Safe and efficient grooving machine

A slotting machine, high-efficiency technology, applied in the direction of sawing equipment, wood processing equipment, circular saws, etc., can solve the problems of unstable slotting quality, complicated slotting operation, low safety, etc., to reduce equipment purchase expenses, The effect of convenient and quick operation and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

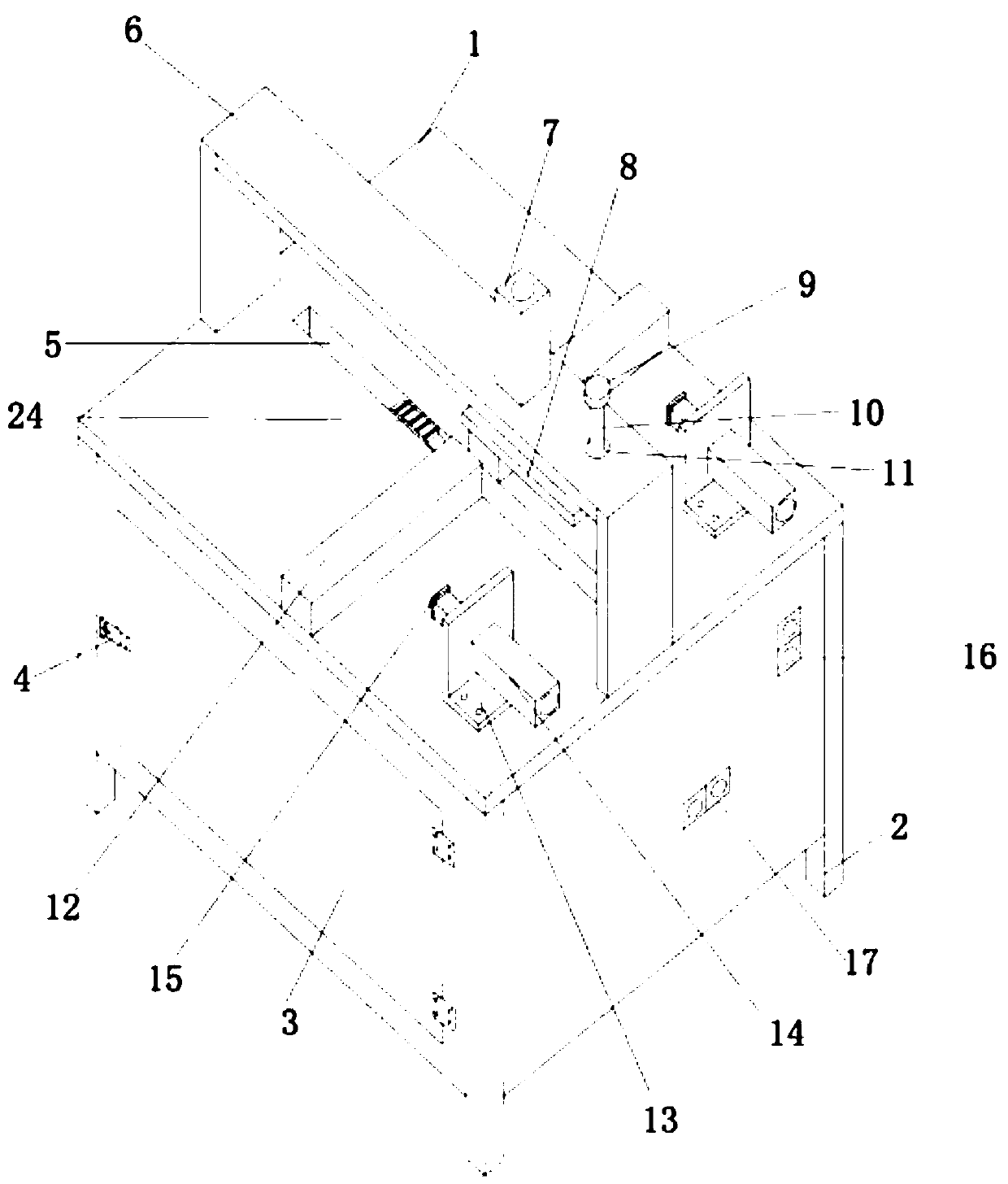

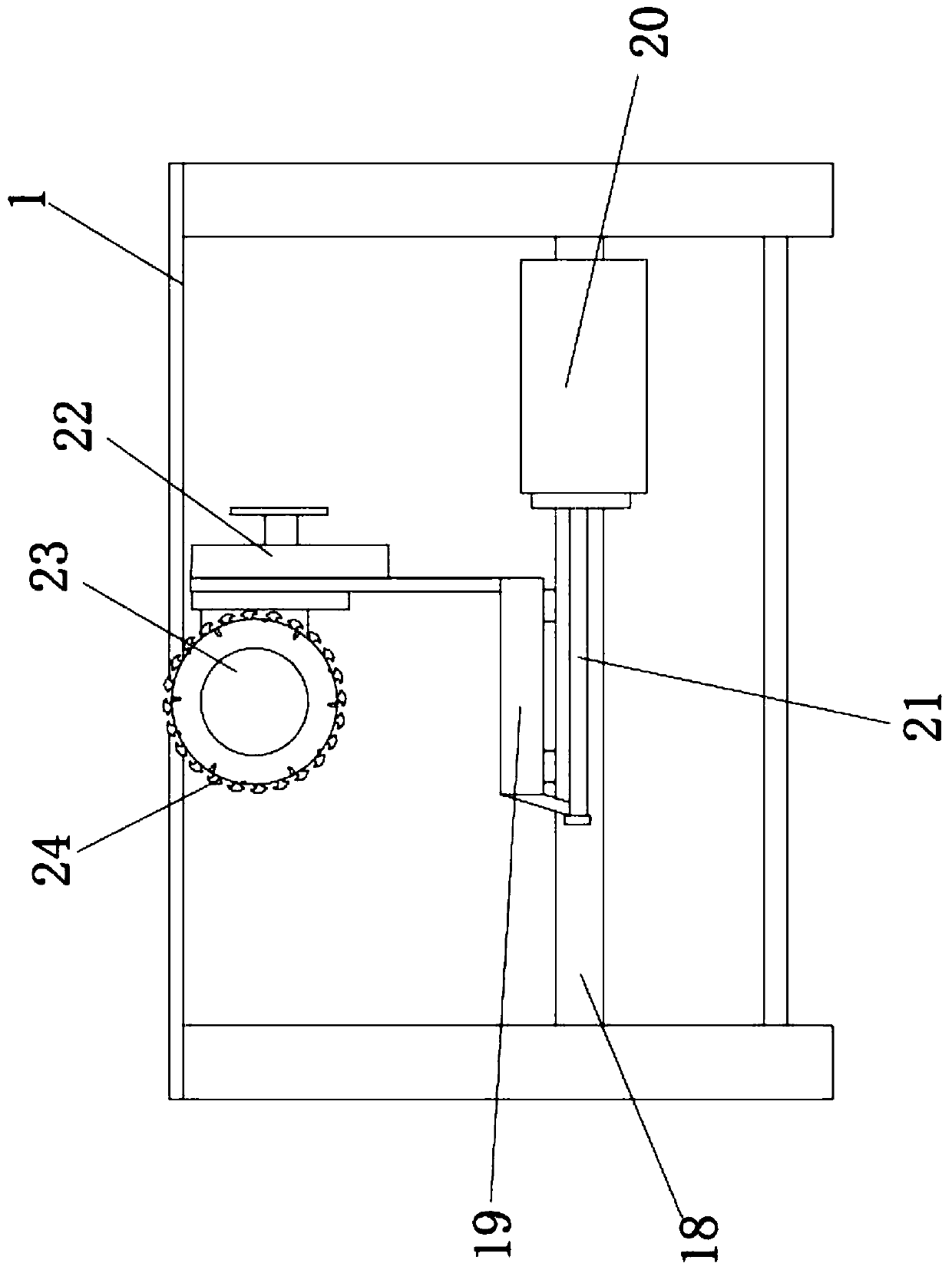

[0027] Such as figure 1 As shown, a safe and efficient slotting machine includes a workbench 1, and legs 2 are correspondingly provided at the bottom of the workbench 1. The workbench 1 is a hollow and airtight frame structure. The upper surface of the upper surface is correspondingly provided with a plurality of saw grooves 5 penetrating through the upper surface of the workbench 1, and a top beam 6 is correspondingly provided above the saw grooves 5;

[0028] The top of the top beam 6 is correspondingly provided with a top cylinder 7, the output shaft of the top cylinder 7 faces the saw groove 5, and the output shaft of the top cylinder 7 is connected with the plate-shaped top fastening block 8 correspondingly, so The top fastening block 8 is parallel to the saw groove 5, and a material fixing column 12 is correspondingly provided on the upper surface of the workbench 1, and the material fixing column 12 is perpendicular to the saw groove 5;

[0029] The upper surface of th...

Embodiment 2

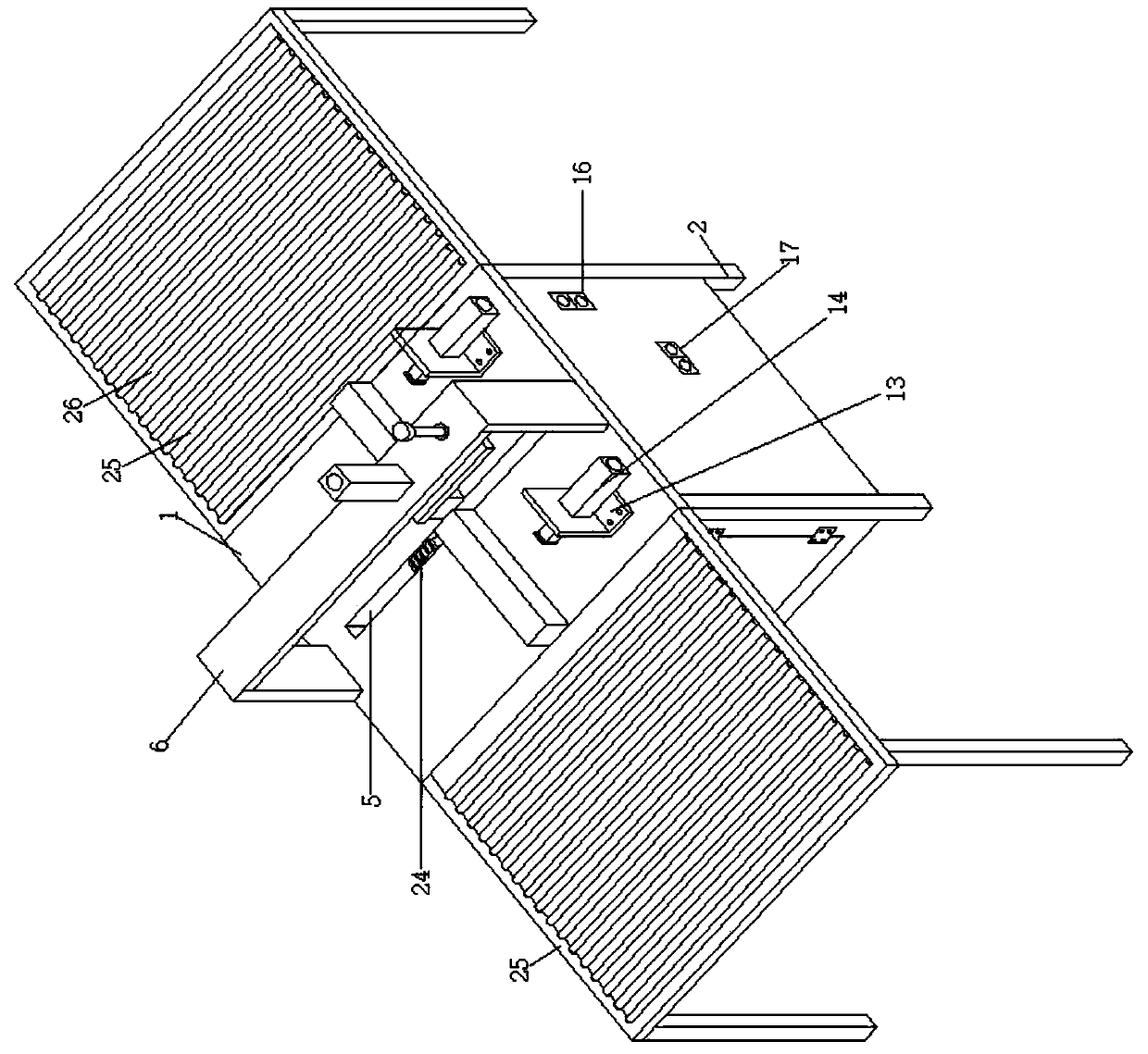

[0038] Such as figure 2 As shown, in this embodiment, the similarities with Embodiment 1 will not be repeated, and the difference is that a pair of outwardly protruding wingspans 25 are correspondingly provided on the upper surface of the workbench 1, so The upper surface of the wingspan 25 is flush with the upper surface of the workbench 1 , and the extending direction of the wingspan 25 is parallel to the material fixing column 12 . A plurality of rollers 26 are correspondingly arranged on the surface of the wingspan 25 , and the plurality of rollers 26 are parallel to the telescopic direction of the output shaft of the horizontal cylinder 14 . The setting of the cylinder 26 is conducive to the movement of the wood and improves work efficiency. When the length of the material to be grooved is long, the material to be grooved can be stably placed on it by setting the wingspan 25, avoiding the safety risk caused by the material to be grooved protruding too much from the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com