Automatic three-gear reset shunt valve

A technology of automatic reset and water diversion valve, applied in the direction of valve details, multi-way valves, valve devices, etc., can solve problems such as not smooth enough hand feeling, untimely positioning and return, and restrictions on the application field of water diversion valve core, etc. Affect the feel and use effect, the positioning effect is stable, and the positioning function is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

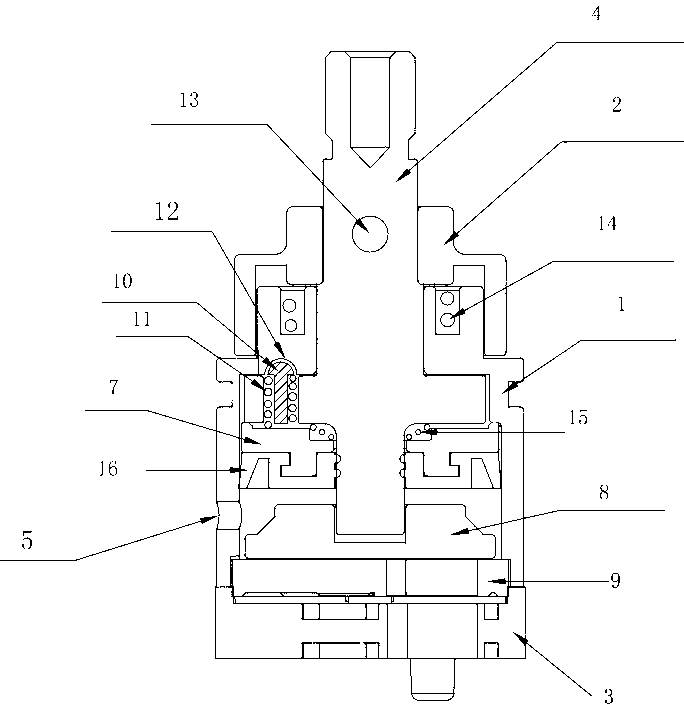

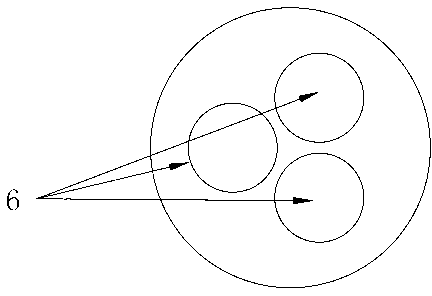

[0021] A three-speed automatic reset water diversion valve described in Embodiment 1, such as figure 1 , figure 2 As shown, it includes a main body 1, an upper cover 2 installed on the upper part of the main body and a base 3 installed on the bottom of the main body. The main body is provided with a skeleton 7 for positioning the transmission rod and a moving piece 8 and a static piece 9 connected with the transmission rod. The transmission rod is provided with a through hole, and a positioning ball 10 and a positioning ball spring 11 are arranged in the through hole. The setting of positioning ball and positioning ball spring is longitudinal setting. The function of the positioning spring is to make the water diversion valve feel smooth when in use. Regardless of whether the water pressure is strong or weak, its positioning function is good, and the return function is not affected, so as to realize the timely opening and closing of the water channel.

[0022] Further, the ...

Embodiment 2

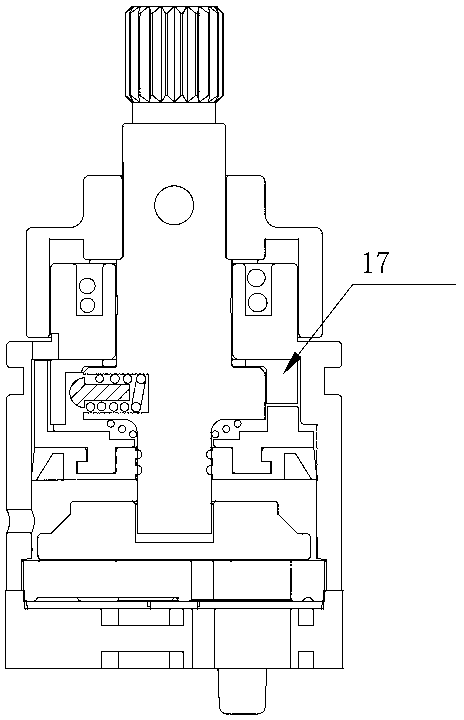

[0027] This embodiment 2 is changed on the basis of embodiment 1, specifically: as image 3 , Figure 4 As shown, the setting of the positioning ball and the positioning spring is horizontal, and the main body is provided with a corresponding clutch plate 17 facing the skeleton. The clutch plate is provided with a clutch plate fixed point 18. Or detached skeleton anchor point 19. The positioning of the clutch plate and the positioning ball, when the water pressure passes through, the skeleton is pushed upward, and the positioning point of the skeleton contacts the fixed point of the clutch plate to position the positioning point of the skeleton; when the water pressure is lost, the positioning ball and the clutch plate rotate together, Return to the initial state.

[0028] Further, the fixed point of the clutch plate is an inverted U shape, and the skeleton positioning point is an inverted T shape. The positioning effect of the fixed point of the clutch plate and the positi...

Embodiment 3

[0030] This embodiment 3 is also changed on the basis of embodiment 1, specifically: as Figure 5 , Image 6 As shown, the setting of the positioning ball and the positioning spring is horizontal, and the main body is provided with a corresponding clutch plate 17 facing the skeleton. The clutch plate is provided with a clutch plate fixed point 18. Or detached skeleton anchor point 19. The fixed point of the clutch plate is circular, and the anchor point of the skeleton is U-shaped. In addition, the upper cover return spring 14 of the present embodiment 3 is as Figure 7 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com