Knife-shaped gate valve for slurry

A knife-shaped, gate valve technology, applied in the direction of sliding valve, valve device, engine components, etc., can solve the problems of short service life, easy entry of dust, affecting the service life of the valve, etc., to improve the service life, good sealing effect, good positioning effect of function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

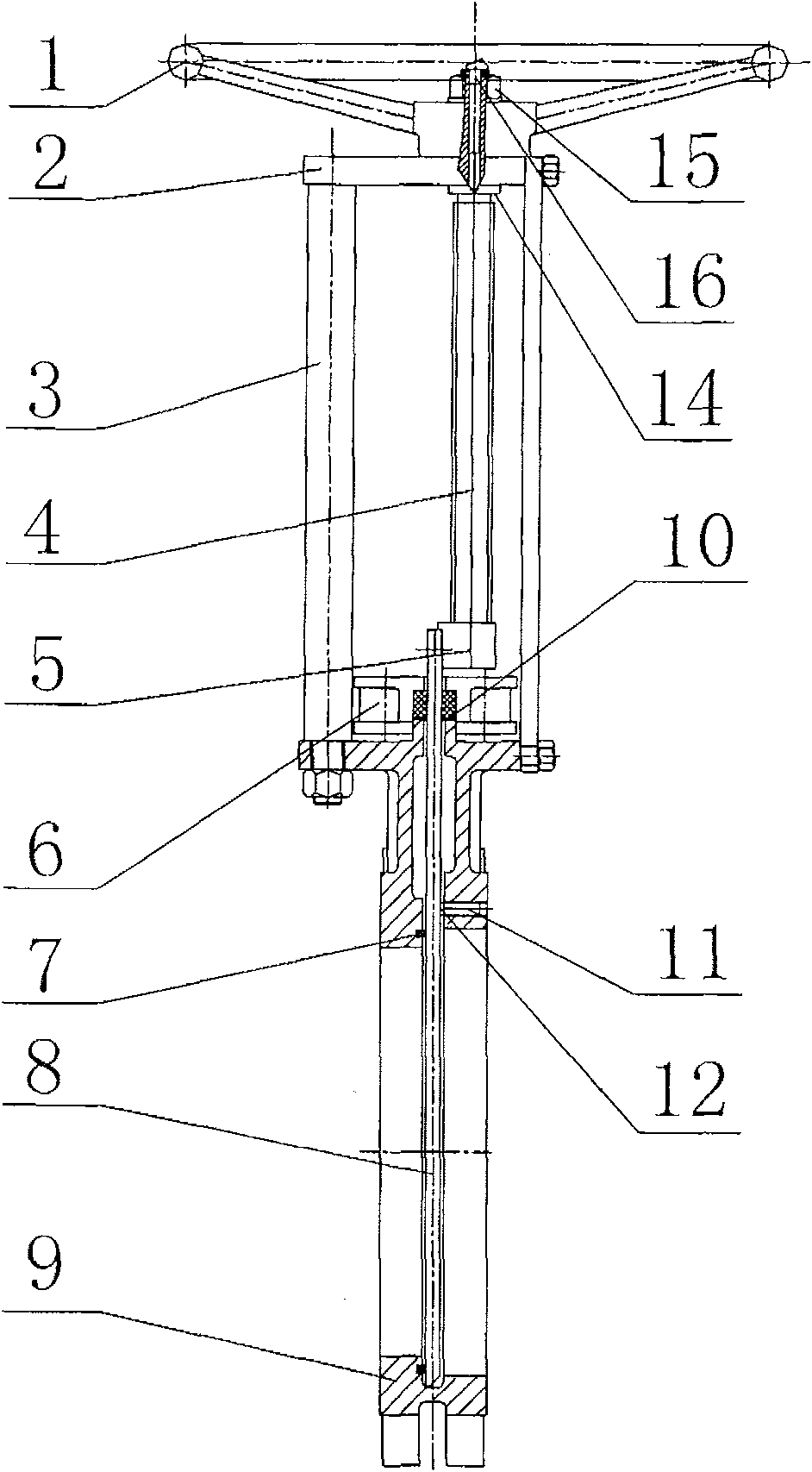

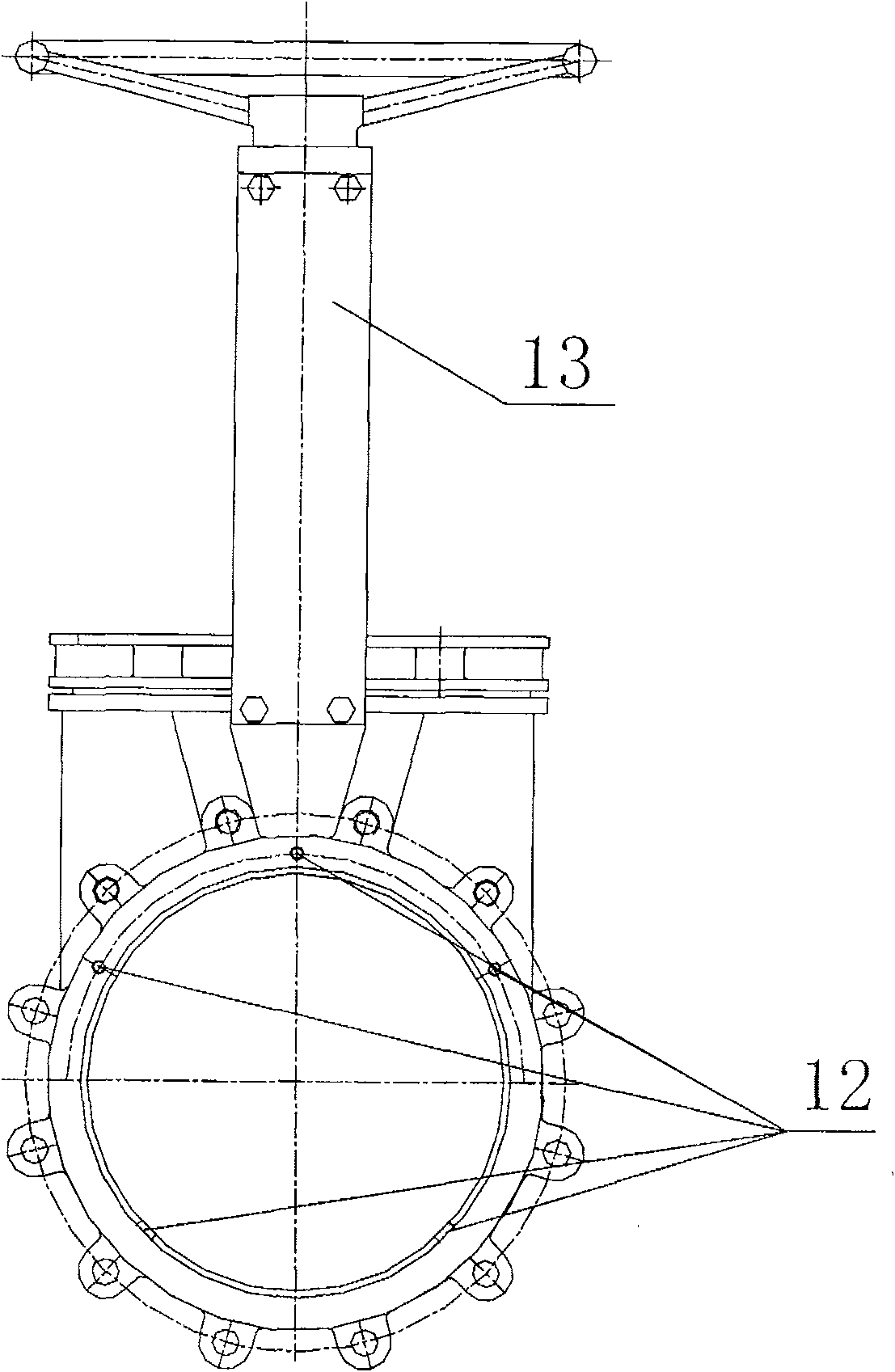

[0018] See figure 1 , figure 2 , Knife-shaped slurry gate valve, consisting of hand wheel 1, triangular plate 2, side support plate 13, column 3, screw 4, screw nut 5, packing gland 6, sealing ring 7, valve plate 8, valve body 9, mud scraper 10. The positioning top wire 11 and the polytetrafluoroethylene positioning point 12 are formed. The hand wheel 1 is set on the top of the valve body. The screw 4 is connected under the hand wheel 1. The screw 4 is formed by the triangular plate 2, the column 3 and the side support plate 13. The fixed bracket is fixed between the hand wheel 1 and the valve body 9, the screw nut 5 is provided at the lower part of the screw 4, and the screw nut 5 is made of zinc-aluminum alloy, and the cost is low; an oil cup 16 is arranged on the top of the screw screw, The leading screw is provided with an oil hole at the matching part of the triangular plate 2 both sides and the bearing, and the oil cup communicates with the oil hole to play the role of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com