Hanging basket equipment for constructional engineering

A technology of construction engineering and equipment, which is applied in the field of hanging basket equipment in construction engineering, can solve the problems of hanging basket material falling, no buffer function, motor damage, etc., to avoid damage caused by direct contact with the ground, good buffer function, and improve The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

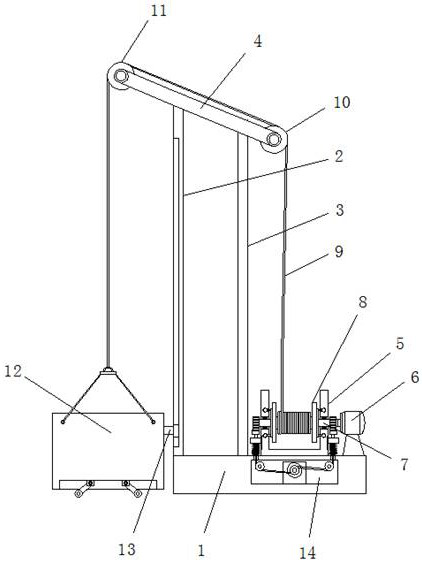

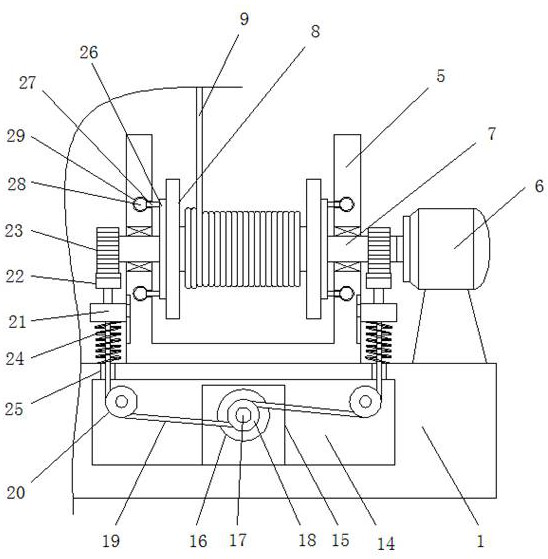

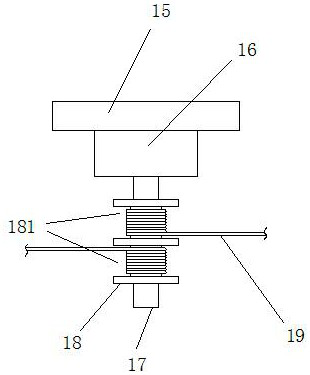

[0030] refer to Figure 1-8 In this embodiment, a hanging basket device for construction projects is proposed, including a base 1, a left stand 2 is fixedly arranged on the left end of the top of the base 1, and a left stand 2 is fixedly arranged on the right side of the left stand 2. Right vertical frame 3, the top of left vertical frame 2 and right vertical frame 3 are fixedly installed with the inclined frame 4 that is provided with an inclination, the right end of inclined frame 4 is rotated to be provided with the first fixed pulley 10, and the left end of inclined frame 4 is rotated to be provided with The second fixed pulley 11 is also fixedly installed with a U-shaped frame 5 on the base 1 on the right side of the right stand 3, and the hoisting motor 6 is fixedly installed on the base 1 on the right side of the U-shaped frame 5. The output shaft of 6 is fixedly connected with a reel 7, and the left end of the reel 7 runs through the U-shaped frame 5 and rotates to ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com