Adhesive interlining device with anti-skid function

A technology of adhesive lining and function, applied in the field of garment processing, can solve the problems of easy degumming and separation, low efficiency, deviation of bonding position, etc., and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is not limited to the following examples in connection with the accompanying drawings.

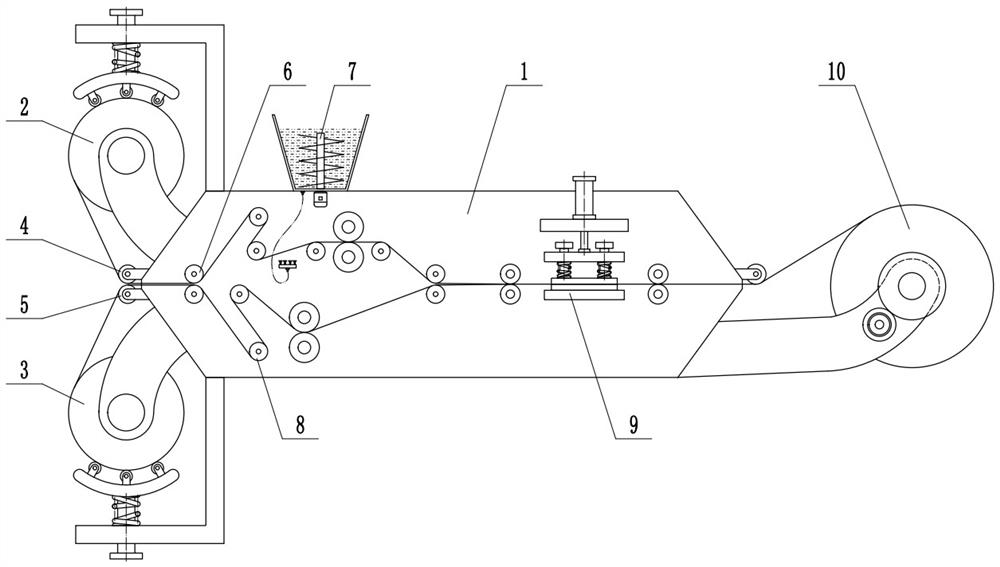

[0039] like figure 1 As shown in a fusing device with anti-skid function, comprising 1, 2 fusible unwinding mechanism, the fabric unwinding mechanism 3, the guide mechanism 4 interlining fabric guide mechanism 5, show frame body interlining leveling mechanism 6, the spray coating mechanism 7 interlining fabric flattened shape means 8, 9 pressing mechanism, winding mechanism 10.

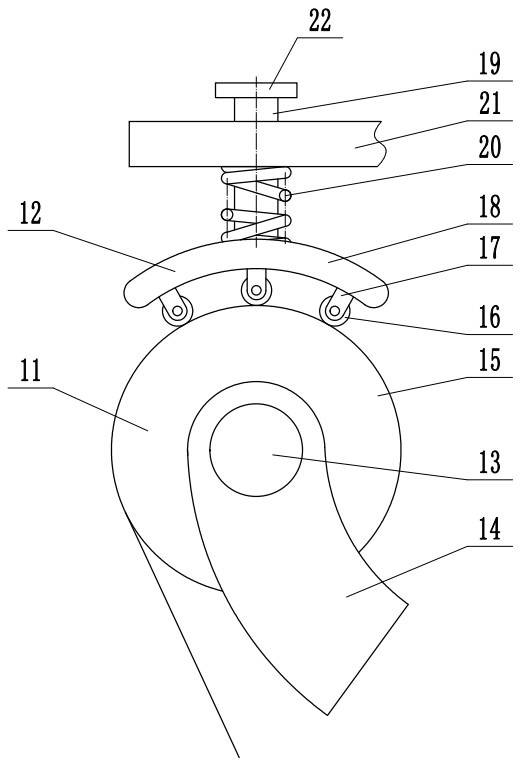

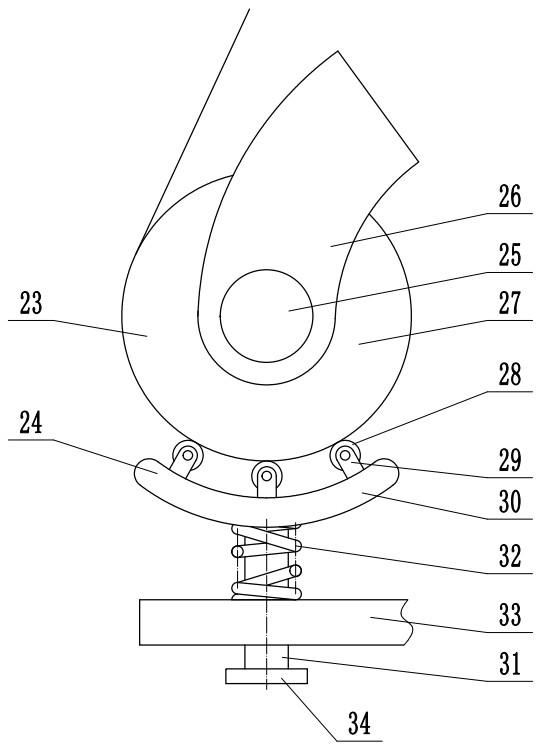

[0040] like figure 1 , figure 2 , image 3As shown in the unwinding means 2 interlining fabric unwinding mechanism 3 is provided vertically symmetric on the left side of the frame body 1, the unwinding mechanism 2 comprises a fusible interlining and the adhesive unwinding assembly 11 the damper assembly of the liner 12 is unwound, the unwinding assembly 11 includes a fusible interlining back reel 13, the unwinding stand interlining 14, 15 volumes interlining, the interlining 14 is mounted i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com