Deep groove ball bearing provided with lubrication oil hole

A technology of deep groove ball bearing and oil hole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

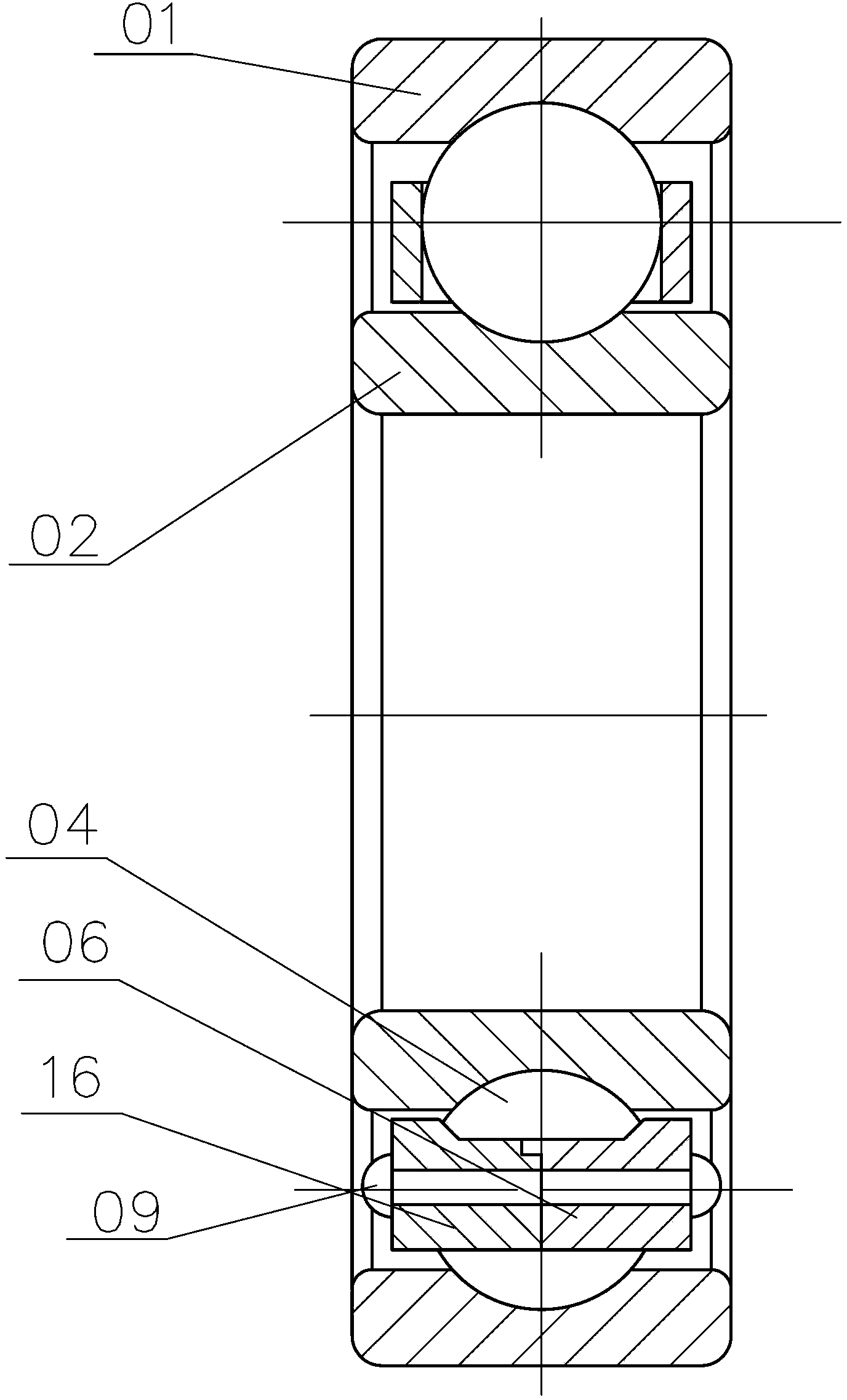

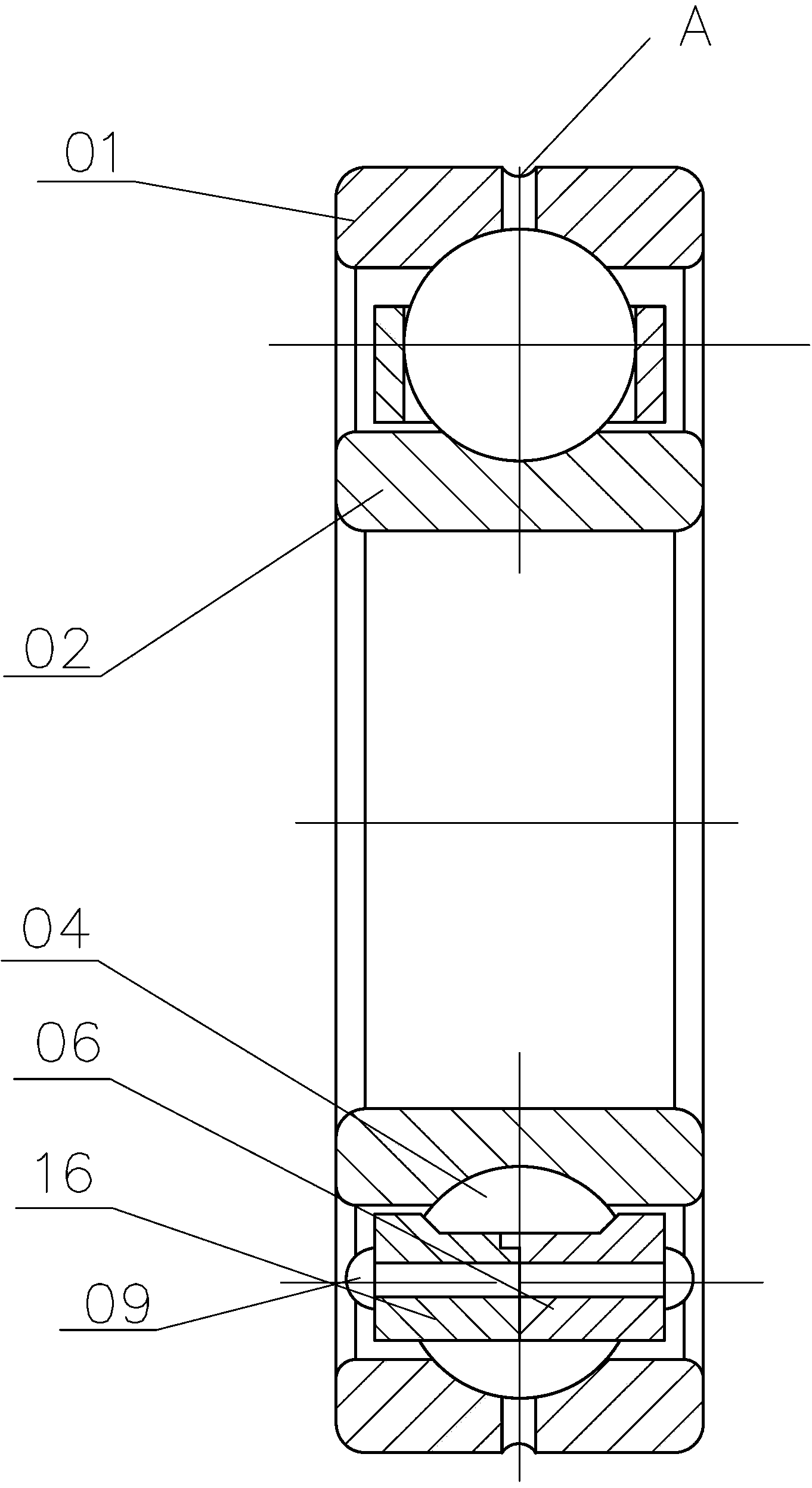

[0009] Such as figure 2 The deep groove ball bearing provided with lubricating holes in the present invention includes an inner ring 02 and an outer ring 01 that are concentrically socketed inside and outside, and a steel ball 04 is fixed between the inner ring 02 and the outer ring 01 by a cage. The cage includes a cage cover 16 and a cage seat 06 bolted by rivets 09; wherein, an oil hole A vertically leading to the steel ball 04 is opened in the middle of the outer cylinder of the outer ring 01; the oil hole A is facing the center of the steel ball 04.

[0010] The above is only a preferred embodiment of the present invention, but the scope of protection of the present invention is not limited thereto. Anyone familiar with the technical field within the technical scope disclosed in the present invention, according to the technical solution of the present invention Any equivalent replacement or change of the inventive concepts thereof shall fall within the protection scope ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com