Fast trenching construction method for underground continuous wall in weakly weathered rock

A construction method and technology for trenching construction, which is applied to earth movers/shovels, construction, etc., can solve the problems of difficulty in trenching in rock formations, construction speed, etc., to solve the problem of verticality control of trenches, ensure construction quality, The effect of ensuring the quality of groove formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

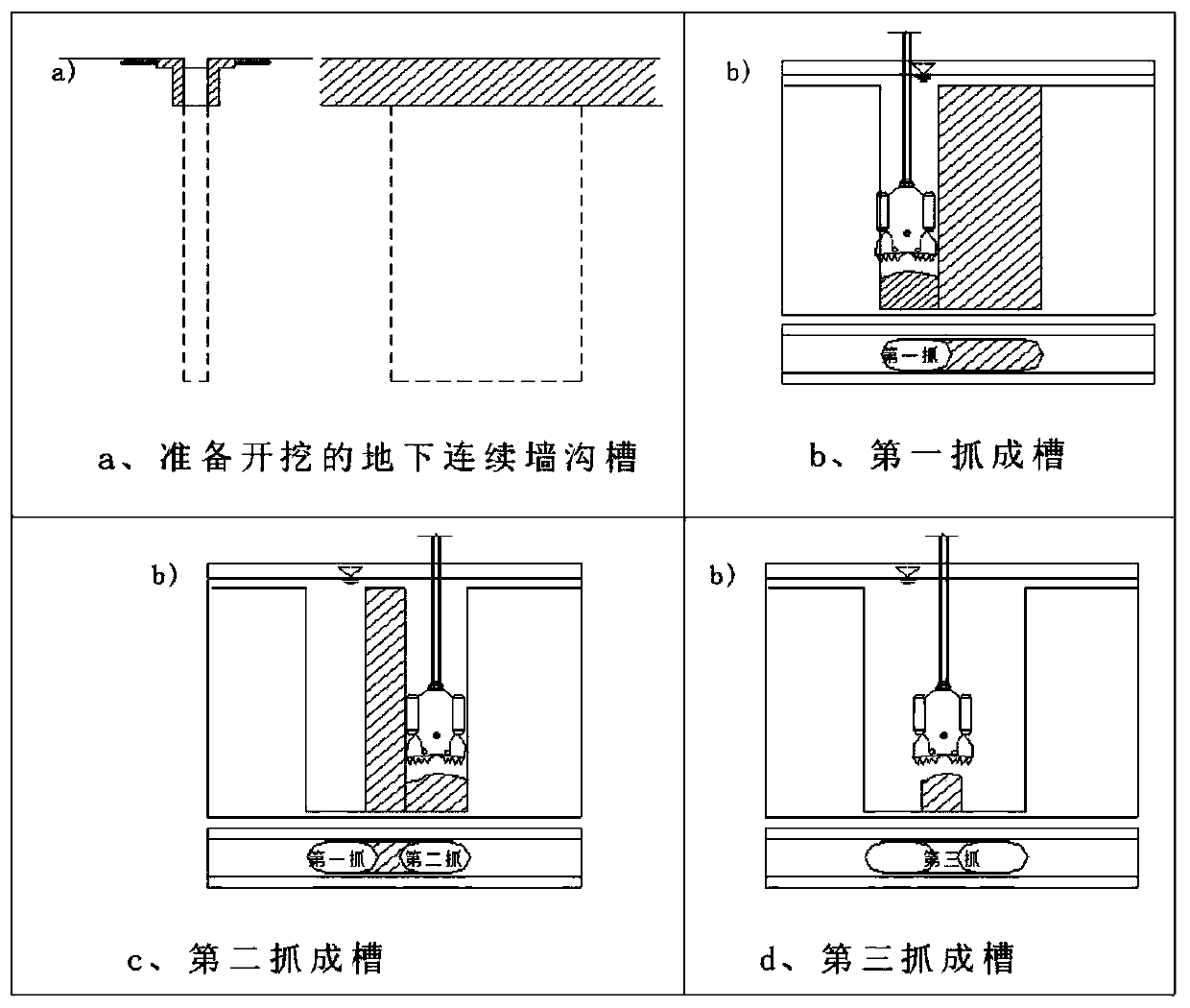

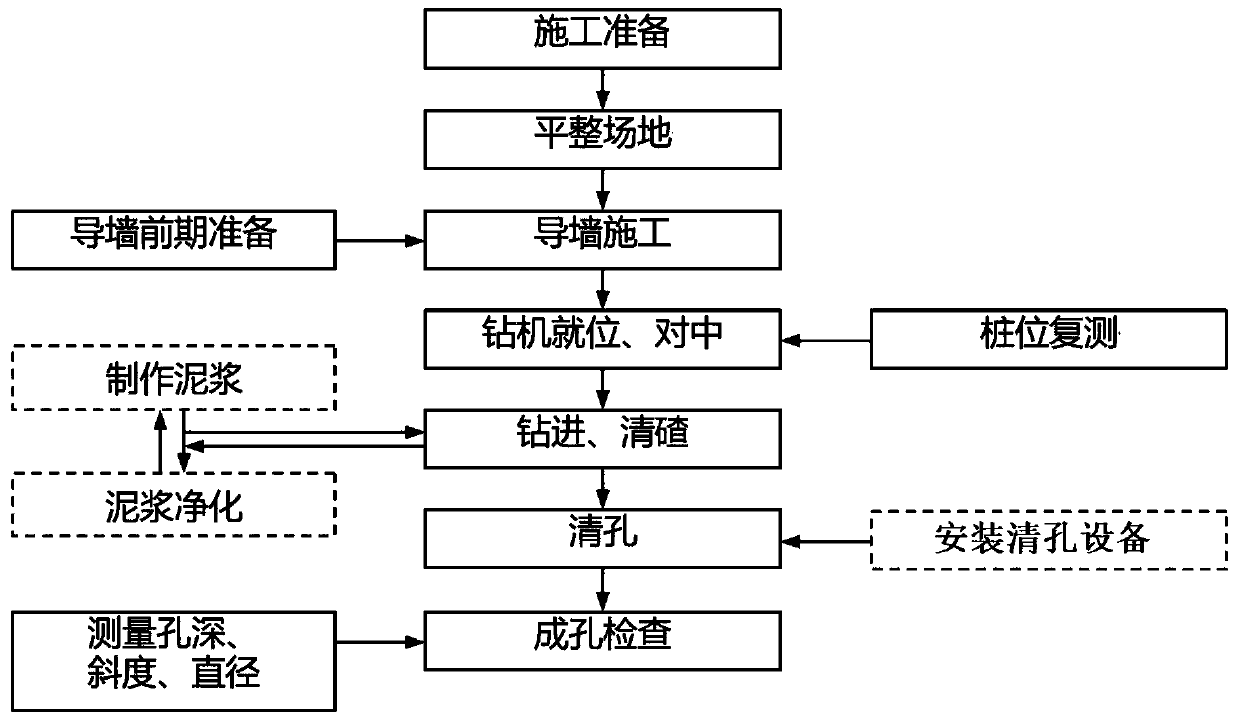

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 Construction line of a certain line of Guangzhou Metro

[0027] According to the construction of a certain line of Guangzhou Metro, there are mainly the following difficulties:

[0028] 1) The bearing capacity of the upper silt layer is extremely poor, and the holes are easy to collapse when forming grooves: the upper silt layer in the field is thick and the bearing capacity is extremely poor, resulting in large-scale equipment such as double-wheel milling, grabbing buckets, down-the-hole hammers, and crawler cranes. The risk is high; when the ground connection wall is grooved, it is easy to collapse the hole, and the concrete disturbance in the first phase of the groove is serious.

[0029] 2) The rock surface fluctuates greatly, the strength is uneven, and it is difficult to correct the deviation of the groove: there are many inclined rocks and the uneven strength makes it difficult to correct the deviation of the lead hole of the pile driver and the doub...

Embodiment 3

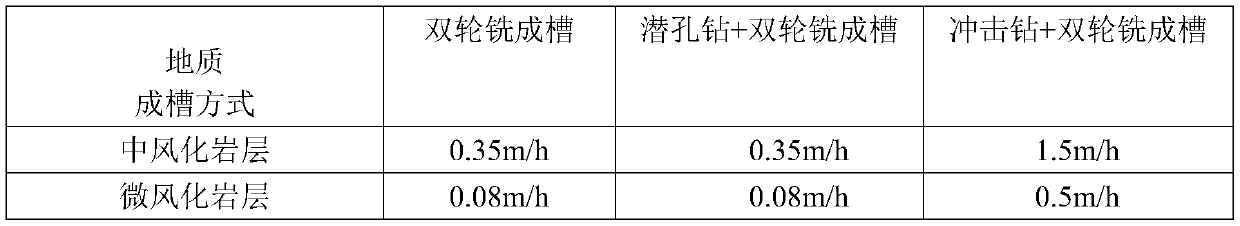

[0120] Embodiment 3 Grooving process contrast

[0121] (1) double wheel milling groove

[0122] The 2A29, 2A31, and 3A1 groove sections are separately formed by double-wheel milling. Among them, the 2A29 groove section enters the medium weathering of 4.2 meters, and the 2A31 and 3A1 enters the micro-weathering. Since the rock formation strength reaches above 100Mpa, the construction time for single-width groove formation exceeds 26 days ( Not yet grooved), the efficiency of double-wheel milling is 0.08m / h, and the double-wheel milling equipment is often damaged, and the double-wheel milling groove operation is suspended. Therefore, the efficiency of double-wheel milling alone in hard rock is extremely low and the cost is extremely high. high;

[0123] (2) Down-the-hole drilling + double-wheel milling into slots

[0124] The 2A34 groove section adopts the down-the-hole drill to guide the hole. In the first and second positions of the double-wheel milling, each knife has a tot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com