A self-exciting back-rotating jet supercharger

A supercharger and self-excitation technology, which is applied in jet pumps, non-displacement pumps, machines/engines, etc., can solve the problems of low momentum exchange efficiency, low injection supercharging efficiency, long injector length, etc., and achieve shortening The effect of injector size, enhanced anti-fluctuation ability, and reduced energy dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

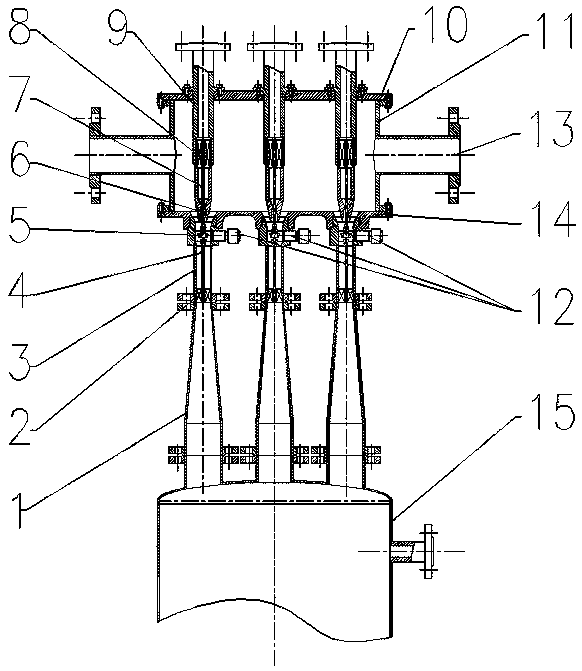

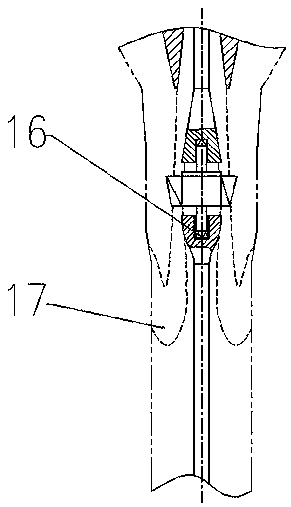

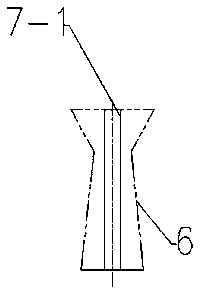

[0026] Figure 1 shows the overall structure of a self-energized back-swivel booster injector. The high-pressure main jet of the self-exciting back-rotating booster injector enters from the driving nozzle seat 9, and after being rectified by the front rectifying support ring 8, the driving nozzle 6 speeds up and reduces pressure, forming a low-pressure area at the front end of the mixing area, driving the suction chamber cylinder 11 The internal fluid is sucked into the supercharger mixing chamber 3 for mixing, usually the injector mixing boundary layer sees figure 2 The common mixed boundary layer schematic area 17 is shown, in which the self-excited swirl rotor 5 is set, and the fluid flow drives the self-excited swirl rotor 5 to rotate, generating disturbance, thickening the mixed boundary layer, and enhancing momentum exchange. The mixed fluid then flows through the supercharger diffuser chamber 1 and supports the rectification ring 2 for energy recovery and pressure recov...

Embodiment 2

[0029] Image 6 It shows the actual assembly of 7 sets of self-excited back-rotating booster injectors in parallel. Multiple sets of injectors are arranged in parallel in a circular ring, independent of each other and independent of each other. The number of openings can be selected by oneself. The suction chamber is shared by multiple sets of equipment, and two suction chamber suction ports 13 are welded symmetrically on the left and right sides of the suction chamber cylinder body 11, which are low-pressure fluid suction ports. The upper end cover 10 of the suction chamber and the lower end cover 14 of the suction chamber are connected with the flange bolts of the cylinder body 11 of the suction chamber, and the gaskets are sealed to form an integrally sealed low-pressure fluid suction chamber. The self-excited back-spin booster injector drive nozzle seat 9 is bolted to the upper end cover 10 of the suction chamber, and the supercharger mixing chamber 3 is threaded to the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com