Locating grid

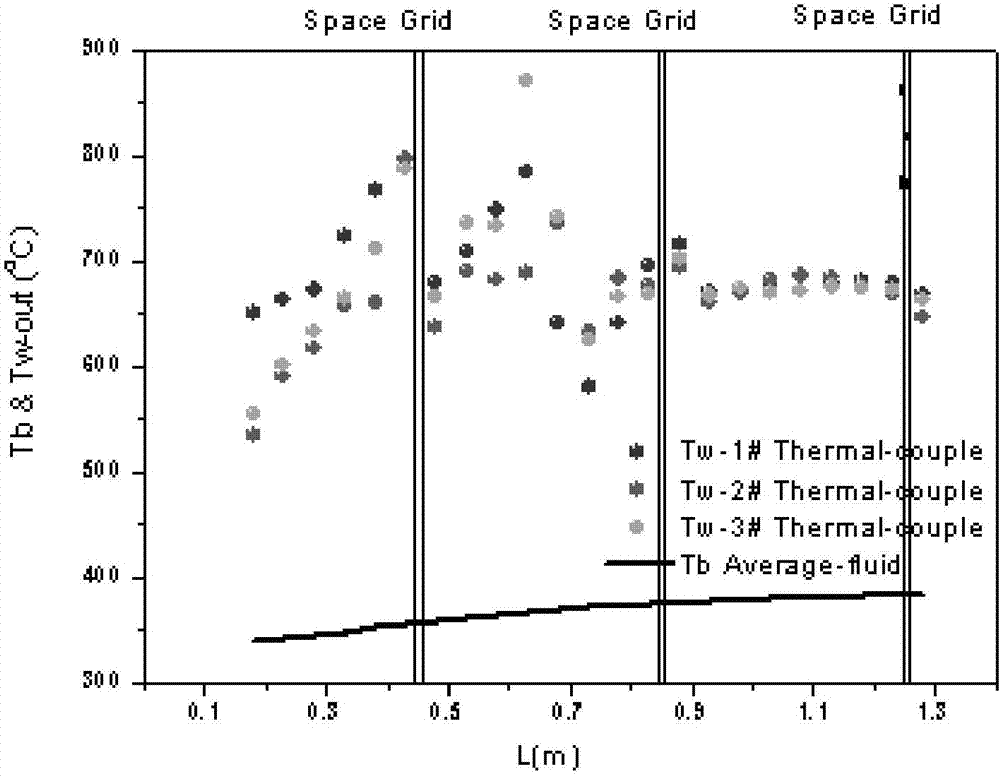

A technology for positioning grids and grids, which is applied in the direction of reducing greenhouse gases, nuclear power generation, and climate sustainability. The distribution is regular, avoiding a substantial increase and reducing the effect of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

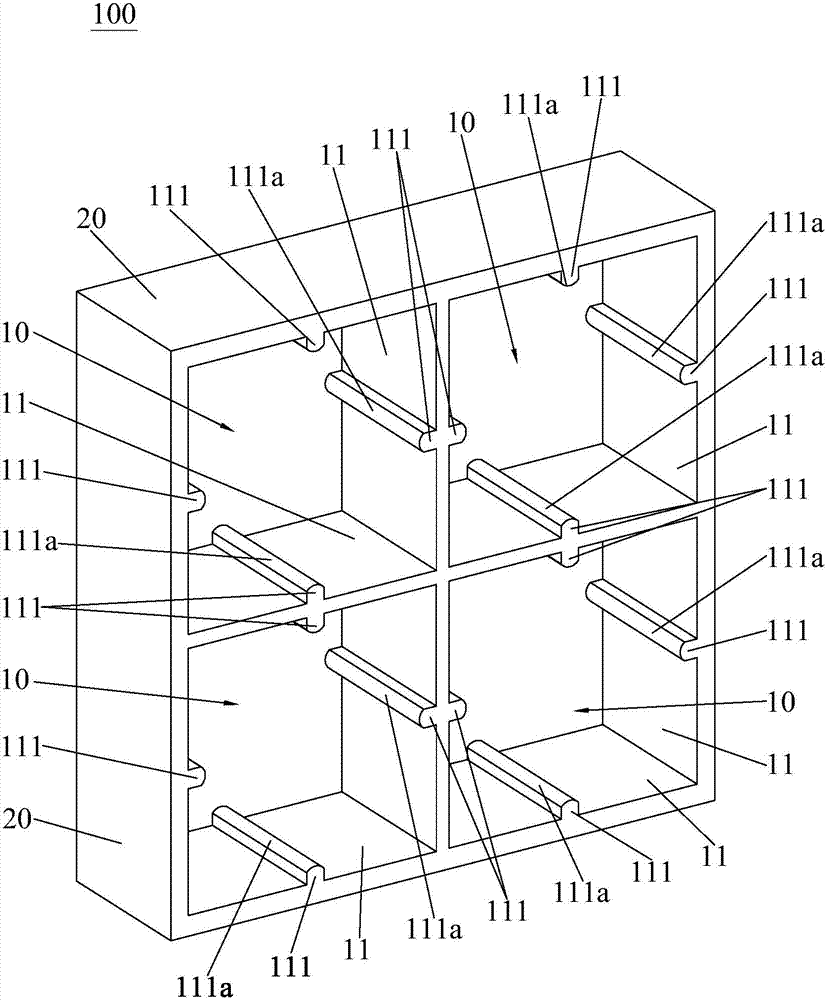

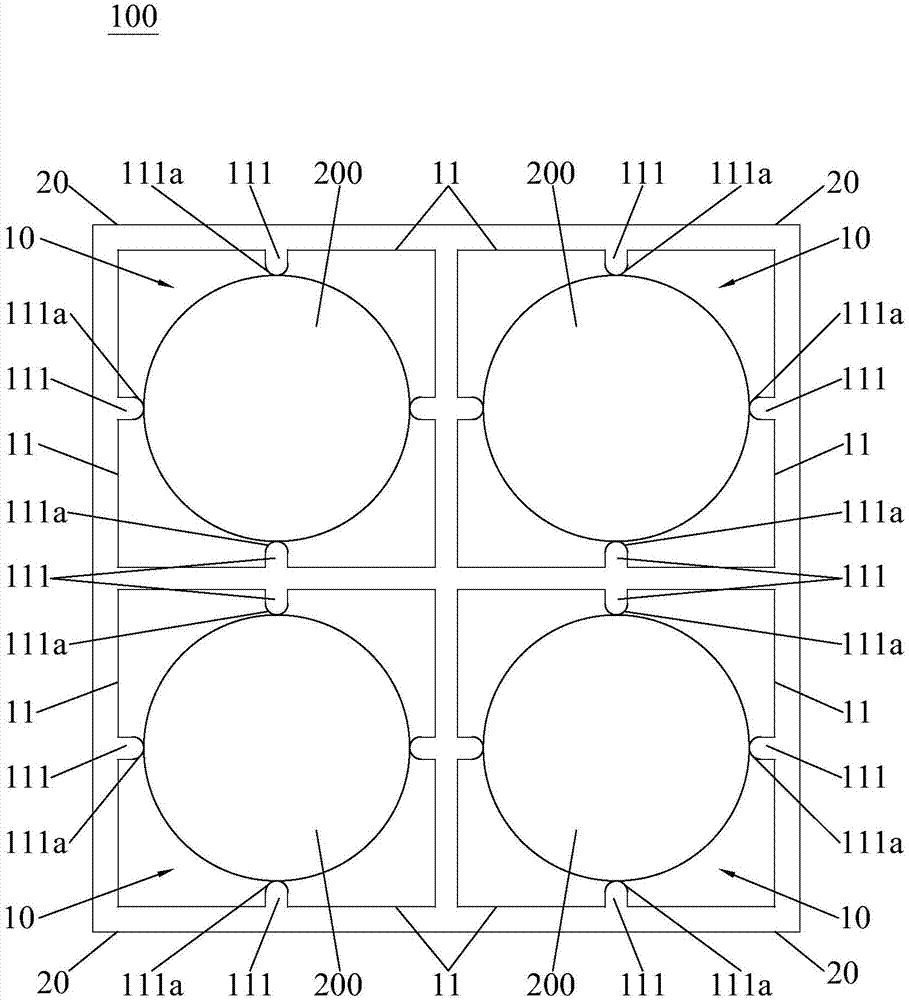

[0022] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

[0023] see figure 2 and image 3 , the positioning grid 100 of the present invention is suitable for positioning fuel rods 200 such as rod bundle components, wherein the positioning grid 100 of the present invention has a grid unit 10 with a hollow structure, and the fuel rods 200 are inserted into the grid unit 10 , the inner side wall 11 of the grid unit 10 is in point contact or line contact with the wall surface of the fuel rod 200 . Therefore, the spacer grid 100 of the present invention ensures a good positioning function for fixing the fuel rods 200, and enhances the fluid disturbance near the spacer grid 100; The structure of contact or line contact strengthens the fluid heat transfer in the area near the positioning grid 100, that is, the heat transfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com