Double-shaft oblique slot forming machine

A trough machine, inclined technology, applied in the direction of earth mover/shovel, construction, etc., can solve the problems of complex equipment, low trough forming efficiency of the trough machine, etc., to achieve high vertical trough, simple type, Slightly worn effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

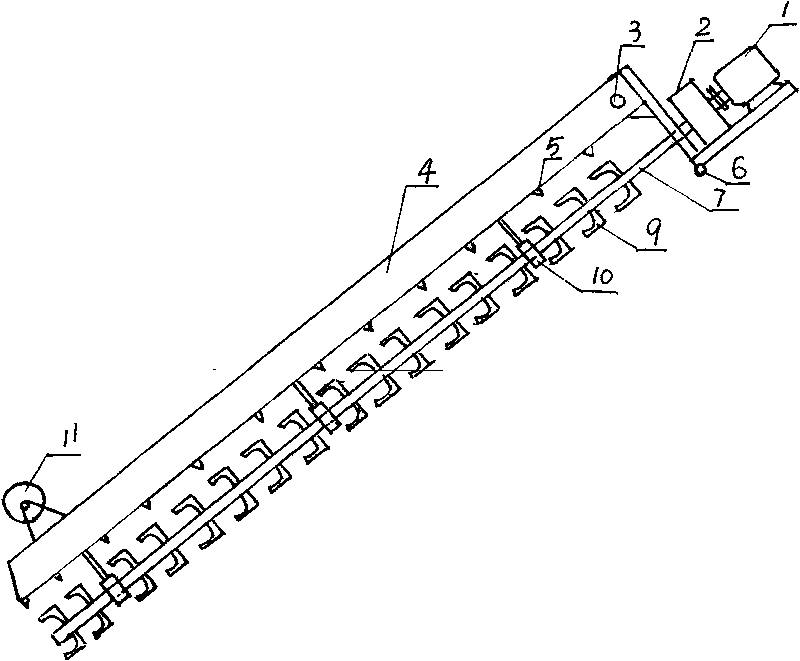

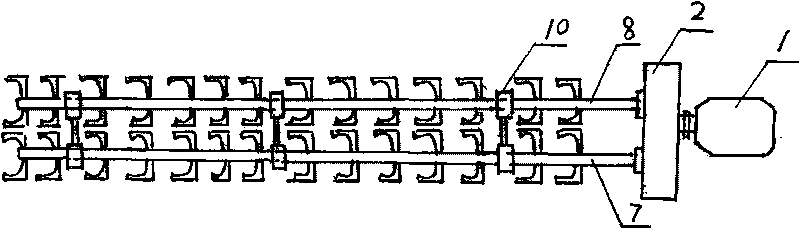

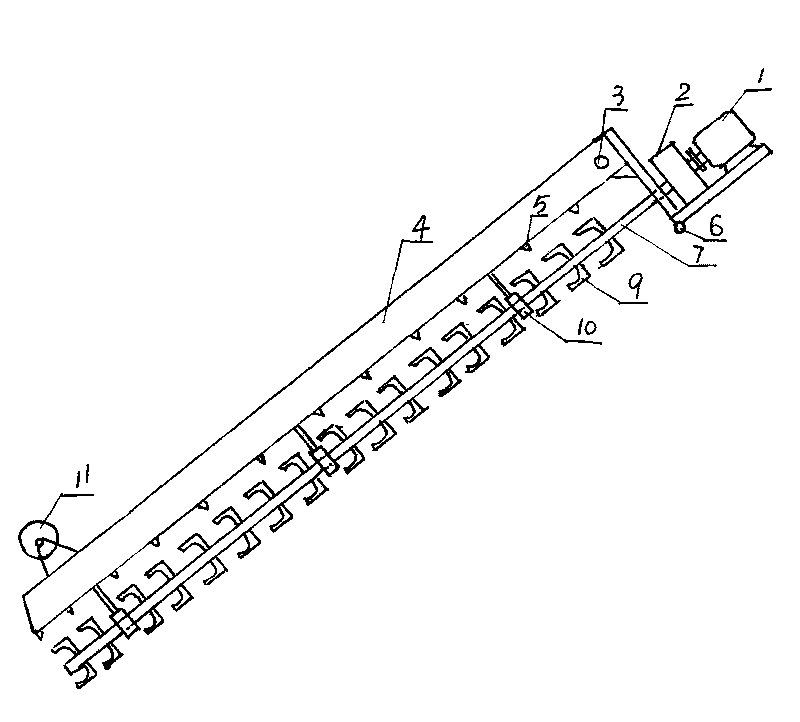

[0014] The accompanying drawing is a specific embodiment of the present invention, and the present invention will be described in detail below through the accompanying drawings.

[0015] A two-axis inclined groove forming machine, including a water inlet hose 3, a water inlet pipe 4, and a water nozzle 5. The water inlet pipe is welded with a thick-walled pipe. In addition to being used for water inlet, it also supports the biaxial A , B. A motor 1 drives the power box 2, and drives the power shaft A7 and the power shaft B8 to be opposite to each other and rotate synchronously. Shafts A and B are respectively equipped with a number of soil cutting and digging knives 9, and the two shafts A and B are supported by several supporting bushes 10 on the water inlet pipe, and the lifting pulley 11 is used to lift the bottom of the slotting machine and the upper part of the slotting machine. , supported on the walking chassis by the upper support shaft 6.

[0016] The trough forming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com