Shaping method and manufacturing method for involute straight tooth planetary transmission gear

A planetary transmission and involute technology, applied in the direction of components with teeth, belts/chains/gears, gear teeth, etc., can solve the problems of unstable transmission, poor bearing capacity, and easy early failure, and achieve shape modification The effect of small difficulty, improving bearing capacity and eliminating partial load phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

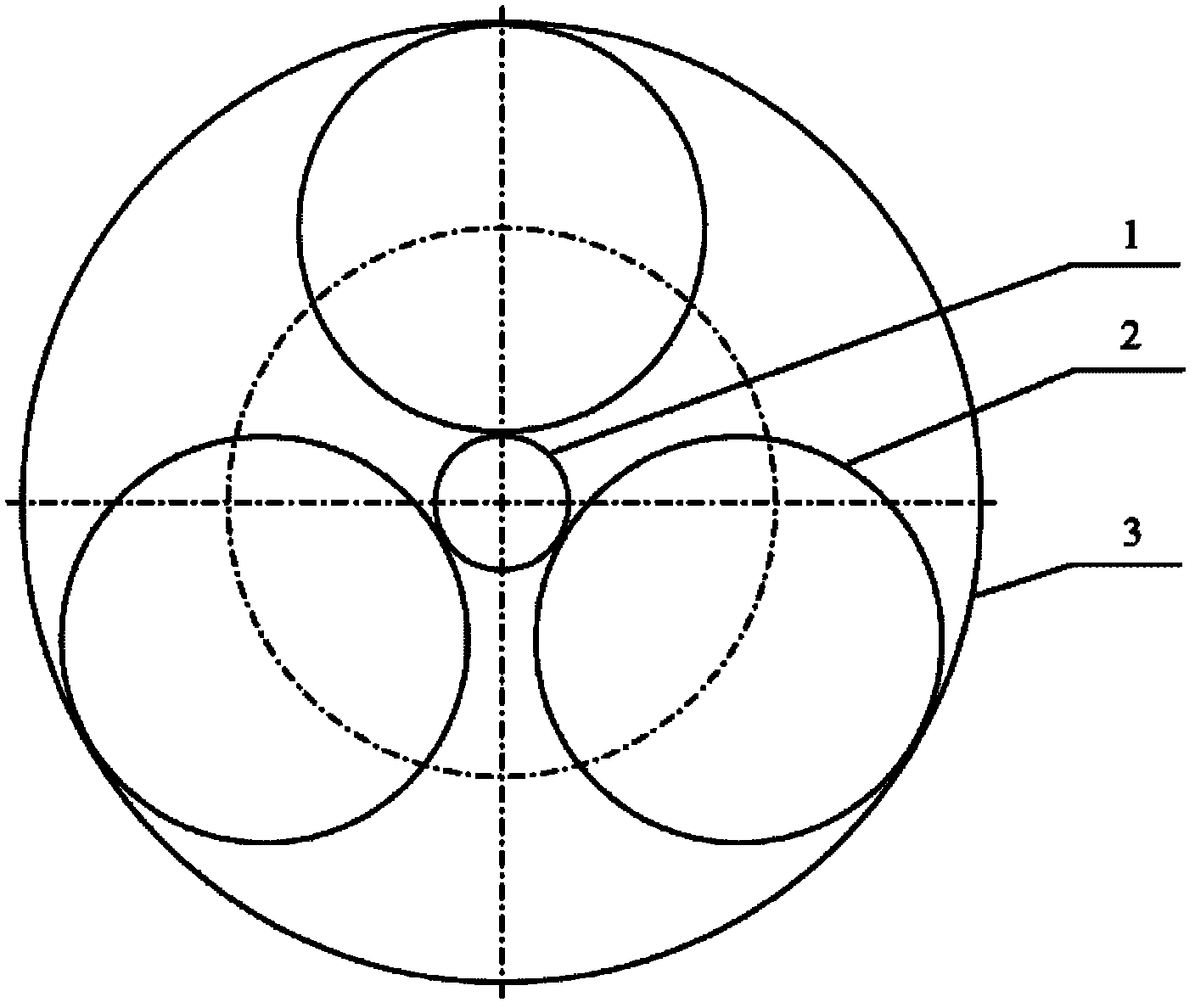

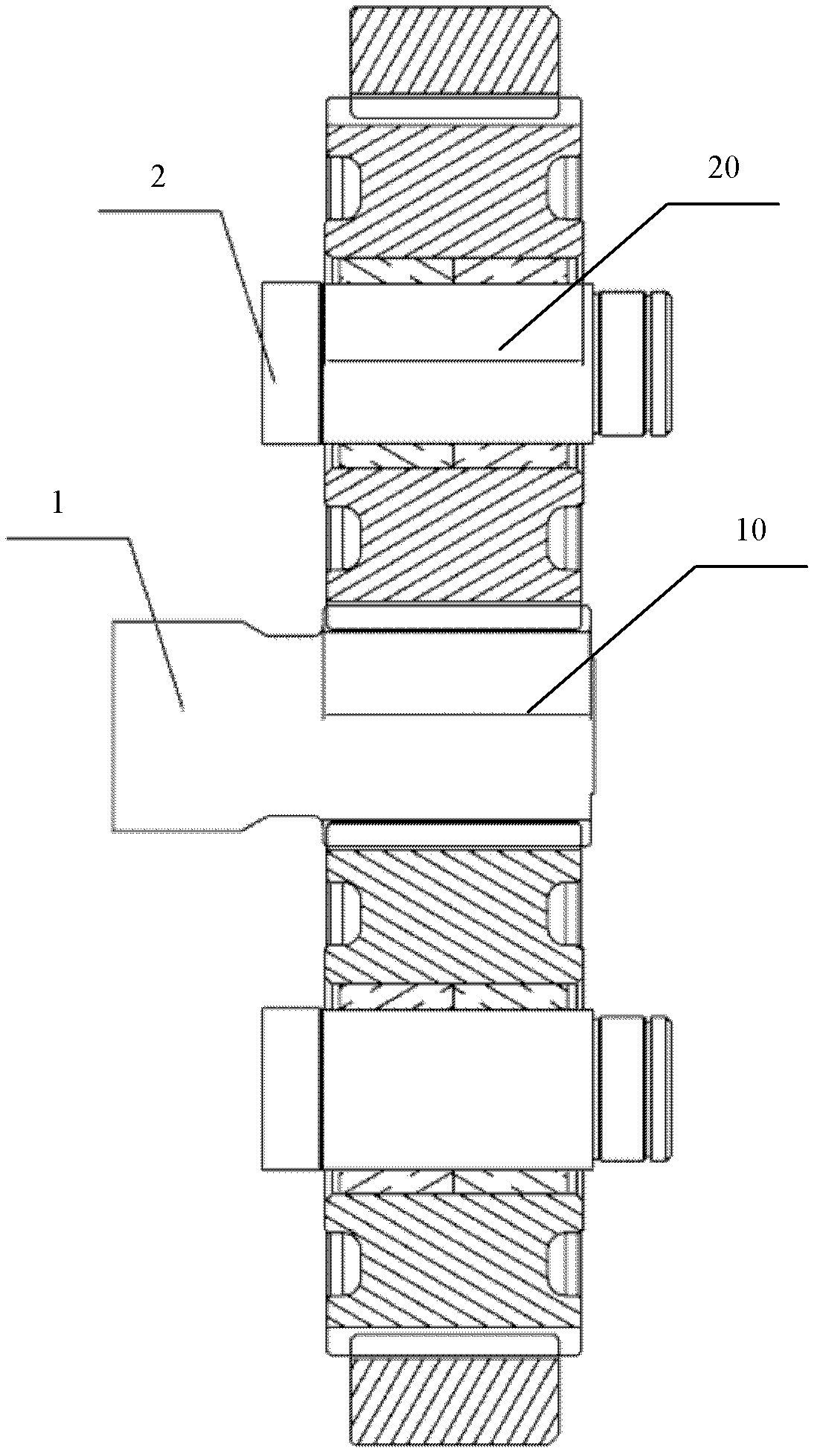

[0021] see in conjunction Figure 1 to Figure 2 , shows the schematic diagram of the structure and top view of the involute spur planetary transmission gear. It can be seen from the figure that the involute spur planetary gear generally includes: a sun gear 1, a ring gear 3 and a plurality of planetary gears 2. The modifying method of the present invention includes modifying the sun gear 1 and the planetary gear 2 without modifying the ring gear 3 .

[0022] The modification method of the involute spur planetary transmission gear includes the following steps:

[0023] Step 1. Obtain the predetermined load value.

[0024] Specifically, the predetermined load value is the rated working load o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com