Gearbox

A gearbox and box technology, applied in the field of gearboxes, can solve problems such as high gearbox noise, and achieve the effect of solving large noise, high meshing coincidence, and satisfying noise reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

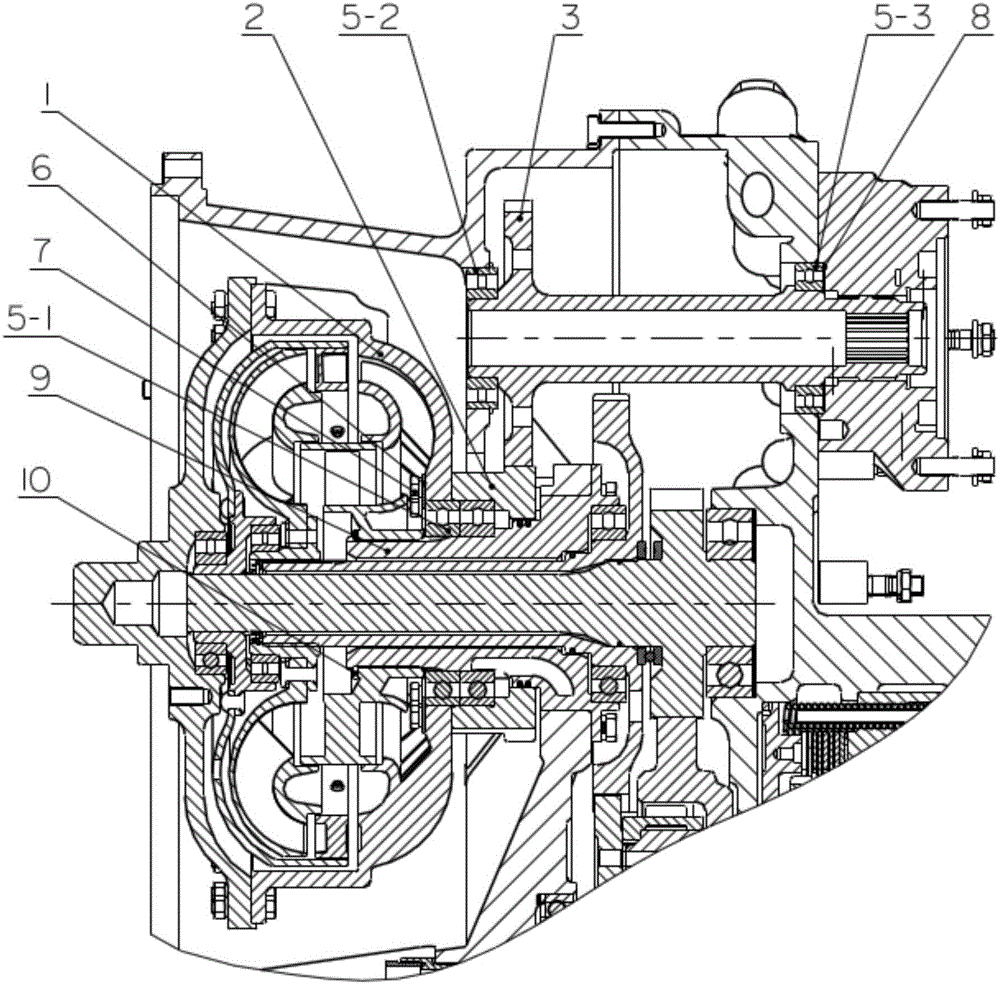

[0020] The specific implementation will be described below in conjunction with the accompanying drawings.

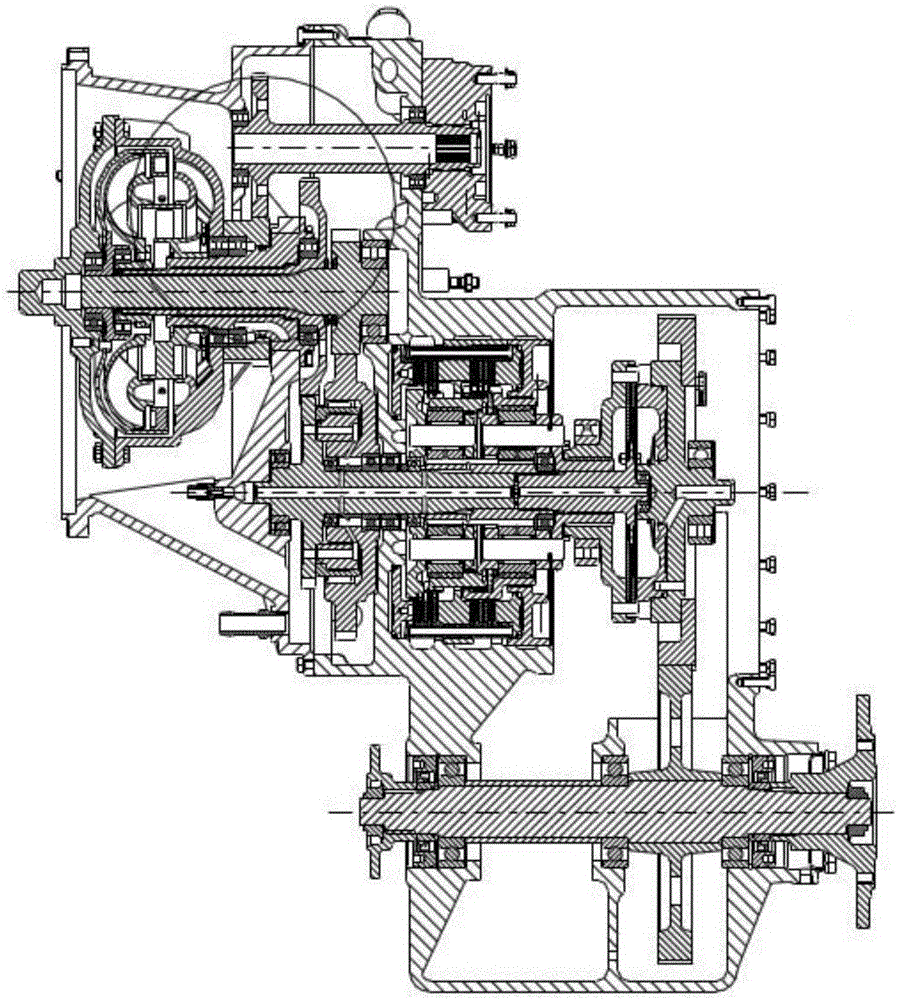

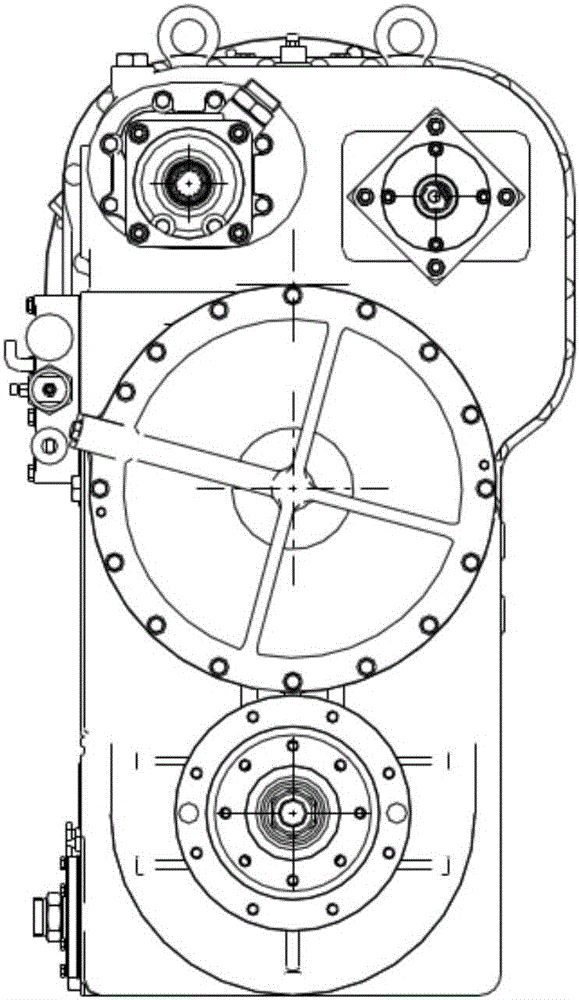

[0021] In this embodiment, the gearbox is a planetary gearbox driven by a power take-off helical gear, such as figure 1 and figure 2 As shown, the transmission is composed of a twin-turbine torque converter, an overrunning clutch, a reverse clutch, a first-gear clutch, a second-gear clutch, a variable speed pump, a variable speed control valve and an output assembly, and can realize two forward gears and one reverse gear . The power take-off of the gearbox includes a transfer gear 2 and two power take-off shaft gears, namely a first power take-off shaft gear 3 and a second power take-off shaft gear 4 .

[0022] Such as image 3 and Figure 4 As shown, the two ends of the rotating shaft of each power take-off shaft gear are installed through the first thrust bearing 5-2 and the second thrust bearing 5-3, so that the power take-off shaft gear can be installed on the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com