Steel body type diamond-impregnated bit

A diamond-impregnated, steel-body type technology, which is applied to drill bits, drilling equipment, and earthwork drilling and production, can solve problems such as difficulty in developing large-size drill bits, improving quality restrictions, and complex drill bit structures, so as to speed up replacement and improve mechanical performance. Drilling speed and the effect of reducing the cost of the drill bit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

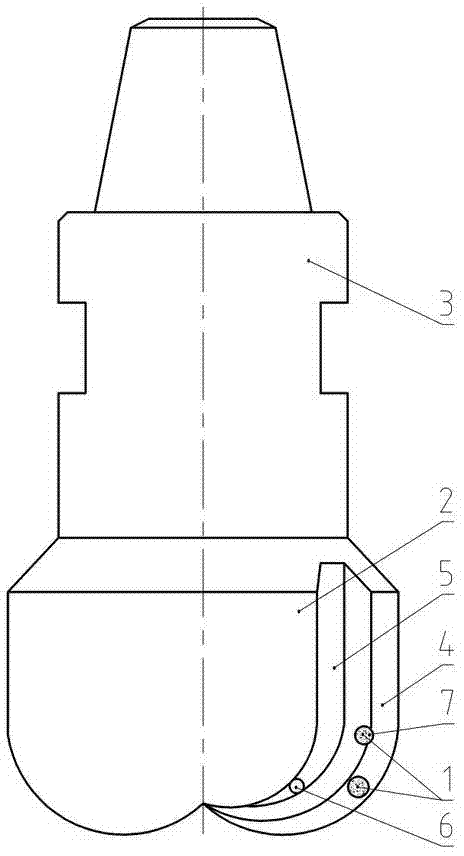

[0009] The present invention will be further described in detail below in conjunction with the figures. figure 1 The shown steel body impregnated diamond drill bit is composed of an impregnated body 1 , a drill body 2 and a joint 3 . The drill bit body 2 is a steel body type drill bit body, on which a blade 4 , a runner 5 and a nozzle 6 are processed. The impregnated body 1 is impregnated with cutting material 7, and the impregnated body 1 is regularly arranged on the blade 4 of the drill bit body 2 and exposes the drill bit body 2, and the impregnated body 1 is mounted to the drill bit by low-temperature brazing or interference mounting On the blade 4 of the body 2, the drill body 2 improves the erosion resistance through surface strengthening, and the drill body 2 is integrally connected with the joint 3.

[0010] The impregnated body 1 is cylindrical, elliptical cylindrical, wedge-shaped, prismatic, truncated cone and / or disc-shaped, and the cutting material 7 in the impre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com