An absorption type fully welded plate and shell heat exchanger

An all-welded, plate-and-shell technology, which is applied in the direction of indirect heat exchangers, heat exchanger types, heat exchanger shells, etc., can solve the problem of high temperature resistance, high pressure resistance, poor corrosion resistance of rubber pads, and liquids that are prone to failure of plates. Distributed, uneven heat transfer area and other issues, to achieve the effect of self-cleaning, reducing ineffective heat transfer area, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

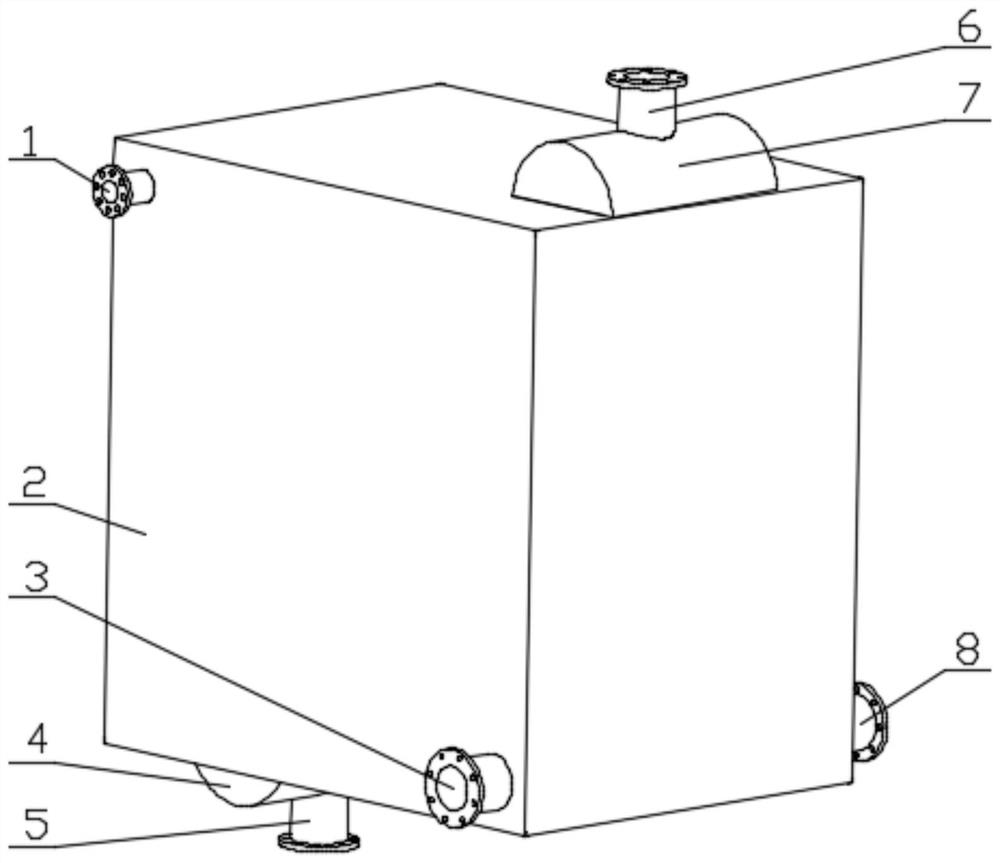

[0037] With reference to the accompanying drawings, an absorption type fully welded plate and shell heat exchanger includes a shell 2 and a core installed inside the shell 2 . Such as figure 1 As shown, the housing 2 is provided with a refrigerant water inlet connecting pipe 1, a concentrated absorbent solution inlet connecting pipe 3, a dilute absorbent solution outlet connecting pipe 8, a low-temperature hot water sealing head 7 and a high-temperature hot water outlet sealing head 4. The hot water sealing head 7 is connected with the low-temperature hot water connecting pipe 6, and the high-temperature hot water outlet sealing head 4 is connected with the high-temperature hot water connecting pipe 5.

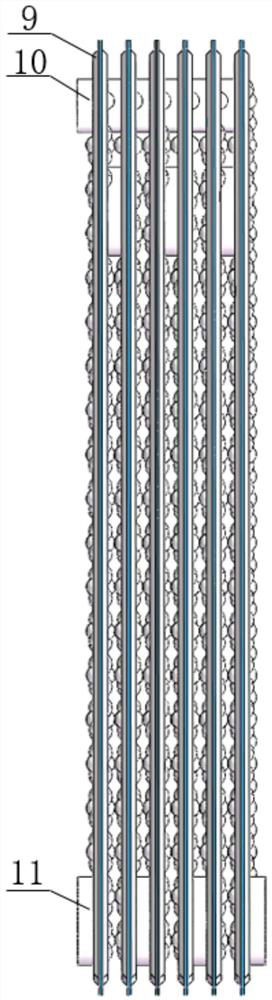

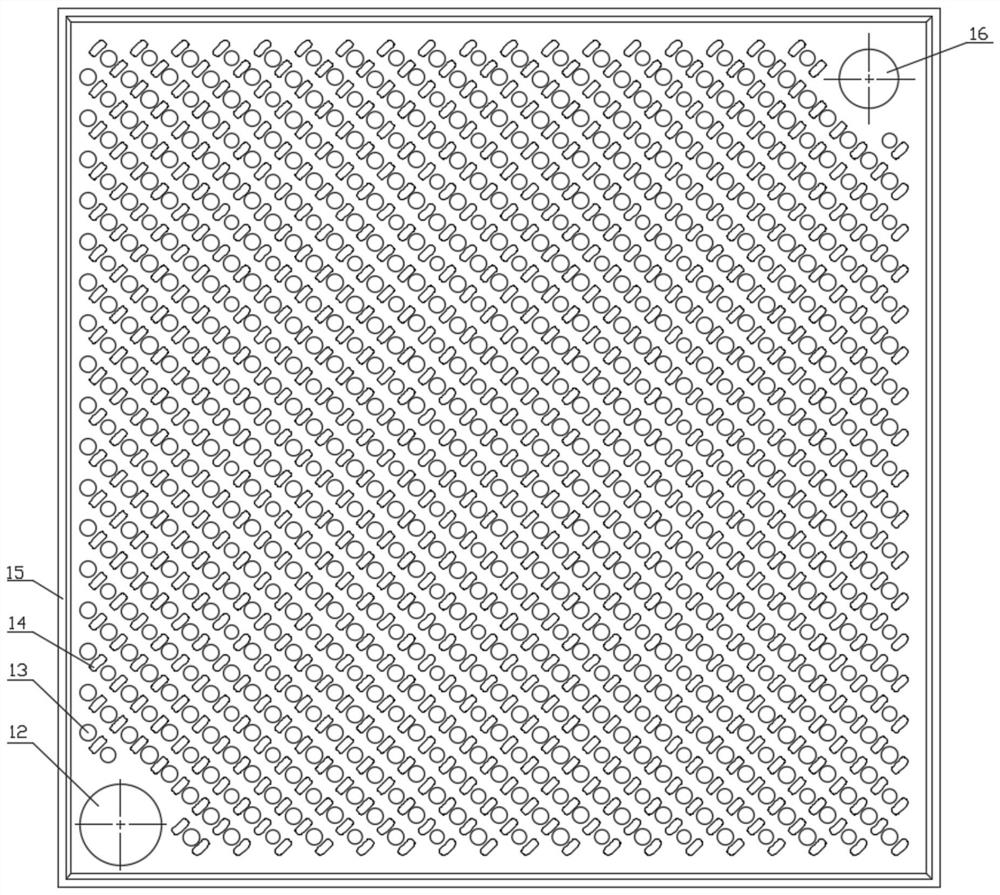

[0038] Such as figure 2 As shown, the core body is composed of several heat exchange plate pairs 9, and the heat exchange plate pairs 9 are formed by laser welding of two metal plates. The heat exchange fluid circulates, and the heat exchange plate pairs are connected throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com