General three-coordinate tool for measuring side plate product

A three-coordinate measurement and side plate technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of uncontrollable pressing force, no support limit mechanism, inaccurate clamping and positioning, etc., to ensure reliability and repeatability, Improve detection efficiency and improve the effect of positioning function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

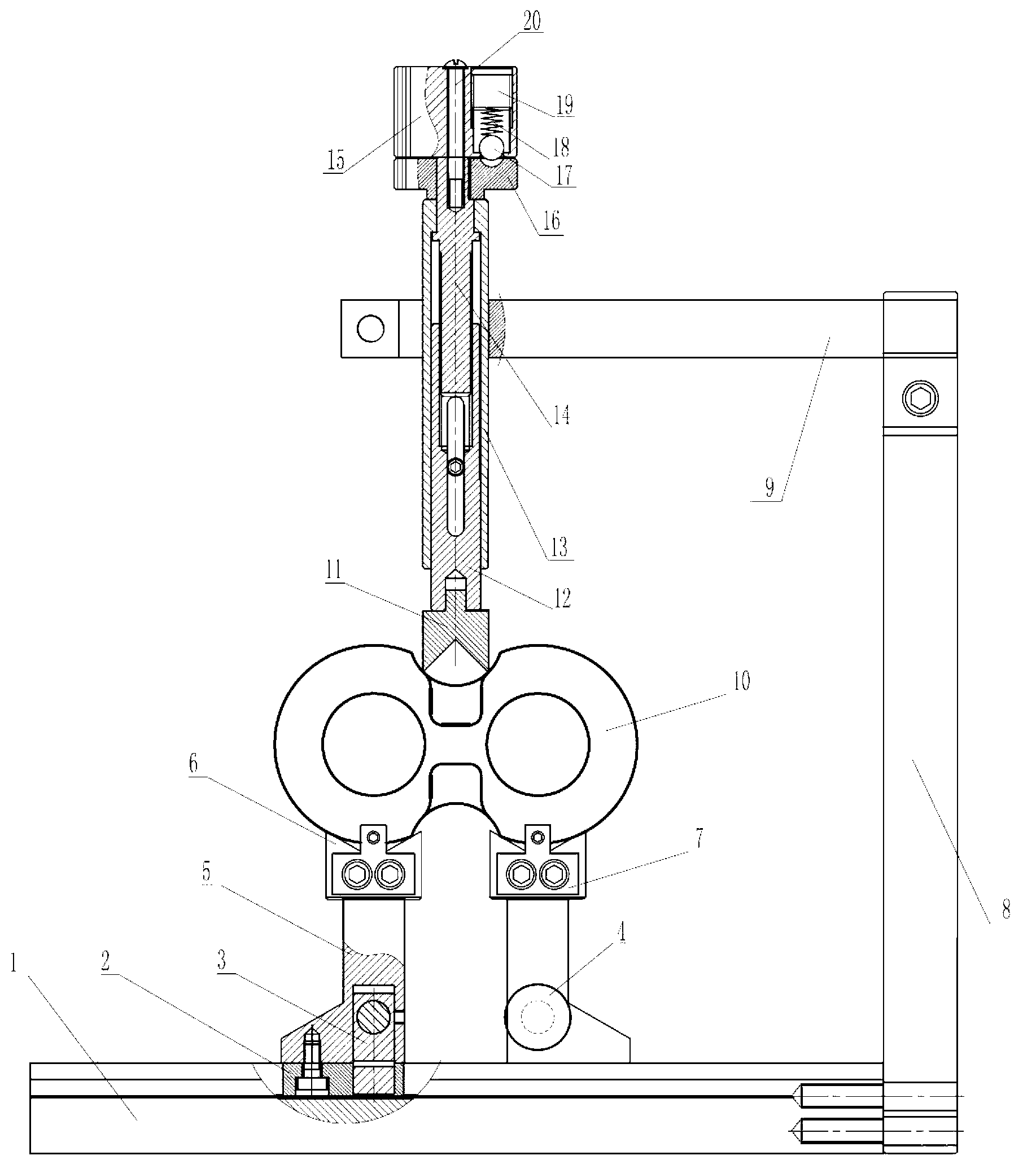

[0020] see figure 1 , the general tooling of the three-coordinate measurement side plate products of the present invention is composed of a guide rail 1, a pillar 8 and a cantilever 9 with threaded connections to form a frame that is not closed on one side, and a compression adjustment mechanism is provided at the cantilever end of the cantilever 9. On the guide rail 1 Equipped with a support limit mechanism.

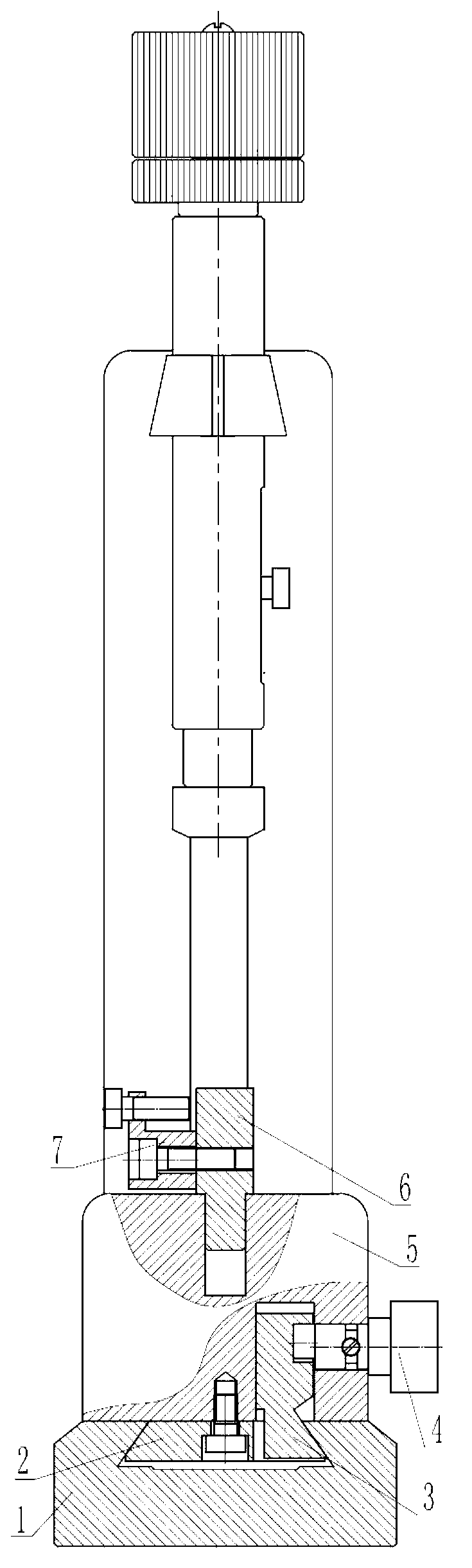

[0021] The compression adjustment mechanism is: the pressure head fixing sleeve 13 is fixed on the cantilever end of the cantilever 9, the upper pressure head 11 is installed on the lower end of the pressure rod 12; the pressure rod 12 is installed in the pressure head fixing sleeve 13; The rod 12 is threaded, the knob 16 is mounted on the upper end of the adjusting rotary rod 14, the screw 20 limits the force limiting adjusting knob 15 to the end face of the knob 16, there is a gap between the force limiting adjusting knob 15 and the end face of the knob 16, and the fo...

Embodiment 2

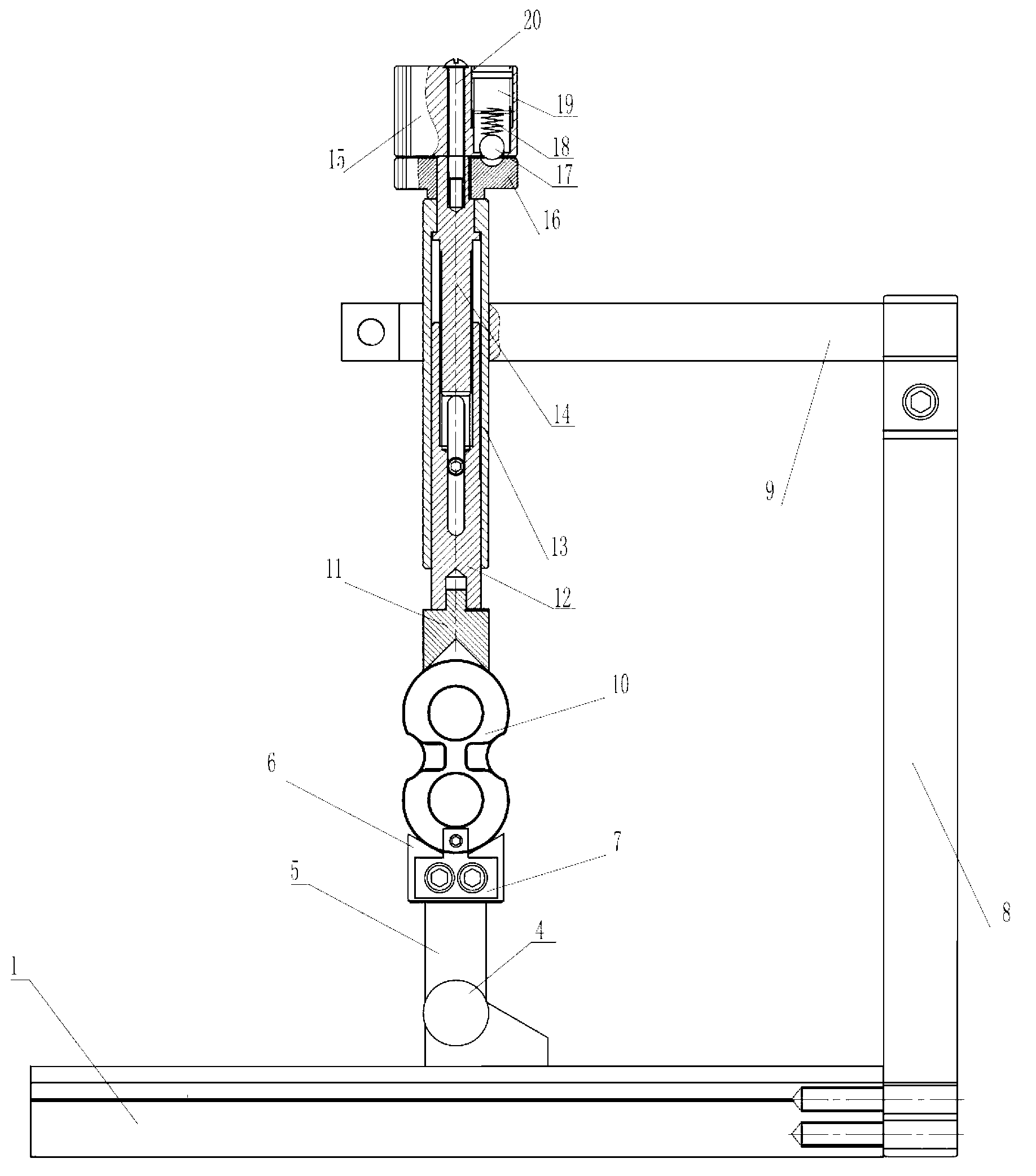

[0027] see image 3 , a support limit mechanism is installed on the guide rail 1, and the others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com