Combined metallurgical furnace taphole drill bit and tooth fixing process thereof

The invention relates to a metallurgical furnace and tap hole technology, which is applied to the field of combined metallurgical furnace tap hole drill bit and its tooth fixing process, and can solve the problems of easy falling off of the upper column tooth alloy, easy wear of the flake alloy, and low service life of the drill bit, etc. Achieve the effect of ensuring wear resistance, easy slag discharge, and easy footage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

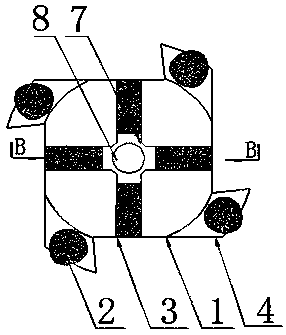

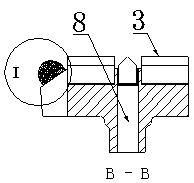

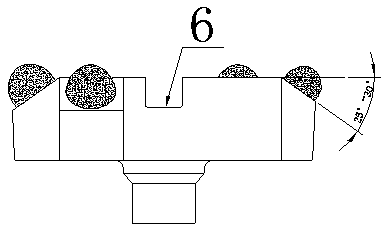

[0025] Such as Figure 1 to Figure 4 Shown is a combined metallurgical furnace tapping hole drill bit, which includes a square prism-shaped drill bit body 1 with a horizontal top surface, four alloy bases 4 are arranged at the four corners of the side wall of the drill bit body 1 along the tangential direction of the side wall, The alloy base 4 is in the shape of a windmill, and the top center of each alloy base 4 is provided with a blind hole 5, and the stud alloy 2 is welded in the blind hole 5; the top surface of the drill body 1 is provided with a cross-shaped alloy groove 6. A flake alloy 3 is welded in each alloy groove 6; a positioning block 7 is provided at the center of the end face of the drill body 1, and a ventilation hole 8 coincident with the central axis of the drill body 1 is provided on the positioning block 7.

[0026] The upper surface of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com