Three teeth roller bit for mining

A technology of three cones and drill bits, which is applied in drill bits, drilling equipment, earthwork drilling, etc., can solve the problems of difficult bearing lubrication, non-lubrication, high price, etc., and achieve the effect of improving service life and good lubrication.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

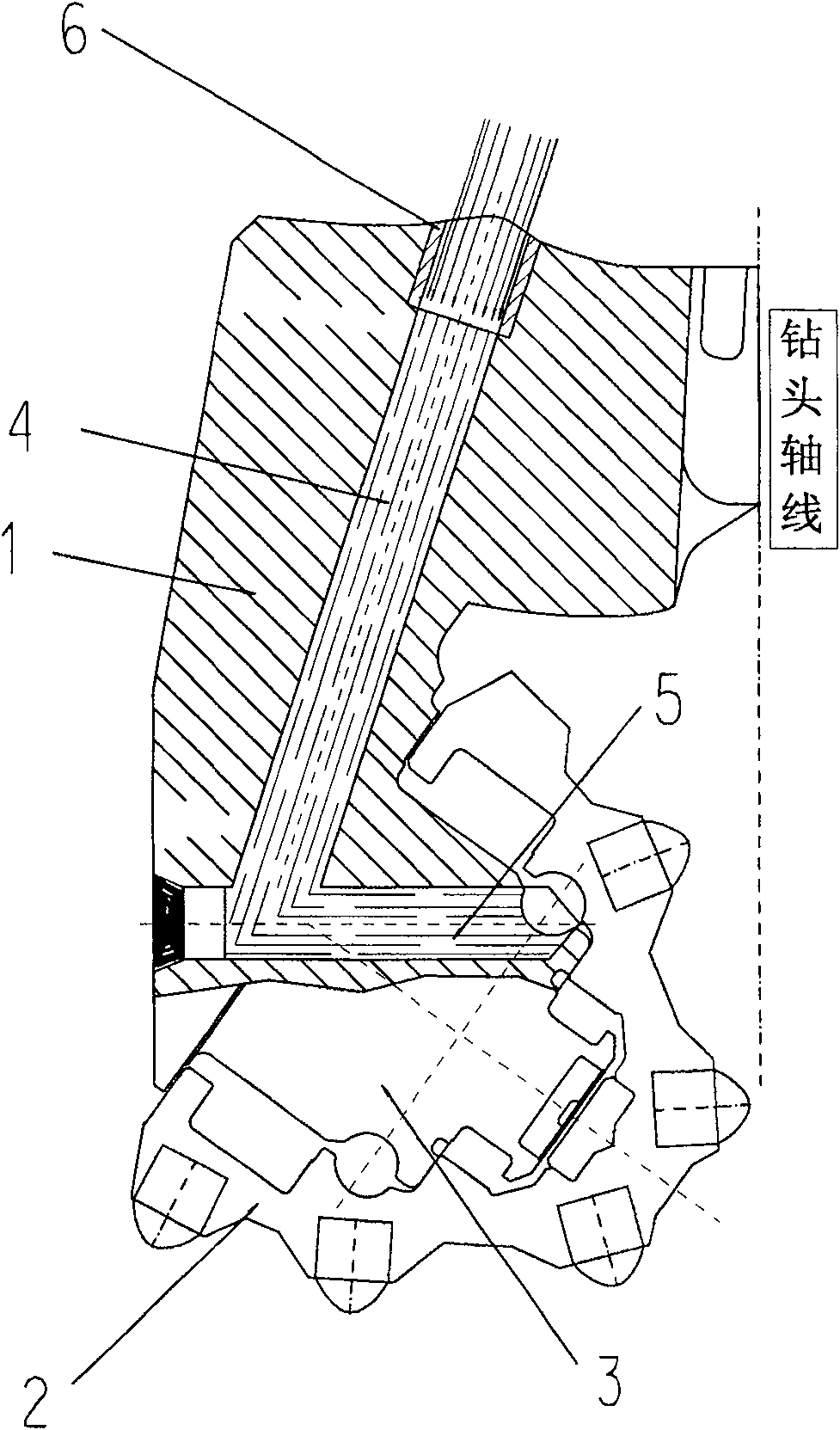

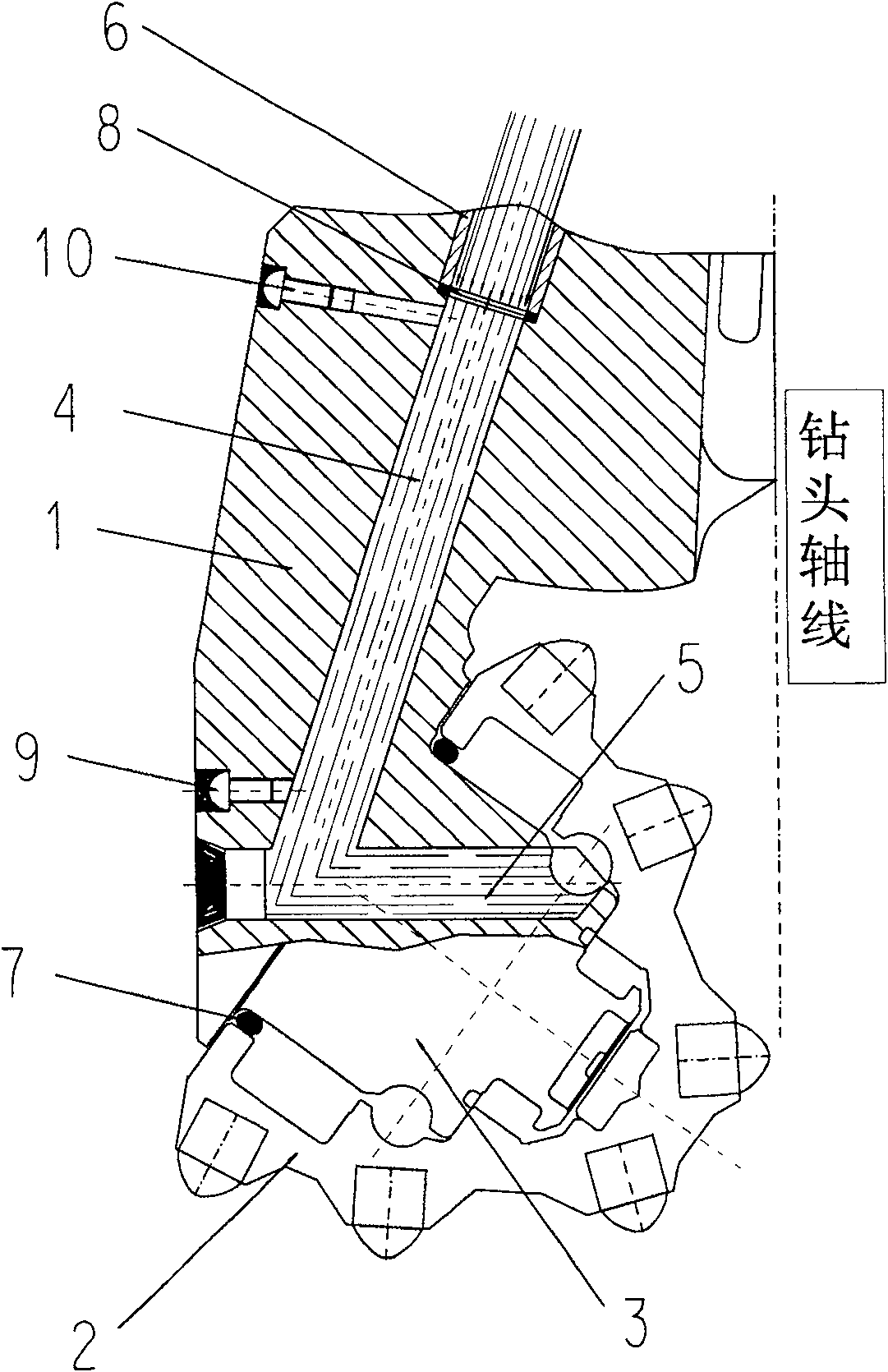

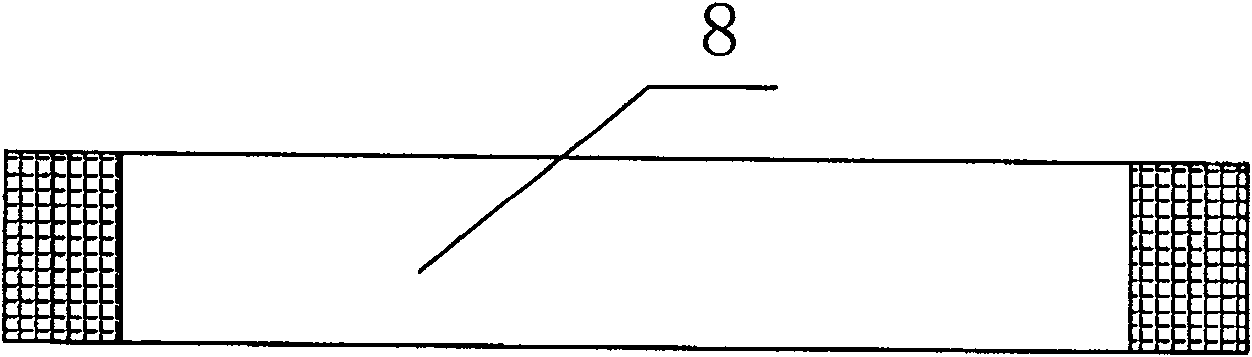

[0022] figure 2 Shown is an embodiment of the present invention, a kind of tri-cone drill bit for mining, including tooth palm 1, cone 2, journal 3, long air hole 4, vent hole 5, dregs retaining pipe 6, and journal 3 and The sealing device provided between the cones 2 is a seal ring 7 (other forms of seals can also be used), and what the present embodiment uses is a "○" type seal ring 7. The upper end of the long air hole 4 is provided with a sealing film 8, and the sealing film 8 is located at the junction of the long air hole 4 and the dregs retaining pipe 6. The structure of the sealing membrane assembly is as follows image 3 As shown, there is a heat insulating pad respectively on the upper and lower sides of the sealing film 8, and the sealing film 8 is made of plastic wrap or polyethylene film. Periphery, the dregs retaining pipe 6 is connected with the long air hole 4 by welding. The cross-sectional compression rate of the "○" type sealing ring 7 is 6 to 23%. The "...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com