An automatic unloading plank slotting device

A technology of automatic cutting and driving device, applied in slotting machines, mortising machines, wood processing appliances, etc., can solve the problems of complexity, waste of time and energy, and difficulty in realizing rapid slotting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

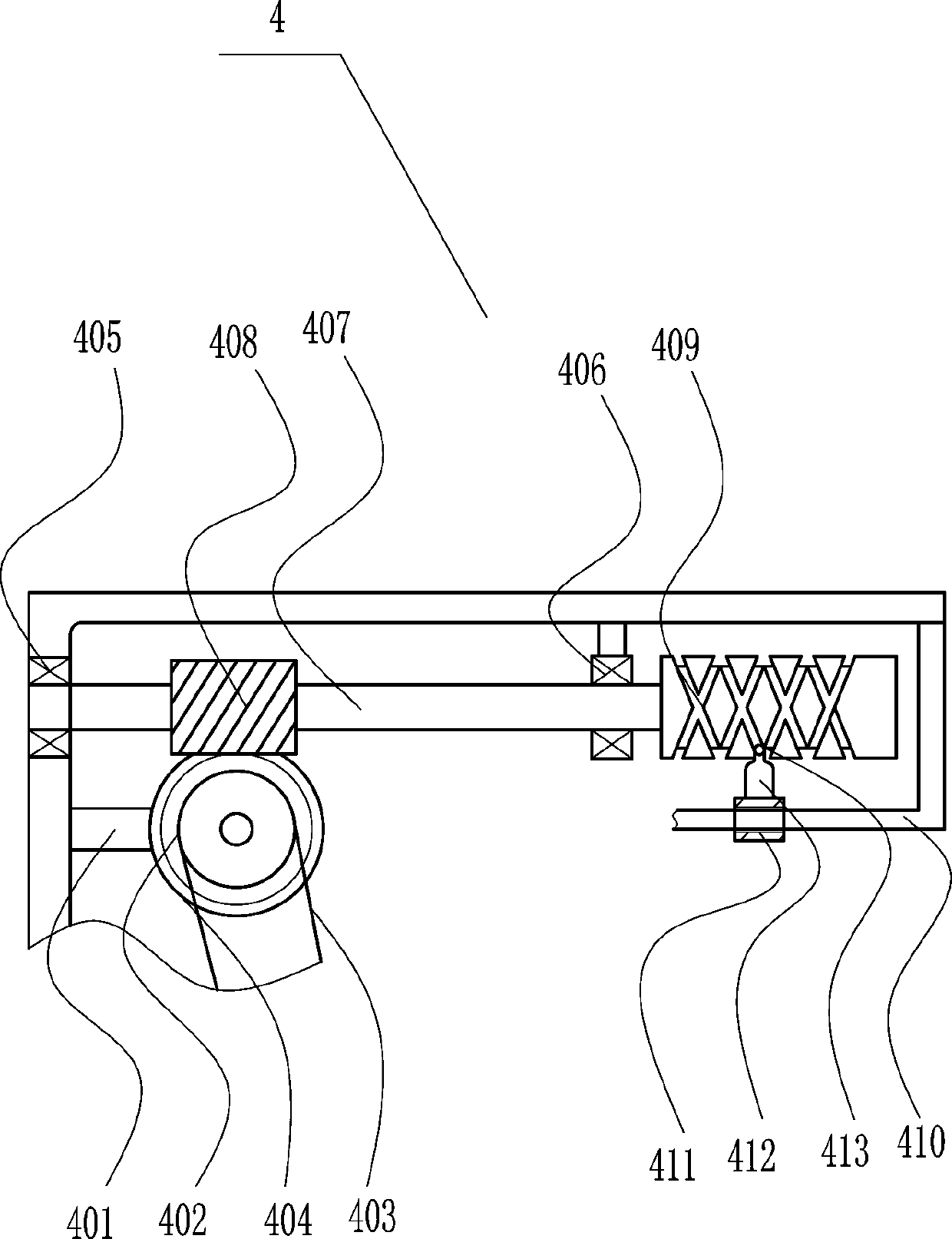

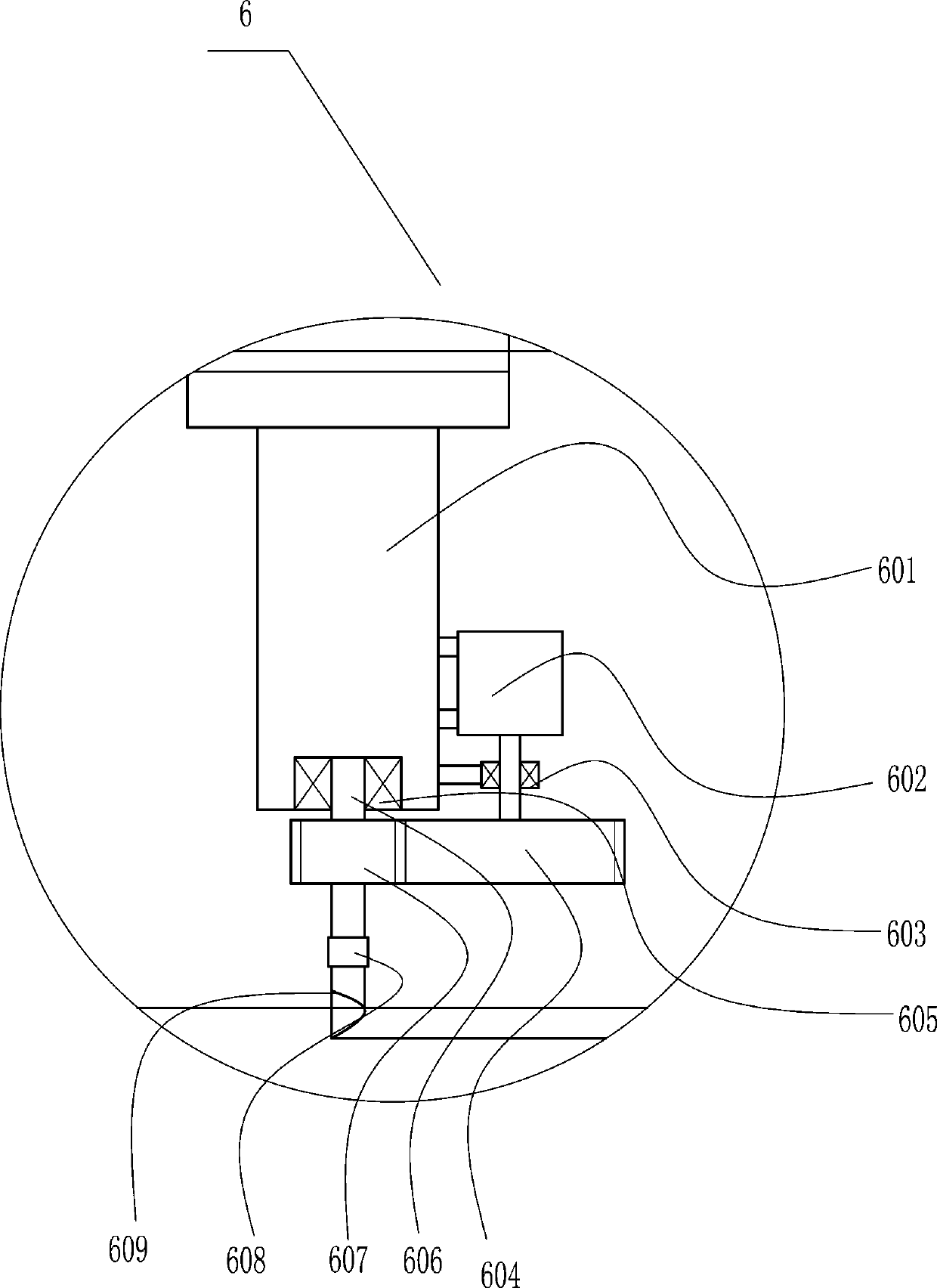

[0037] An automatic unloading plank slotting device, such as Figure 1-8 As shown, it includes a frame 1, a driving device 2, a transmission device 3, a cam device 4, a feeding device 5, a slotting device 6 and a switch device 7, and the top of the frame 1 is provided with a driving device 2, and the right side of the driving device 2 The side is provided with a conveying device 3, the cam device 4 is arranged above the drive device 2, the lower part of the cam device 4 is provided with a feeding device 5, the lower part of the cam device 4 is provided with a slotting device 6, and the lower side of the feeding device 5 is provided with a There is a switching device 7 .

Embodiment 2

[0039] An automatic unloading plank slotting device, such as Figure 1-8 As shown, it includes a frame 1, a driving device 2, a transmission device 3, a cam device 4, a feeding device 5, a slotting device 6 and a switch device 7, and the top of the frame 1 is provided with a driving device 2, and the right side of the driving device 2 The side is provided with a conveying device 3, the cam device 4 is arranged above the drive device 2, the lower part of the cam device 4 is provided with a feeding device 5, the lower part of the cam device 4 is provided with a slotting device 6, and the lower side of the feeding device 5 is provided with a There is a switching device 7 .

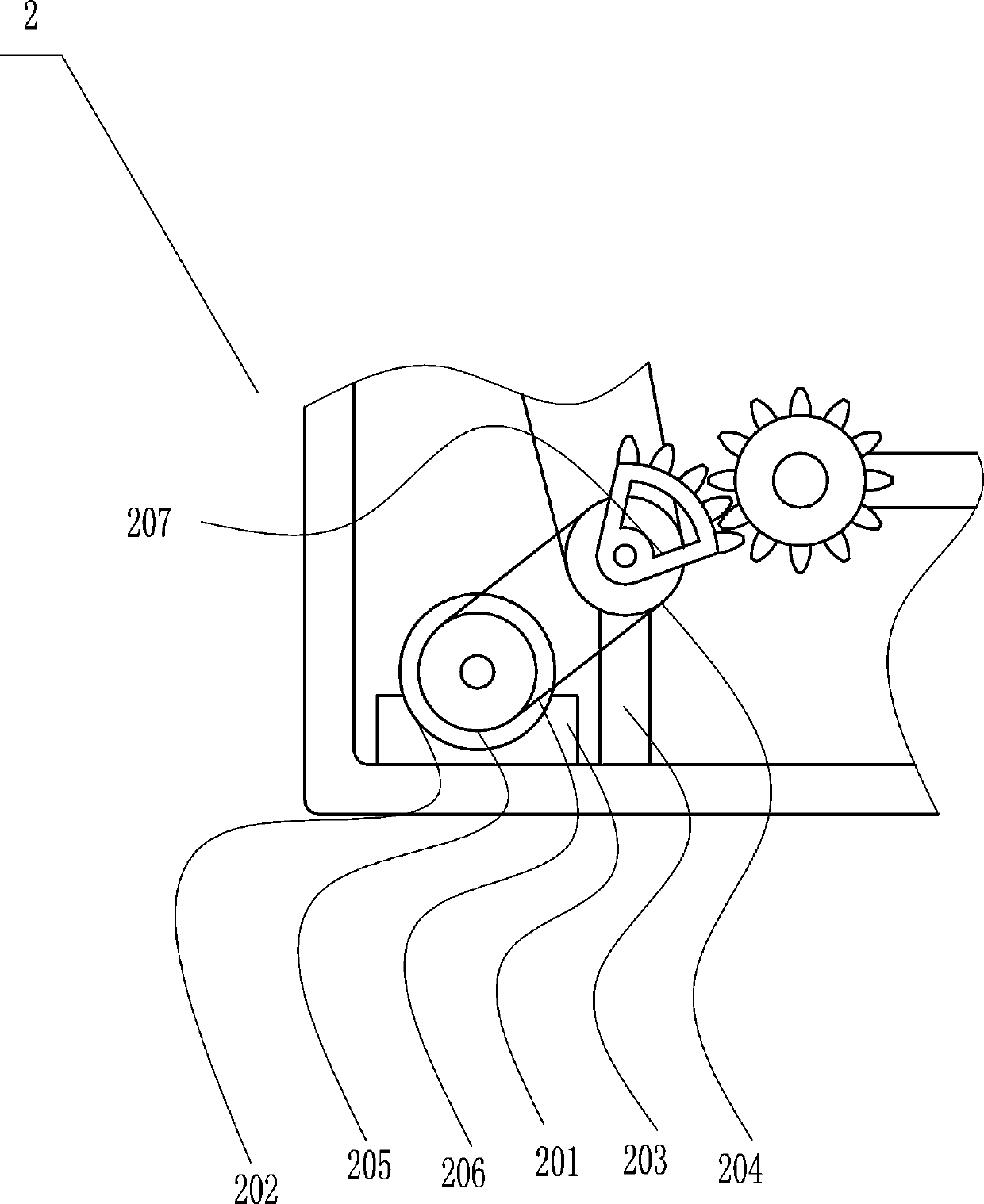

[0040] The driving device 2 includes a base 201, a first motor 202, a first support 203, a first pulley 204, a second pulley 205, a first belt 206 and a first sector gear 207, and the upper left of the frame 1 is provided with a base 201, the first motor 202 is fixed above the base 201, the output shaft of t...

Embodiment 3

[0042] An automatic unloading plank slotting device, such as Figure 1-8 As shown, it includes a frame 1, a driving device 2, a transmission device 3, a cam device 4, a feeding device 5, a slotting device 6 and a switch device 7, and the top of the frame 1 is provided with a driving device 2, and the right side of the driving device 2 The side is provided with a conveying device 3, the cam device 4 is arranged above the drive device 2, the lower part of the cam device 4 is provided with a feeding device 5, the lower part of the cam device 4 is provided with a slotting device 6, and the lower side of the feeding device 5 is provided with a There is a switching device 7 .

[0043] The driving device 2 includes a base 201, a first motor 202, a first support 203, a first pulley 204, a second pulley 205, a first belt 206 and a first sector gear 207, and the upper left of the frame 1 is provided with a base 201, the first motor 202 is fixed above the base 201, the output shaft of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com