Projective jacket for wire harness of automobile

A technology for automotive wiring harnesses and sheaths, which is applied in the direction of electrical components, etc., can solve the problems of reduced service life of rubber sheaths, unreliable fixing of rubber sheaths, poor sealing effect, etc., and achieve simple structure, enhanced structural strength and fixing reliability , Enhance the effect of structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

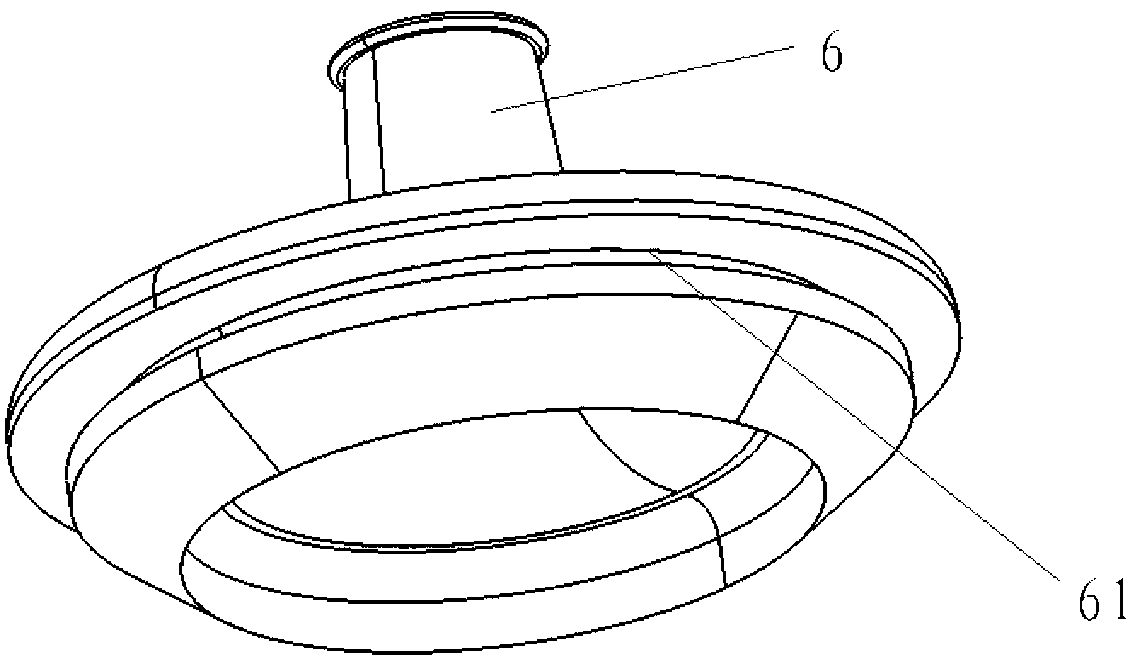

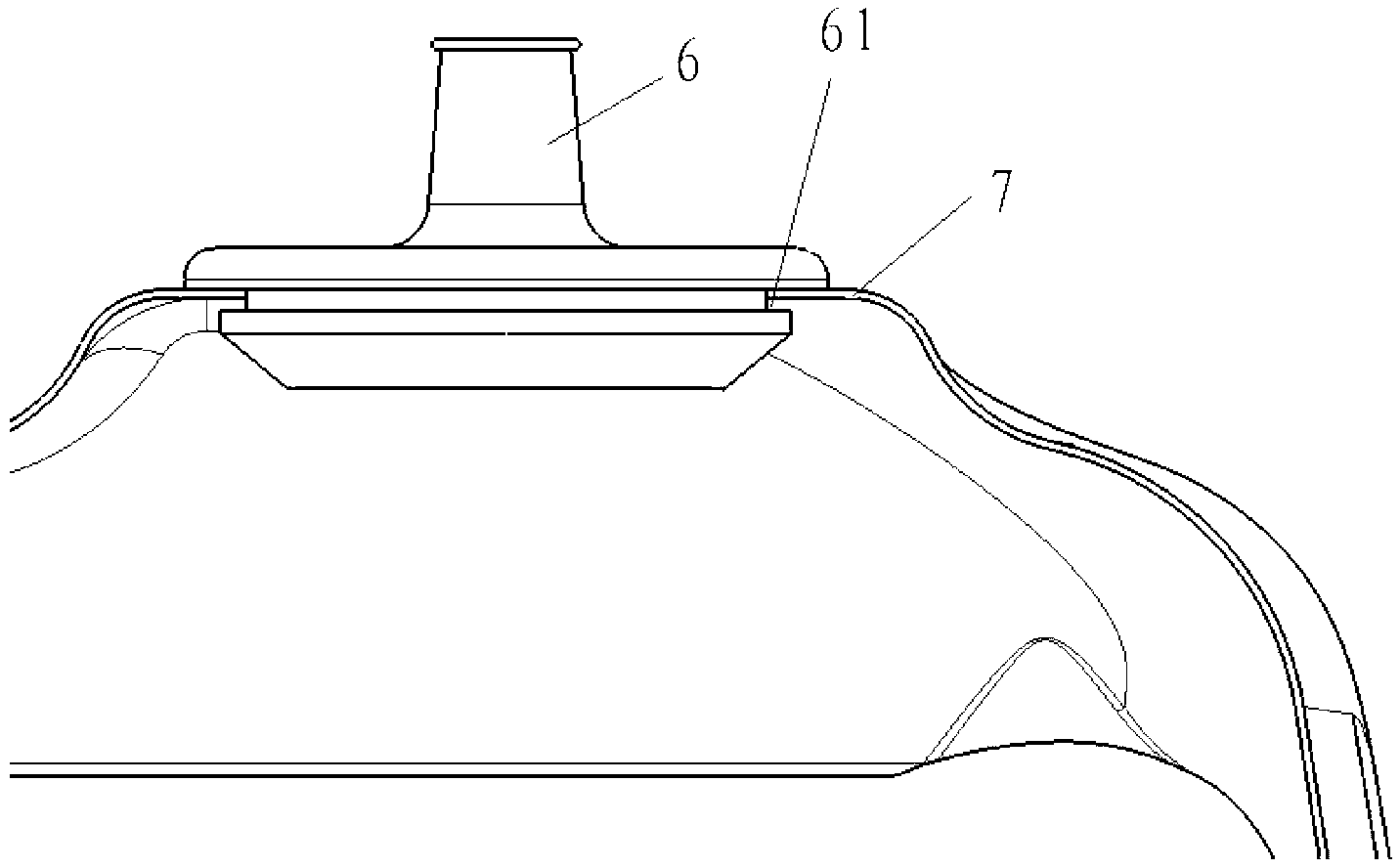

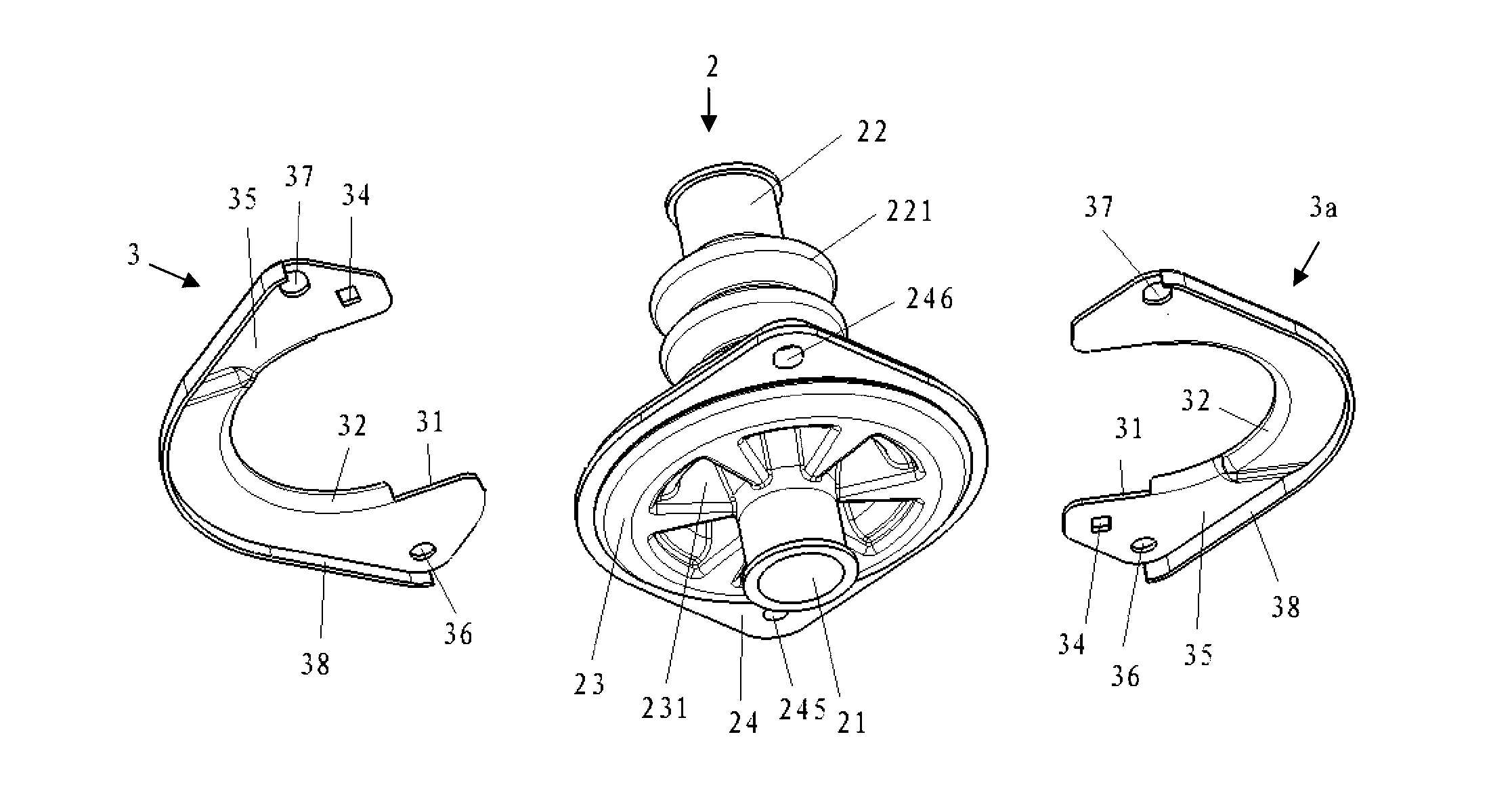

[0042] Such as Figure 3-5 As shown, the automotive wire harness sheath 1 includes a rubber sheath 2 and two semi-circular fixing covers, the two fixing covers are respectively a first fixing cover 3 and a second fixing cover 3a. The rubber sleeve 2 includes a cover body 22, an intrusion portion 23, a flange 24 and a groove 25, the intrusion portion 23, the flange 24 are integrated with the sleeve body 22, the intrusion portion 23 is cylindrical, and the intrusion portion 23 The outer diameter is greater than the outer diameter of the sleeve body 22, the circumferential outer wall of the protruding part 23 cooperates with the fixing hole 43 of the body sheet metal part 4, and the lower surface 242 of the flange 24 is bonded to the surface 41 of the body sheet metal part 4. The first fixed cover 3 and the second fixed cover 3 a clamp the groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com