In-container large flat heavy cargo loading and unloading machine

A container and loading and unloading machine technology, applied to cranes, hoisting devices, traveling mechanisms, etc., can solve problems such as loss of balance, personal injury and property, and prone to accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

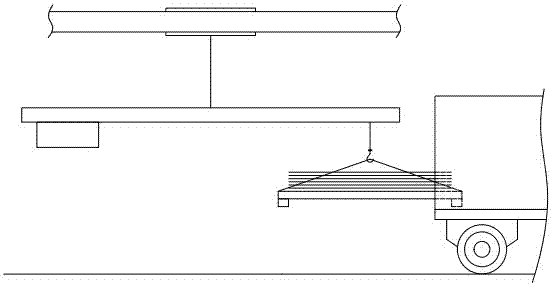

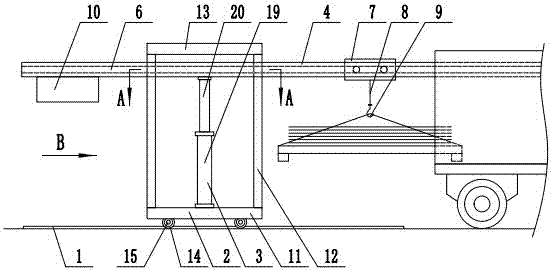

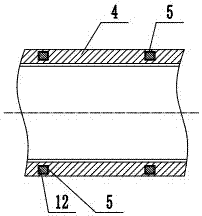

[0018] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown in the figure, a loading and unloading machine for a container with a large flat plate and heavy objects includes a translation vehicle track 1, a translation vehicle 2, a lifting cylinder 3, a lifting beam 4, a sliding sleeve 5, a lifting device guide rail 6, a lifting device 7, and a hoisting wire rope 8, hook 9, weight 10, described translation car 2 comprises car base 11, vertical beam 12, roof seat 13, wheel 14, wheel axle 15, first transmission gear 16, second transmission gear 17, drive Motor 18, described car base 11 and car roof seat 13 are connected by vertical beam 12, and the quantity of described vertical beam 12 is fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com