Grooving machine cutter

A slotting machine and cutter technology, applied in roads, road repairs, roads, etc., can solve problems affecting work efficiency and slow slotting speed, and achieve the effect of increasing slotting speed and reducing slotting workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

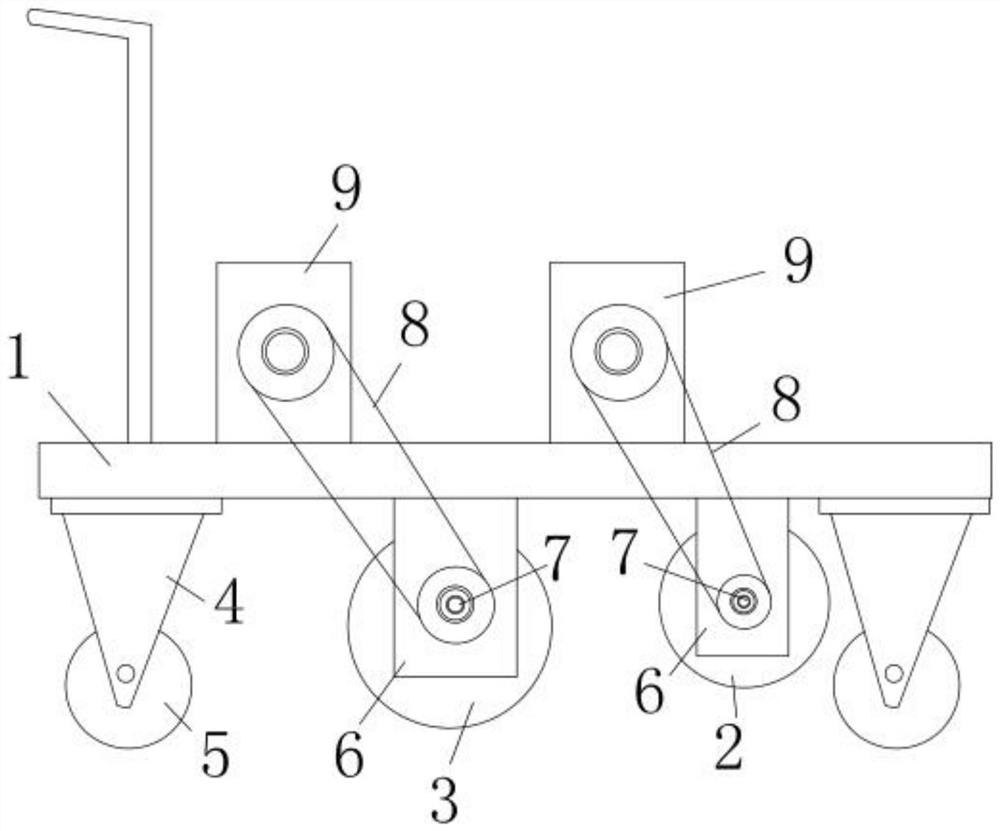

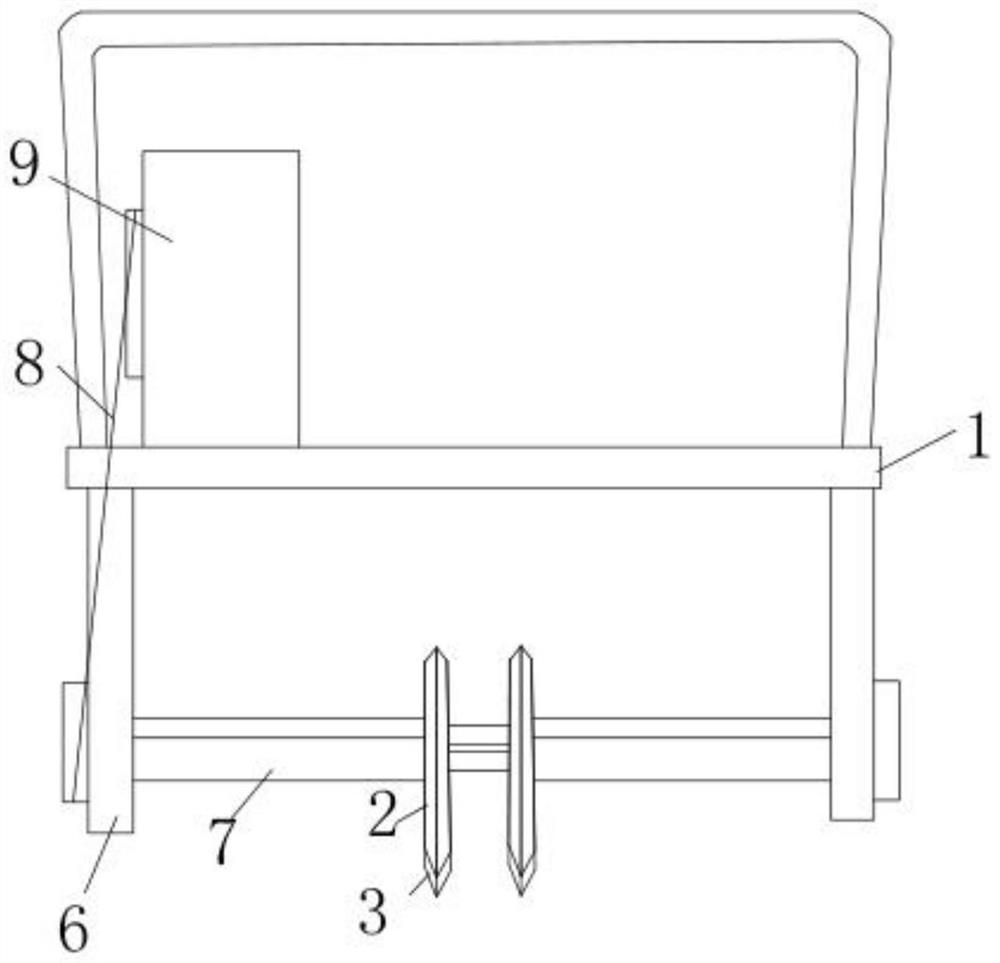

[0019] A slotting machine tool of this embodiment, Figure 1-2 As shown, a moving frame 1 is included, and the moving frame 1 is provided with a downward rotary knife, and the rotary knife includes a first rotary knife group 2 and a second rotary knife group 3 arranged in sequence along the advancing direction of the mobile frame 1 , so that the second rotary knife group 3 can replenish the first rotary knife group 2 in time to slot, and each rotary blade on the first rotary knife group 2 is connected with each rotary knife on the second rotary knife group 3 respectively. On the same plane so that the grooves opened are on a straight line, the axes of the first rotary knife group 2 and the second rotary knife are all perpendicular to the plane where the rotary knife is located, and each of the first rotary knife group 2 The rotary knives have the same size and are coaxial, and the rotary knives of the second rotary knife group 3 have the same size and are coaxial, and the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com