Grooving machine

A grooving machine and grooving technology, used in metal processing machinery parts, large fixed members, feeding devices, etc., can solve the problems of high labor intensity of workers, unstable product quality, and large error fluctuation range, and achieve stable product quality. , The effect of fast grooving speed and high grooving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

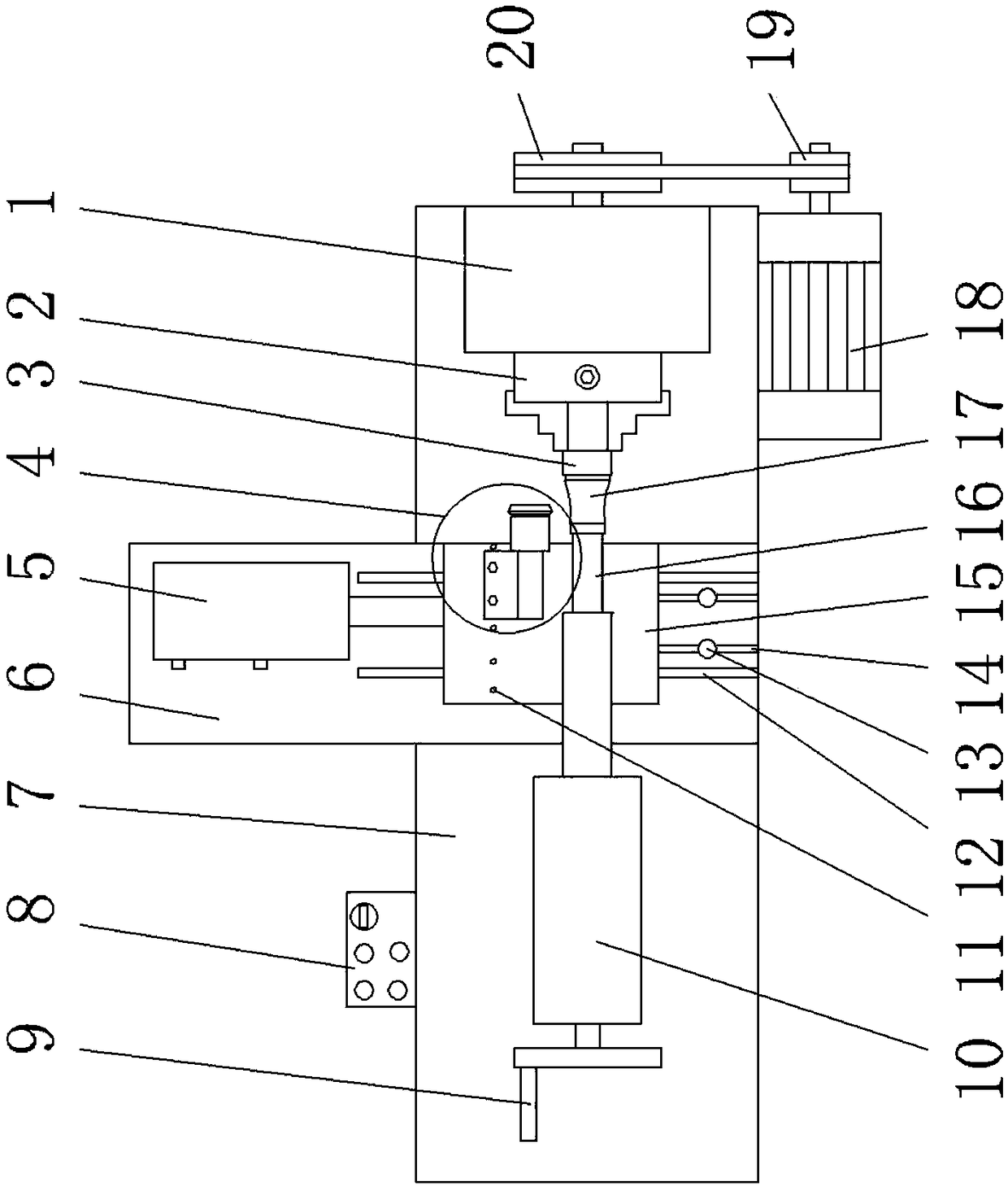

[0018] Such as figure 1 As shown, the present invention includes a base 7, one end on the base 7 is provided with a headstock 1, and the other end on the base 7 is provided with a tailstock 10 corresponding to the headstock 1. One end near the tailstock 10 on the headstock 1 is provided with a chuck 2, and a supporting sleeve 3 for placing workpieces is arranged in the chuck 2 to protect the workpieces from being damaged by clamping. The base 7 on one side of the spindle box 1 is provided with a motor 18, the motor 18 is provided with a driving wheel 19, and the other end of the spindle box 1 is provided with a driven wheel 20, and the driving wheel 19 is connected with the driven wheel 20 by a belt. One end of the tailstock 10 close to the headstock 1 is provided with a push rod 16 , and the other end of the tailstock 10 is provided with a hand wheel 9 . A workbench 6 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com