Cycloidal gear tooth profile correction method, cycloidal gear and RV (rotary vector) reducer

A cycloidal gear tooth and cycloidal gear technology, which is applied in instruments, special data processing applications, electrical digital data processing, etc., can solve problems such as jamming, assembly difficulties, processing errors, etc. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

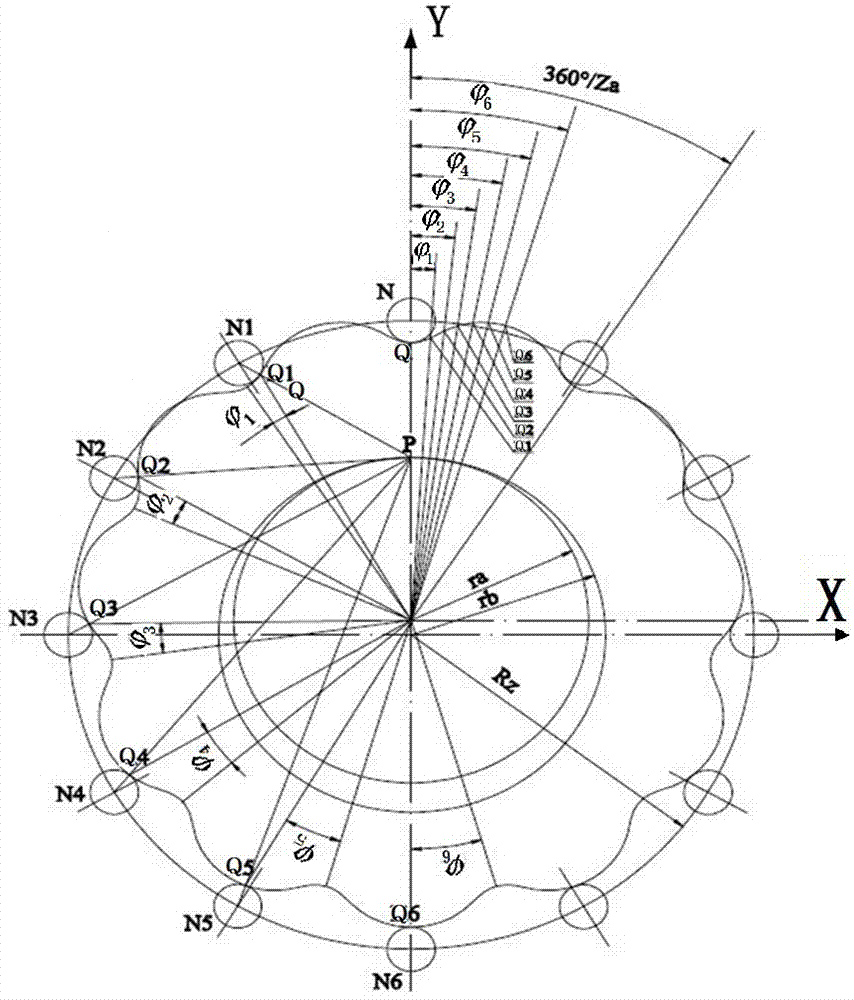

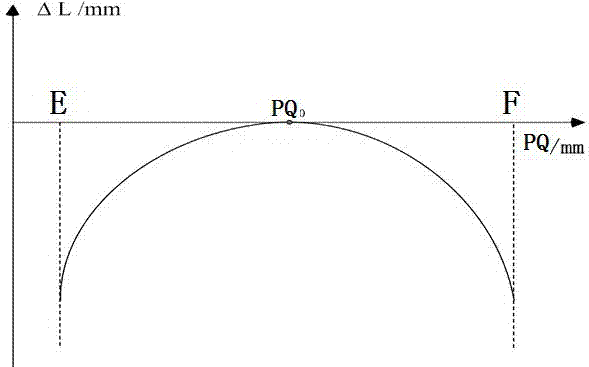

[0030] A specific embodiment of the method for modifying the tooth profile of the cycloid wheel of the present invention, the meshing phase angle of half the pin wheels in the transmission state and the cycloid wheel After transformation, it can be expressed in the right half cycloid tooth shape, such as figure 1 As shown in the figure, the geometric center of the cycloid wheel is taken as the origin, the axis passing through the origin and coincident with the symmetry axis of the cycloid wheel is selected as the Y axis, and the axis perpendicular to the Y axis passing through the origin is used as the X axis to establish a coordinate system. The tooth profile equation of a standard cycloidal wheel is:

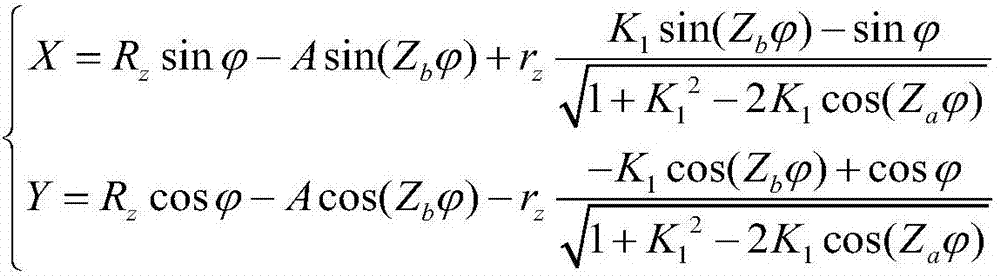

[0031]

[0032] In the formula: X, the horizontal axis coordinate of the cycloid gear profile; Y, the vertical axis coordinate of the cycloid gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com