Hardness testing device and method for intelligent printed board of automobile

A technology for hardness testing and printed boards, applied in the direction of measuring devices, testing material hardness, strength characteristics, etc., can solve the problems of increasing the work intensity of workers and damage to printed boards 10, so as to reduce the work intensity of workers and prevent printed boards Damage, the effect of improving the efficiency of hardness testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

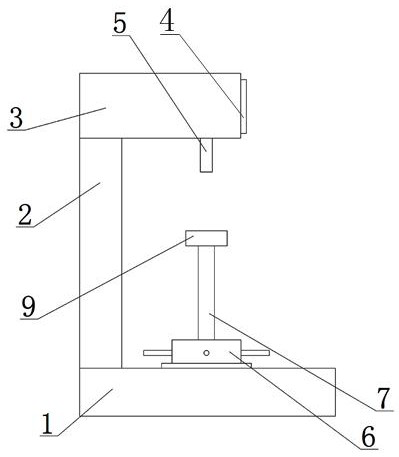

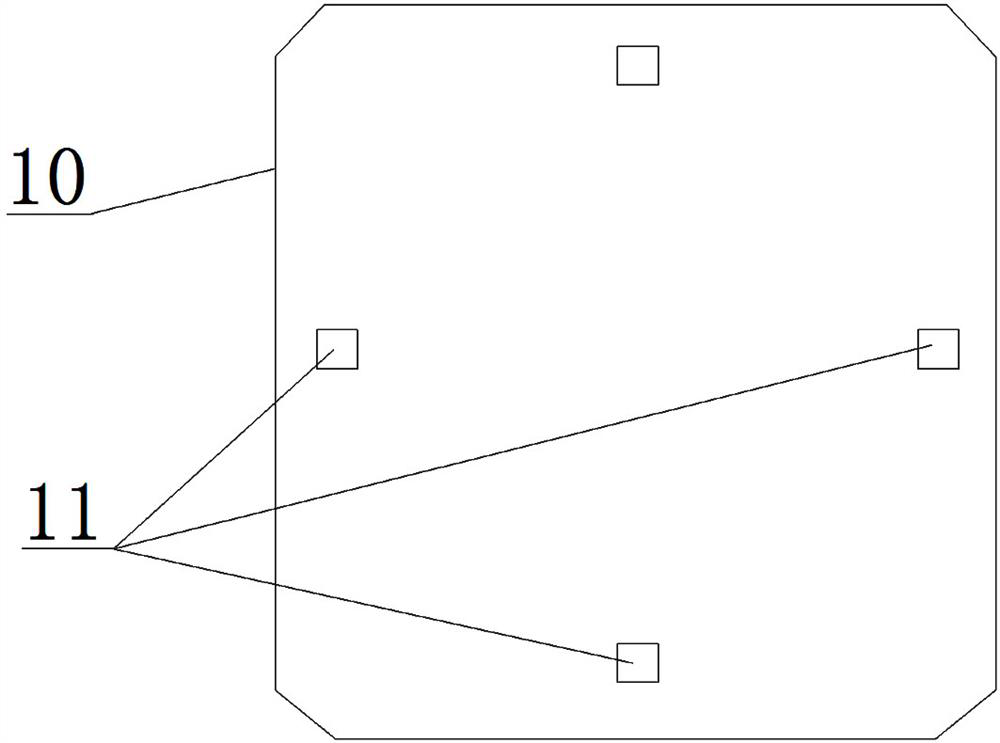

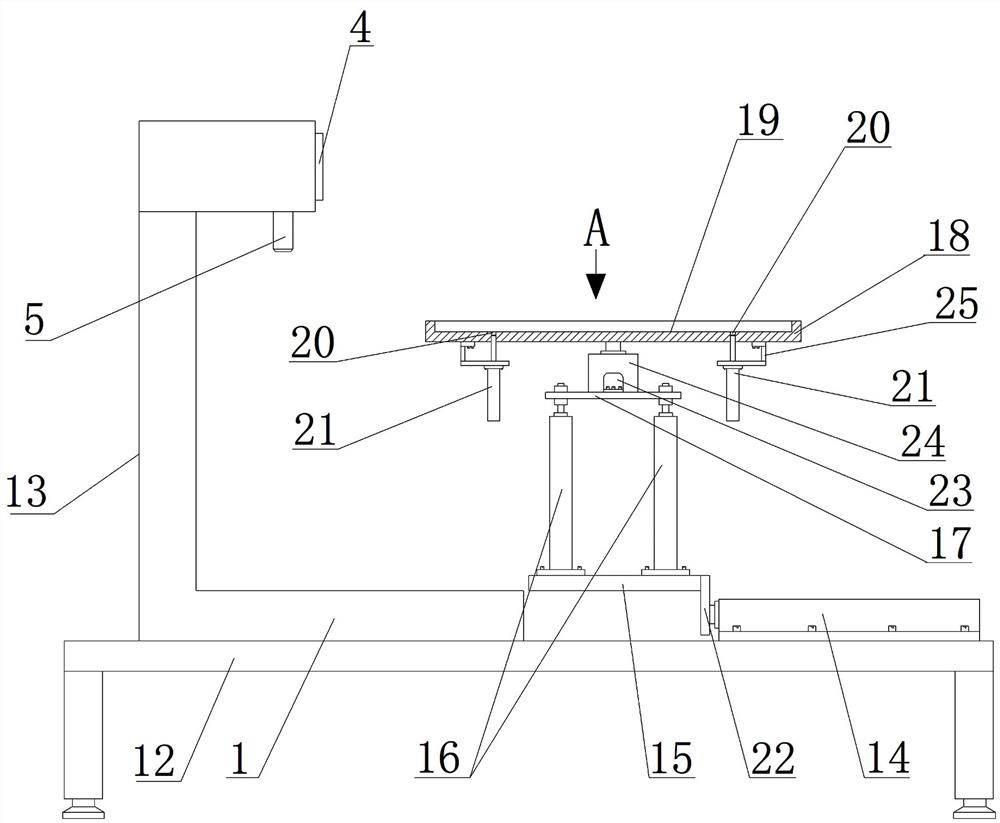

[0028] Such as Figure 3~4 Shown, a kind of hardness testing device of automobile intelligent printed board, it comprises the Rockwell hardness tester 13 that is arranged on workbench 12 tabletops, and the tabletop of described workbench 12 is also fixedly provided with Rockwell hardness tester 13 Opposed to the horizontal cylinder 14, a mounting plate 15 is fixed on the acting end of the piston rod of the horizontal cylinder 14, a lifting cylinder 16 is fixed on the top surface of the mounting plate 15, and a lifting cylinder 16 is fixed on the acting end of the piston rod of the lifting cylinder 16. Plate 17, a power unit is fixed on the top surface of the lifting plate 17, the output shaft of the power unit is arranged upwards, and the output shaft is welded with a rotating disk 18, the center of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com