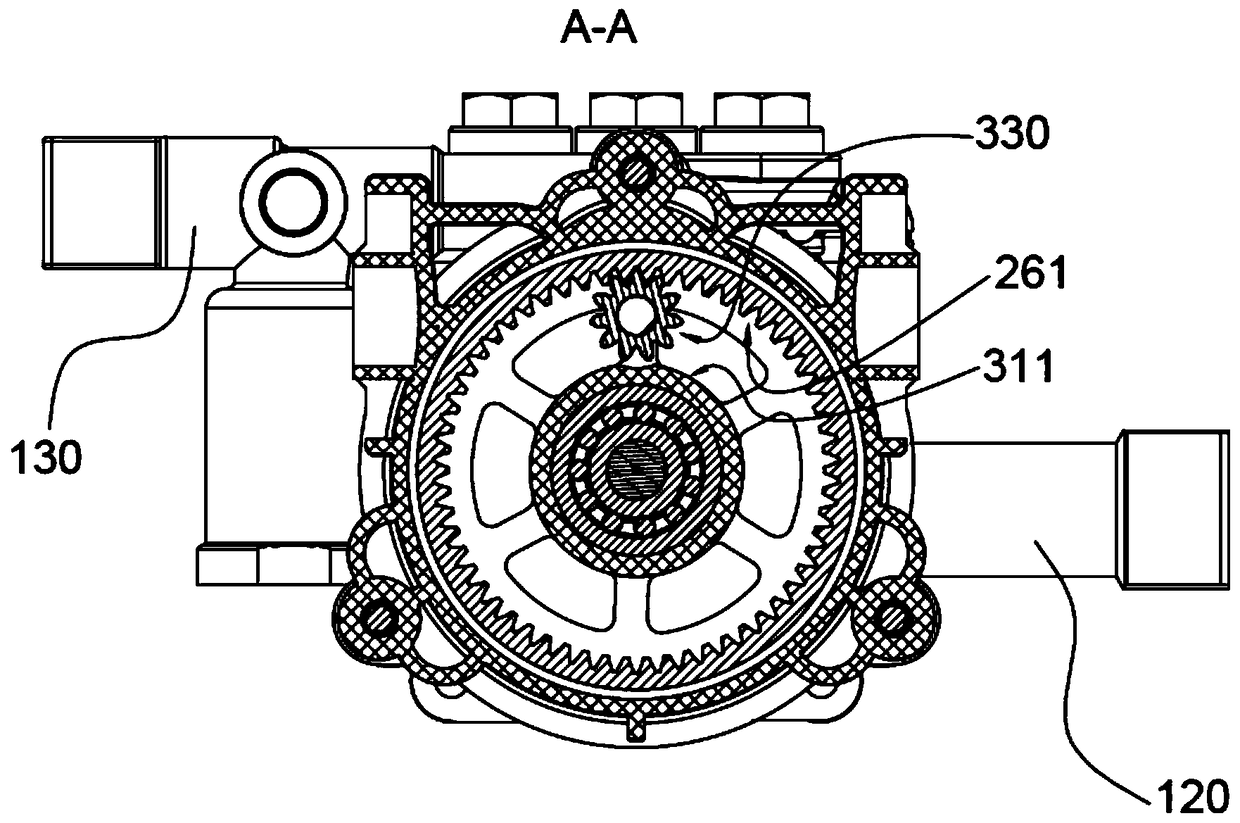

Motor pump unit

PendingCN109209809AHigh coincidenceSmooth transmissionPositive displacement pump componentsPositive-displacement liquid enginesDrive shaftEngineering

The invention provides a motor pump unit which comprises a pump assembly, a transmission box device and a motor assembly. The transmission box device comprises an inner gear part. The inner gear partat least comprises three end faces, the first end face, the second end face and the third end face, in the thickness extending direction. The inner gear part comprises an inner gear ring portion, a connecting portion and a fixed ring portion from outside to inside in the radial direction, wherein the inner gear ring portion, the connecting portion and the fixed ring portion are connected in sequence. The inner gear ring portion comprises an inner gear ring. The fixed ring portion comprises a driven shaft mounting hole. A driven shaft is relatively fixedly mounted in the driven shaft mounting hole in the circumferential direction and is connected with the pump assembly. An outer gear is relatively fixedly mounted on a motor shaft included in the motor assembly in the circumferential direction. The outer gear is mounted on the inner gear ring portion in an eccentric engagement manner. In the motor pump unit, due to the fact that inner engagement is adopted by large and small gear engagement, the overlap ratio of the two gears is higher than that of outer engagement, transmission is more stable, and noise is lower.

Owner:SHANGHAI YILI ELECTRIC

Large-scale horizontal type machining center

InactiveCN108098369AImprove reliabilityEasy to controlFeeding apparatusLarge fixed membersEngineeringScrew thread

The invention provides a large-scale horizontal type machining center and belongs to the technical field of machine tool equipment. The large-scale horizontal type machining center comprises a workbench translation device and a main shaft device, a workbench of the workbench translation device can realize translation in the X-direction and the Y-direction, a Z-direction support seat of the main shaft device can be slidably arranged on a Z-direction rail, a Z-direction screw rod is in threaded connection with a Z-direction screw rod nut, a pushing screw rod is in threaded connection with a pushing screw rod nut, one end of a winding connector is installed on a pushing support seat, the other end of the winding connector is clamped into a winding clamping groove at the right end of a main shaft, a second gear is installed on the main shaft through a flat key, the second gear and the flat key can slide relatively in the Y-direction, first support rolling balls and a first annular rail canbe connected in a rolling manner, second support rolling balls and a second annular rail can be connected in a rolling manner, and a first gear is engaged with the second gear. According to the large-scale horizontal type machining center, the main shaft can stretch out in the Y-direction, drilling and milling machining is realized, and the machining precision of workpieces is greatly improved.

Owner:TONGXIANG SHENGHUI PRECISION MACHINERY

Two-way taking and hot sealing device for mustard packing bags

InactiveCN108482757AAchieve clampingAchieve releaseWrapper twisting/gatheringConveyor partsReciprocating motionTransmission belt

The invention provides a two-way taking and hot sealing device for mustard packing bags, and belongs to the technical field of mustard processing. The device comprises a two-way taking mechanism, a two-way hot sealing mechanism and an unloading transmission mechanism; a taking turntable of the two-way taking mechanism is coaxially arranged at the upper end of a taking support shaft; a first takingmodule and a second taking module are arranged at the side ends of the taking turntable; a first hot sealing module and a second hot sealing module of the two-way hot sealing mechanism are symmetrically arranged on the front and back sides of a frame; the first hot sealing module comprises a first clamping part and a first hot sealing part; the second hot sealing module comprises a second clamping part and a second hot sealing part; a transmission belt of the unloading transmission mechanism is encircled on a front transmission roller and a back transmission roller; and the transmission beltis positioned below a first unloading tank and a second unloading tank. The device quickly realizes two-way taking and hot sealing of the mustard packing bags; twice taking of the mustard packing bagsonly can be realize through each reciprocating motion of the two-way taking mechanism; and the structure is reasonable.

Owner:桐乡市大周商贸有限公司

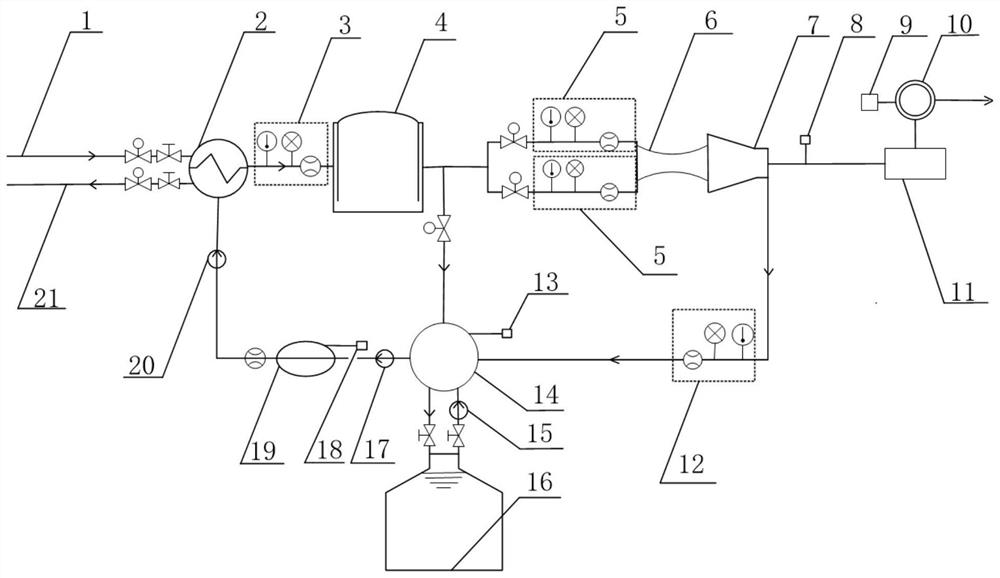

A low-quality waste heat recovery and utilization system

ActiveCN111749742BIncrease profitHigh heat conversion efficiencyLiquid degasificationFeed water supplyProcess engineeringGas holder

The invention discloses a low-quality waste heat recovery and utilization system, which includes a waste heat recovery system and a circulation system; the waste heat recovery system includes a waste heat inlet pipeline, a heat pipe steam generator and a waste heat outlet pipeline; the circulation system includes a gas storage tank sensor group, a storage tank Air tank, air inlet sensor group, Laval nozzle, Roots power machine, air outlet sensor group, condenser liquid level gauge, condenser, condensate make-up pump, make-up liquid tank and feed liquid pump. This system uses low-quality waste heat gas as the heat source. The waste heat recovery system makes the liquid working fluid absorb the heat in the waste heat gas and convert it into a gaseous state. The vapor is condensed into a liquid state through the condenser, and continues to be recycled. This system realizes the high-efficiency recovery and reuse of low-quality waste heat, with simple structure, high energy utilization rate and high heat conversion efficiency.

Owner:江苏科瑞德智控自动化科技有限公司 +1

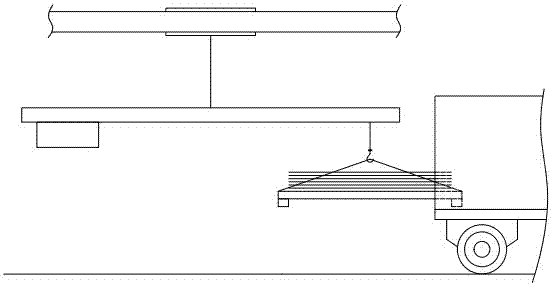

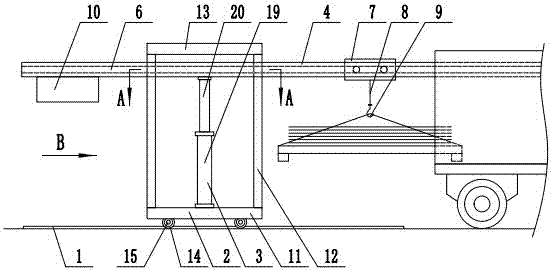

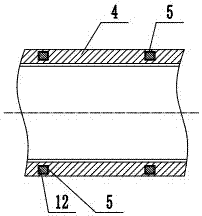

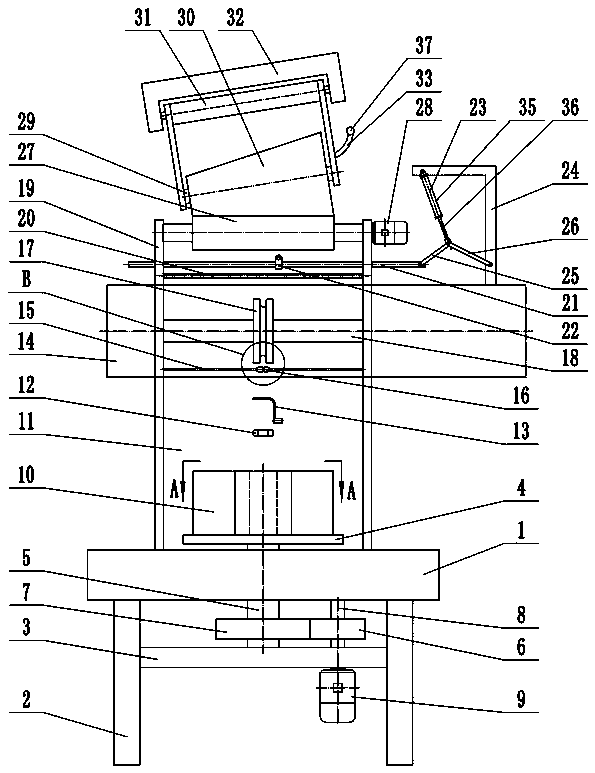

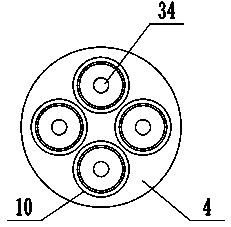

In-container large flat heavy cargo loading and unloading machine

PendingCN107954354AReduced stabilityImprove stabilityBase supporting structuresBraking devices for hoisting equipmentsLarge sizeHeavy load

The invention provides an in-container large flat heavy cargo loading and unloading machine, and belongs to the technical field of loading and unloading equipment. The in-container large flat heavy cargo loading and unloading machine comprises a moving vehicle, a lifting cylinder, a hoisting cross beam and a lifting device. A vehicle bottom base and a vehicle roof base of the moving vehicle are connected through vertical beams; the hoisting cross beam is arranged on the vertical beams of the moving vehicle in an up-down sliding mode; the upper end of a lifting piston rod of the lifting cylinder is connected with the hoisting cross beam; the direction of a lifting device guide rail is parallel to the moving direction of the moving vehicle; the lifting device can walk on the lifting device guide rail on the hoisting cross beam; a hoisting steel wire rope is arranged on the lifting device, and a lifting hook is connected with the lower end of the hoisting steel wire rope. By means of thein-container large flat heavy cargo loading and unloading machine, loading and unloading of large flat heavy cargo are quickly completed, the structure is reasonable and compact, the machine is safe and reliable, and moreover, the machine can be suitable for various types of containers and is high in applicability and reliability.

Owner:ZHEJIANG HUASHUN METAL MATERIAL CO LTD

Twisting equipment for wool yarn

InactiveCN109234860AAchieve orientationImplement bufferingContinuous wound-up machinesYarnEngineering

The invention provides twisting equipment for wool yarn and belongs to the technical field of textile machinery. The equipment comprises a yarn return twisting disc, yarn return cylinders, a hairinessyarn removal ring, a drafting guide wheel, a yarn guide shaft and a swing-type yarn guide ring. The yarn return twisting disc is coaxially fixed to the upper end of a yarn return twisting supportingshaft, the four yarn return cylinders are evenly distributed on the yarn return twisting disc, and a fixing-type yarn guide ring is located above the four yarn return cylinders; a swing-type yarn guide rack is located above the fixing-type yarn guide ring, the hairiness yarn removal ring is located above the swing-type yarn guide rack, and the drafting guide wheel is located above the hairiness yarn removal ring; the swing-type yarn guide ring is installed on a swing-type yarn guide ring supporting shaft, the left end of a first swing rod is hinged to the right end of the swing-type yarn guidering supporting shaft, the right end of a second swing rod is hinged to an L-shaped supporting base, and the lower end of a swing driving piston rod of a swing driving air cylinder is hinged to the right end of the first swing rod and the left end of the second swing rod. According to the twisting equipment, the wool yarn can be quickly twisted, and yarn hairiness can be removed.

Owner:嘉兴厚亿纺织股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com