Patents

Literature

100results about How to "Good positioning function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

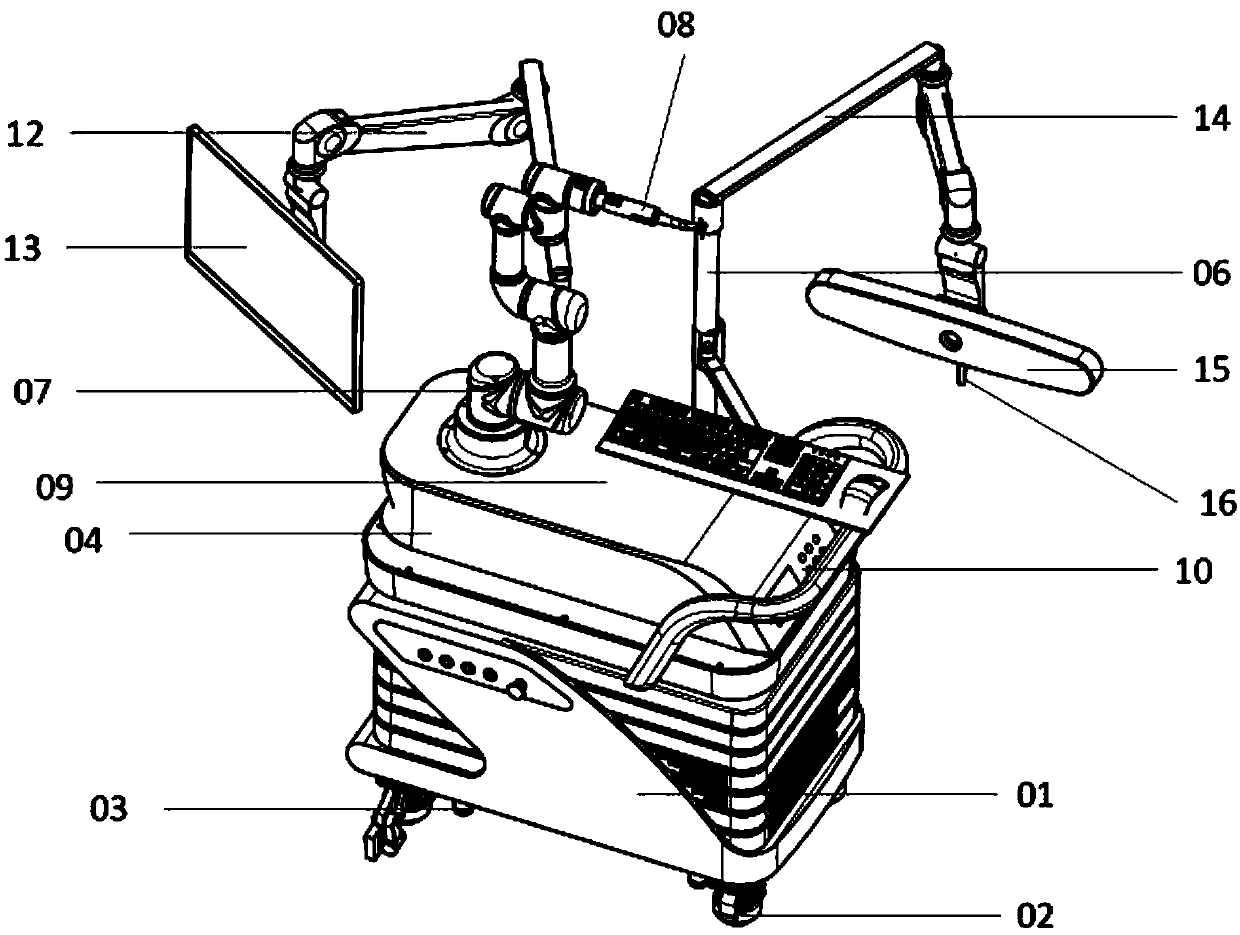

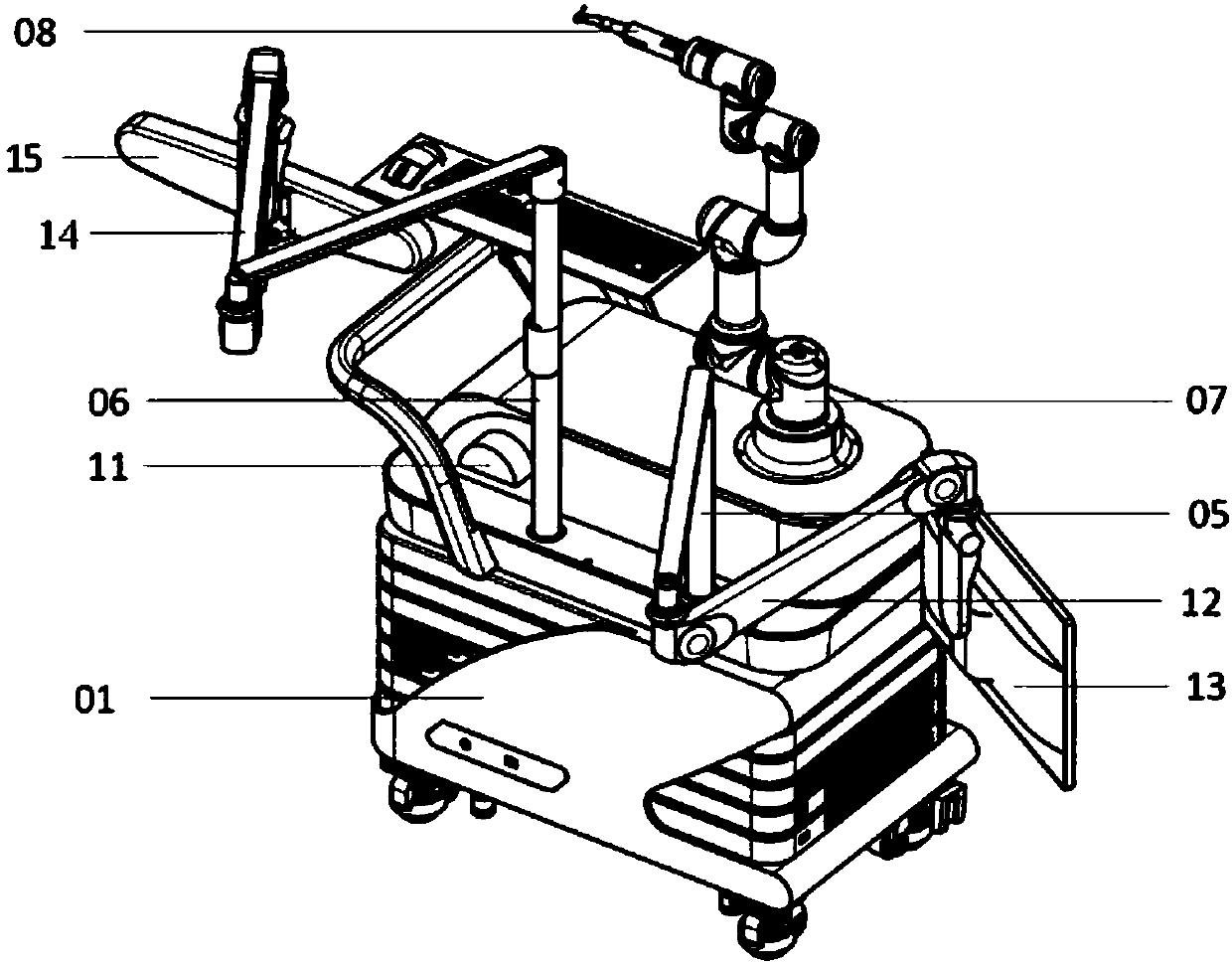

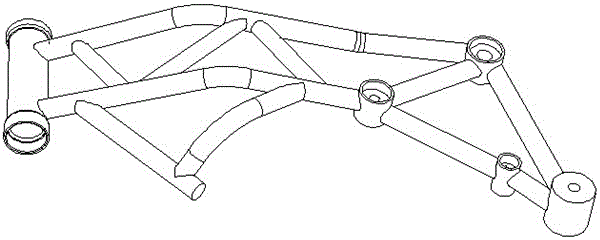

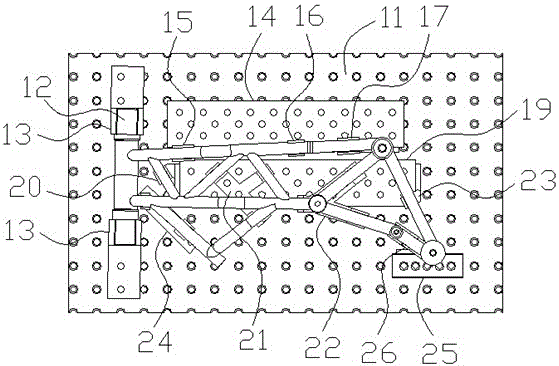

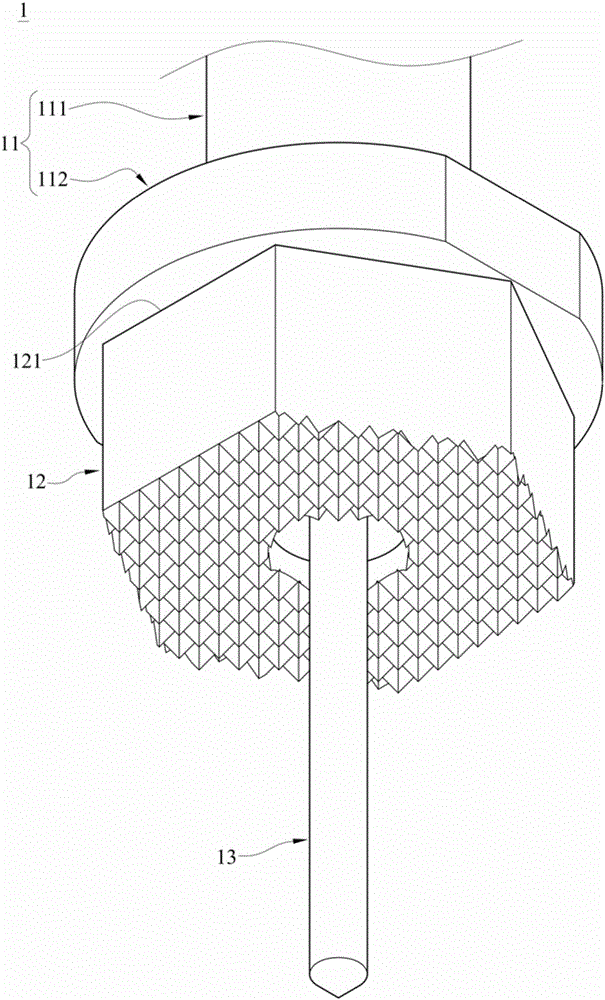

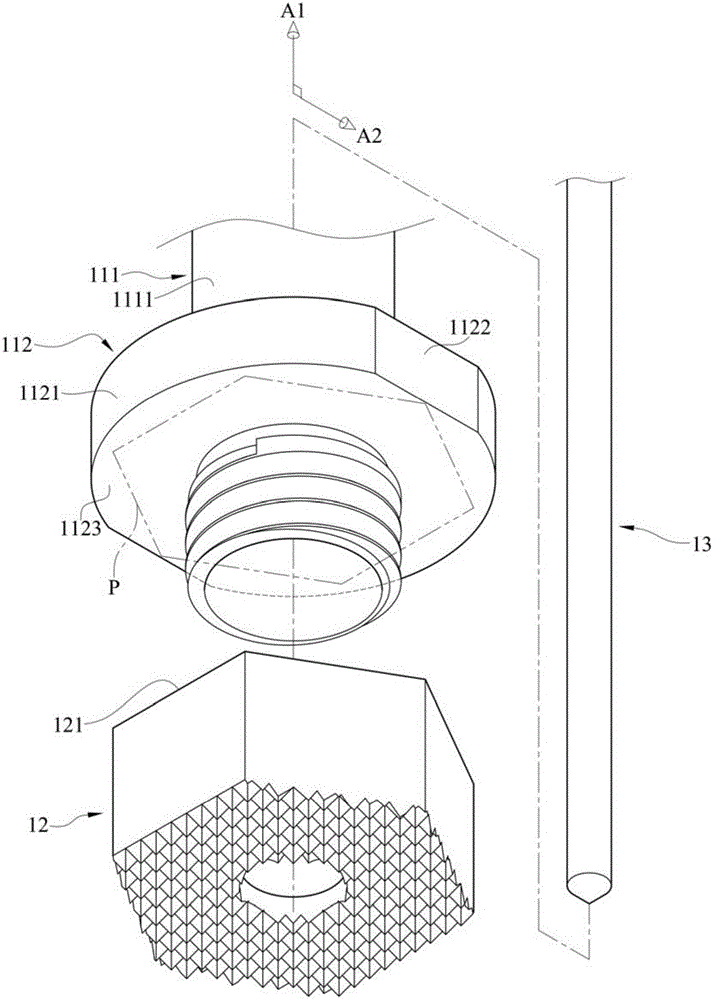

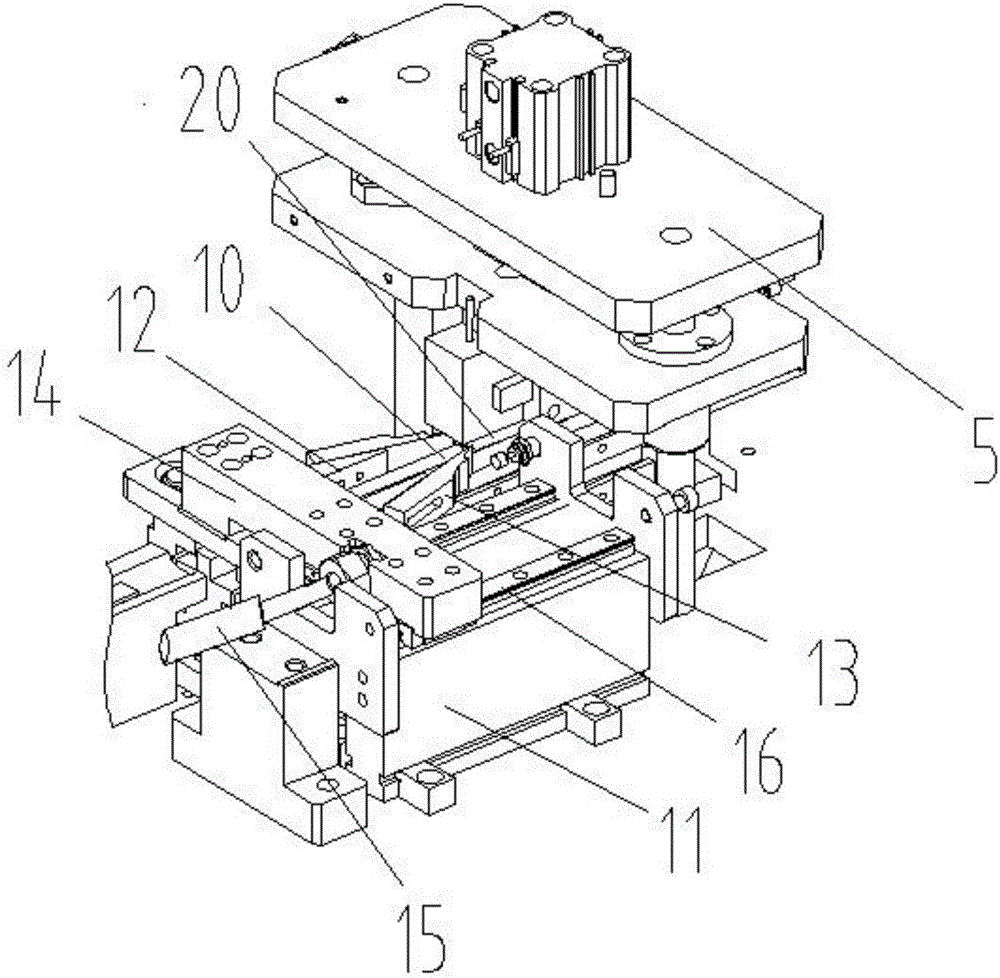

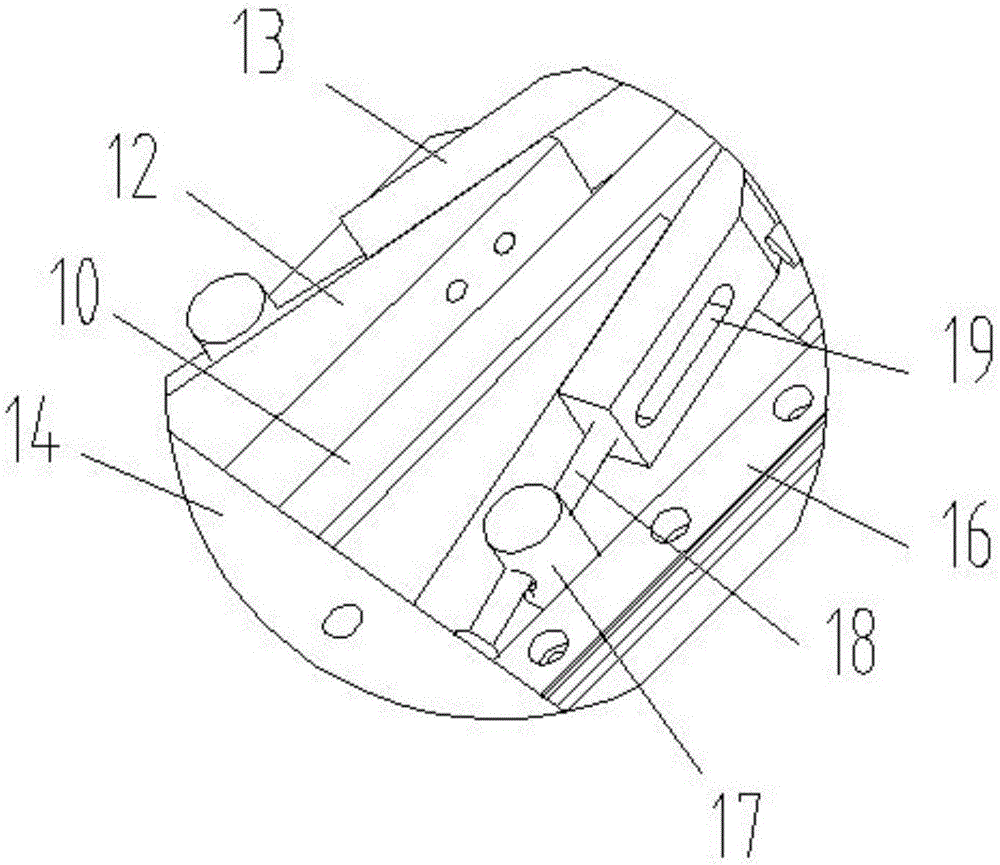

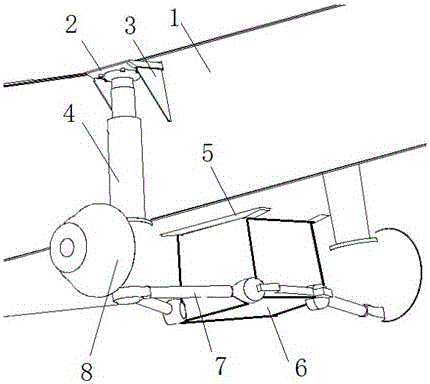

Auto-implanting dental robot

InactiveCN107595418AGood positioning functionWith positioning functionDental implantsImage analysisPoint registrationDisplay device

The invention relates to the field of dental department and particularly relates to an auto-implanting dental robot. The oral implantology robot includes: a modularized structure, an implanting navigation system, a tracing and positioning system, a mechanical arm system, an implanting driving system, and a control system. The oral implantology robot can integrate and analyzes information from allunits, including: CT information, implantology scheme, oral cavity information and mechanical arm information, thereby sending a command to control a mechanical arm to achieve automatic implantology.The modularized structure includes a trolley structure and a support structure connected thereto, wherein the support structure is connected to all the functional units, including the mechanical arm,a tracer and a monitor. The implanting navigation system can achieve pre-operation implanting scheme design, intraoperative registration, information integration and analysis, command sending and feedback receiving. Implantology drill point registration tools are individually designed on the basis of implantology tools in different brands, thus solving a problem of low accuracy of manual registration. Due to the modularized structure, dental implantology operation situations are fully considered, so that auto-implanting operation has better operability.

Owner:杭州术康医疗科技有限公司 +1

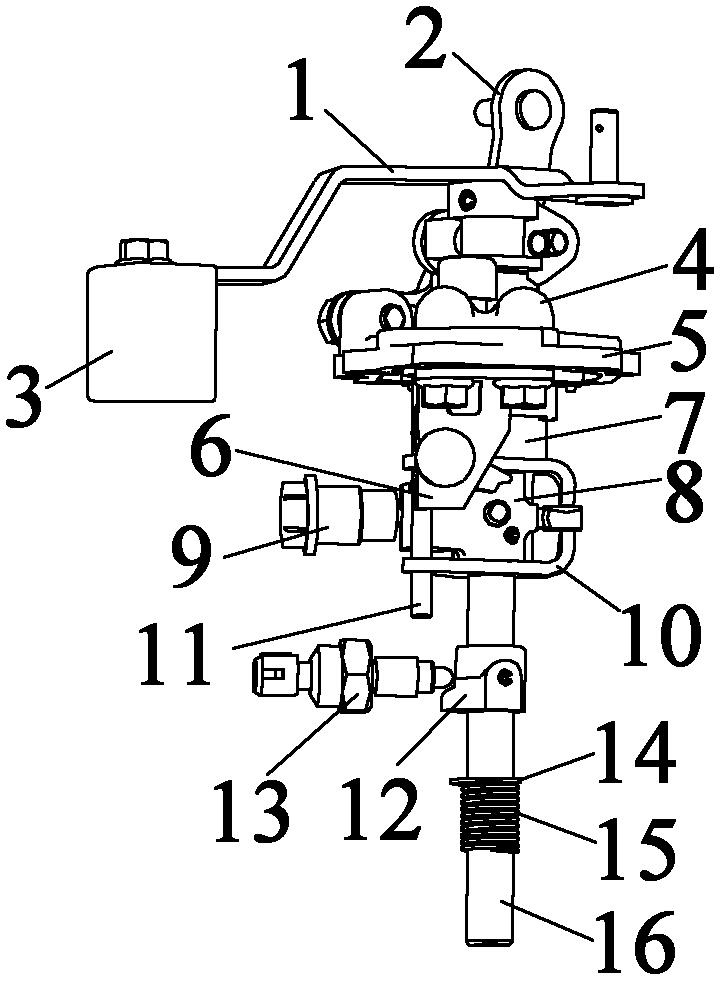

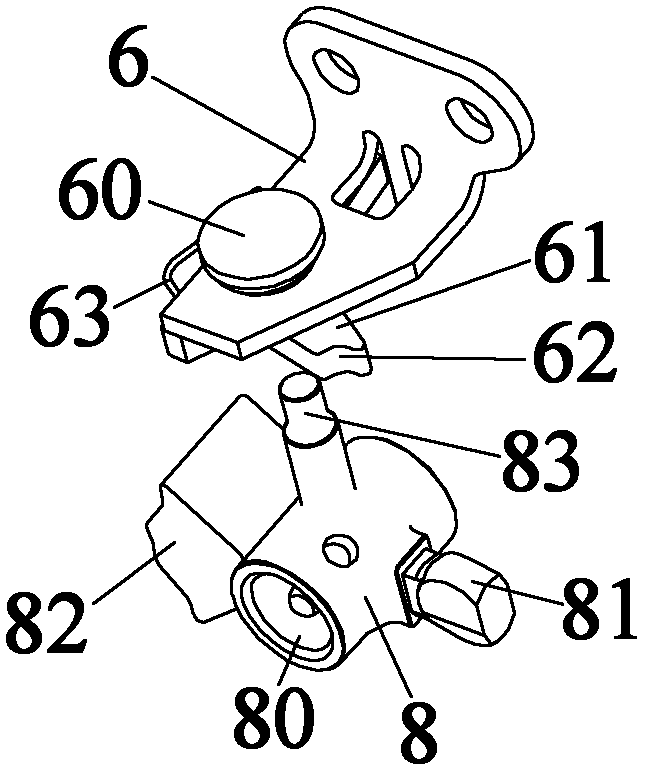

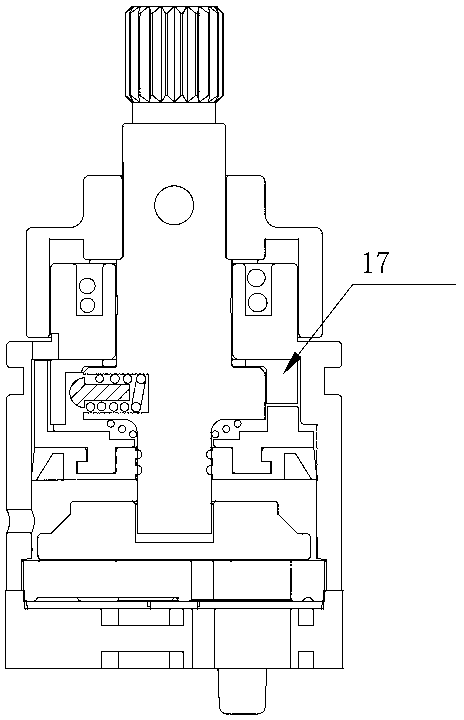

Gear selecting and shifting mechanism for automobile transmission

InactiveCN102425655AAvoid compromising shift qualityShifts smoothly and smoothlyGearing controlVariatorLocking plate

The invention discloses a gear selecting and shifting mechanism for an automobile transmission. The gear selecting and shifting mechanism comprises a gear selecting and shifting shaft, and a gear shifting arm assembly and a gear selecting arm which are connected with the top of the gear selecting and shifting shaft, wherein a reverse gear V return spring assembly, a reverse gear V interlocking mechanism and a gear shifting finger are arranged in sequence below a gear shifting shell on the gear selecting and shifting shaft; one end of the gear shifting finger is provided with a gear shifting block for pushing a gear shifting yoke; the reverse gear V interlocking mechanism comprises a locking plate which is hinged on a reverse gear V interlocking mechanism body and a torsional spring which is arranged between the reverse gear V interlocking mechanism body and the locking plate; the end part of the locking plate is provided with a guide groove; and the guide groove on the corresponding locking plate on the gear shifting finger is provided with a locking post. When a gear V is shifted to a gear IV, the locking post is guided by using the guide groove and moves along a guided locus for shifting gears, so that gear shifting is smoother, and the phenomena of clamping and sticking existing in the gear shifting process are avoided.

Owner:WUHU WANLIYANG TRANSMISSION CO LTD

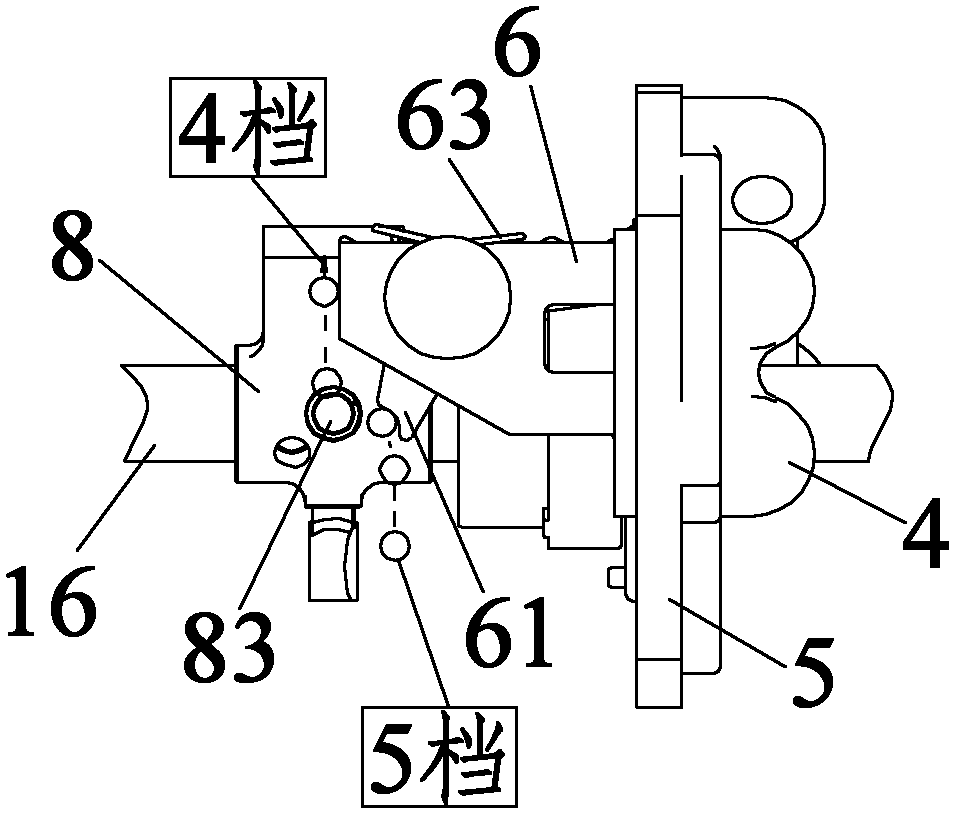

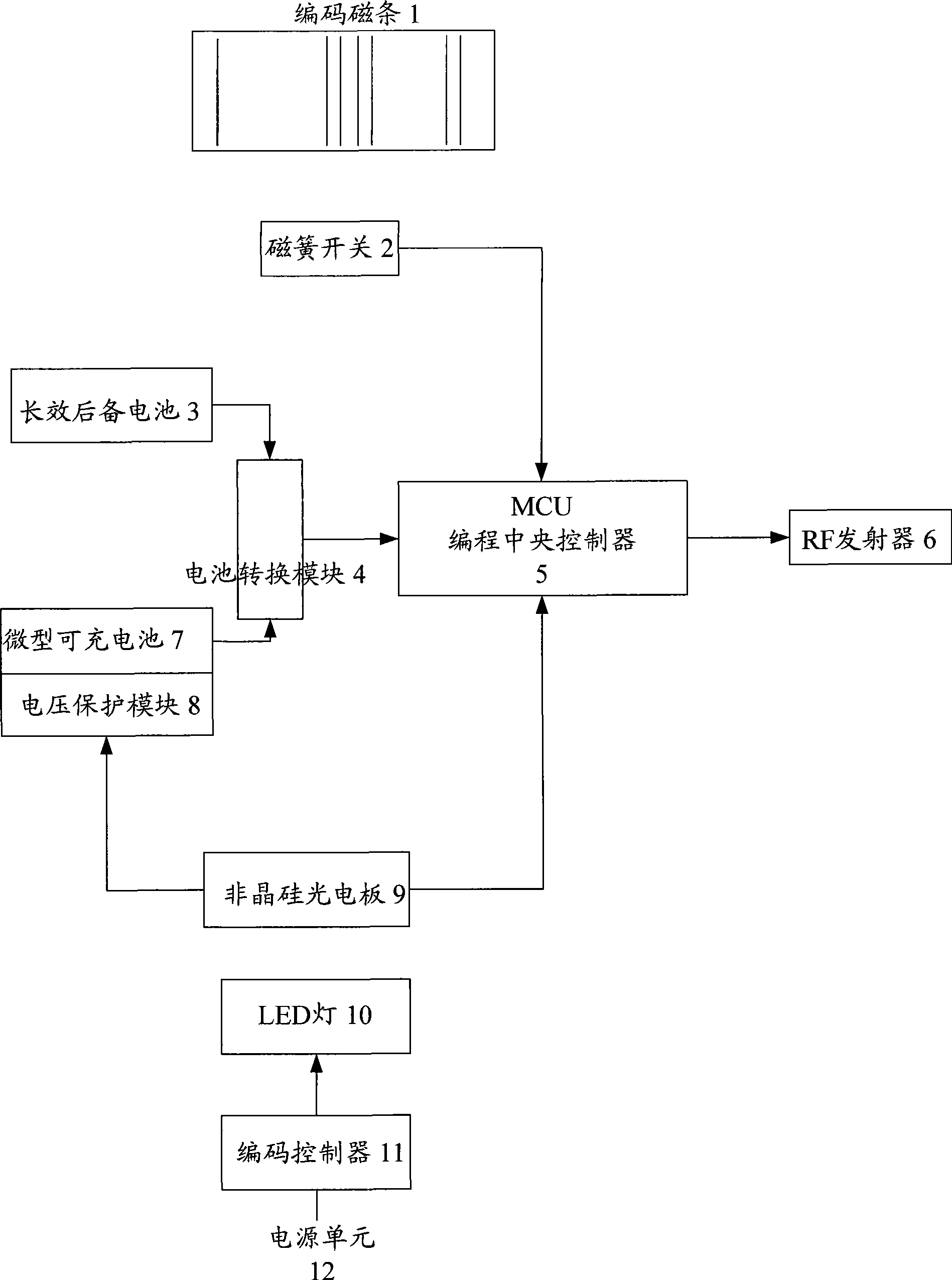

Photomagnetically coded electronic tag, real-time equipment monitoring and engine frame positioning system and real-time equipment monitoring and engine frame positioning method

InactiveCN101546388AExtended service lifeRealize smart switchingRecord carriers used with machinesSensing by electromagnetic radiationElectrical batteryRechargeable cell

The invention relates to a photomagnetically coded electronic tag, which comprises an RFID transmitter, an antenna, a central controller and a power module, wherein the power module is connected with the antenna through the central controller and the RFID transmitter. The photomagnetically coded electronic tag also comprises a magnetic induction device and a photoinduction device, wherein the magnetic induction device and the photoinduction device are connected with the central controller respectively; the power module comprises a rechargeable battery unit, a backup battery and a battery conversion unit; the photoinduction device is connected with the rechargeable battery unit; and the rechargeable battery unit and the backup battery are connected with the central controller through the battery conversion unit. The invention also relates to a real-time equipment monitoring and engine frame positioning system which comprises the electronic tag and a real-time equipment monitoring and engine frame positioning method. Due to adoption of the photomagnetically coded electronic tag, the real-time equipment monitoring and engine frame positioning system and the real-time equipment monitoring and engine frame positioning method, the invention greatly prolongs the service life of the electronic tag, realizes maintenance free in deed, realizes perfect real-time monitoring and engine frame positioning functions, not only has low cost but also has stable and reliable operating performances, and has wide application scope.

Owner:上海晶舜信息科技有限公司

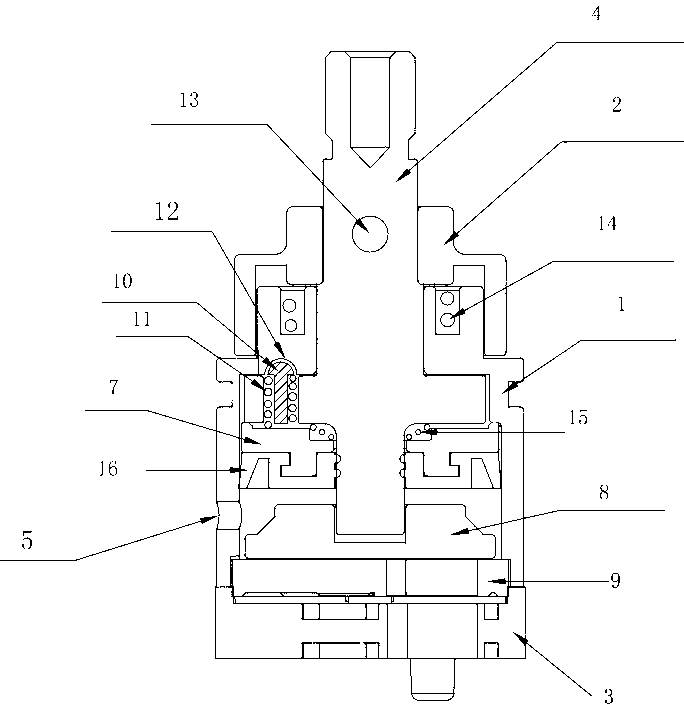

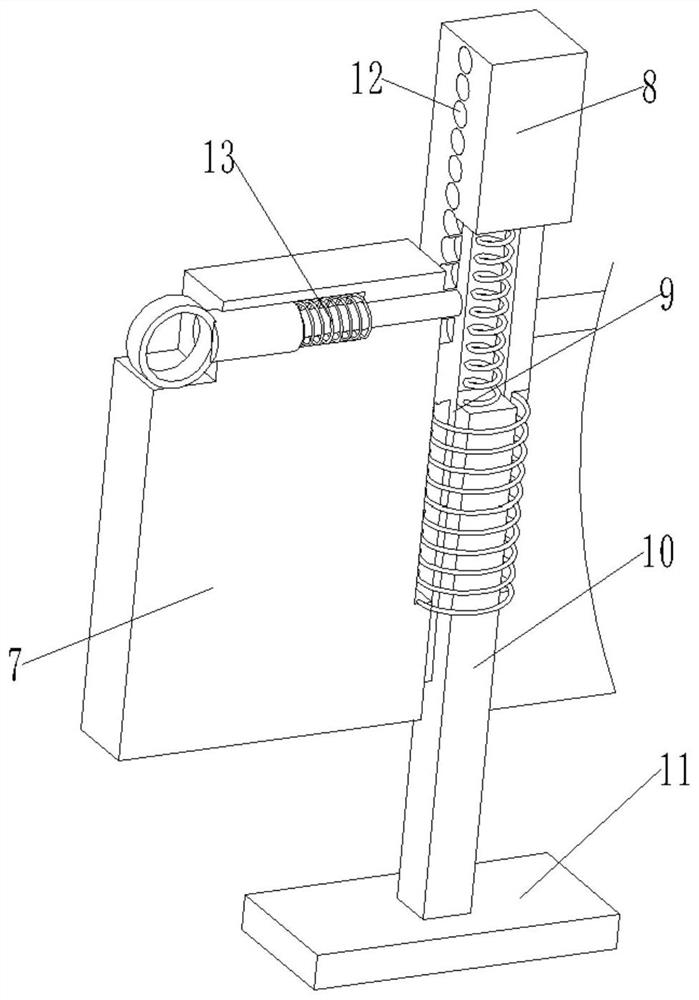

Automatic three-gear reset shunt valve

ActiveCN103291955AAccurate water dischargeFeel smoothOperating means/releasing devices for valvesMultiple way valvesReturn functionEngineering

The invention discloses an automatic three-gear reset shunt valve comprising a body, an upper cap and a base. The upper cap is fittingly installed on the upper portion of the body, and the base is fittingly installed at the bottom of the body. A transmission rod and a water inlet are arranged on the body. The base is provided with water outlets with three gears, a frame for positioning the transmission rod, a movable piece and a fixed piece are arranged in the body, the movable piece and the fixed piece are connected with the transmission rod, the transmission rod is provided with a through hole, and a positioning ball and a positioning ball spring are arranged in the through hole. Under the action of the positioning spring, the shunt valve is smooth in touch, no matter water pressure is high or low, positioning function of the positioning spring is good, return function is unaffected, and water channels can be opened and closed in time.

Owner:吕忠岩

Slide hinge

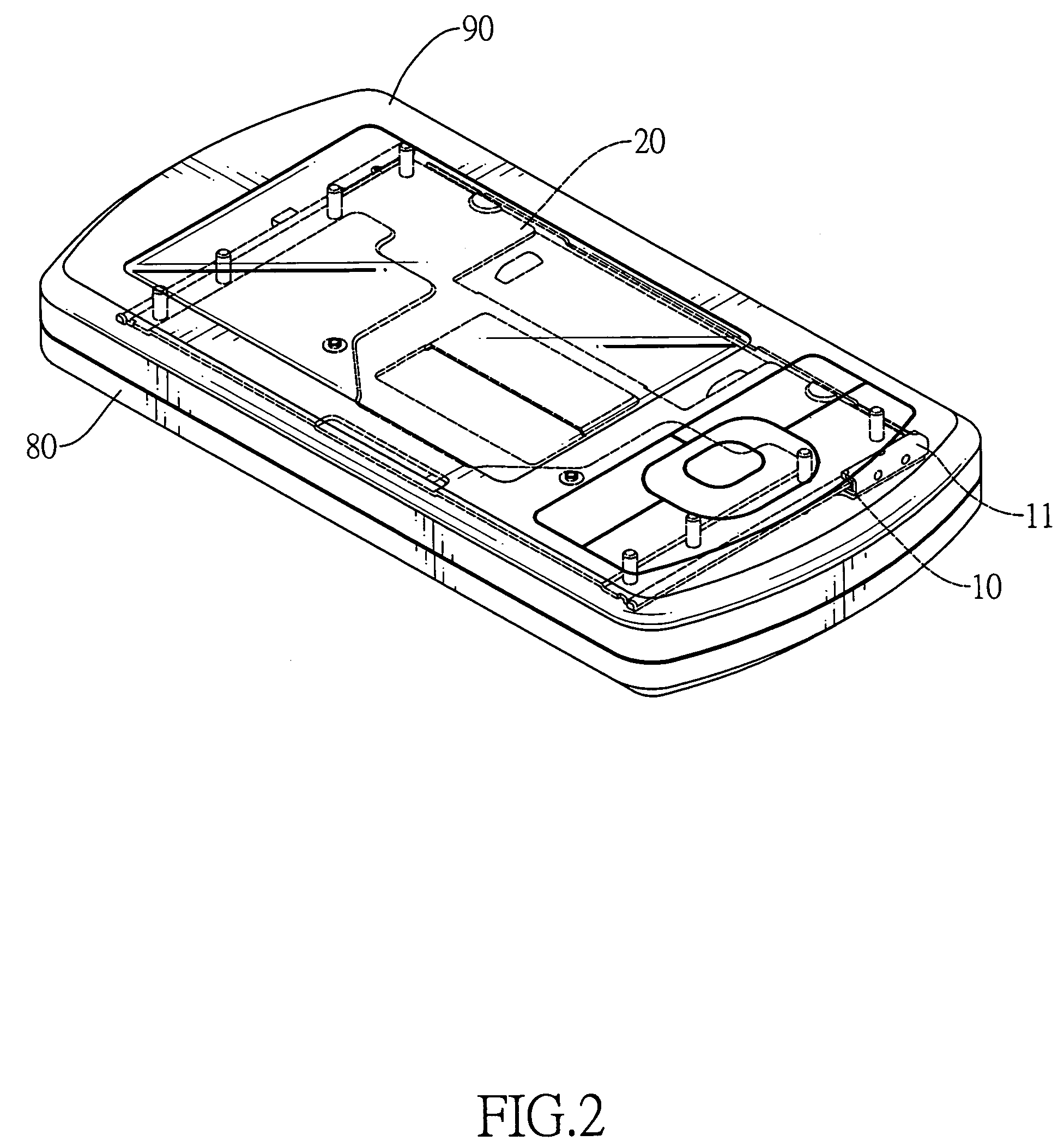

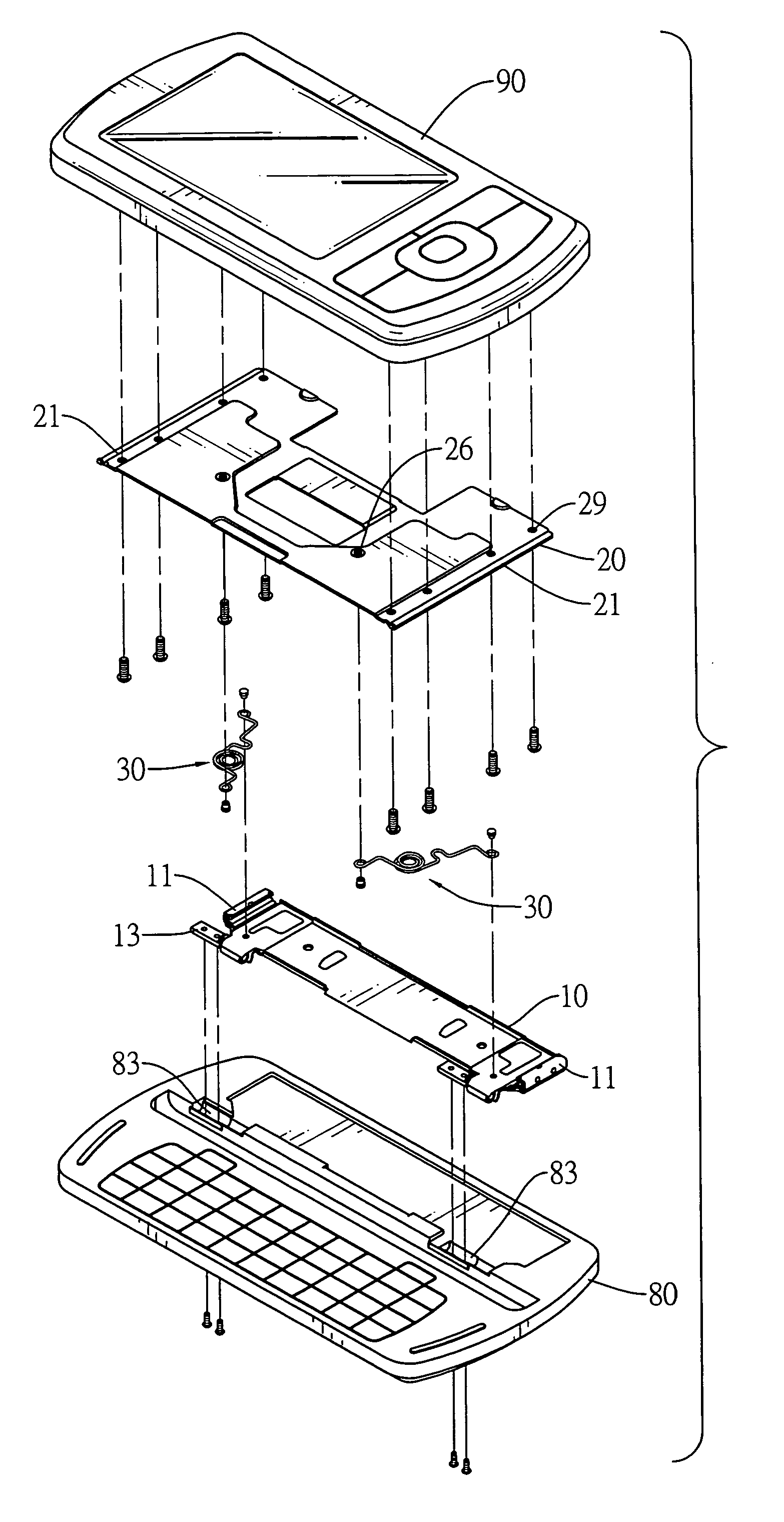

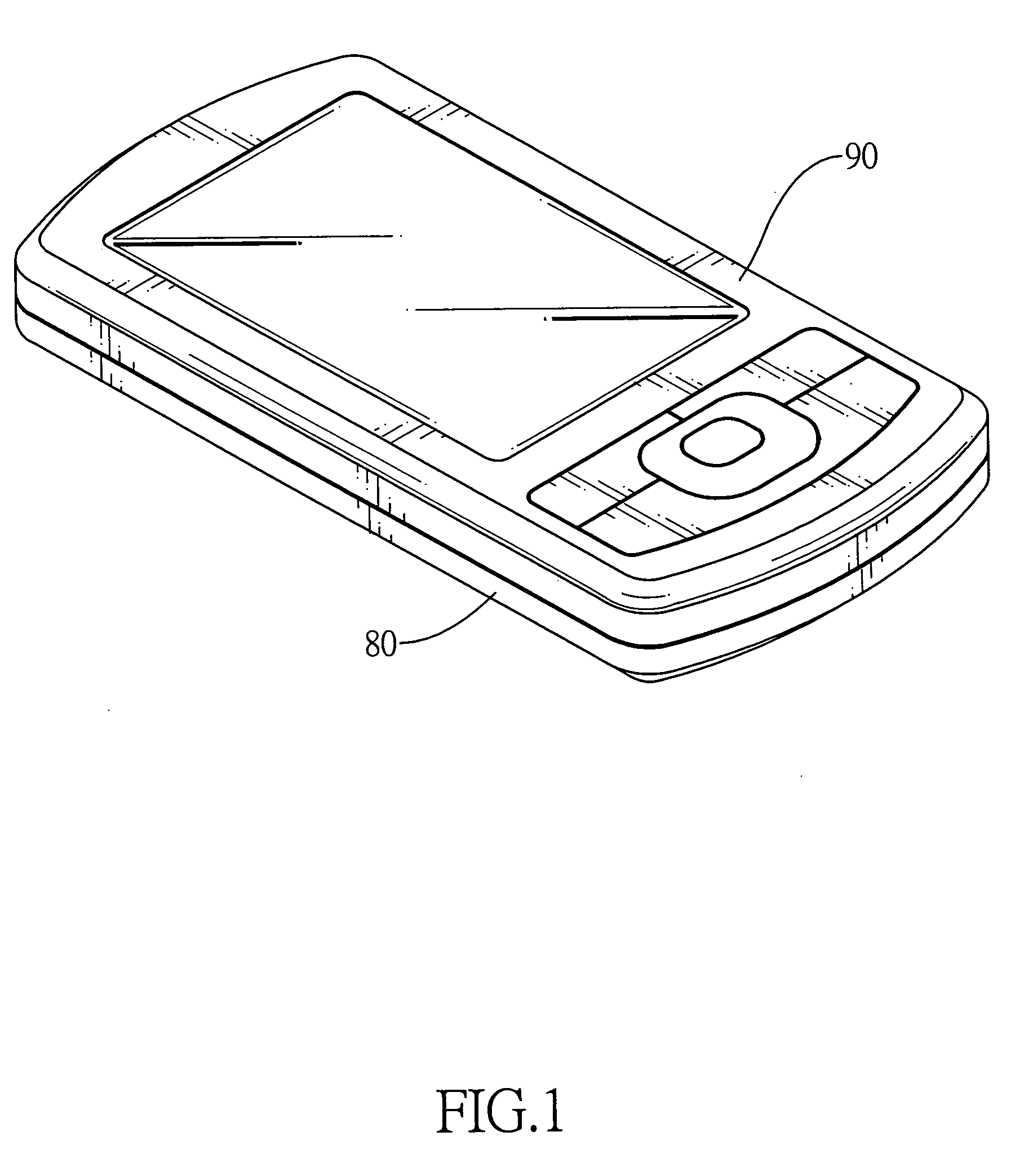

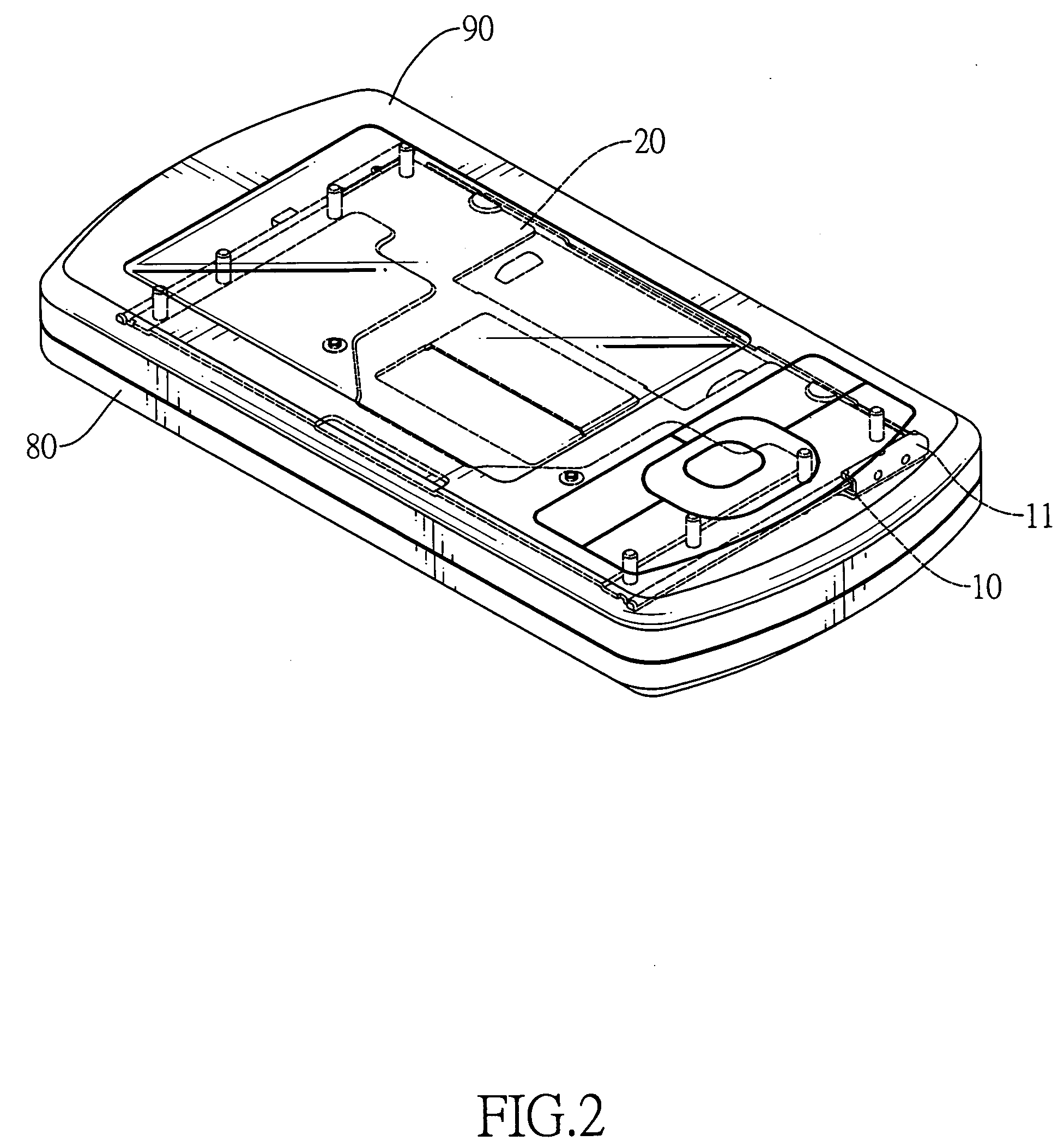

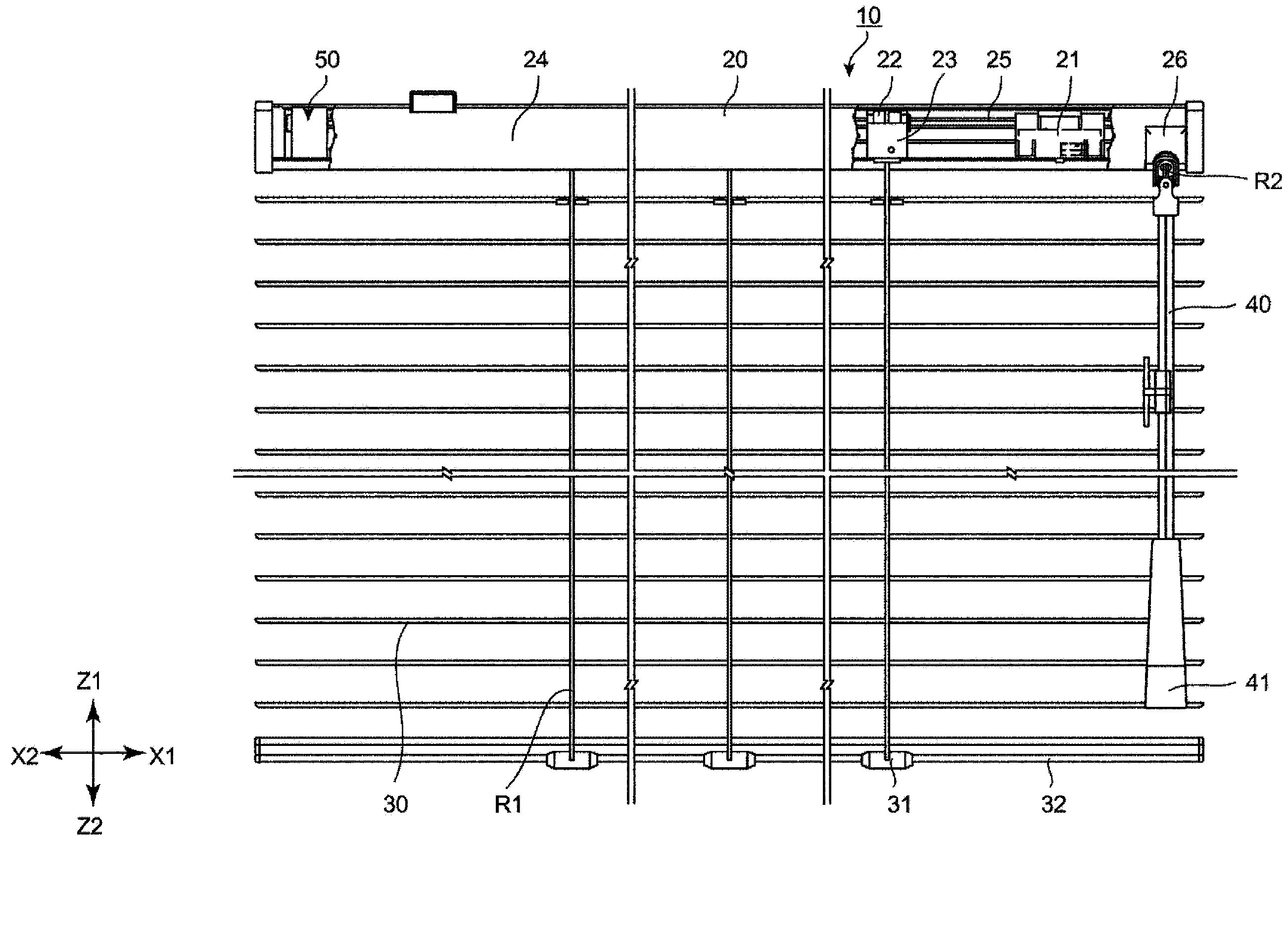

InactiveUS7716786B2Good positioning functionIncrease elasticityPin hingesWing openersEngineeringTorsion spring

A slide hinge is connected a cover to a base of a portable electronic device and has a stationary bracket, two pivot members, a sliding bracket and two torsion springs. The pivot members are mounted rotatably on the sliding bracket and are mounted to the base. The sliding bracket is mounted slidably on the stationary bracket and is mounted to the cover. The torsion springs are connected between the stationary bracket and the sliding bracket and each torsion spring multiple looped segments. The torsion springs with the looped segments provide an excellent resilient force to position the stationary bracket in one edge of the sliding bracket and therefore stably hold the cover in opened or closed positions without inadvertently sliding relative to the base.

Owner:SHIN ZU SHIN

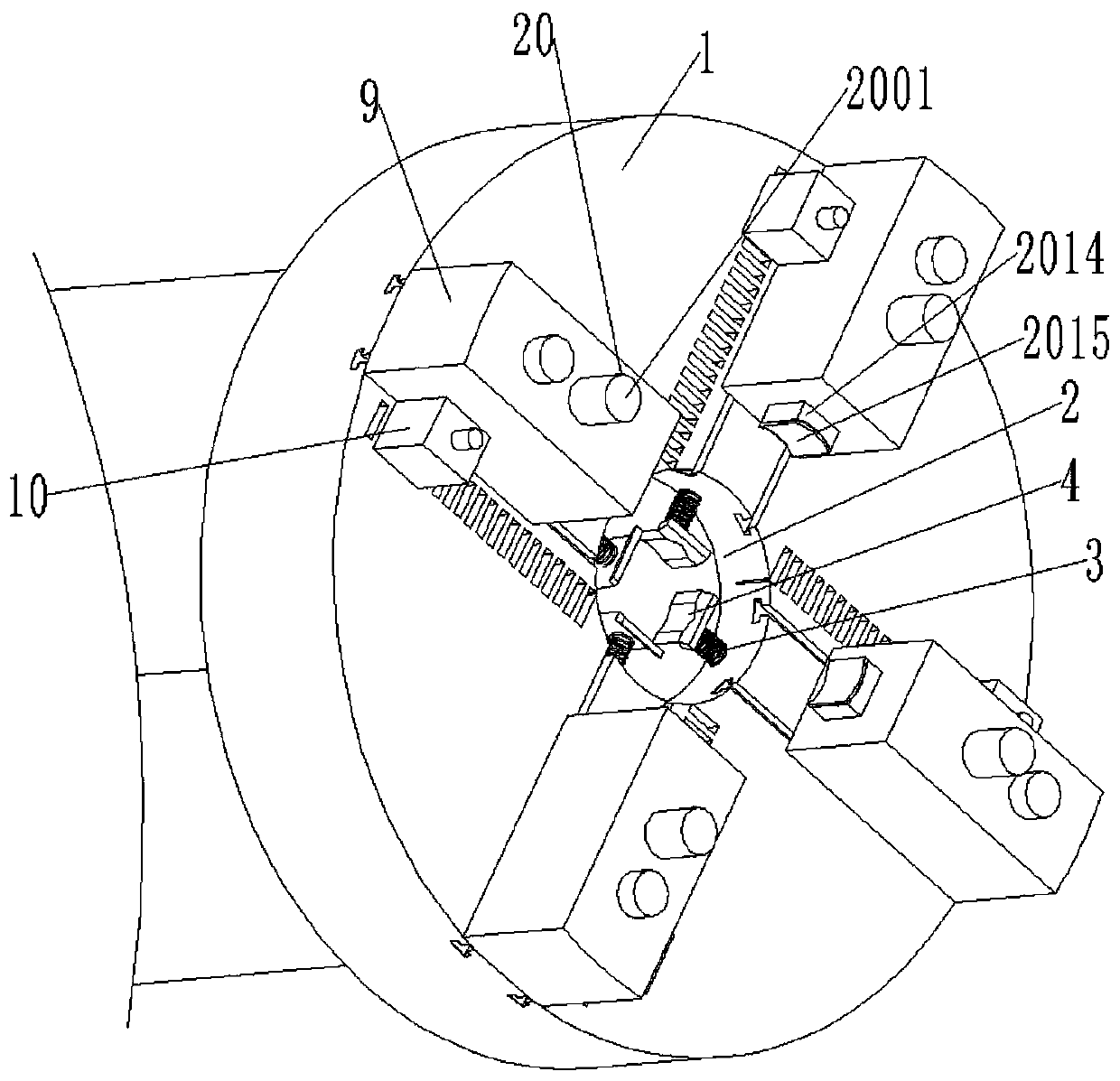

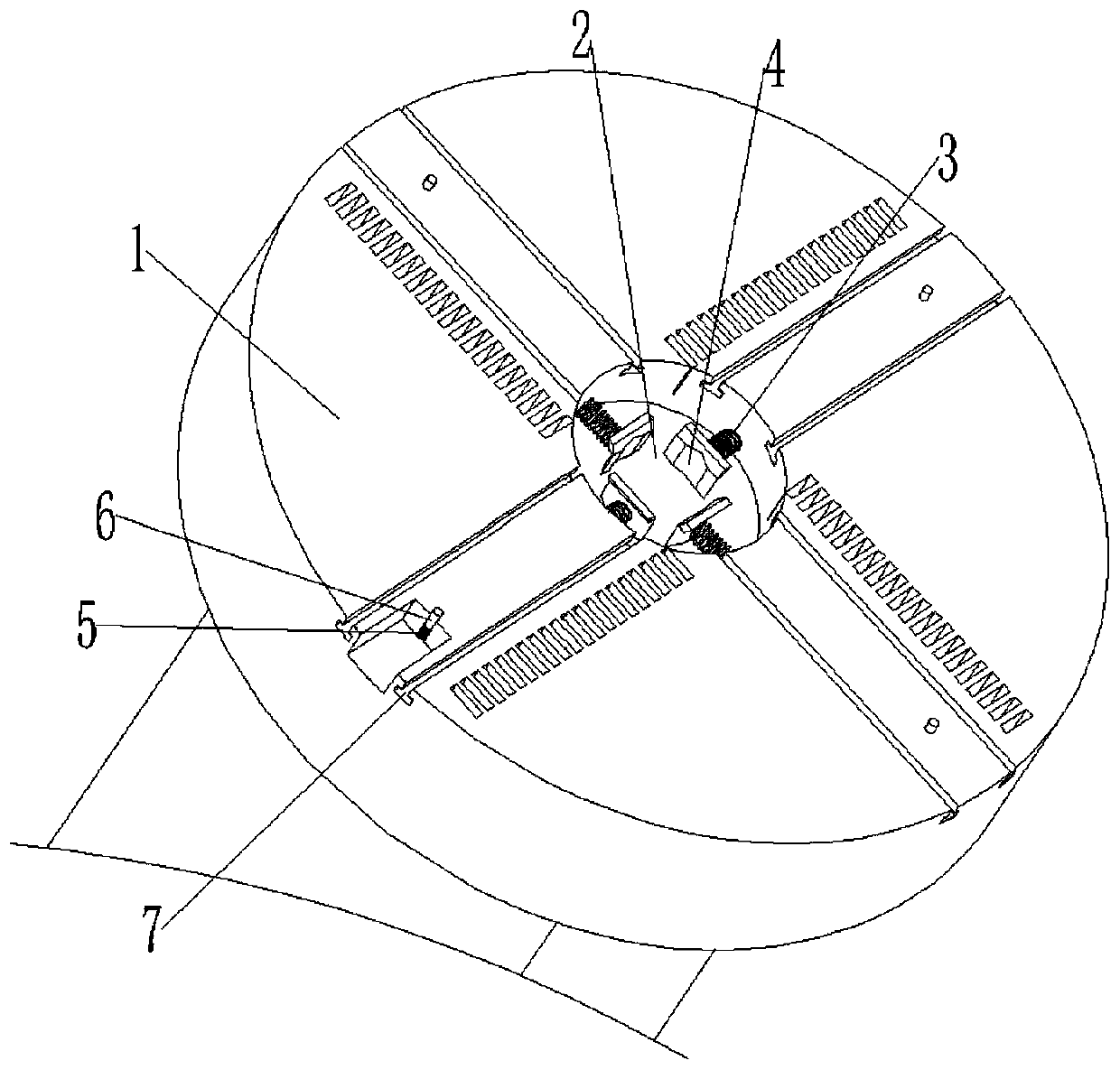

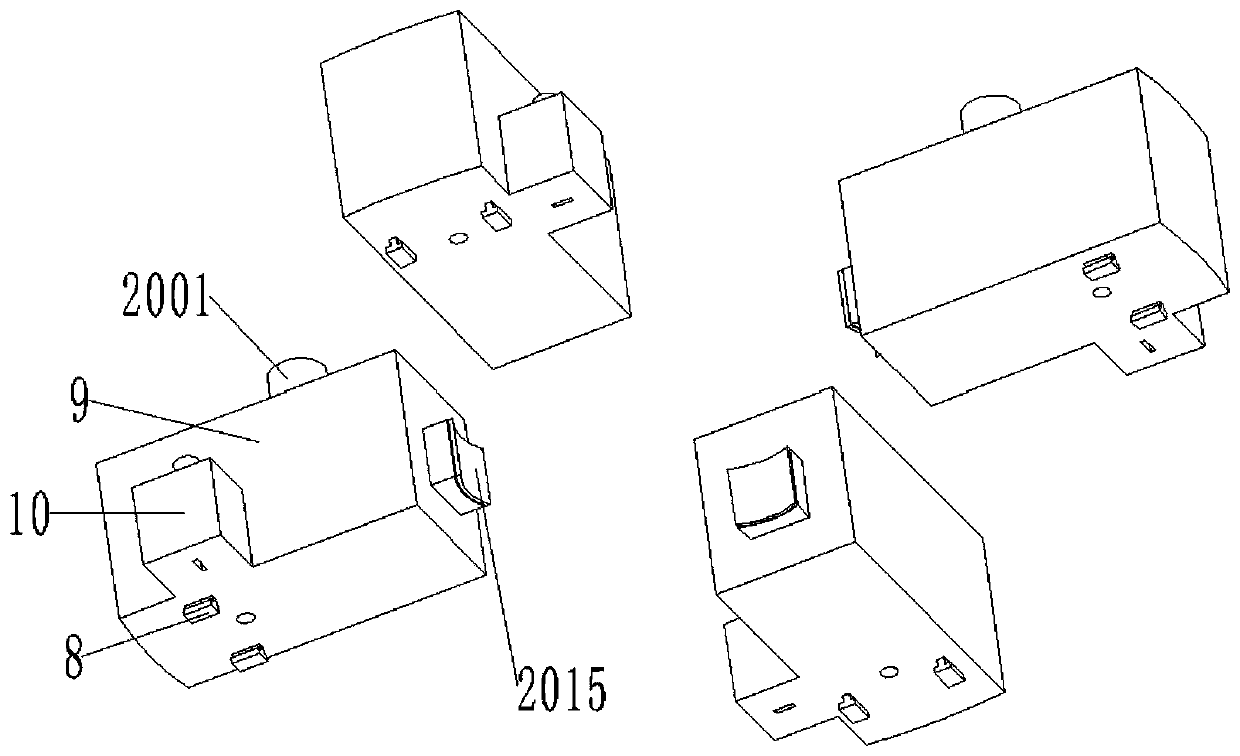

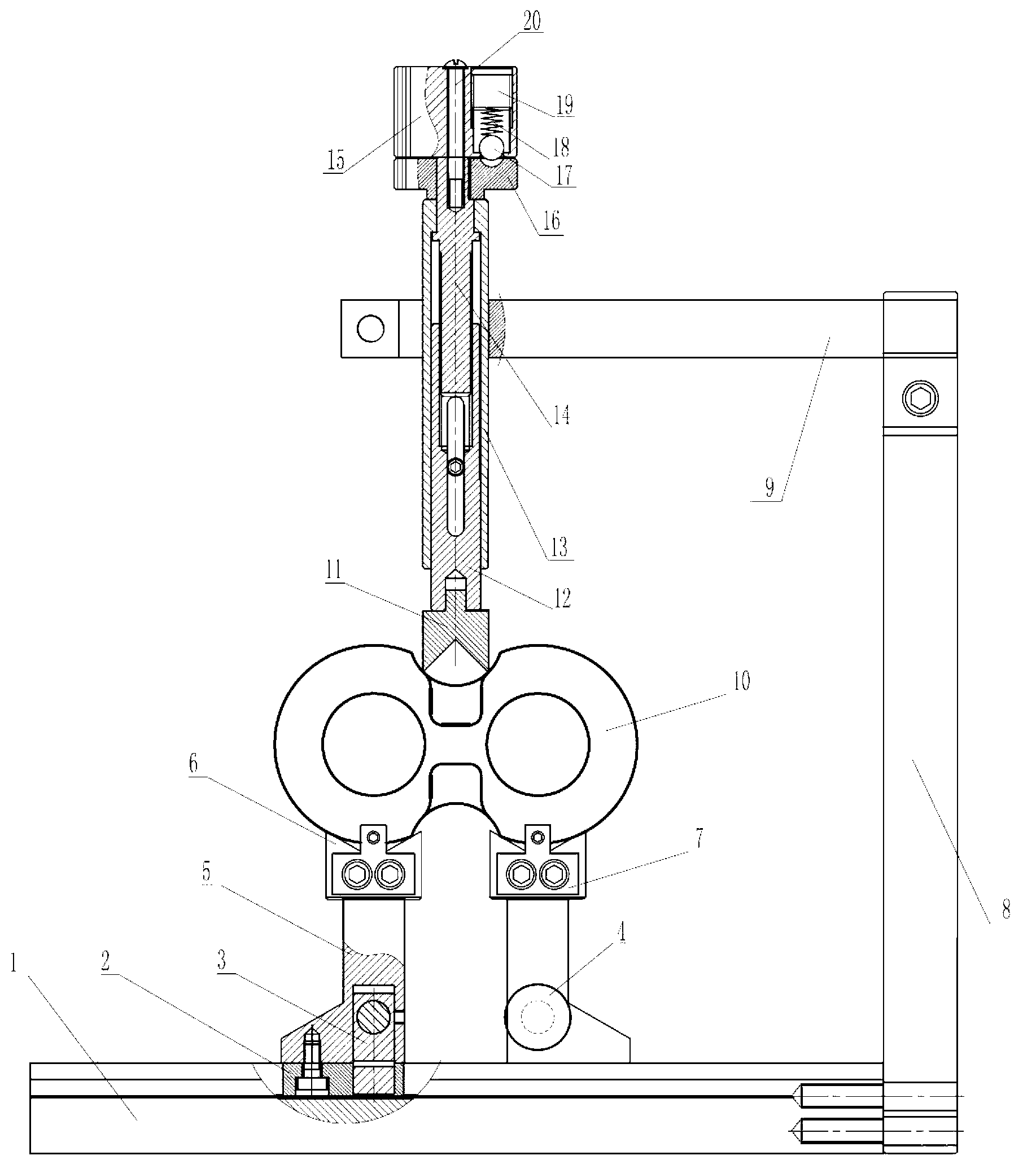

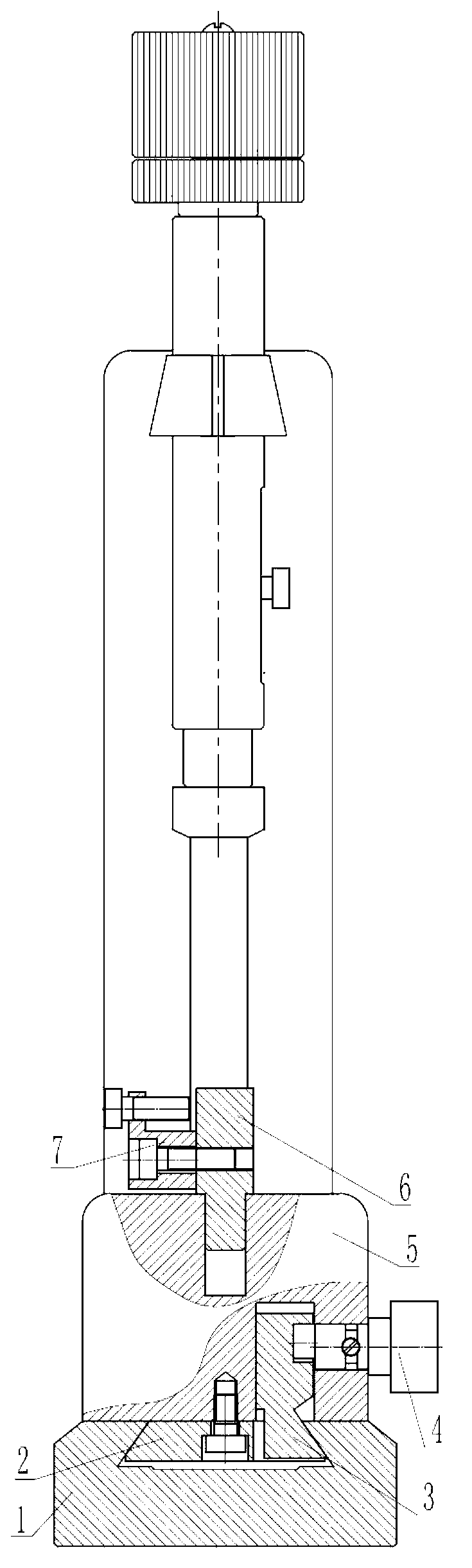

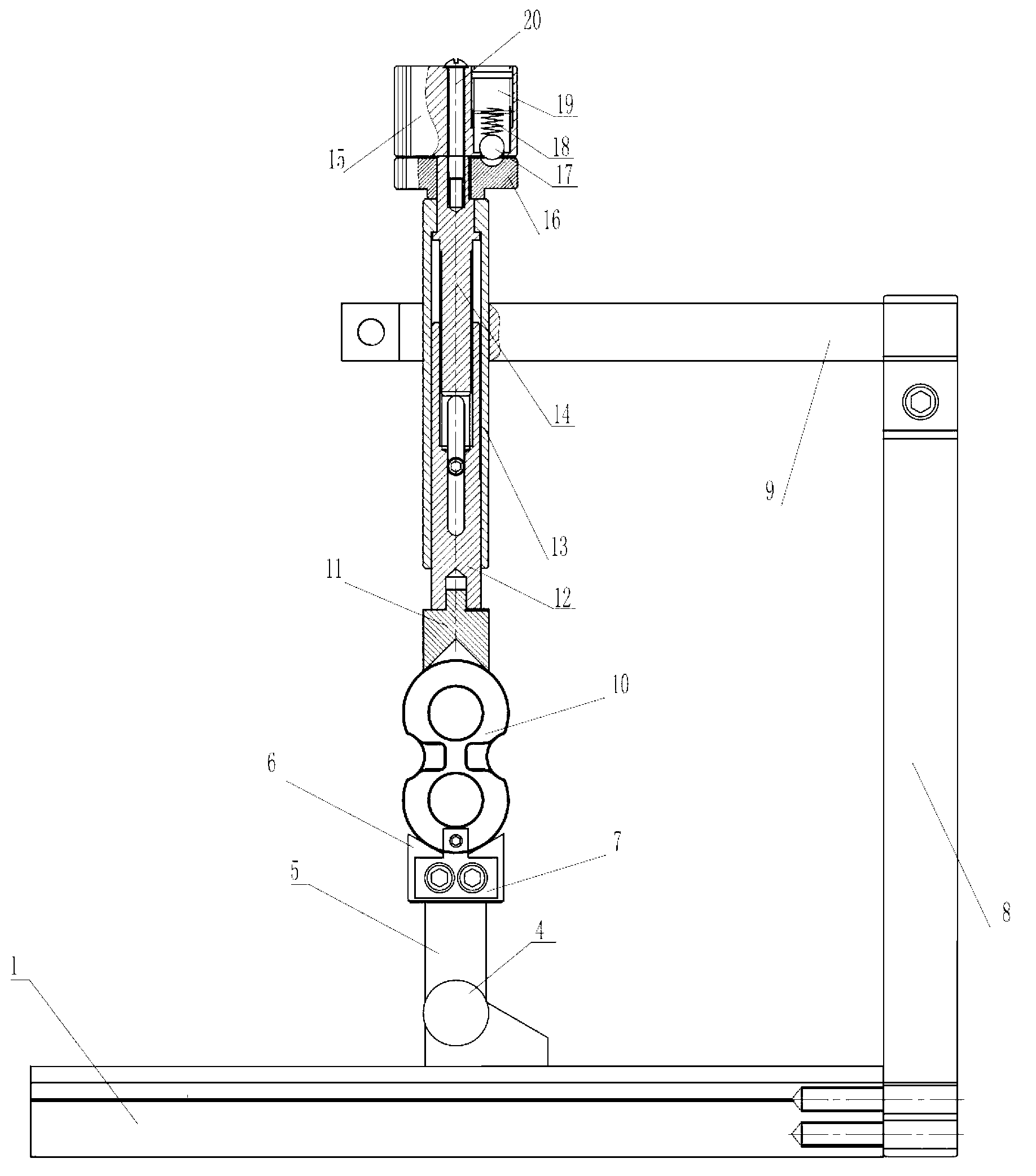

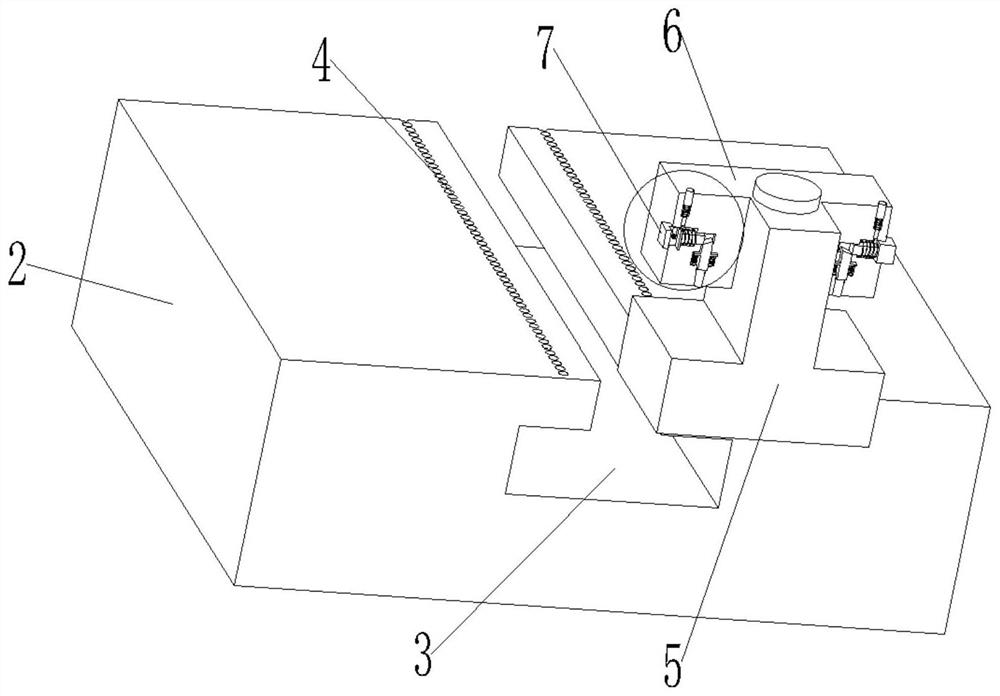

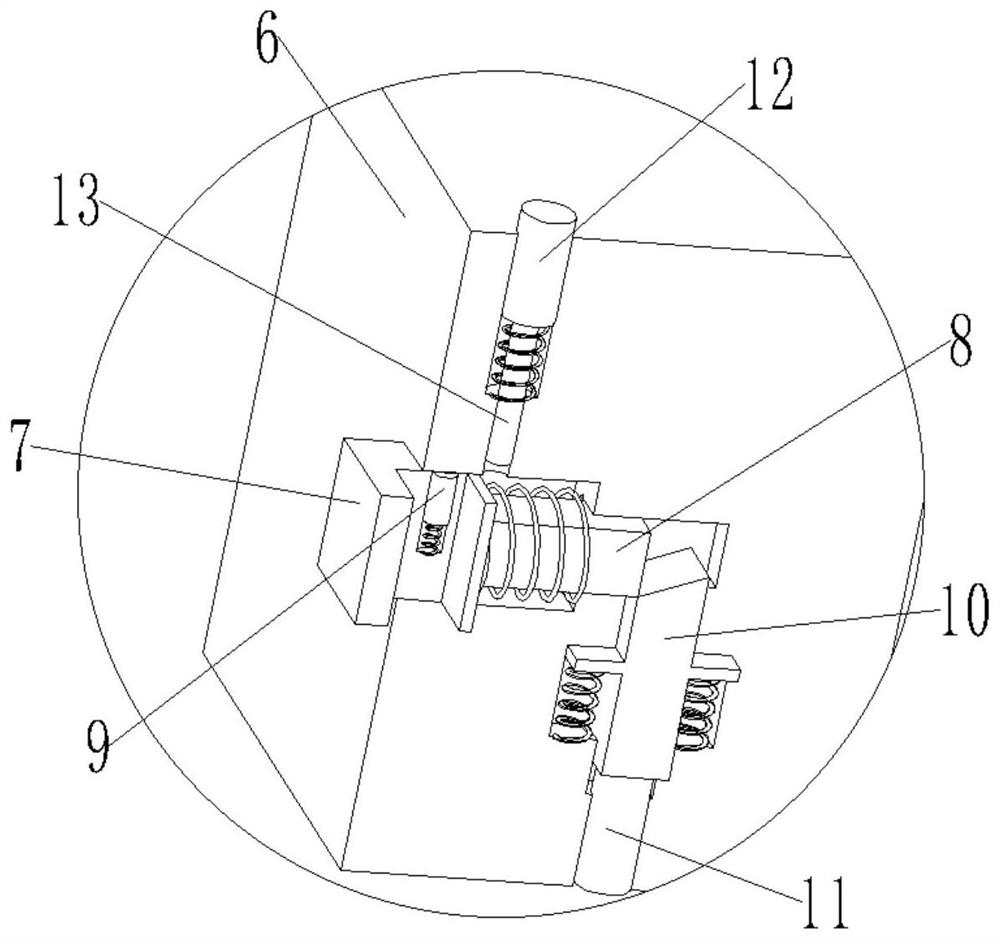

Machined part positioning mechanism for numerical control machining lathe

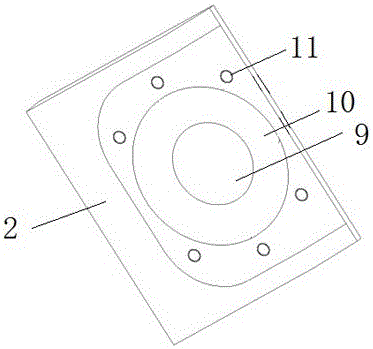

ActiveCN111496559AGood positioning functionRapid positioningPositioning apparatusMetal-working holdersNumerical controlMachine parts

The invention discloses a machined part positioning mechanism for a numerical control machining lathe. The machined part positioning mechanism comprises a rotary disc, a containing groove, a sliding body and a positioning and clamping structure; the containing groove is formed in the circle center position of one side of the rotary disc, first connecting springs are symmetrically arranged on the inner side wall of the containing groove in an integrally-formed mode, and an arc-shaped plate is arranged at the other ends of the first connecting springs in an integrally-formed and connected mode.According to the machined part positioning mechanism for the numerical control machining lathe, through the arrangement of the containing groove, the first connecting springs, the arc-shaped plate andthe sliding body, good positioning function is achieved on a machined workpiece, rapidly positioning and fixing the workpiece can be carried out, convenience is brought to workers, the working efficiency is improved; and through the arranged positioning and clamping structure, the firmness of workpiece positioning and fixing can be improved, looseness is not likely to be generated in the machining work, the fact that normal work is carried out is guaranteed, the machining quality is guaranteed, and then the work economic benefits are improved.

Owner:广东巡峰精密制造有限公司

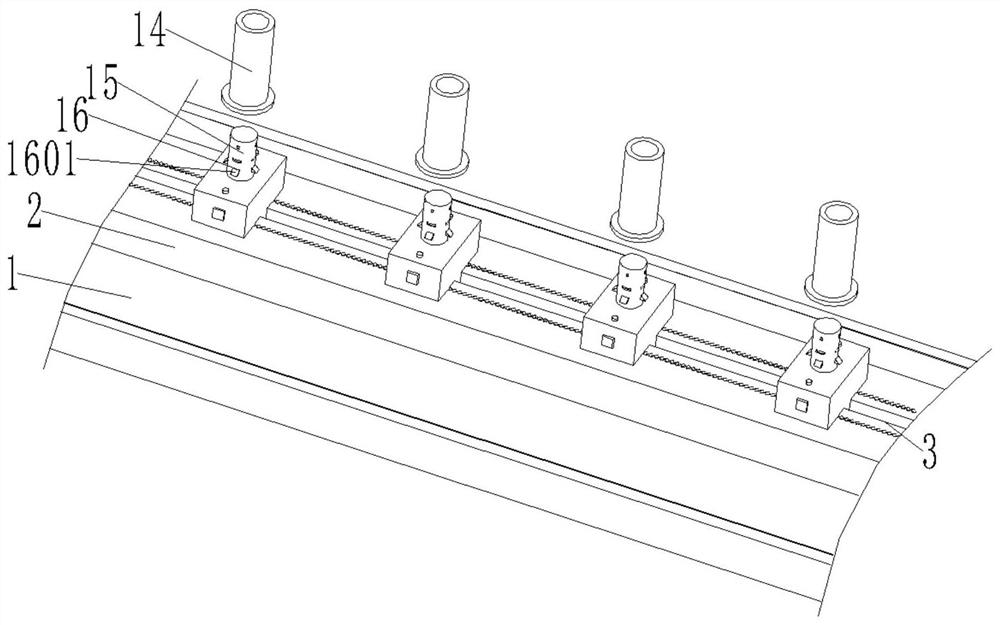

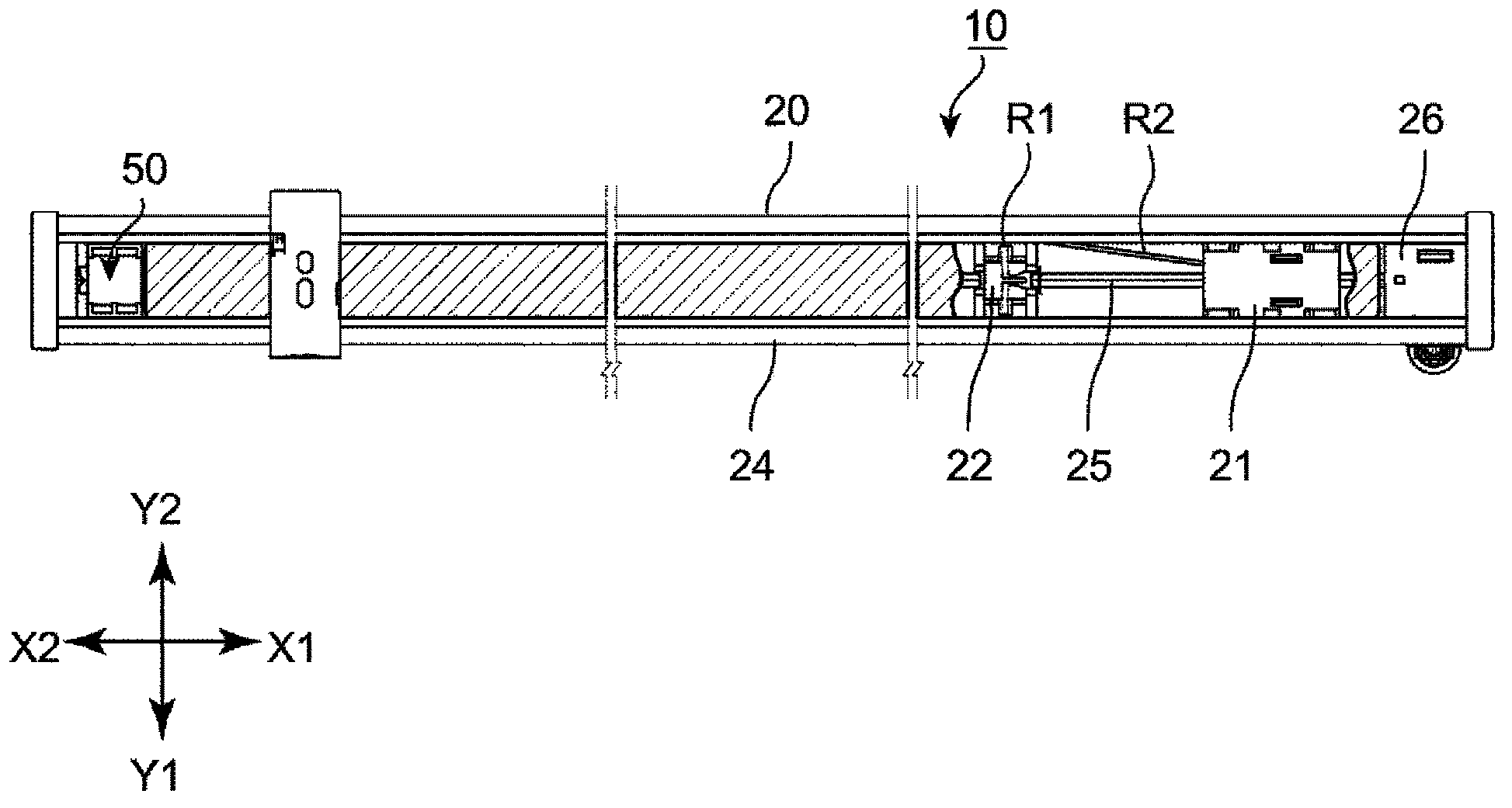

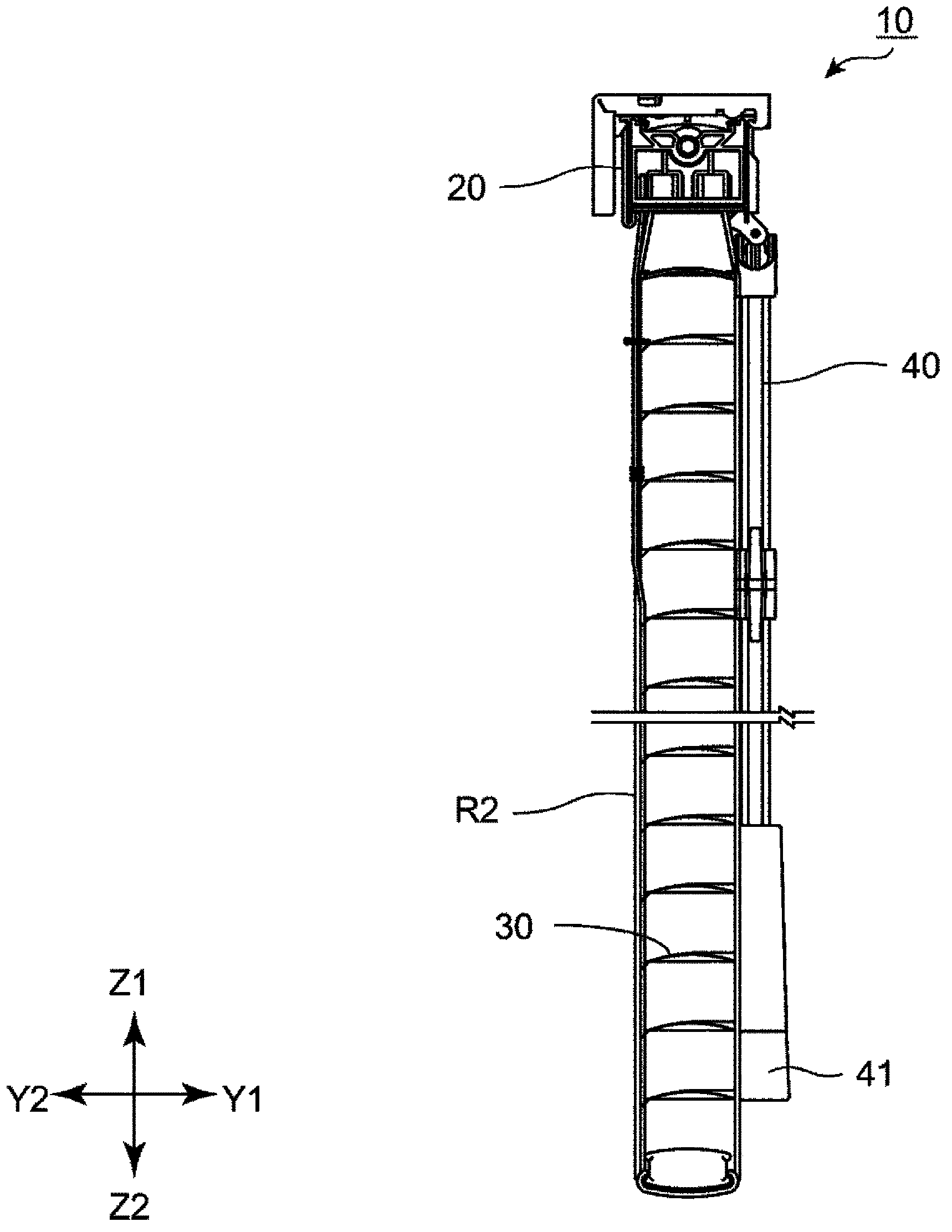

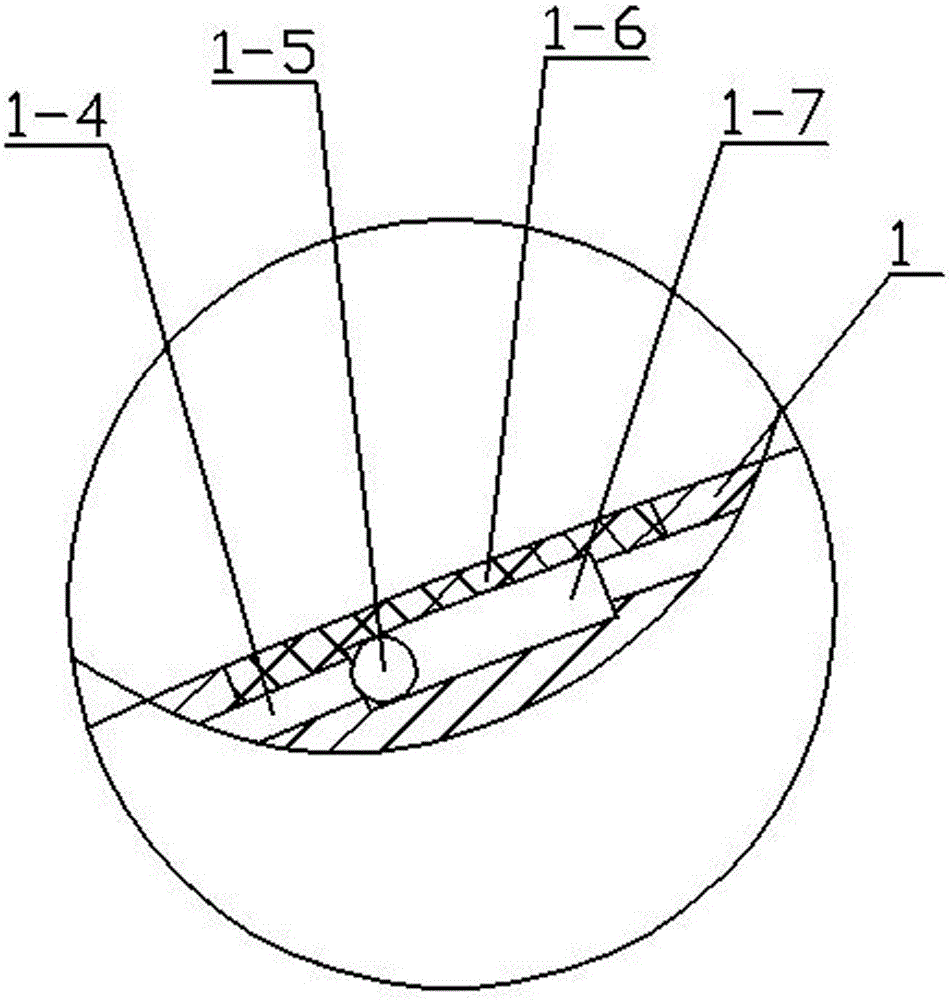

Pipeline outer wall bionic groove surface machining device and machining method thereof

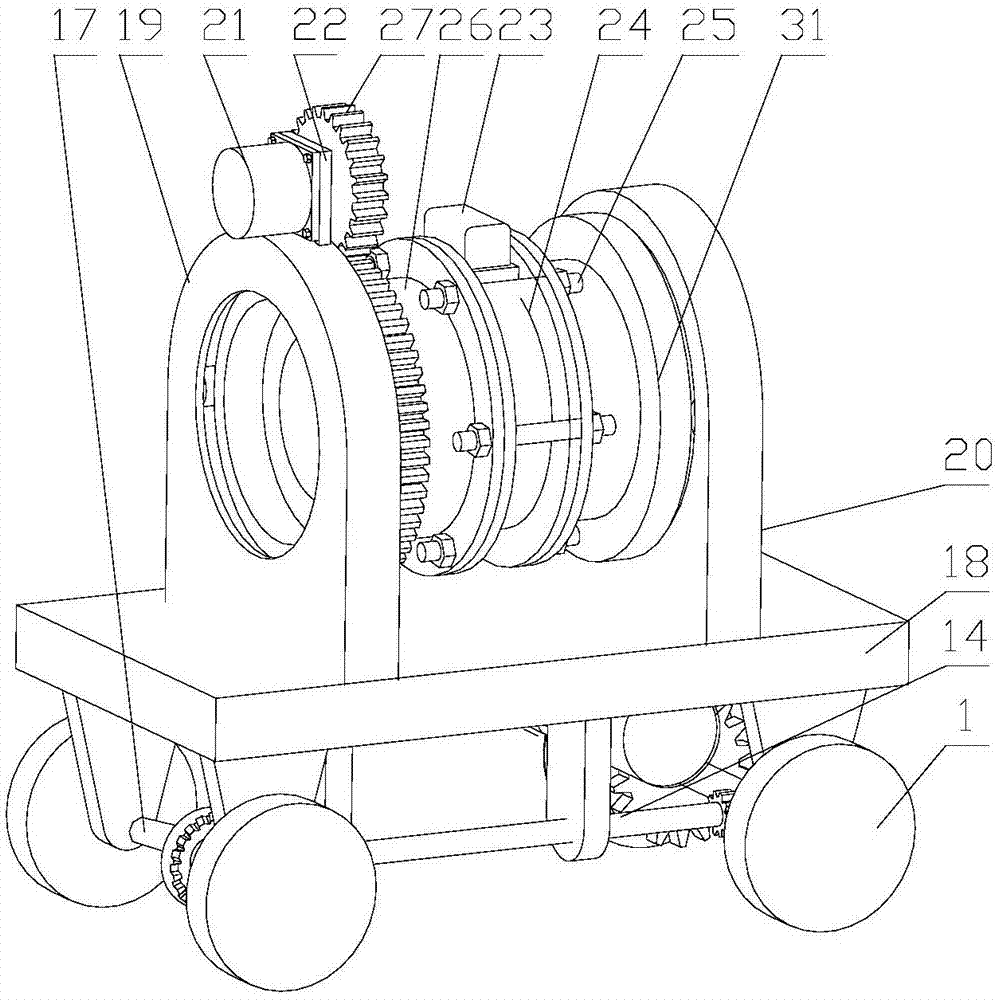

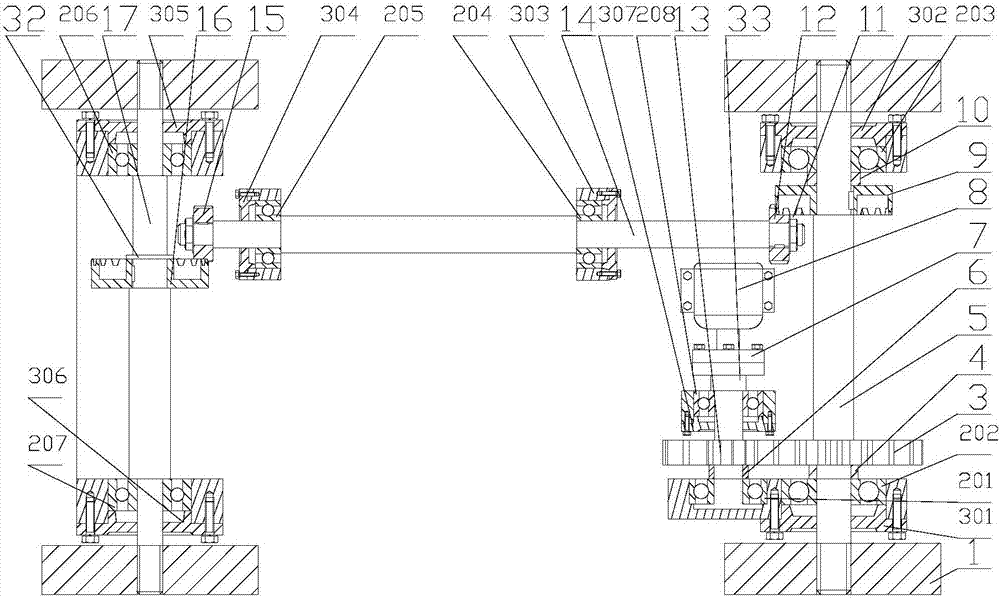

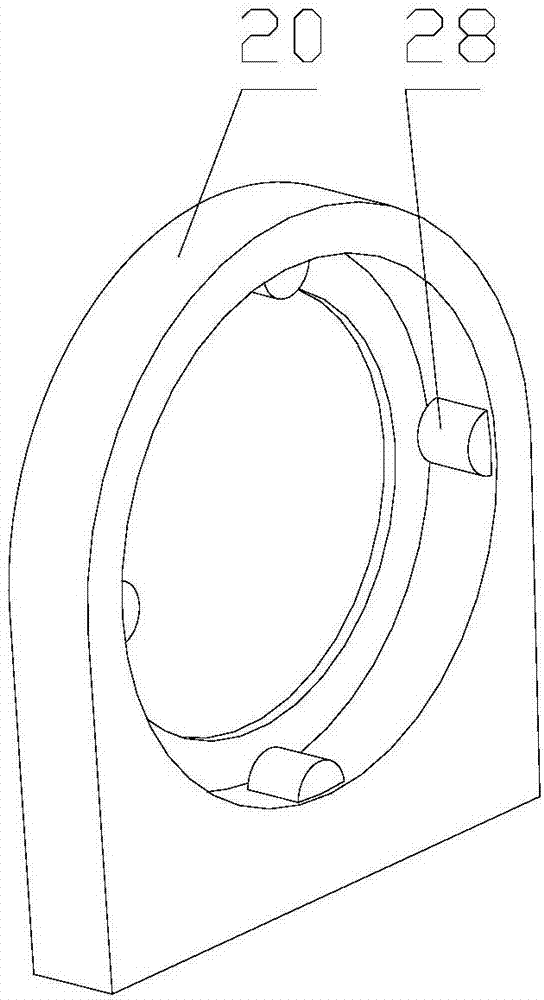

ActiveCN107020409AImprove athletic abilityImprove stabilityFeeding apparatusLarge fixed membersEngineeringDrive motor

The invention relates to a pipeline outer wall bionic groove surface machining device and a machining method thereof. The pipeline outer wall bionic groove surface machining device comprises a driving mechanism used for providing driving force, a supporting base used for being connected with the driving mechanism and supporting a machining mechanism, the machining mechanism used for machining bionic grooves in a pipeline outer wall and a controller; a first supporting table and a second supporting table are installed above the supporting base and are coaxially and symmetrically arranged at the two ends of the supporting base; the driving mechanism is installed below the supporting base; the machining mechanism is installed between the first supporting table and the second supporting table in a clamped manner; the driving mechanism and the machining mechanism are both electrically connected with the corresponding control ends of the controller; and the machining method includes the steps that the devices are firstly placed, the positions of the device are adjusted, a driving motor is started, and the driving motor is stopped after the devices are adjusted to the appropriate positions; and the position of a cutter is adjusted through an adjusting pressure control device, and cutting is started. The pipeline outer wall bionic groove surface machining device has the beneficial effects that the structure is simple, operation is easy, and bionic groove structures can be machined on the pipeline outer wall protection coating surface.

Owner:ZHEJIANG UNIV OF TECH

Child missing preventive garment accessory on basis of GPS (global positioning system) positioning

InactiveCN104223507AEfficiently provideEffective anti-lost methodGarmentsSatellite radio beaconingEngineeringGlobal Positioning System

The invention relates to a child garment accessory implanted with a GPS (global positioning system) positioning module, in particular to a child missing preventive garment accessory on the basis of GPS positioning and belongs to the technical field of clothes design. The technical scheme includes that a GPS missing preventive module implanted in the child garment is not fixed, and continuous practicality of the GPS positioning module and feasibility of the garment during washing are improved. The accessory combined with the GPS positioning module is a plush cartoon accessory, on one hand, the GPS positioning module has no hurt to tender skin of a child, on the other hand, the GPS positioning module cannot be damaged initiatively by the child and found by lawbreakers. The GPS missing preventive module implanted in the child garment is not fixed, and various garments can be provided with a GPS positioning function when garment accessories are combined with the GPS positioning module; the garment accessories can be detached during washing of the garments, practicality is improved and the child missing preventive garment accessory is compact in structure, wide in application range, convenient to detach, safe and reliable.

Owner:JIANGNAN UNIV

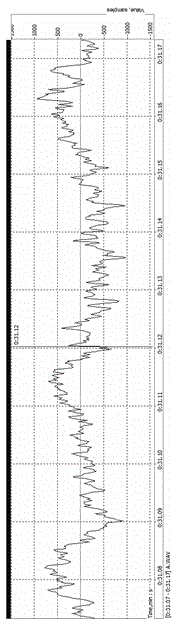

Detecting method based on digital audio waveform sudden changes

ActiveCN104021791AGood detection and positioning functionAccurate location of tampering timeSpeech analysisDigital Audio TapeSpeech spectrum

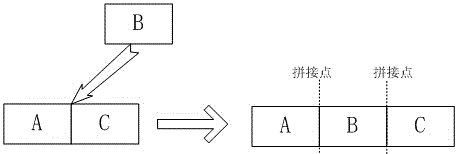

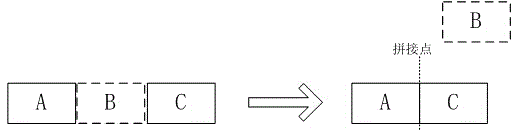

The invention discloses a detecting method based on digital audio waveform sudden changes, which is a statistical judging method disclosed according to the characteristic of a ridge of a speech spectrum caused by audio waveform sudden changes, and belongs to the multimedia information safety field. For waveform sudden change detection due to copying-pasting operation of a digital audio, ridge span changes before and after audio joint points in a speech spectrum log domain are analyzed, and a ridge factor is constructed to describe ridge bandwidth of a one-frame audio log speech spectrum to represent short-time energy change characteristics, and a difference operator is utilized for distinguishing sudden noises of audio, and ridge factor identification is caused by audio waveform sudden changes. The method comprises the following steps of carrying out short-time Fourier transformation and logarithmic transformation on an audio signal to obtain an audio spectrum of the log domain; calculating the ridge factor of each frame in the speech spectrum; and detecting and judging the difference transformation result for the ridge factor. The detecting method disclosed by the invention can identify audio waveform sudden changes effectively, and provides an effective method for detecting a digital audio editing operation boundary.

Owner:广西平果润民脱贫发展有限公司

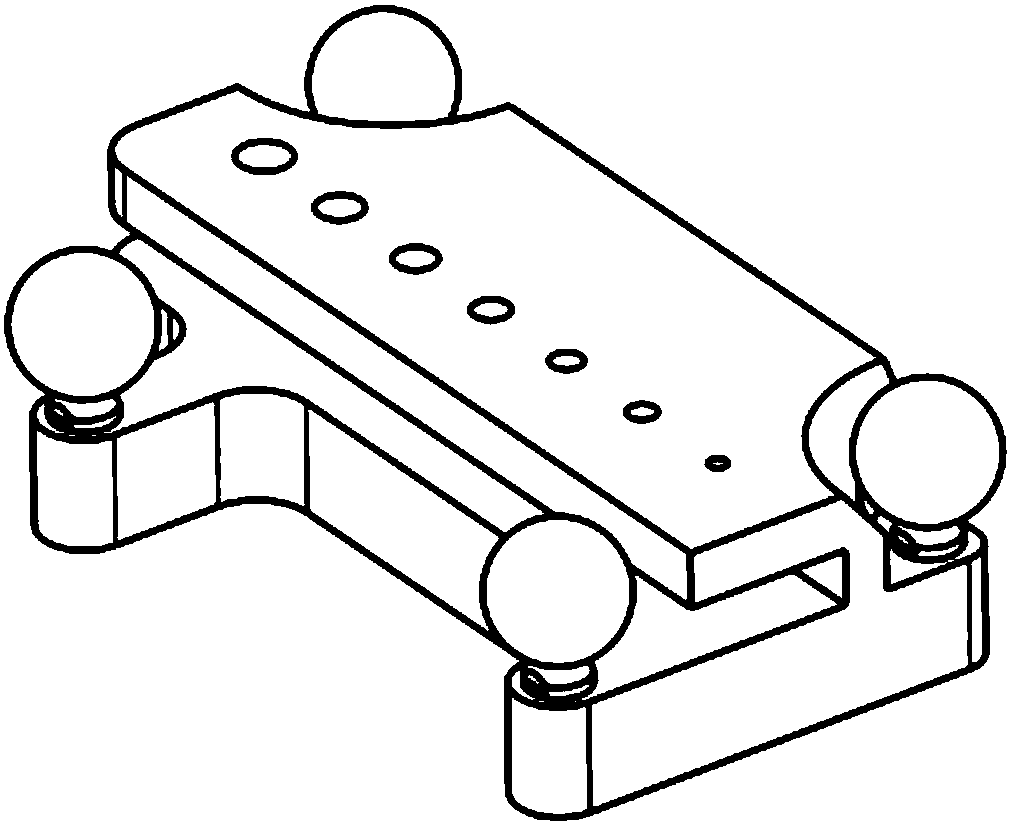

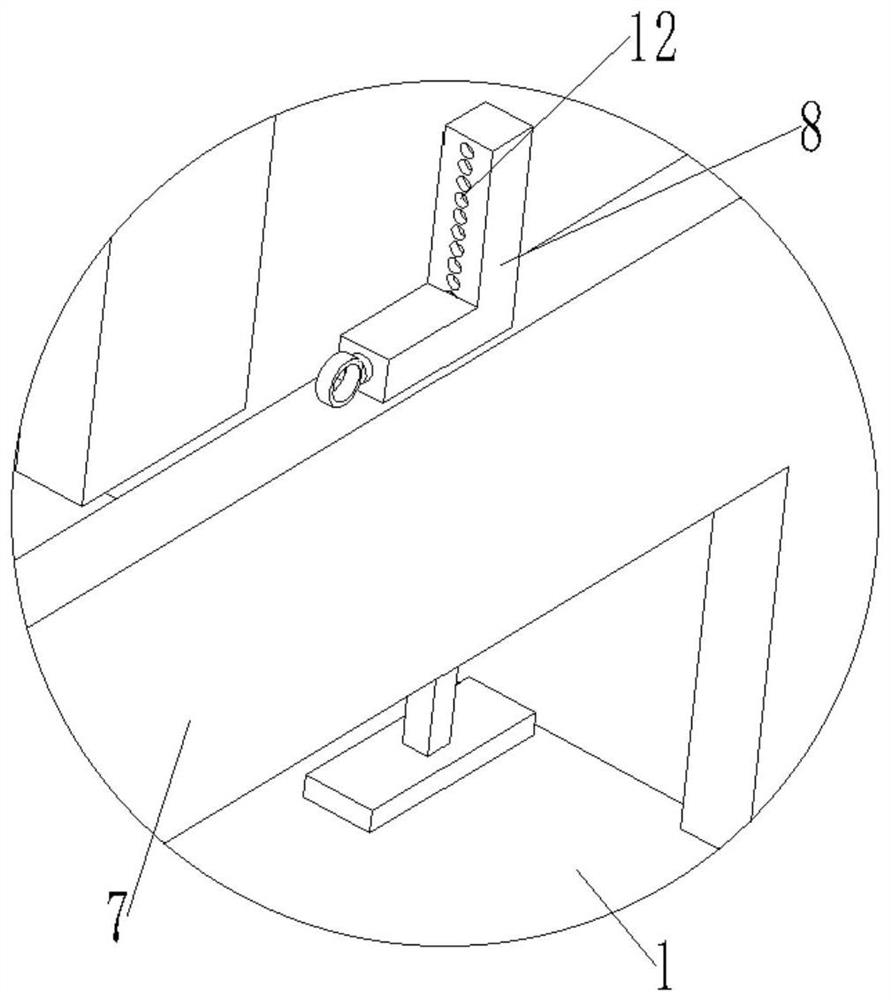

General three-coordinate tool for measuring side plate product

ActiveCN102937430AAdjust the elastic sizeAdjust the size of the pressing forceMeasurement devicesCantileverRepeatability

The invention discloses a general three-coordinate tool for measuring a side plate product. A guide rail, a strut and a cantilever are connected by threads to form a frame with an opened edge; a cantilever end is provided with a compacting and adjusting mechanism; and the guide rail is provided with a support limiting mechanism. The compacting and adjusting mechanism ensures that the product does not deform during clamping, and the reliability and the repeatability for detecting data can be ensured; the support limiting mechanism has a favorable positioning function and is convenient to operate; corresponding brackets are replaced for different types of products; the products with the same type can be programmed for one time and can be recycled. The tool is suitable for batch detection, and the detection efficiency is improved. The general tool is not only suitable for the detection of the side plate products, but also suitable for the detection of part non-side plate products, such as gear rings and shaft sleeves.

Owner:合肥波林新材料股份有限公司

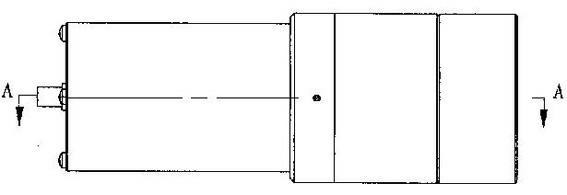

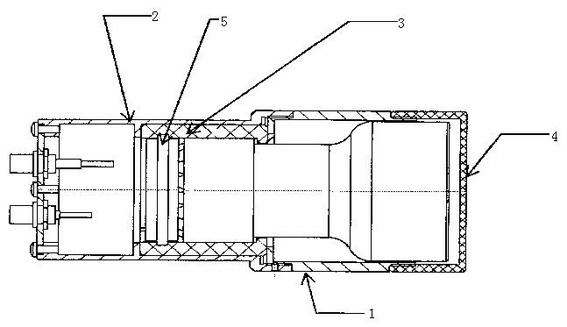

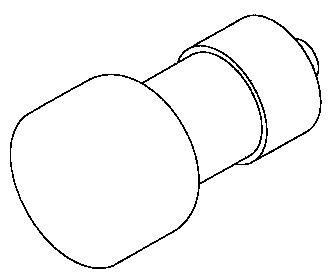

Photomultiplier installation protection structure

InactiveCN102110575ASolve the axial movementAvoid the problem of strong light damageElectron multiplier detailsLight irradiationPhotomultiplier

Owner:THE THIRD RES INST OF MIN OF PUBLIC SECURITY

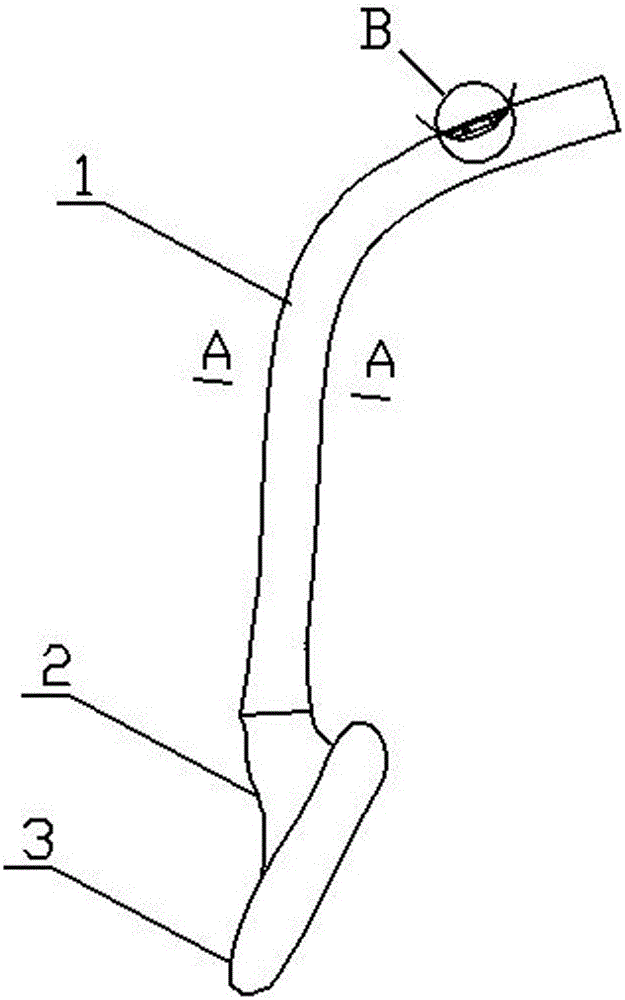

Processing method for front half body combination of riding type motorcycle frame

InactiveCN106181179AClear and reasonable structureReduce processing difficultyWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameEngine mount

The invention discloses a processing method for a front half body combination of a riding type motorcycle frame. The processing method is characterized by comprising the following steps: firstly, independently finishing the process of a front upper pipe, a front lower pipe, an inclined reinforcing pipe, a front inclined support reinforcing pipe, a shaft sleeve connecting pipe, a cross rod positioning shaft sleeve, an engine mounting shaft sleeve, a suspension shaft sleeve and a flat fork mounting shaft sleeve; positioning the front upper pipe, the front lower pipe, the inclined reinforcing pipe, the front inclined support reinforcing pipe, the shaft sleeve connecting pipe, the cross rod positioning shaft sleeve, the engine mounting shaft sleeve, the suspension shaft sleeve and the flat fork mounting shaft sleeve by a welding clamp; welding and connecting the contact parts of the above components to form the front half body combination of the riding type motorcycle frame. The processing method is convenient to operate, and the front half body combination of the riding type motorcycle frame can be quickly processed and manufactured.

Owner:力帆科技(集团)股份有限公司

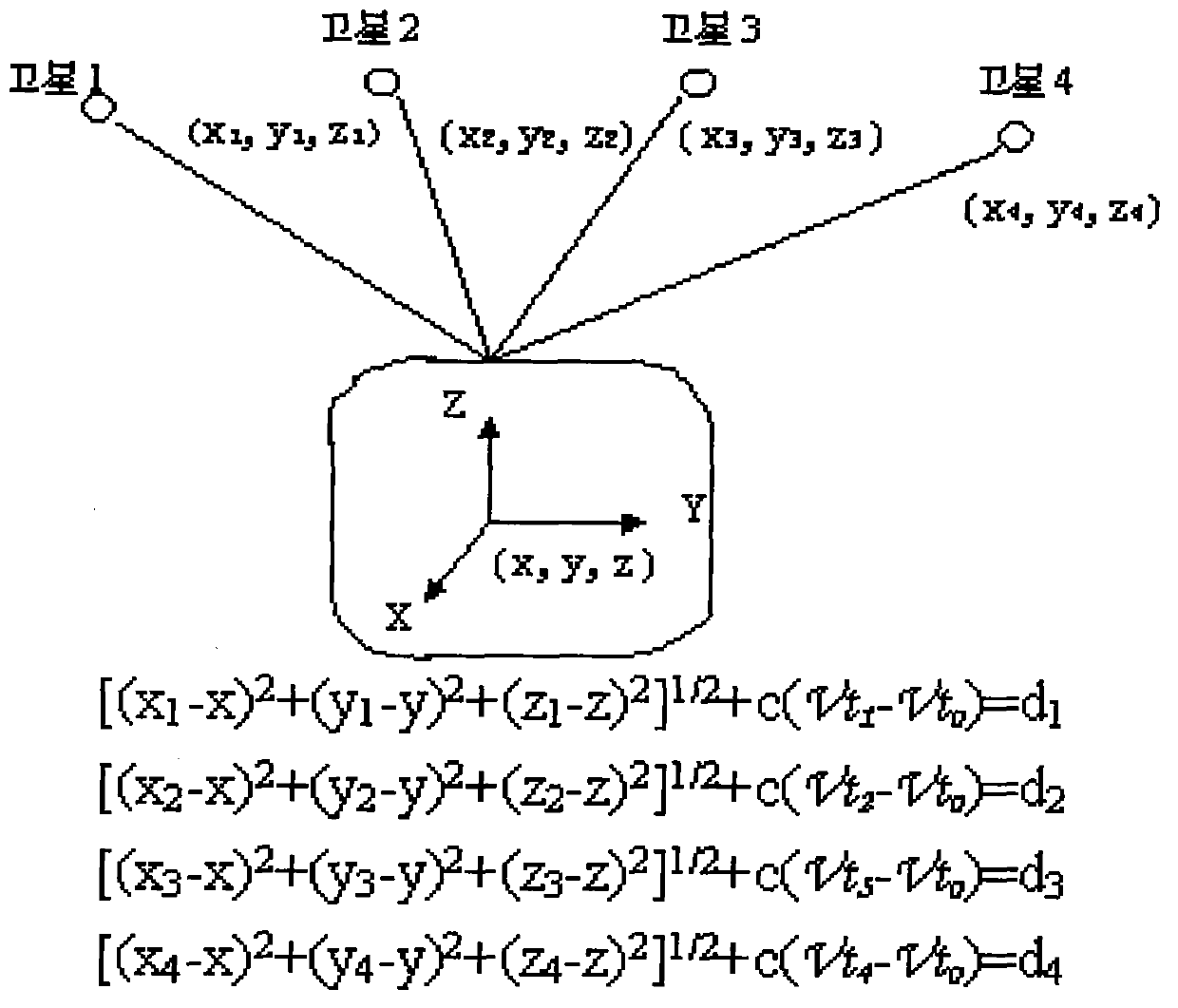

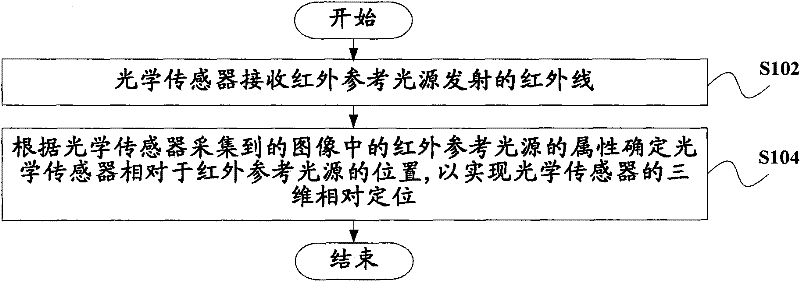

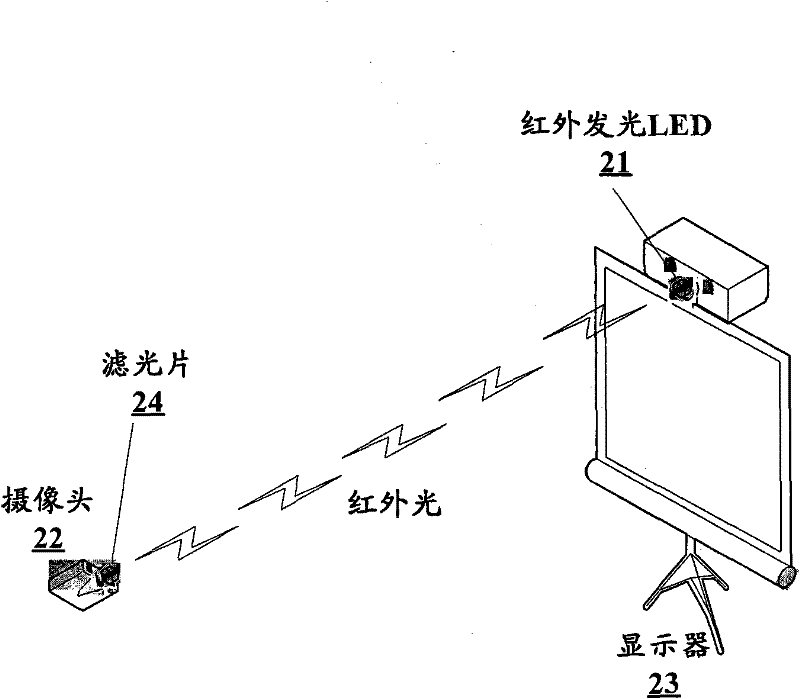

Method and system for realizing three-dimensional location

Owner:CHINA TELECOM CORP LTD

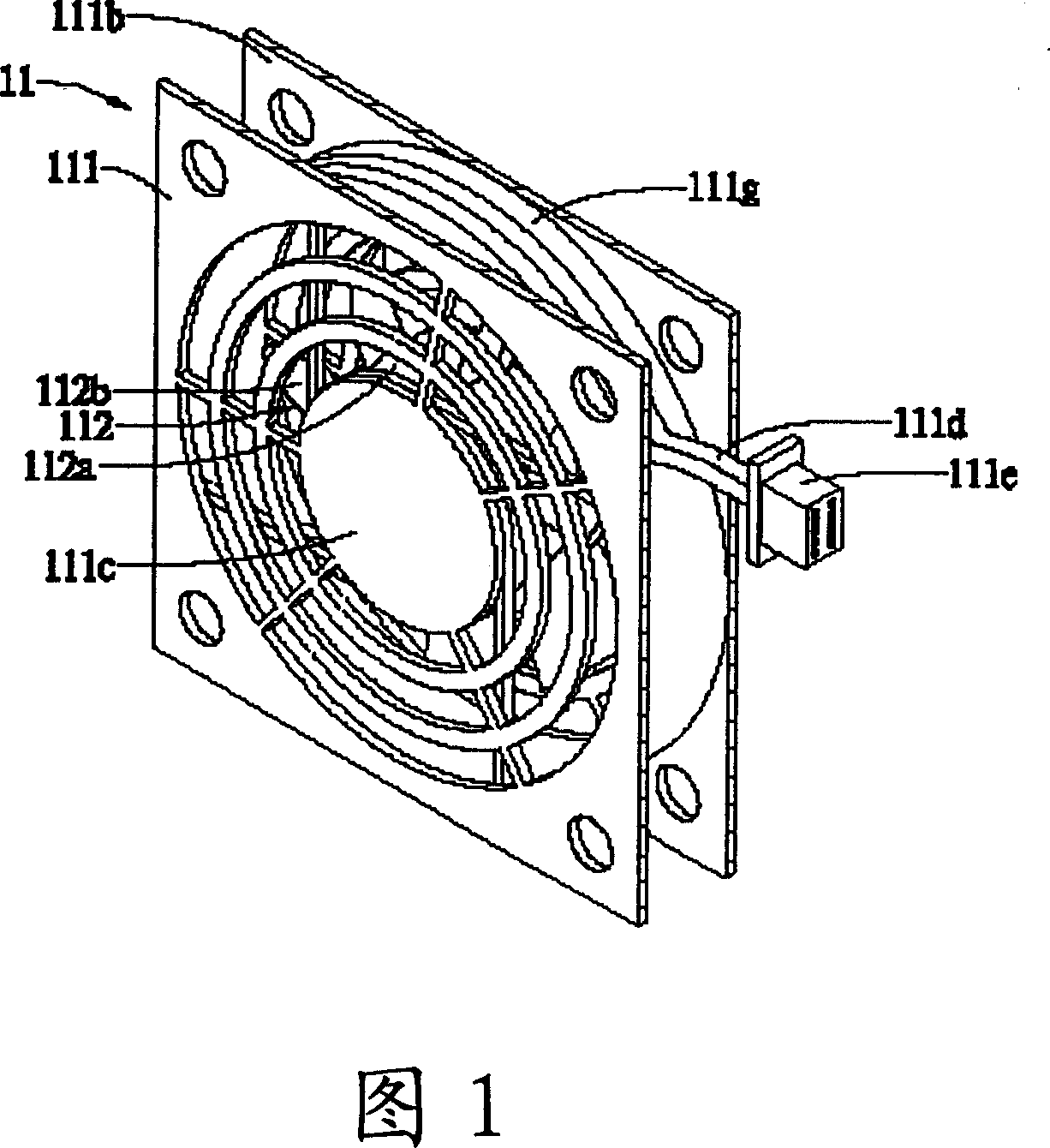

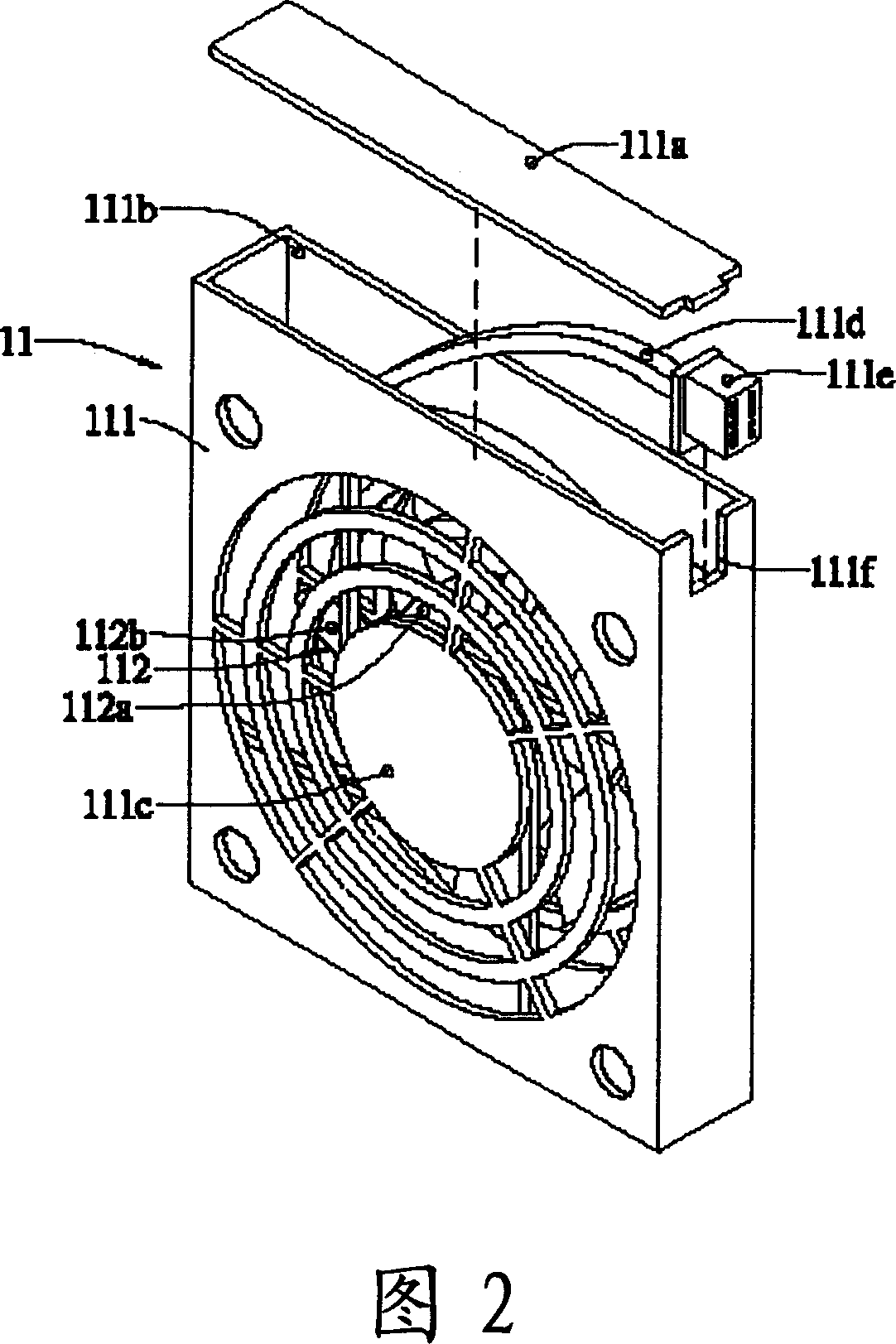

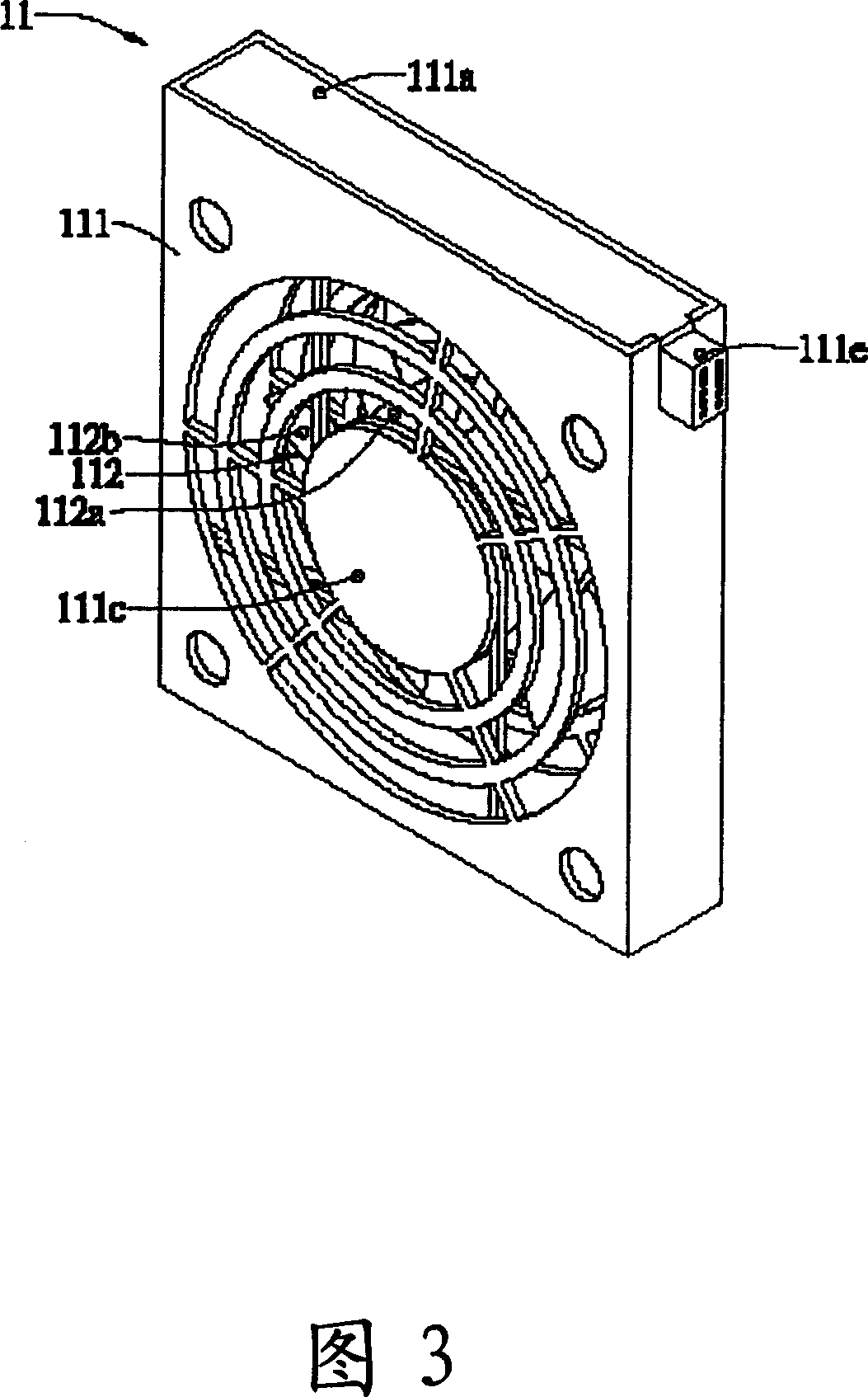

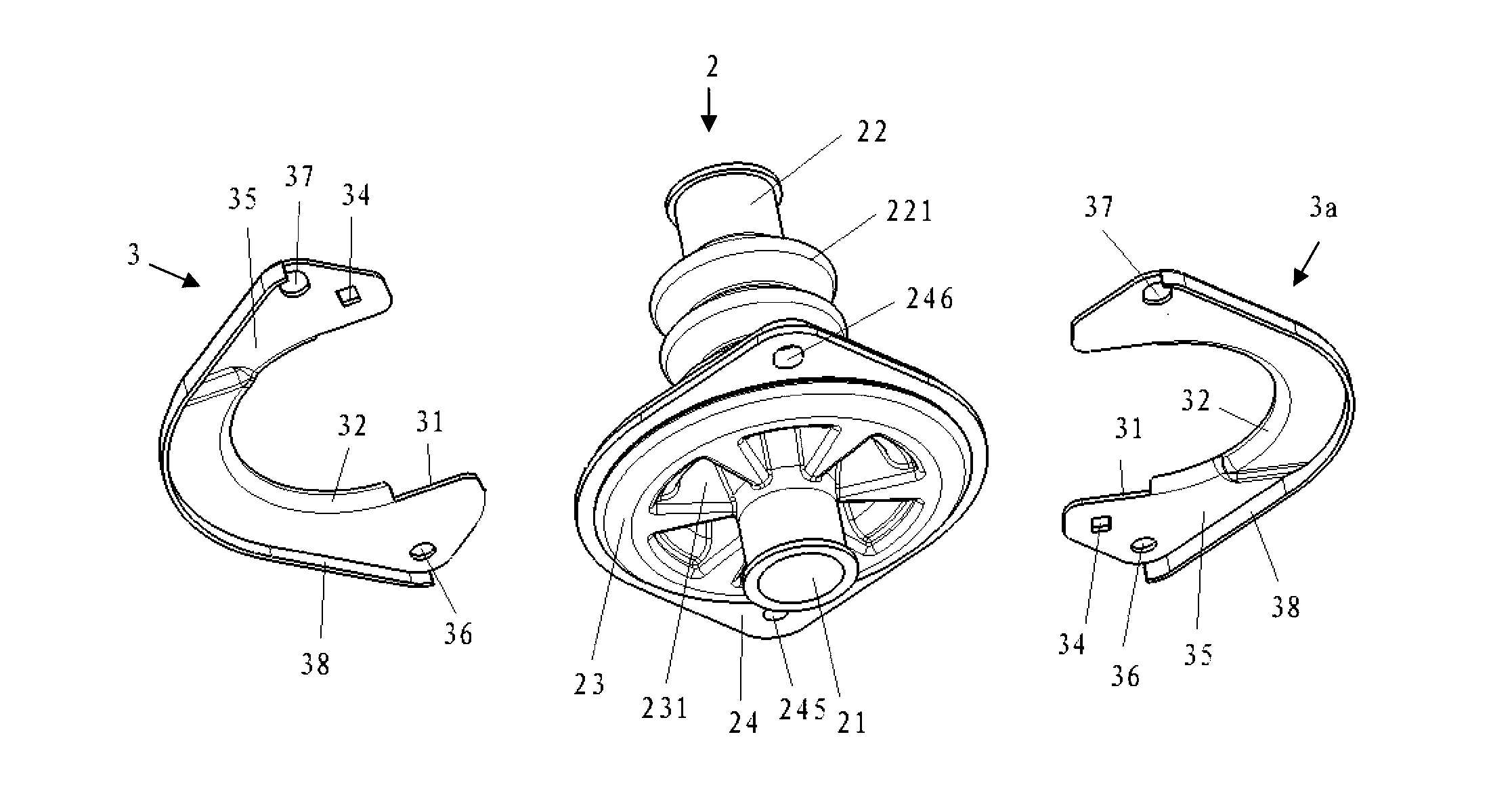

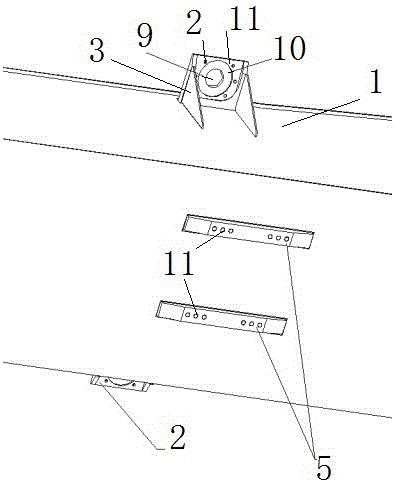

Arrangement of cable for fan

InactiveCN1940304AGood positioning functionPrecise positioningPump componentsCircuit arrangements on support structuresYarnEngineering

A fan cable yarn arranging structure is mainly made up of a frame body and a fan blade part. The frame body has a drive part and a mid-section part opened a groove on it. The fan blade part consists of a fan hub and fan blades around the hub. In the drive part of the frame body is set a fan hub and is connected the cable yarn. At the end of the cable yarn is disposed a connector. When taking in the cable yarn, it needs only to connect the cable yarn in the drive part into the groove of the mid-section part.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

Positioning mechanism for aluminum profile cutting machining

ActiveCN111872486AAchieving horizontal positioning requirementsHigh positioning accuracyPositioning apparatusMetal-working holdersEconomic benefitsEngineering

The invention discloses a positioning mechanism for aluminum profile cutting machining. When the positioning mechanism is used for cutting aluminum profiles, an arranged positioning bracket is firstlyused for primarily positioning the aluminum profiles, and when equal-section cutting positions of the aluminum profiles are determined, the upper sides of the aluminum profiles are pressed through anarranged first positioning pressing plate, so that positioning in the vertical direction is achieved; and then one side of each aluminum profile is pressed and positioned through a second positioningpressing plate arranged in an auxiliary positioning mechanism, and a transverse positioning requirement of the aluminum profiles is met, so that the positioning accuracy, firmness and stability of the aluminum profiles during cutting work are improved, the cutting work of the aluminum profiles can be carried out more smoothly, the cutting quality of the aluminum profiles is guaranteed, the actualrequirements of production work are guaranteed, the production work quality is improved, and the economic benefits of the production work are guaranteed.

Owner:辽宁永壮铝业集团有限公司

Projective jacket for wire harness of automobile

ActiveCN103296618ANot easy to moveGood positioning functionElectrical apparatusEngineeringSurface fitting

The invention provides a protective jacket for a wire harness of an automobile. The protective jacket comprises a rubber jacket and two semicircular fixing covers. The rubber jacket comprises a jacket body, an extending portion and a flange, the extending portion and the flange are integrally connected with the jacket body, the extending portion is cylindrical, the outer diameter of the extending portion is larger than that of the jacket body, the circumferential outer wall of the extending portion is matched with a fixing hole of a sheet metal part of an automobile body, the lower surface of the flange clings to the surface of the sheet metal part of the automobile body, the two fixing covers clamp a groove of the rubber jacket and cling to the upper surface and the side surfaces of the flange, and the fixing covers and the flange are connected with the sheet metal part of the automobile body by bolts. The protective jacket for the wire harness has the advantages of good integral structural strength and sealing performance.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Packaging device for spinning yarns

The invention discloses a packaging device for spinning yarns. When work of packaging yarn ball single bodies is carried out, by means of the cooperation effect of an arranged placing belt, an inverted-T-shaped sliding groove and an inverted-T-shaped sliding block, the distance among the yarn ball single bodies can be well controlled, by means of fixedly clamping of arranged positioning columns and positioning circular grooves, the distance among the yarn ball single bodies is kept the same, moreover, the distance among the yarn ball single bodies can be controlled in a ball manner, then the package work can be carried out according to the actual requirement of package production and processing, and the quality of the package work is ensured. According to the device, by means of arranged sleeve columns and positioning mechanisms, the package processing quality of the device can be ensured, normal operation of a package processing and production line can be ensured, the processing and production quality is ensured, and economic benefits of the work are ensured.

Owner:安福风起科技有限公司

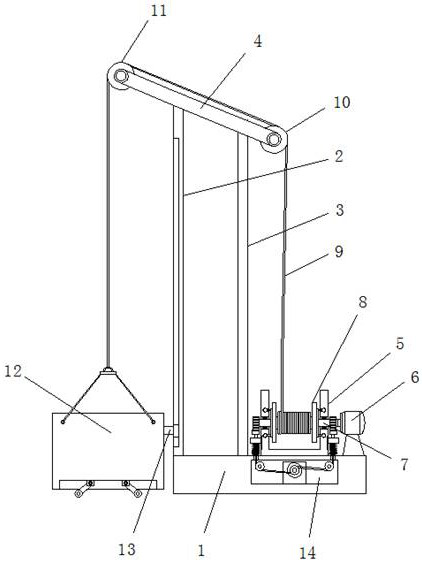

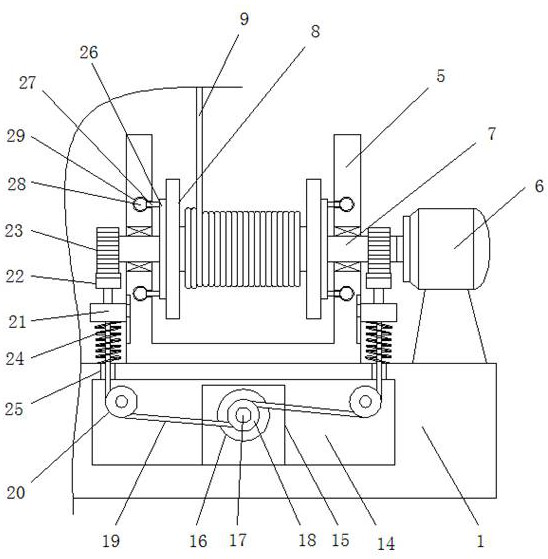

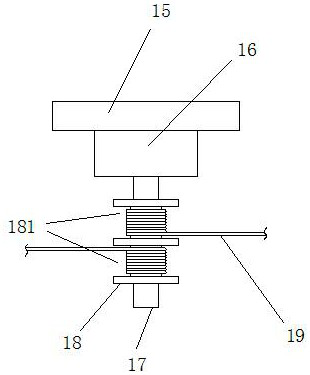

Hanging basket equipment for constructional engineering

InactiveCN112374387AAnti-damagePrevent the phenomenon of winding reel rotationNon-rotating vibration suppressionWinding mechanismsArchitectural engineeringElectric machinery

The invention discloses hanging basket equipment for constructional engineering. The hanging basket equipment comprises a base; a left vertical frame is fixedly arranged at the left end of the top ofthe base; a right vertical frame is further fixedly arranged on the right side of the left vertical frame; the top of the left vertical frame and the top of the right vertical frame are fixedly provided with the same inclined frame arranged in an inclined mode; a first fixed pulley is rotationally arranged at the right end of the inclined frame; and a second fixed pulley is rotationally arranged at the left end of the inclined frame. According to the hanging basket equipment, a winding disc can have a good positioning function, the situation that a hoisting motor is prone to damage due to lackof the positioning function in the discharging process after a hanging basket is lifted is prevented, and the hidden danger that the hanging basket directly falls to the ground due to damage of the hoisting motor is avoided; and meanwhile, a good buffering function is achieved in the process that the hanging basket descends to the ground, the problem that the hanging basket is damaged due to direct contact with the ground in the descending process is avoided, and the service life of the hanging basket is greatly prolonged.

Owner:张宝玉

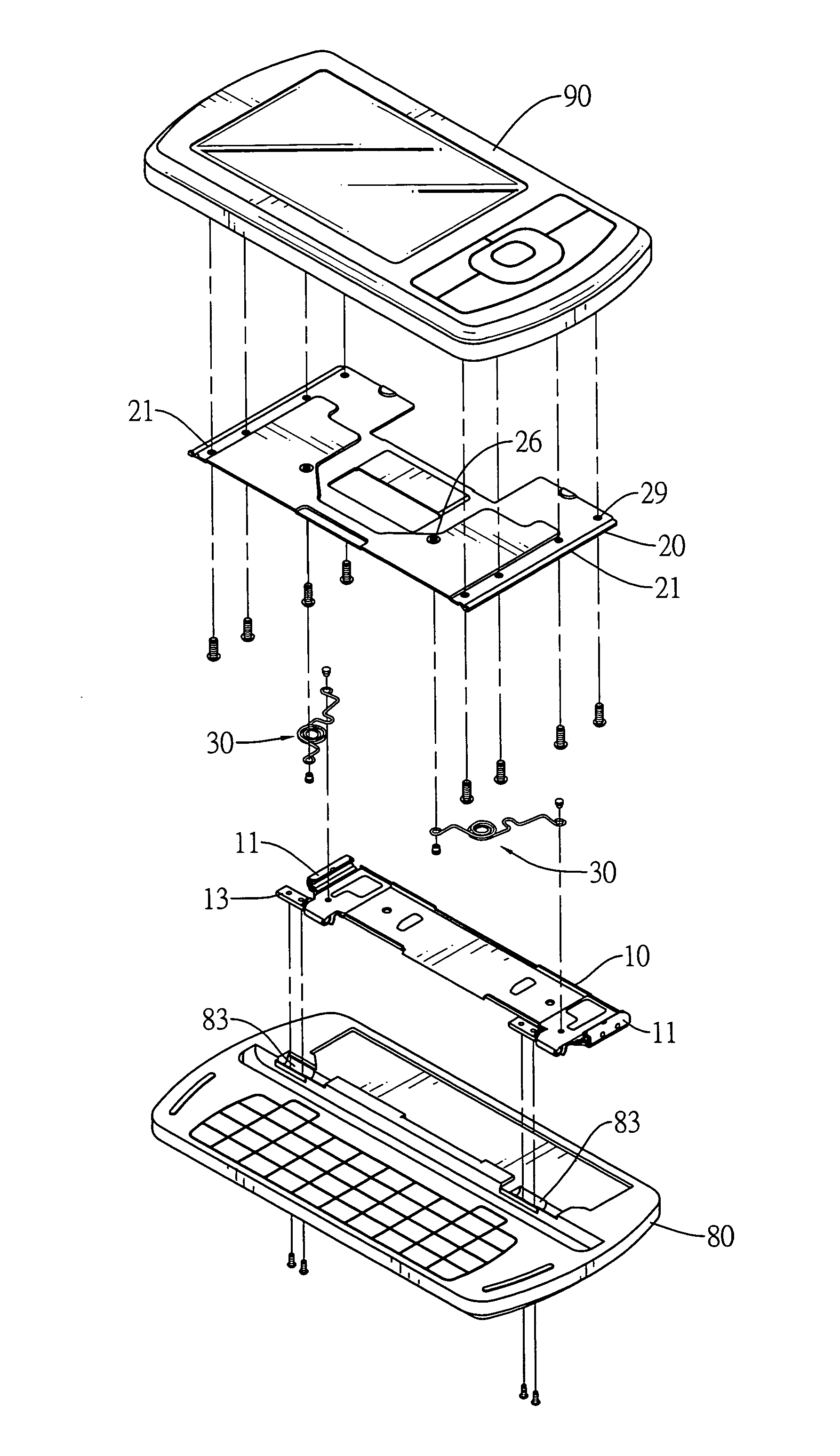

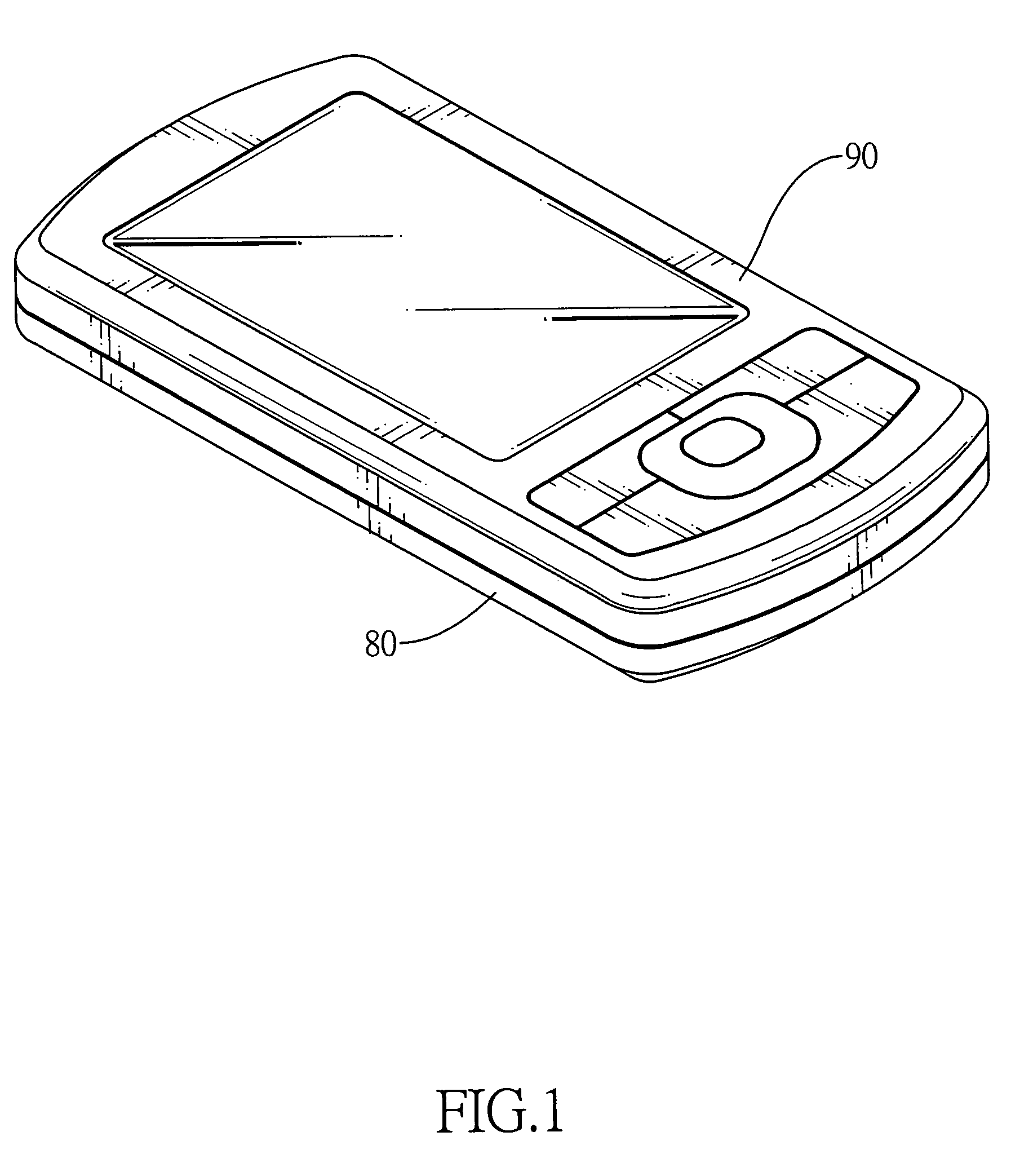

Slide Hinge

InactiveUS20090151119A1Good positioning functionIncrease elasticityPin hingesWing openersTorsion springElectronic equipment

A slide hinge is connected a cover to a base of a portable electronic device and has a stationary bracket, two pivot members, a sliding bracket and two torsion springs. The pivot members are mounted rotatably on the sliding bracket and are mounted to the base. The sliding bracket is mounted slidably on the stationary bracket and is mounted to the cover. The torsion springs are connected between the stationary bracket and the sliding bracket and each torsion spring multiple looped segments. The torsion springs with the looped segments provide an excellent resilient force to position the stationary bracket in one edge of the sliding bracket and therefore stably hold the cover in opened or closed positions without inadvertently sliding relative to the base.

Owner:SHIN ZU SHIN

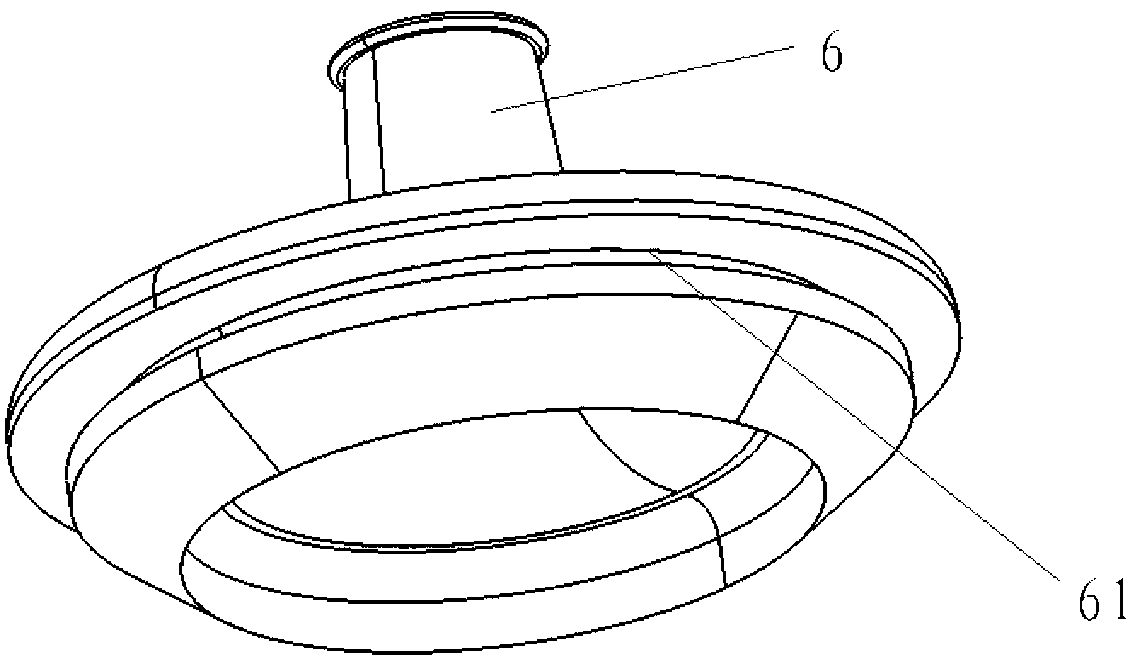

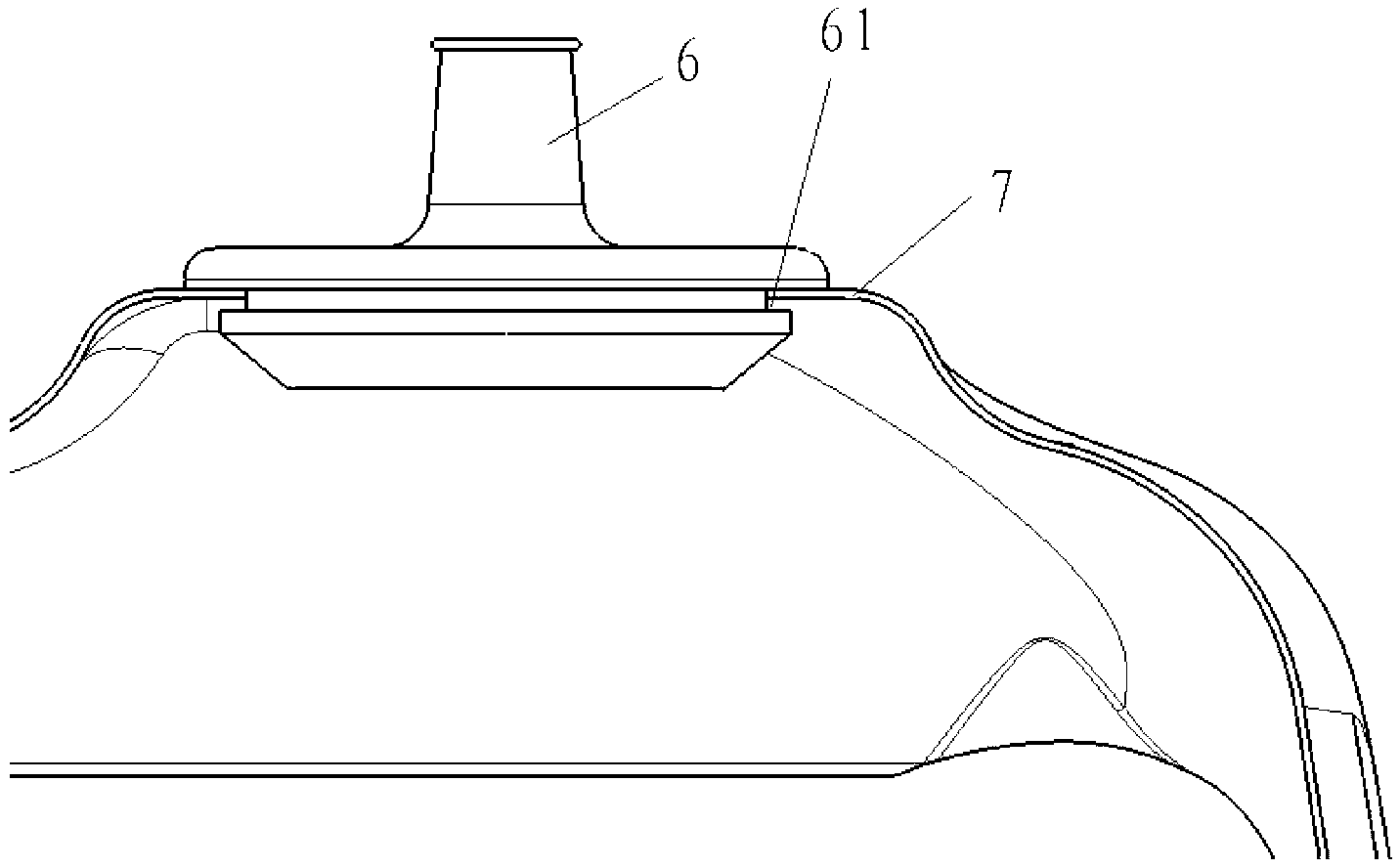

Insolation shielding device

ActiveCN103510829AGood positioning functionLimited rotationDoor/window protective devicesInterior spaceEngineering

The invention provides an insolation shielding device which reliably constrains the rotation of a rotary shaft and achieves an excellent long-term positioning function. The insolation shielding device comprises: an inlaid body (60) which is rotatable in unison with a rotary shaft (25); a rotary body (70) which is mounted to rotate freely with respect to the rotary shaft (25) and is arranged adjacent to the inlaid body (60), and a casing (80), which has an interior space (S) in which the inlaid body (60) and the rotary body (70) are received. The inlaid body (60) is provided with a first engaging section (64) and the rotary body (70) is provided with a second engaging section (75) and a third engaging section (77). The casing (80) is provided with a fourth engaging section (83). Rotating the rotary shaft (25) causes the inlaid body (60) to rotate relative to the rotary body (70) so as to bring the first engaging section (64) and the second engaging section (75) into abutting engagement with each other. After the abutting engagement, the rotary body (70) is rotated in unison with the inlaid body (60), when the third engaging section (77) and the fourth engaging section (83) are brought into abutting engagement with each other, the rotation of the rotary body (70) in a direction of incurring interference with the fourth engaging section (83) is constrained.

Owner:TACHIKAWA

Current probe and jig suitable for replacing current probe

InactiveCN107525952AEasy and efficient replacementAvoid reducing replacement efficiencyElectrical measurement instrument detailsElectrical testingBiomedical engineering

Owner:致茂电子(苏州)有限公司

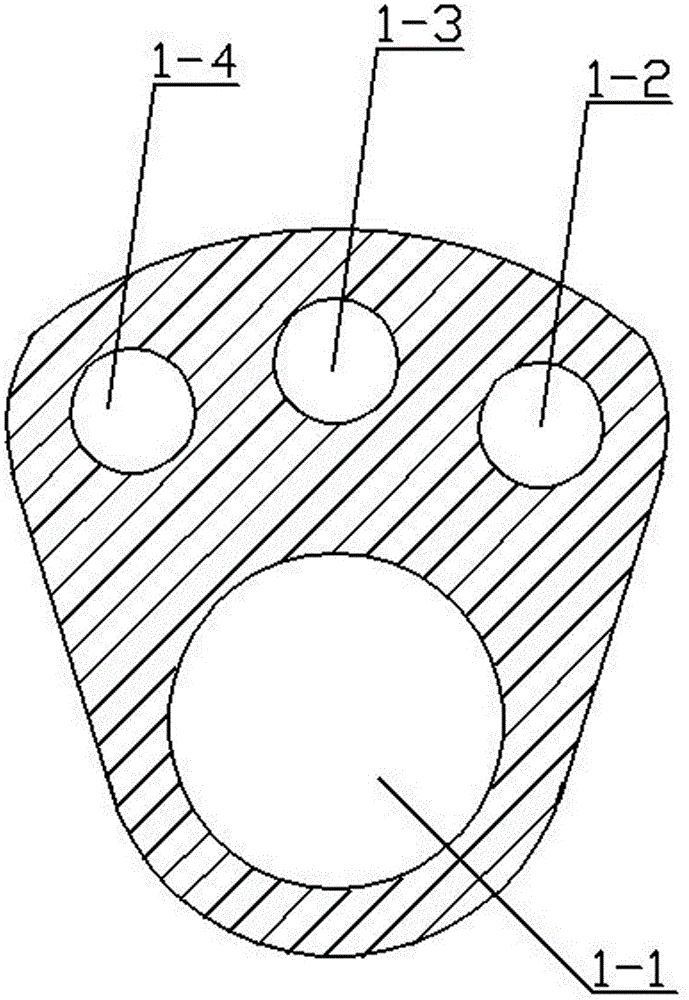

Laryngeal mask airway

ActiveCN105107072AGood positioning functionImprove sealing functionRespiratorsMedical devicesMain channelThroat

The invention discloses a laryngeal mask airway. An air bag of the laryngeal mask airway is a double-layer air bag and comprises an inner layer air bag and an outer layer air bag. Compared with the material of the inner layer air bag, the material of the outer layer air bag is more prone to elastic deformation. Four channels are formed in a catheter and an air bag base and include an inner layer air bag ventilation channel, an outer layer air bag air inlet channel, an outer layer air bag air outlet channel and a main channel used for being communicated with a human body trachea. The inner layer air bag ventilation channel is communicated with the inner layer air bag. The outer layer air bag air inlet channel is communicated with the lower side of the outer layer air bag. The outer layer air bag air outlet channel is communicated with the upper side of the outer layer air bag. When the inner layer air bag and the outer layer air bag are in a normal pressure state, the outer layer air bag is completely attached to the inner layer air bag. The air bag positioning function and the sealing function can be well guaranteed. The air bags and a throat pipe are attached more firmly.

Owner:聊城云购通信息技术有限公司

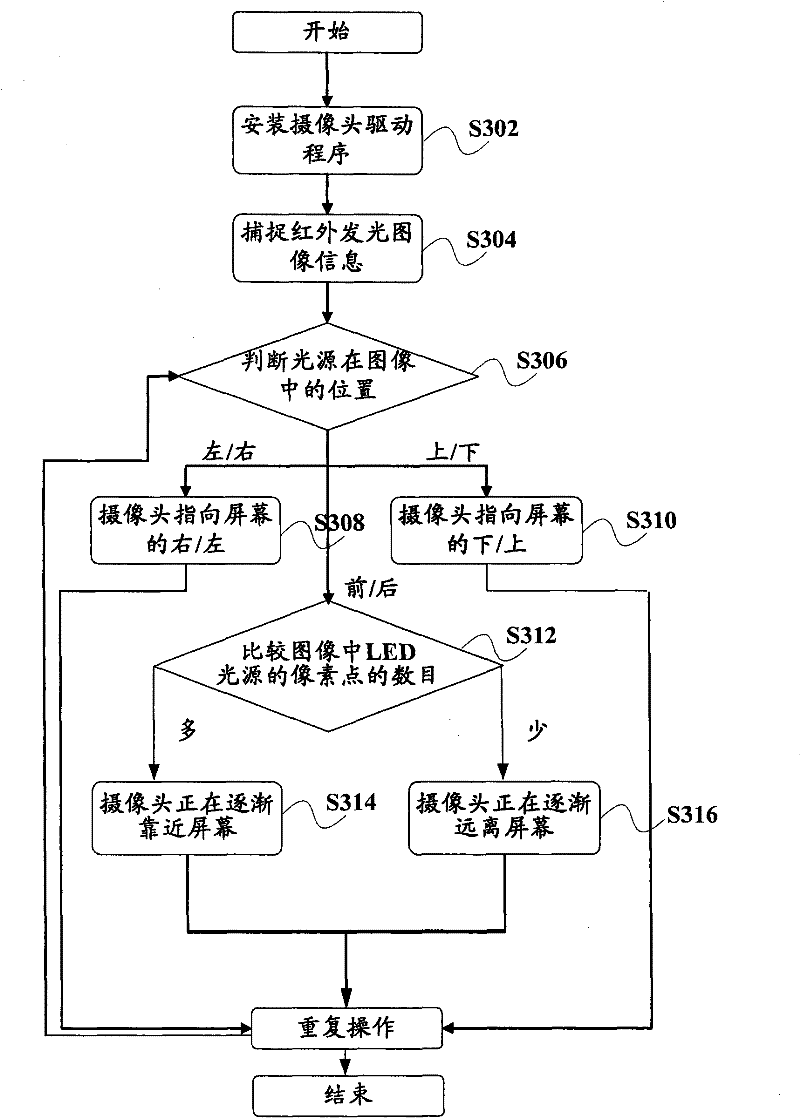

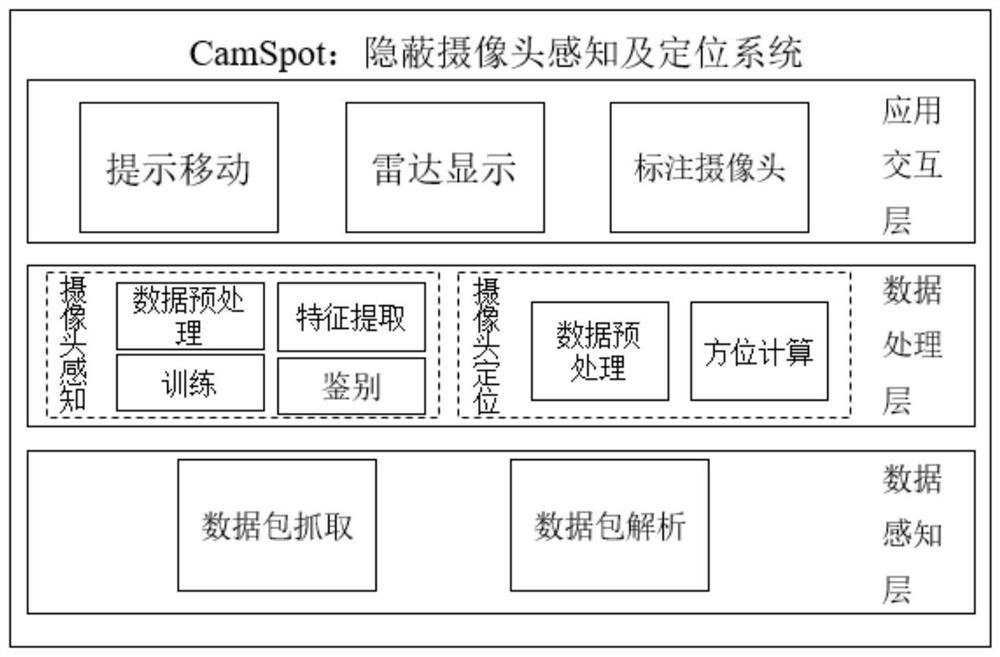

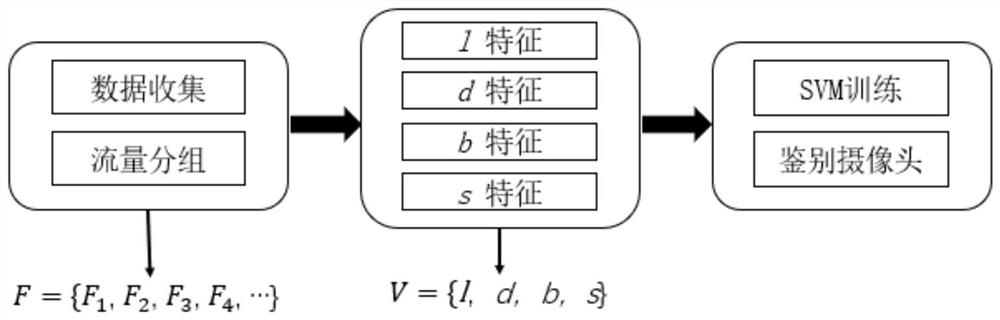

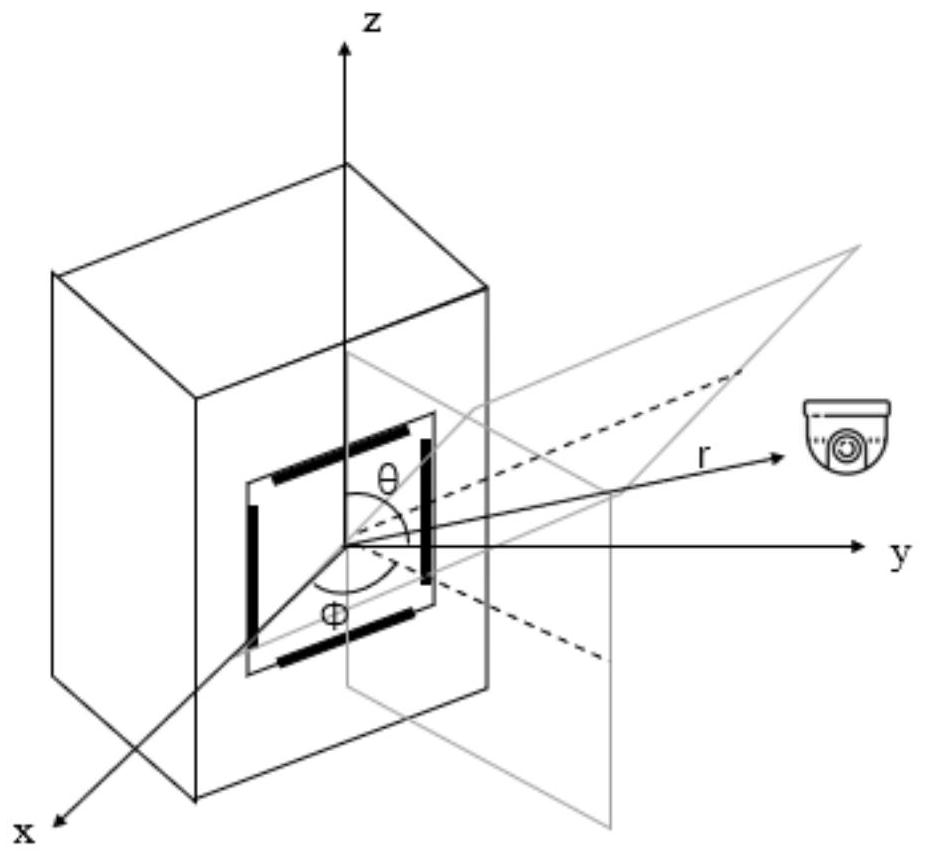

Hidden camera sensing and positioning method and system

ActiveCN113038375AImprove accuracyExpand the range of perceptionTelevision system detailsKernel methodsComputer graphics (images)Engineering

The invention discloses a hidden camera sensing and positioning method and system, and the accuracy of camera sensing is greatly improved by extracting the length, period and bandwidth of a camera flow packet and the stability of each flow, constructing a four-dimensional vector, and carrying out training classification through machine learning. In addition, the invention provides a human body mobility network camera positioning method oriented to encrypted traffic, and the direction of the camera is positioned by capturing the change of the traffic of the camera when the human body moves, drawing a real-time oscillogram of the change of the bit rate and analyzing the trend of the change of the bit rate. According to the invention, the positioning accuracy and the software practicability are greatly improved, and a convenient and rapid camera positioning function is realized.

Owner:WUHAN UNIV

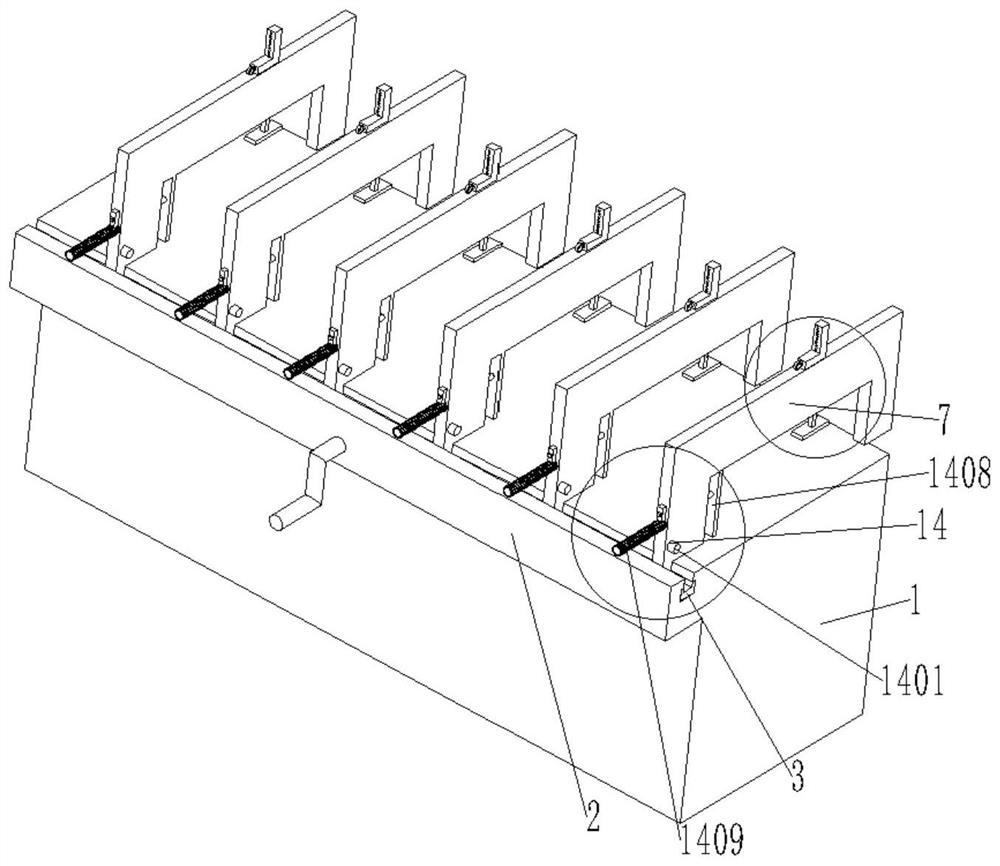

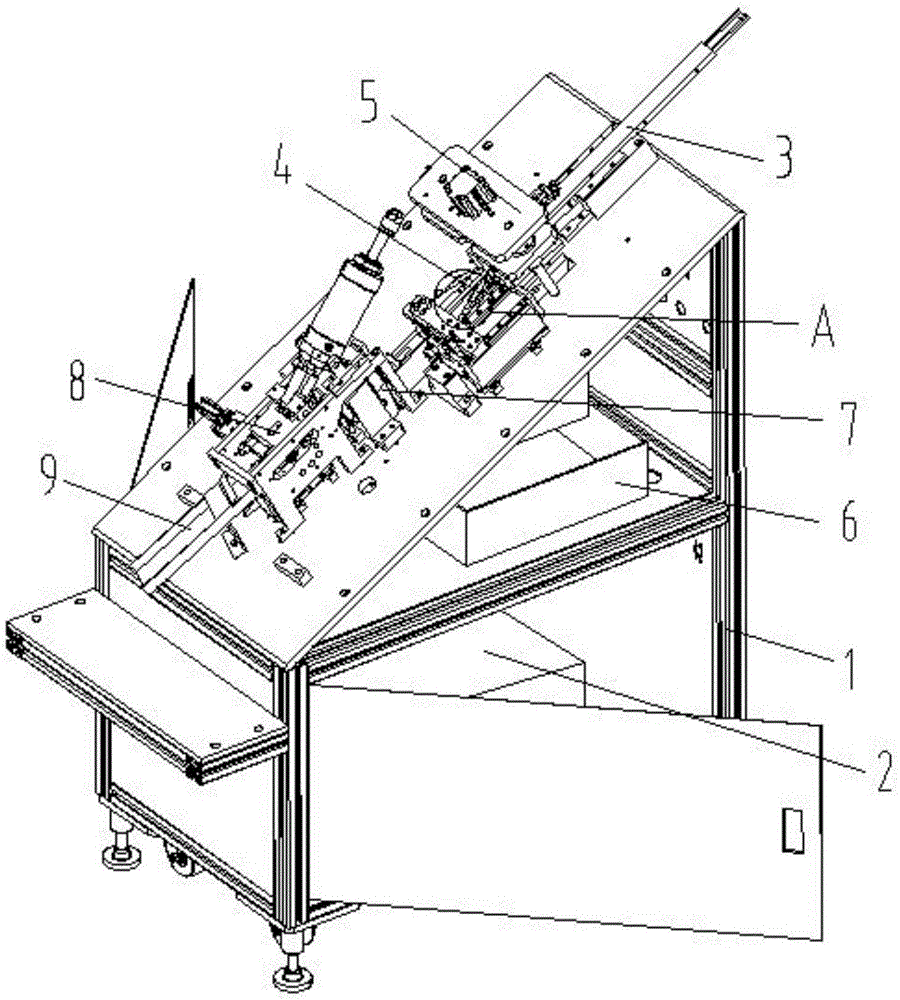

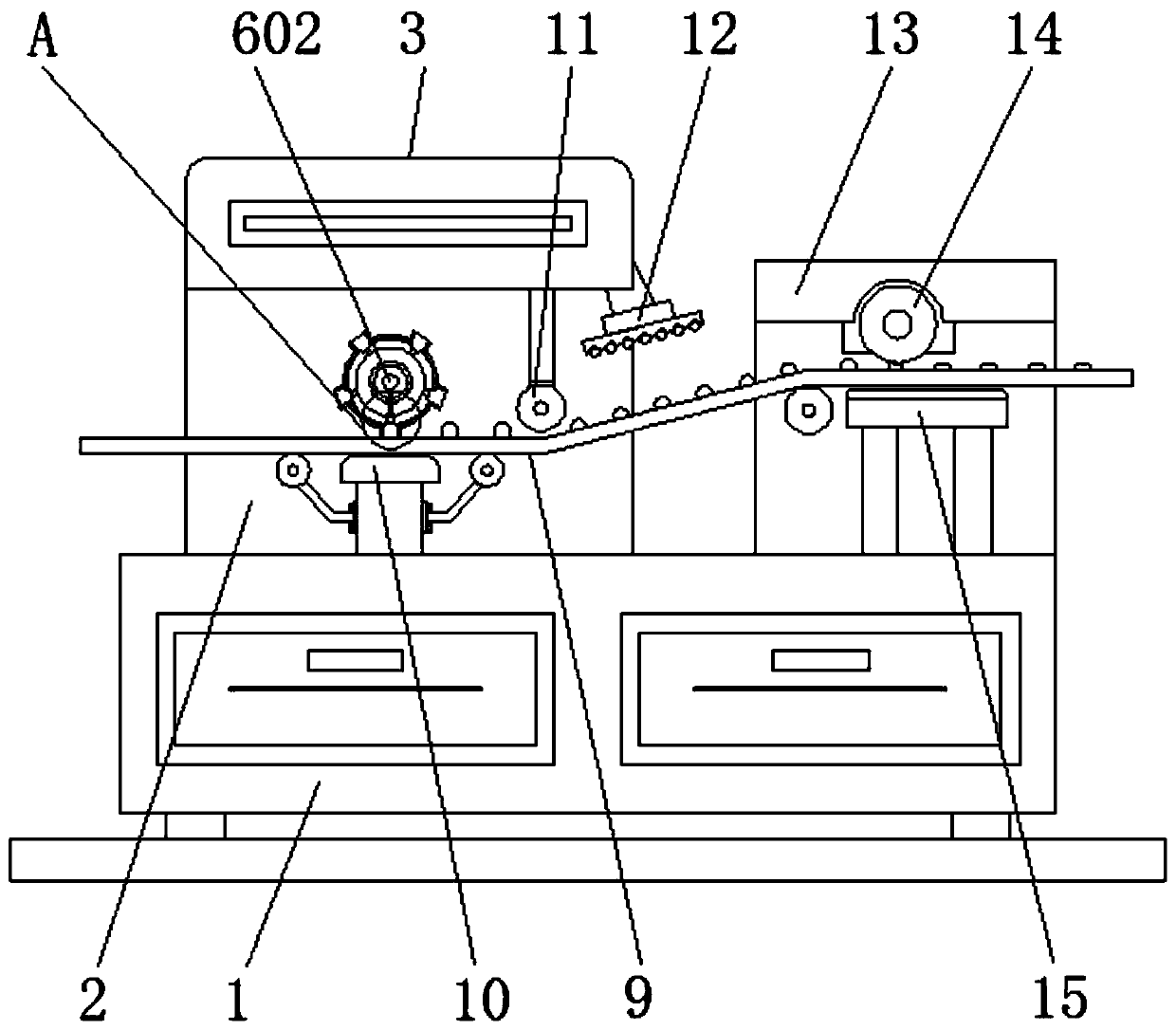

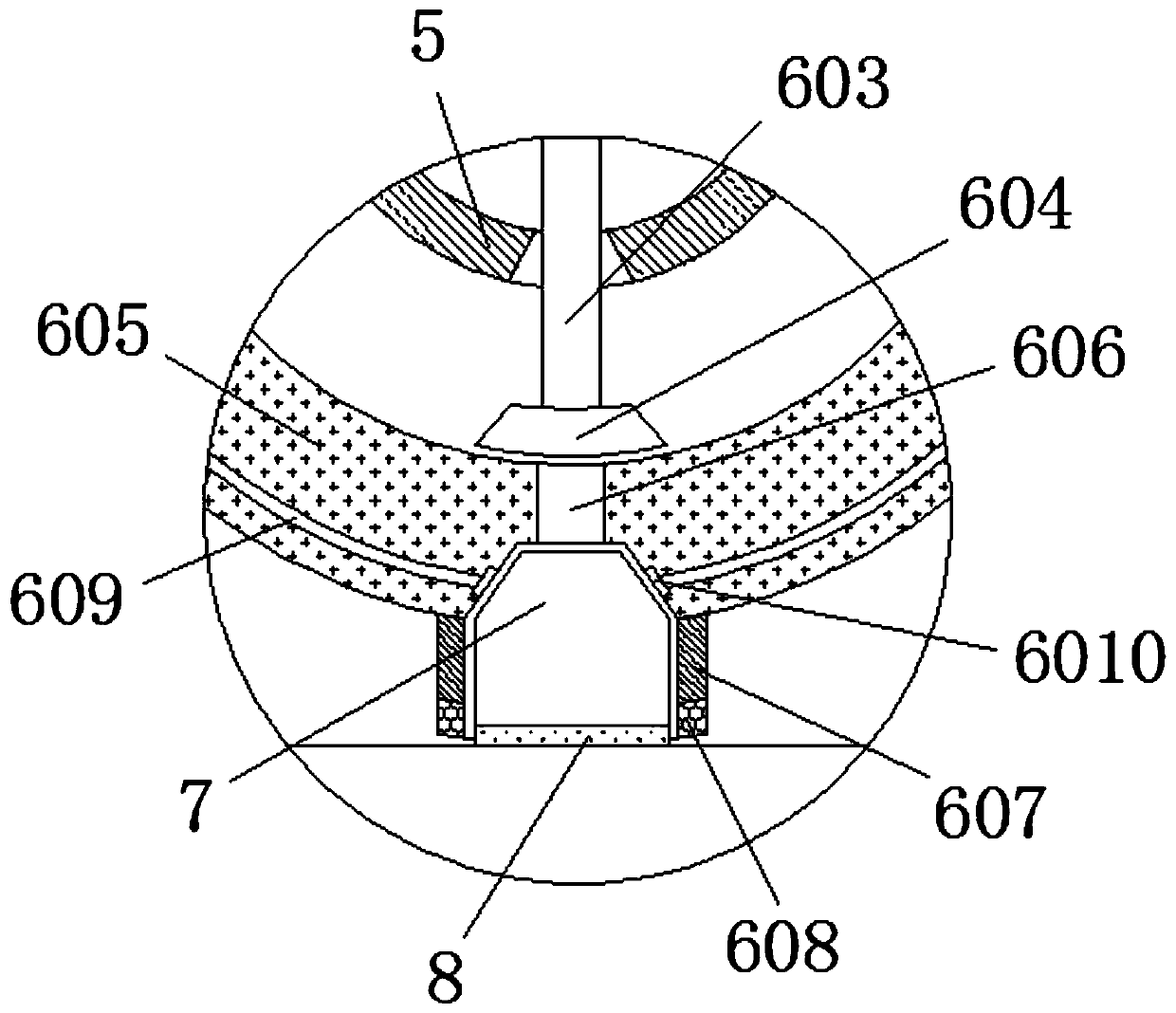

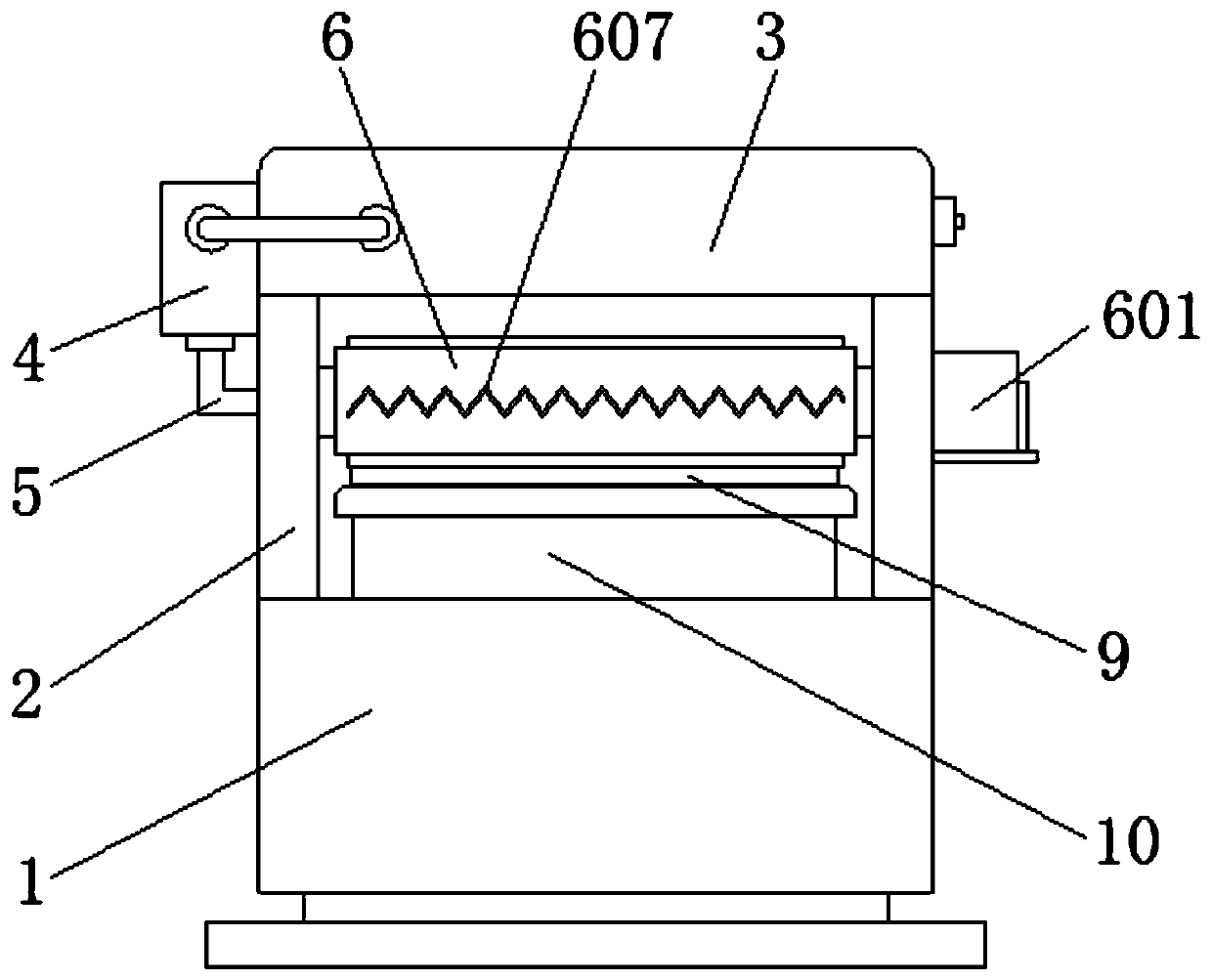

Full-automatic bamboo chip chamfering machine

ActiveCN106564098AImprove efficiencyNo offsetMulti-purpose machinesCane mechanical workingDistribution controlElectrical and Electronics engineering

The invention relates to a full-automatic bamboo chip chamfering machine. The full-automatic bamboo chip chamfering machine comprises a rack and a power distribution control cabinet. An installation plate is obliquely arranged on the rack. A chamfering device is arranged on the installation plate and comprises a chamfering base arranged on the installation plate, a carrier matched with a bamboo chip is arranged on the chamfering base, and a chamfering angle adjustment device is arranged under the carrier. A movable chamfering block is arranged on the carrier. A chamfering cutter matched with the bamboo chip on the carrier is arranged on the lower portion of the movable chamfering block. The side face of the movable chamfering block is matched with a movable chamfering groove formed in the chamfering base through movable chamfering wheels. The upper portion of the movable chamfering block is hinged to a movable chamfering air cylinder arranged on the chamfering base. According to the full-automatic bamboo chip chamfering machine, since the carrier matched with the bamboo chip is arranged, it is guaranteed that the motion track of the chamfering cutter is not prone to deviation through the movable chamfering groove and the movable chamfering wheels; and meanwhile, the angle adjustment device is arranged under the carrier, sharp corner cutting at any angle can be achieved accordingly, and the cutting efficiency and cutting effect are improved.

Owner:DONGGUAN UNIV OF TECH

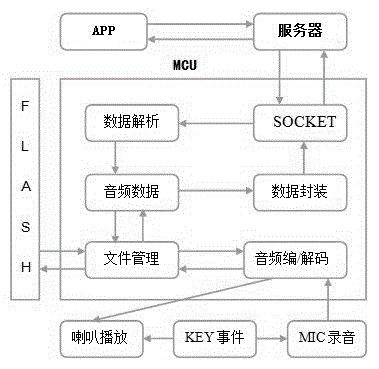

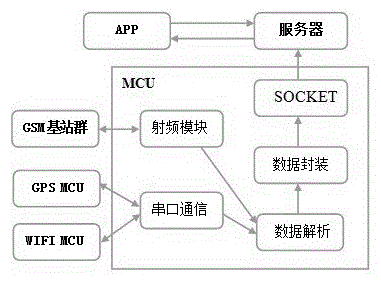

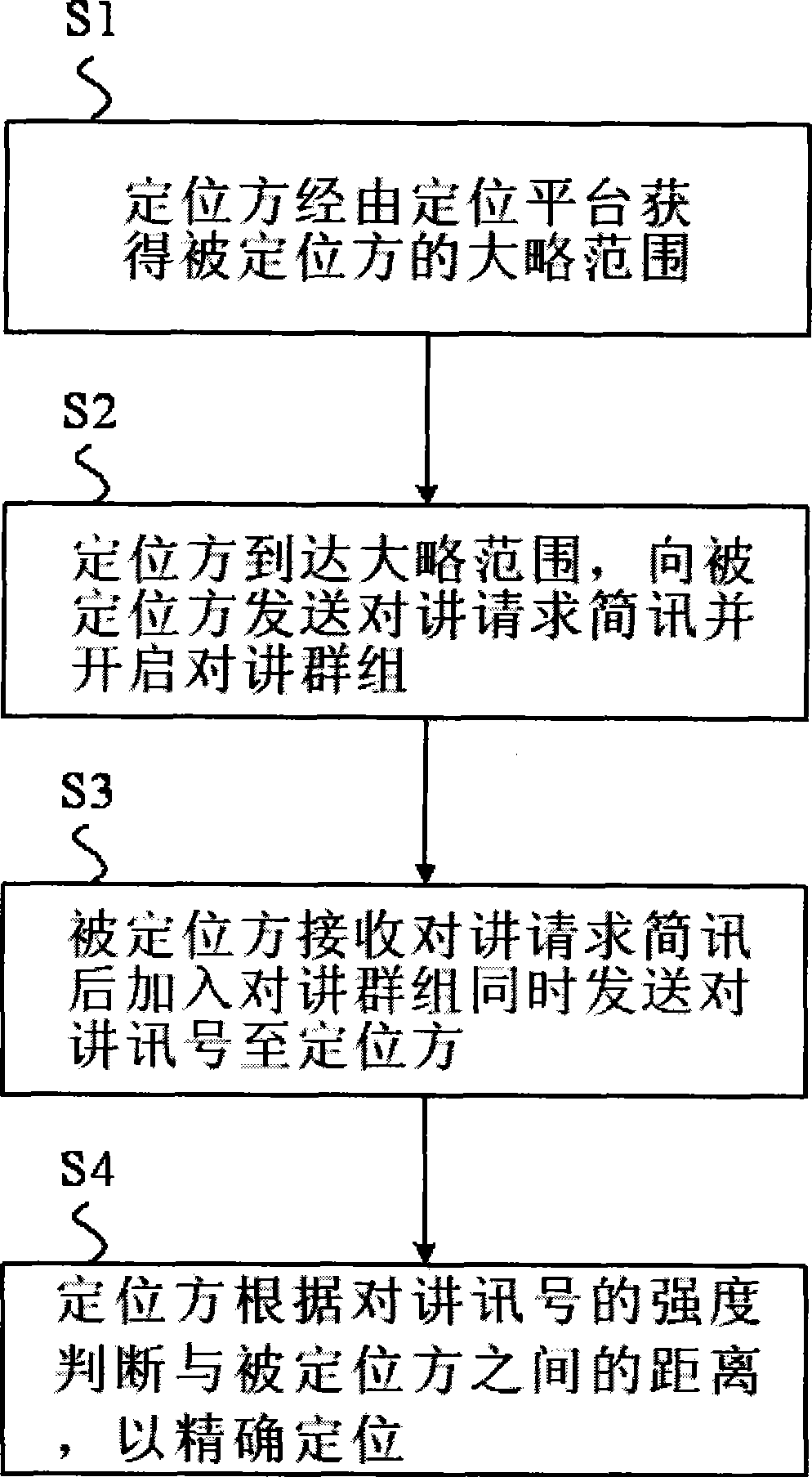

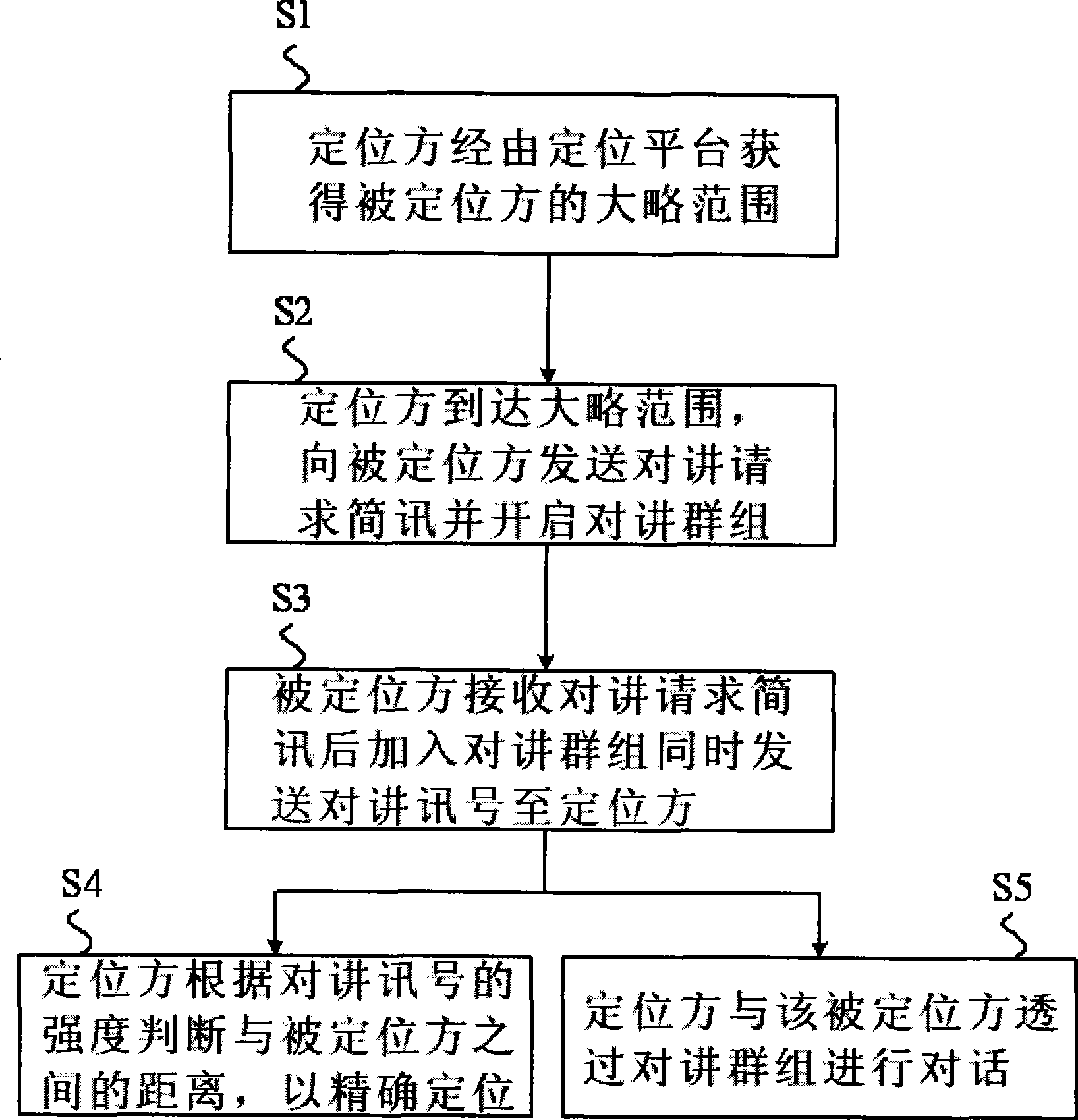

Talkback and positioning system

InactiveCN105025397AGood positioning functionNo call chargesPosition fixationSatellite radio beaconingApplication softwareEmbedded system

The invention discloses a talkback and positioning system comprising a server and a plurality of wearable terminals capable of remotely communicating with the server. Each wearable terminal is provided with a unique ID. Application software on other electronic equipment may perform talkback with each wearable terminal via the server in order to position the wearable terminal. The talkback and positioning system can be used between a guardian and a ward in order that the guardian may get in touch with the ward anytime. The talkback and positioning system generates no telephone expense and saves cost. Further, the guardian may check the specific positional information of the ward anytime in order to easily monitor the ward.

Owner:HUIZHOU WALLMUM TECH CO LTD

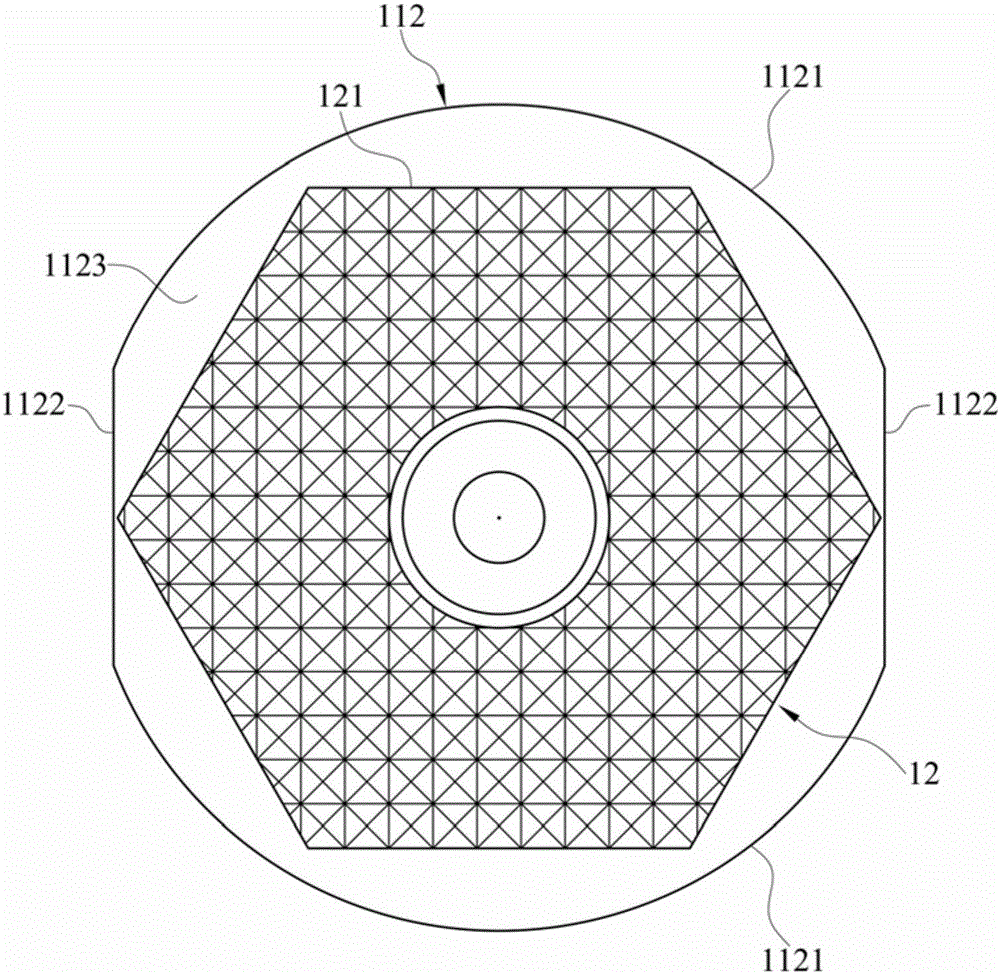

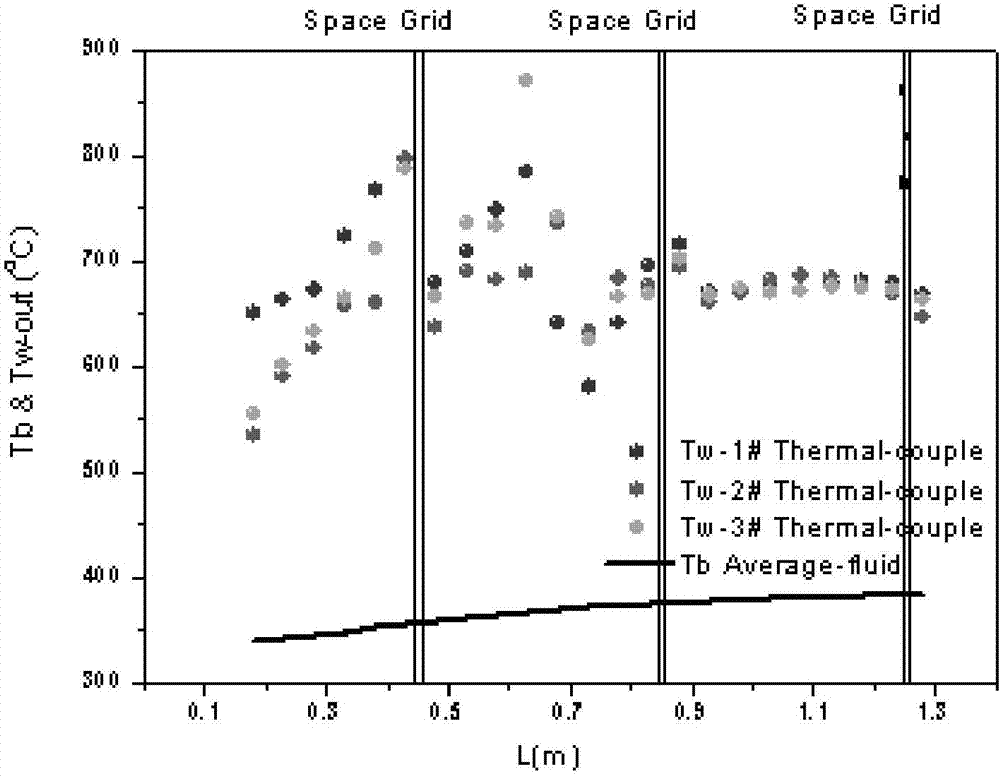

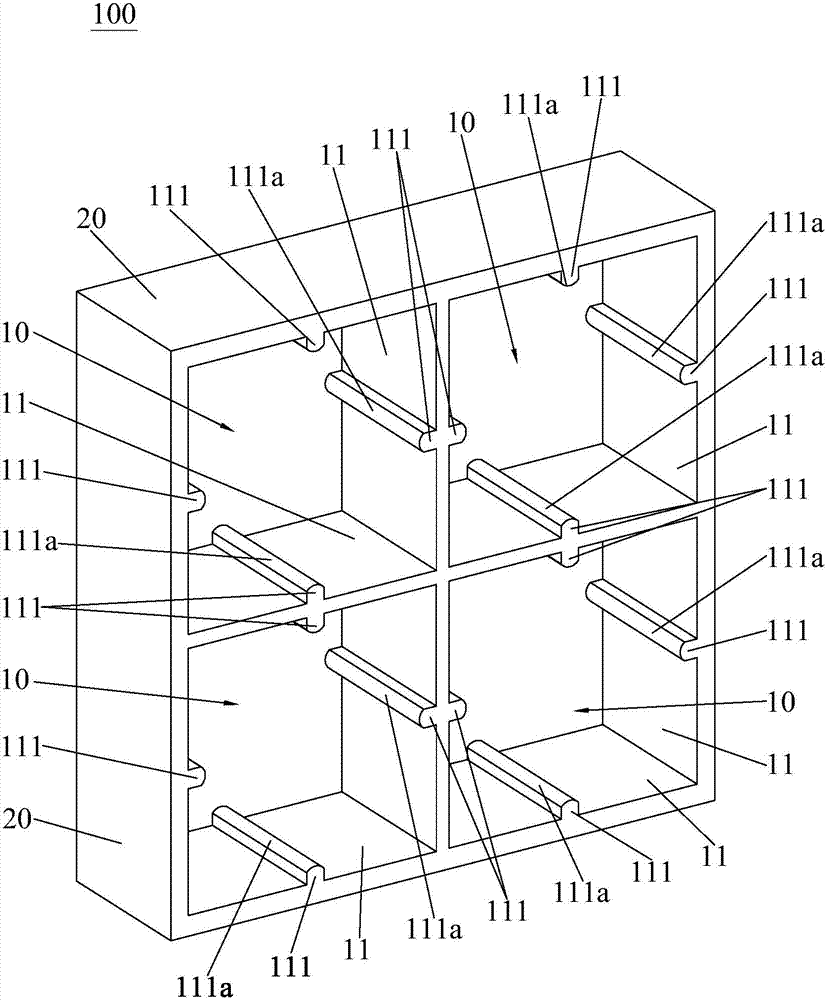

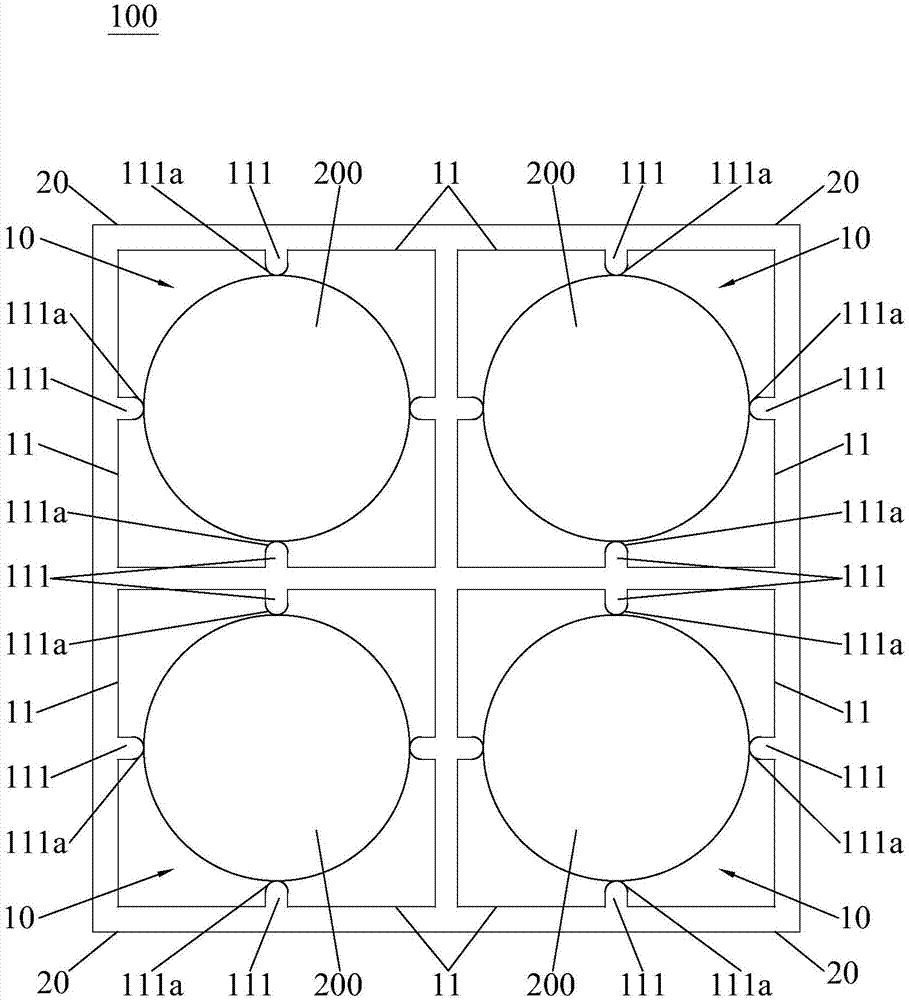

Locating grid

InactiveCN103971759AEnhanced Fluid DisturbanceFixed flexibleNuclear energy generationFuel element assembliesEngineeringPoint contact

The invention provides a locating grid suitable for locating fuel rods. The locating grid comprises a grid unit with a hollow structure, wherein a fuel rod penetrates through the grid unit; an inner side wall of the grid unit is in point contact or line contact with a wall surface of the fuel rod. Therefore, the locating grid has a locating function of well fixing the fuel rod, and fluid disturbance near the locating grid is enhanced; according to the structure that the inner side wall of the grid unit is in point contact or line contact with the wall surface of the fuel rod, fluid heat transfer in an area near the locating grid is intensified, so that temperature distribution on the wall surface of the fuel rod is regular, and a phenomenon that the temperature on the wall surface of the fuel rod is greatly increased is avoided. Compared with a traditional locating grid, contact between the locating grid and the fuel rod is improved from surface contact to point contact or line contact, the influence on heat transfer of the wall surface of the fuel rod is greatly reduced, and the fuel rod is flexibly fixed. Moreover, compared with a wire winding locating mode with low heat transfer influence, the fixing effect is better.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +1

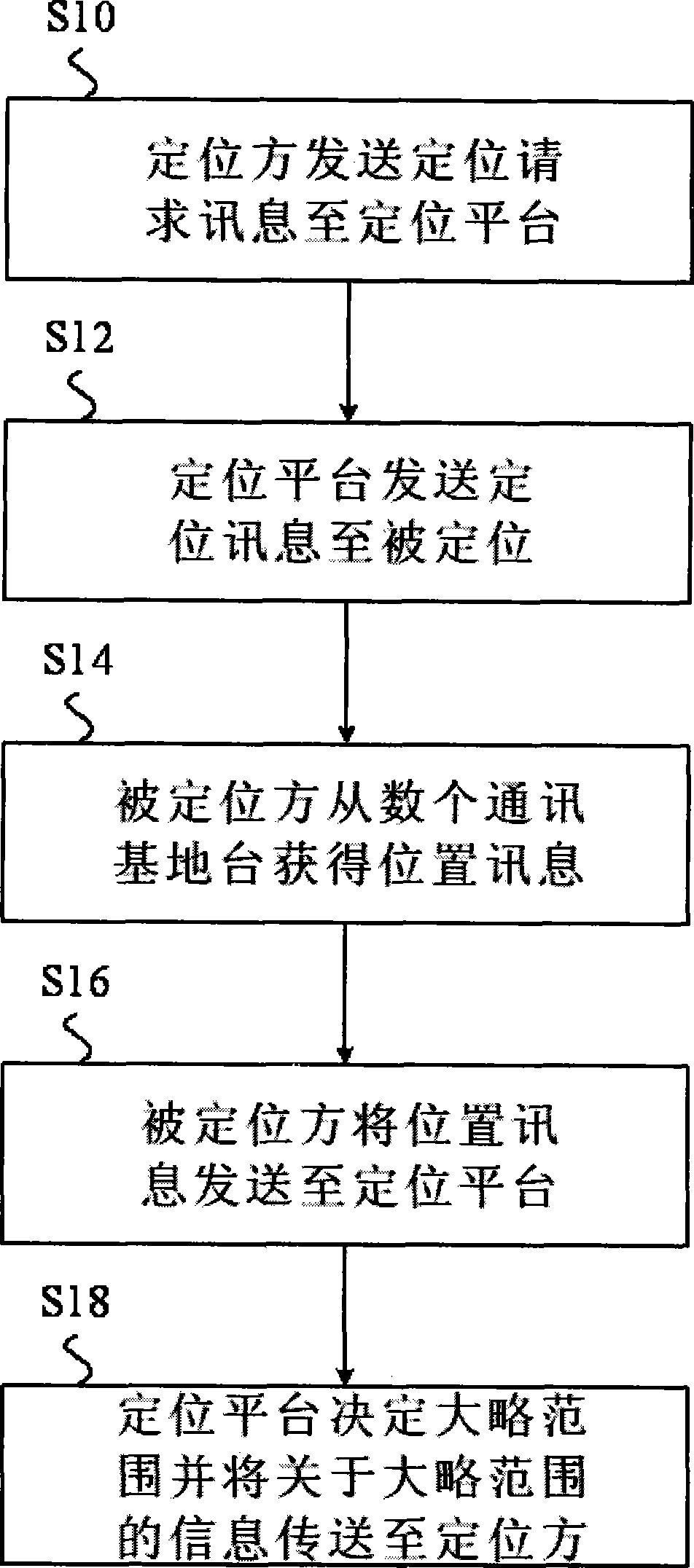

Positioning method and system

ActiveCN101383983APrecise positioningGood positioning functionPosition fixationStations for two-party-line systemsTelecommunications

Owner:INVENTEC(NANJING) TECH CO LTD

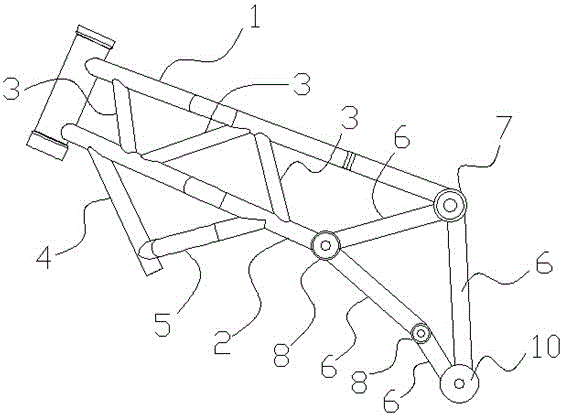

Installing structure of independent suspension system

InactiveCN106515333AReduce stressIncreased Strength and ReliabilityConstruction cranesResilient suspensionsVehicle frameEngineering

The invention discloses an installing structure of an independent suspension system. The installing structure of an independent suspension system is characterized by comprising a plurality of supports, bases and pulling rods. The bases are arranged at the bottom of a vehicle frame; the pulling rods are arranged on the outer side of the bases; the lower end of an oil cylinder is fixed; the supports are horizontally and vertically arranged on the external side surfaces of two sides of the vehicle frame; and the top end of an oil cylinder is fixed. The installing structure of the independent suspension system provided by the invention consists of the supports arranged on the external side surfaces of two sides of the vehicle frame and the bases arranged at the lower portion of the vehicle frame; the top and bottom of the installing structure are positioned and installed, respectively; and thus a flexible dynamic balance mechanism can be formed. When a vehicle runs, longitudinal, horizontal and vertical loads transferred from wheels are effectively separated, thus force of the structure is reduced and strength and reliability of the structure are improved. Simultaneously, impact force applied on parts is small. The requirements for strength and precision of parts are low and vehicle cost is reduced.

Owner:XUZHOU HEAVY MASCH CO LTD

Novel geotextile production process

ActiveCN111549447AAchieve the effect of equidistant operationGood positioning functionRoadwaysSynthetic resin layered productsSoil scienceEngineering

The invention discloses a novel geotextile production process, and belongs to the production field of novel geotextile. Compared with a traditional process, positioning and extruding striped hot meltrubber are added to the geotextile outer surface in the novel geotextile production process and soil carrying capacity of the geotextile is convenient to increase, so that the geotextile processed bythe equipment has a good positioning function. Deviation and relative sliding at the appropriate location are prevented from happening, and the normal construction of the geotextile is ensured. Compared with common production process, the novel geotextile production process is added with anti-ultraviolet fiber. The inner material of the anti-ultraviolet fiber is acrylic, and the acrylic has a goodanti-ultraviolet aging effect, is laid on the upper surface of the geotextile through extrusion molding, and is subjected to waterproof spraying to achieve a good waterproof effect.

Owner:扬州华诚土工材料有限公司

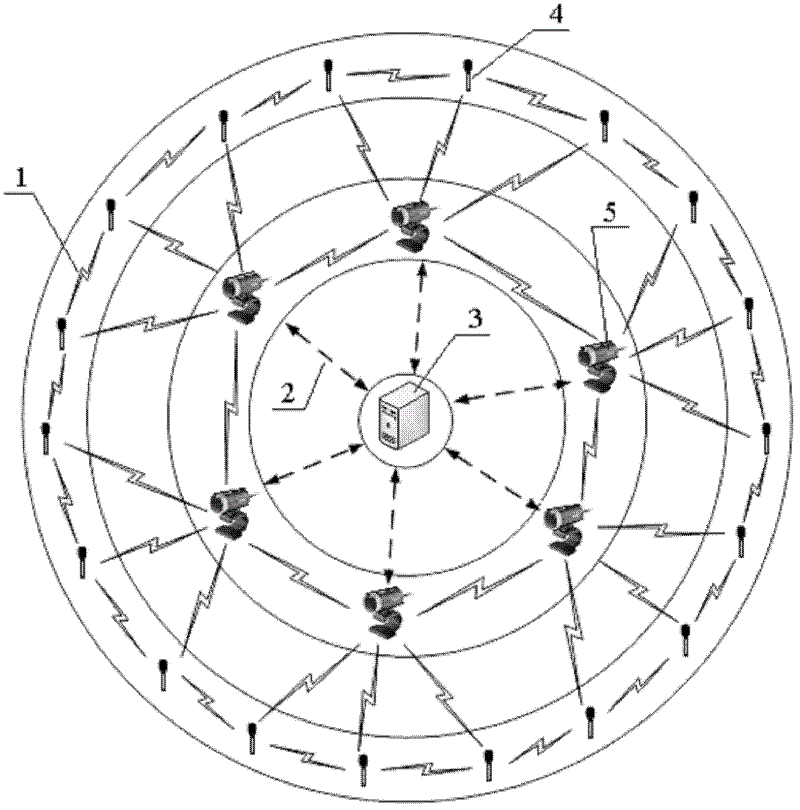

Network system framework of low altitude target detection sensor

ActiveCN102625482AImprove surveillance capabilitiesEasy to manageNetwork topologiesRadarMonitoring system

The invention relates to a network system framework of a low altitude target detection sensor, which comprises a double-layer strip sensor network and a backbone transmission layer network. The outer layer of the double-layer strip sensor network is a network formed by voice sensing nodes which conducts multi-node data fusion and dispersed cooperative data processing to the sensed voice data and guides optical sensing nodes at the inner layer to precisely position and trace a target according to a processing result. The inner layer of the double-layer strip sensor network is a wireless network which can communicate with the voice sensing nodes of the outer layer; the wireless network is formed by the optical sensing nodes; and when the signals of the voice sensing nodes of the outer layer are received, the optical sensing nodes of the inner layer are started and collects the optical information of the target. The backbone transmission layer network is a network used to connect the optical sensing nodes of the inner layer of the double-layer strip sensor network with a command center. The network system framework of the low altitude target detection sensor can make up the disadvantages of a monitoring system which takes radar as a main part in the prior art.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com