Water purification and heating all-in-one machine and control method

A control method and an all-in-one technology, applied in water heaters, temperature control, fluid heaters, etc., can solve problems such as easy breeding of viruses and bacteria, harmful to human health, unfavorable installation and maintenance, etc., to avoid breeding viruses and good results , Easy to install and maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

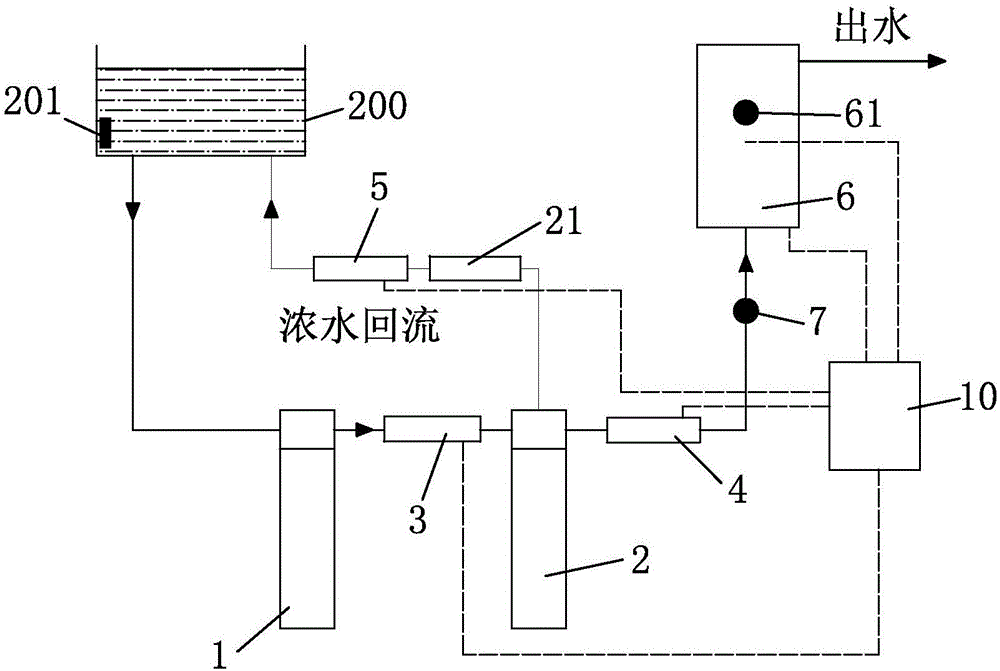

[0023] see figure 1 , the water purification and heating all-in-one machine is characterized in that it includes a booster device 3, a filter element, a heating device 6, a heating device 6, and an outlet water temperature sensor 61 sequentially connected through a waterway; the all-in-one machine also includes an electric control device 10; The pressure device 3 , the heating device 6 and the outlet water temperature sensor 61 are respectively electrically connected to the electric control device 10 .

[0024] The water inlet channel of the heating device 6 is provided with an inlet water temperature sensor 7 . This technical solution enables the instant hot water purification system to adjust the water intake of the heating device 6 at any time according to the change of the water inlet temperature, and the water inlet temperature sensor 7 can be set at any waterway position at the water inlet end of the heating device 6, As long as it can satisfy the detection of its inlet...

no. 2 example

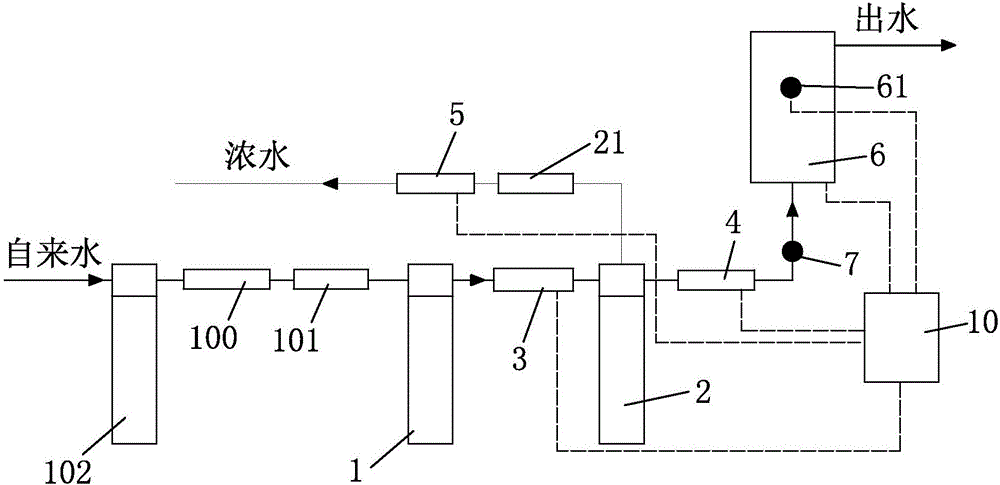

[0037] see figure 2 , the water purification and heating all-in-one machine, its main difference from the first embodiment is that in this embodiment, the water source used at the water inlet end of the booster device 3 is a pressurized pipeline water source (such as tap water), and the pipeline The water source is connected to the pressurization device 3 through a detection device and a water inlet solenoid valve 101. At this time, the detection device is a low pressure switch 100, and a primary filter assembly 102 is also provided on the pipeline water source to further improve the filtering effect. The flushing end of the secondary filter element 2 discharges the flushed waste water to the outside through the second water inlet solenoid valve 5 .

[0038] In addition, the water source used at the water inlet end of the pressurizing device 3 may also be a non-pressure pipeline water source (such as well water). Those skilled in the art can understand that the all-in-one wa...

no. 3 example

[0041] The main difference between this all-in-one water purification and heating machine and the first embodiment is that in this embodiment, the filter element is not an RO reverse osmosis filter element, and no waste water needs to be discharged during the water production process. Therefore, it is not necessary to set a flushing water outlet on the filter element And increase structures such as flushing electromagnetic valve 21, make the structure of all-in-one machine more small and exquisite compact.

[0042] Other unmentioned parts are the same as the first embodiment and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com