Fan control system

A fan control and fan technology, applied in pump control, electric temperature control, non-variable-capacity pumps, etc., can solve problems such as high temperature and damage to working components, reduce huge deviations, stabilize fan speed, solve The effect of high noise and high power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

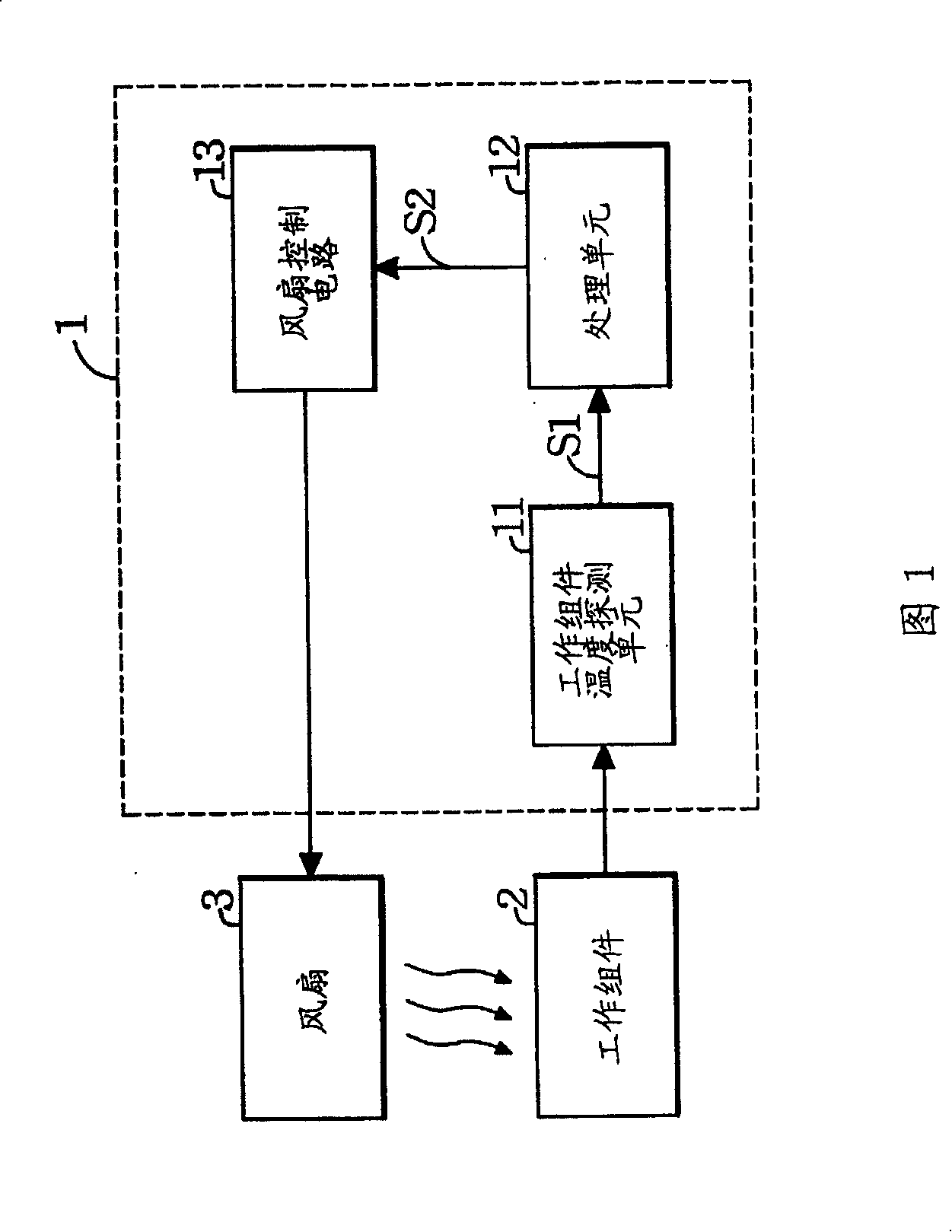

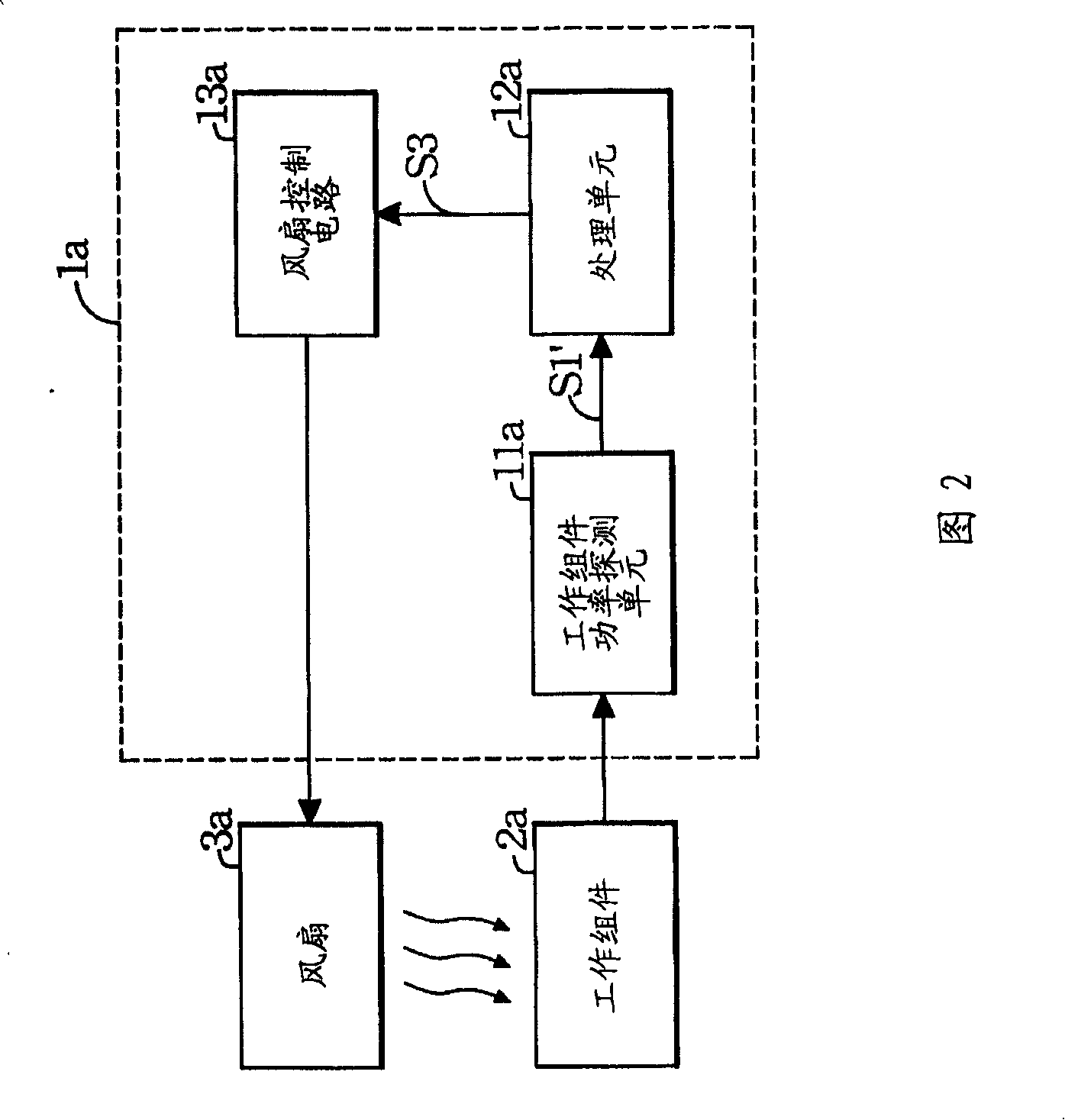

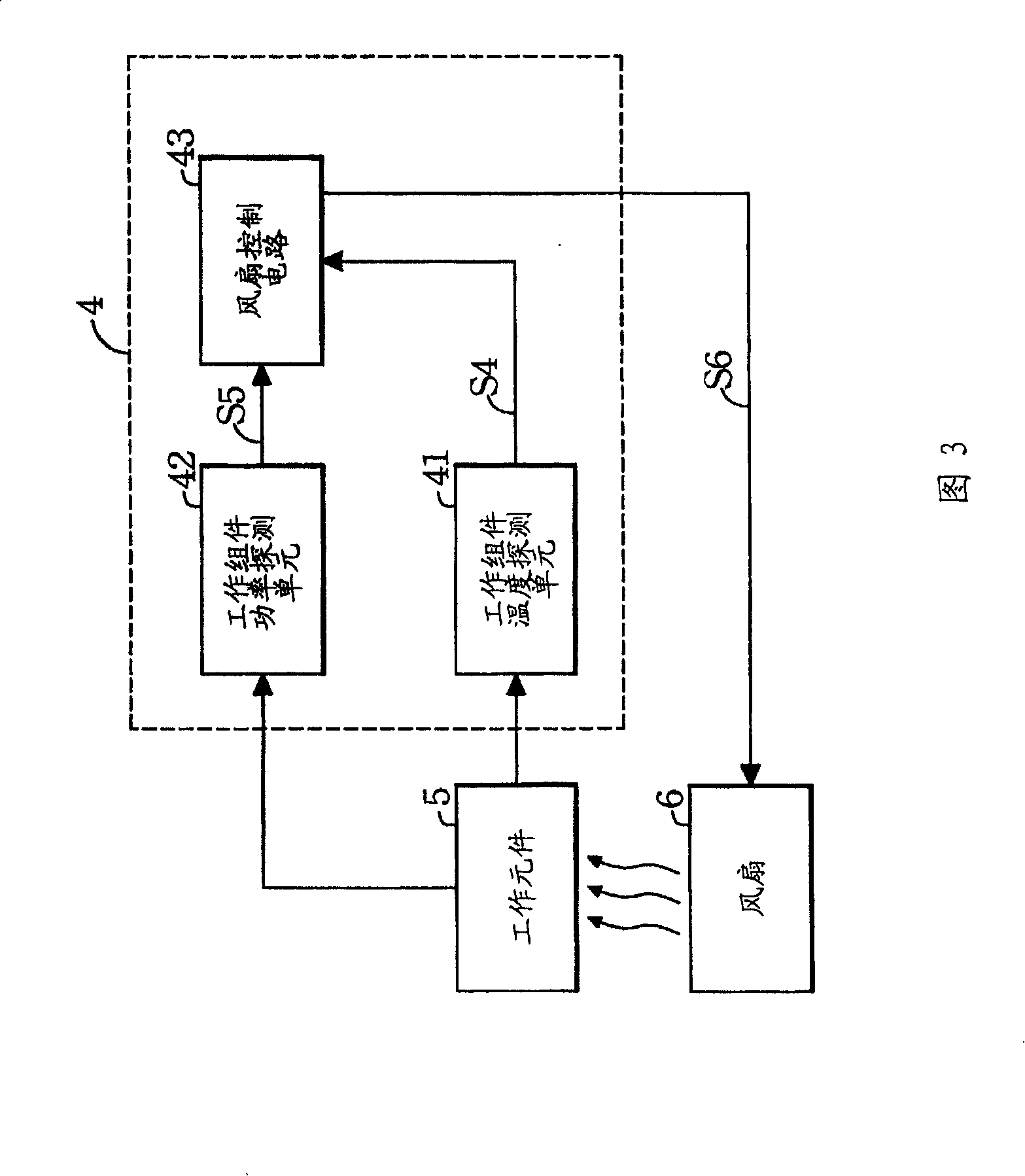

[0061] The specific embodiments adopted by the present invention will be further described through the following embodiments and attached drawings.

[0062] Since the fan control system provided by the present invention can be widely used in various systems with cooling or heat dissipation fans, and its combination implementations are too numerous to enumerate, so it is not repeated here, and only two preferred implementations are listed. example to illustrate.

[0063] Please refer to FIG. 3 , which is a functional block diagram showing the first embodiment of the present invention. As shown in the figure, a fan control system 4 is used to detect the temperature and power of a working component 5 , so as to control the speed of a fan 6 used to cool the working component 5 . The fan control system 4 includes a working component temperature detection unit 41 , a working component power detection unit 42 and a fan control circuit 43 . Wherein, the working component temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com