Patents

Literature

47results about How to "Solve the axial movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

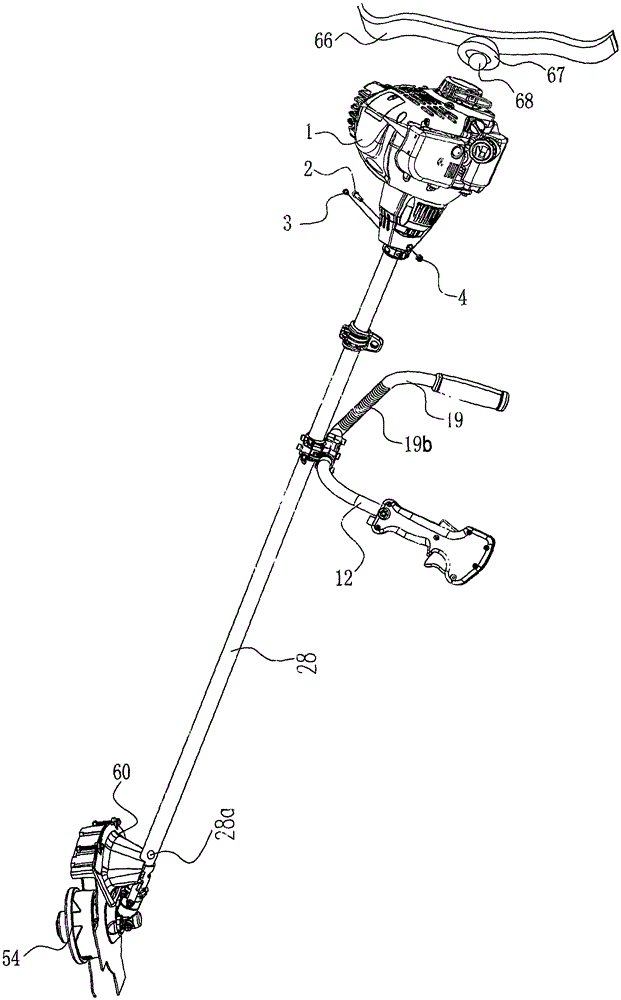

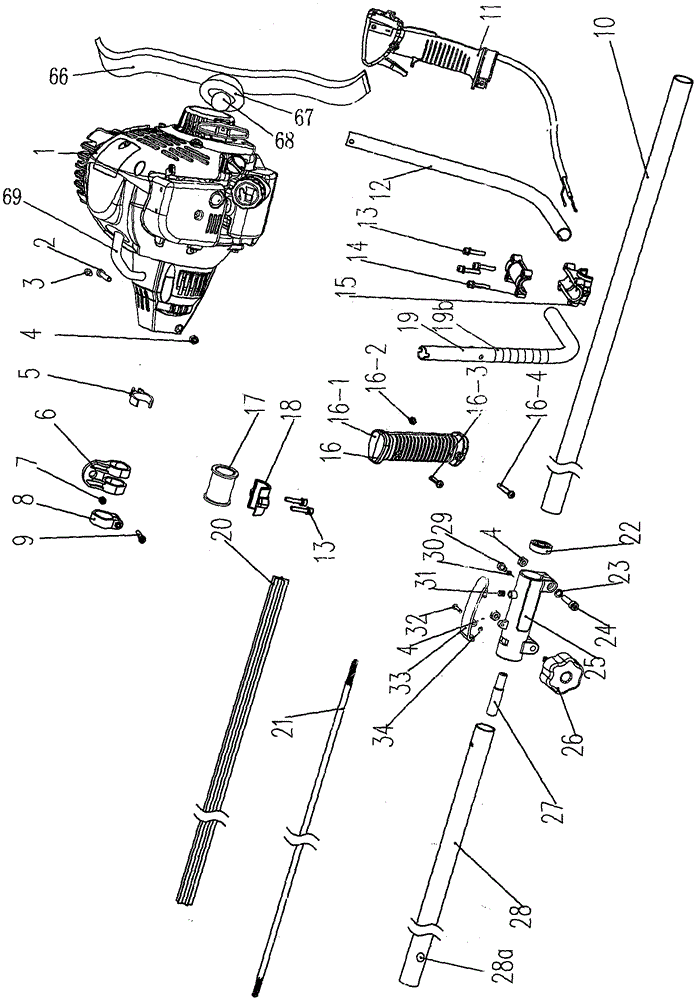

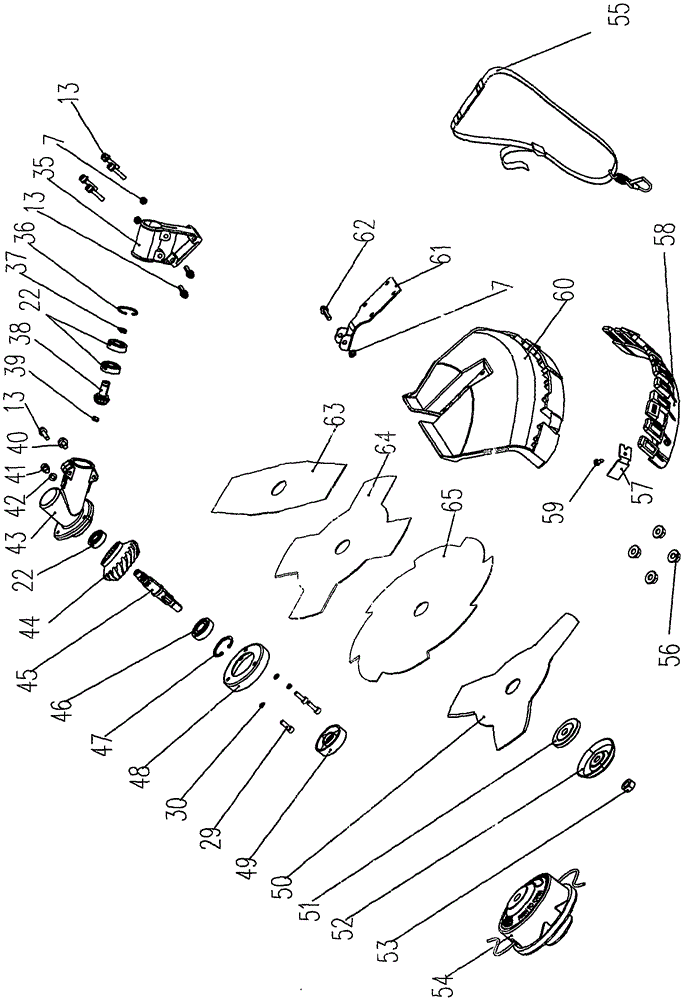

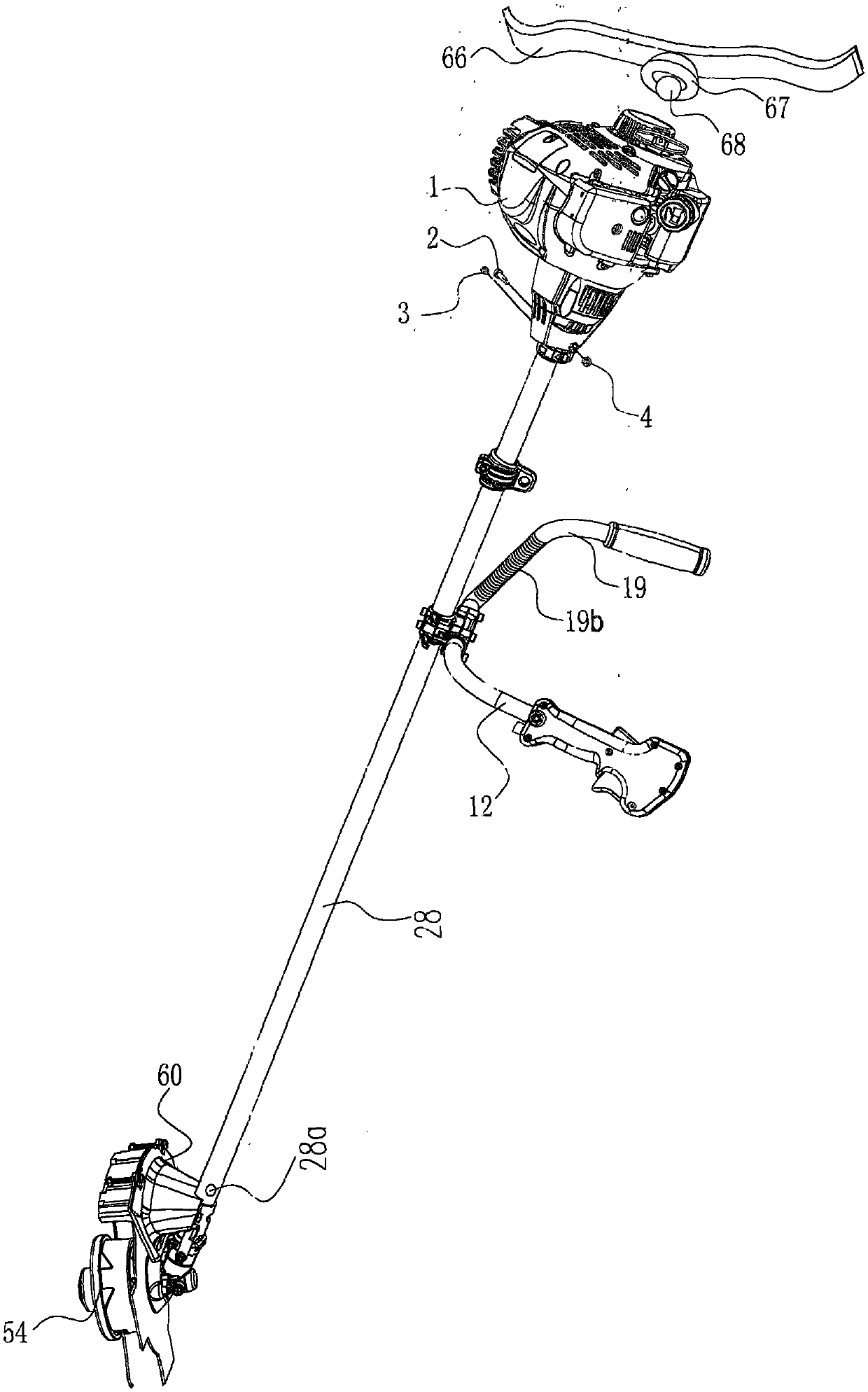

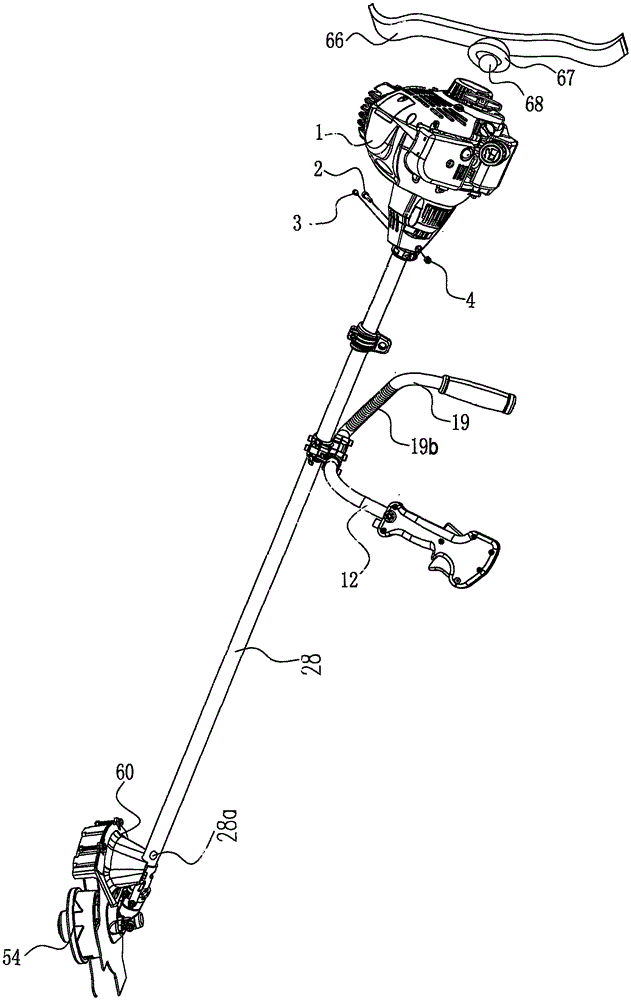

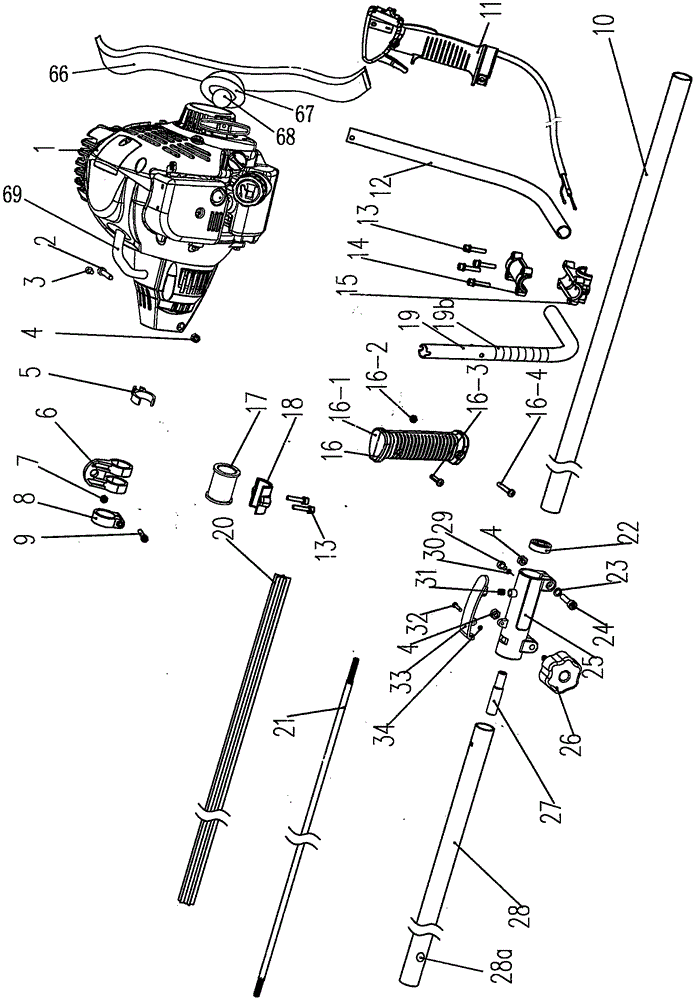

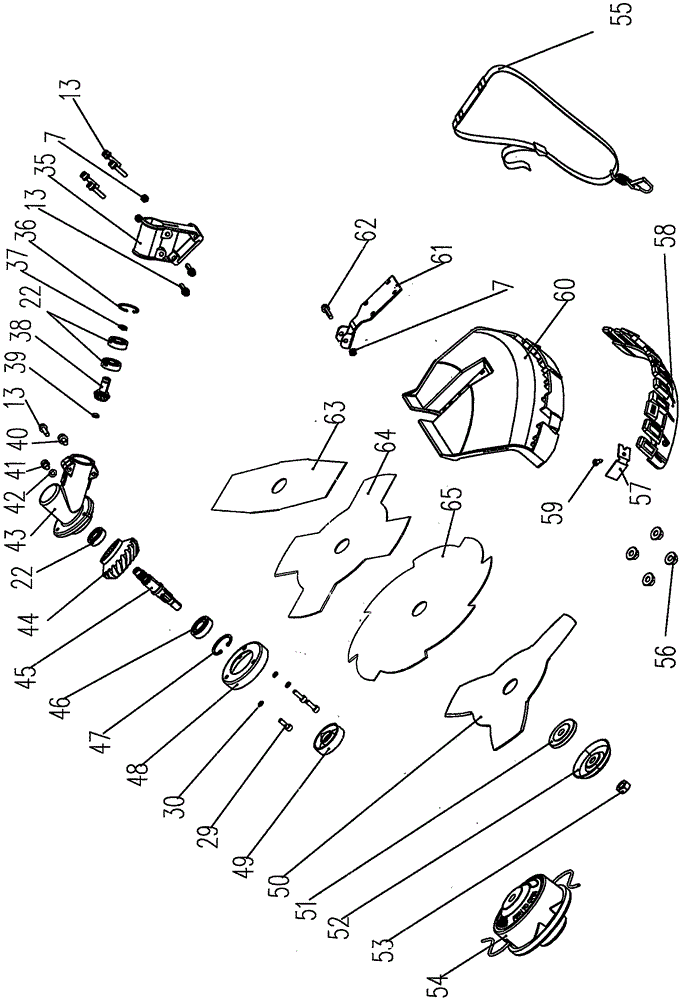

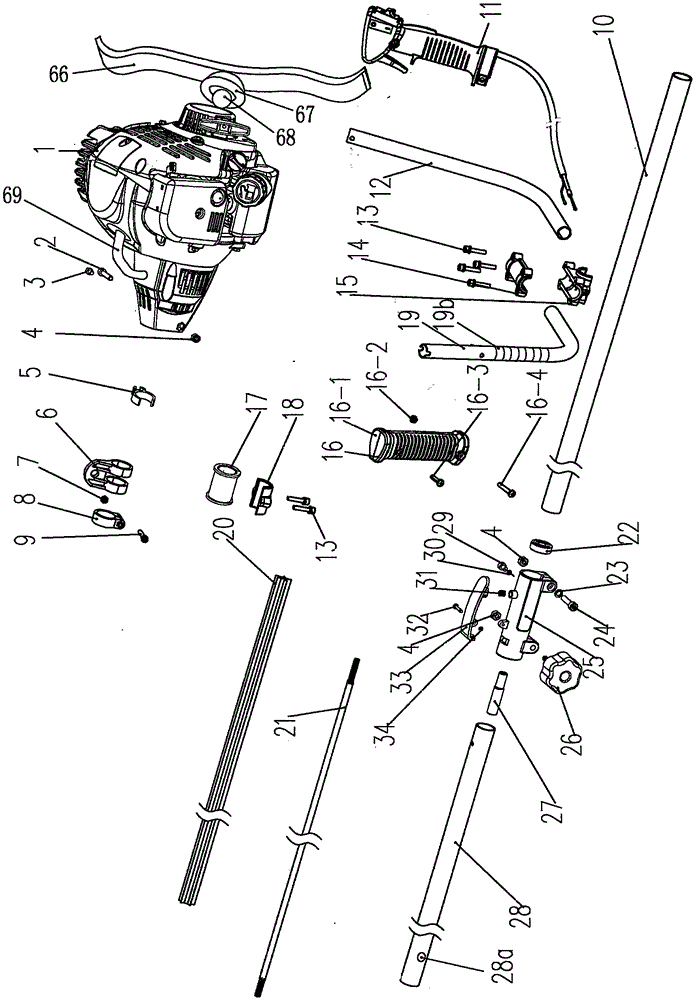

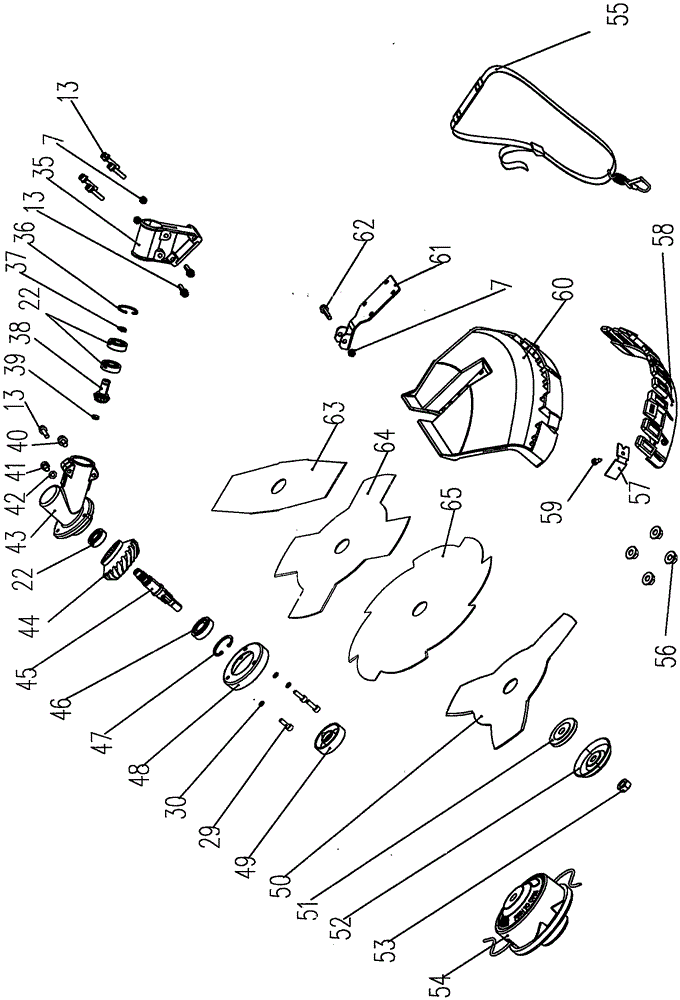

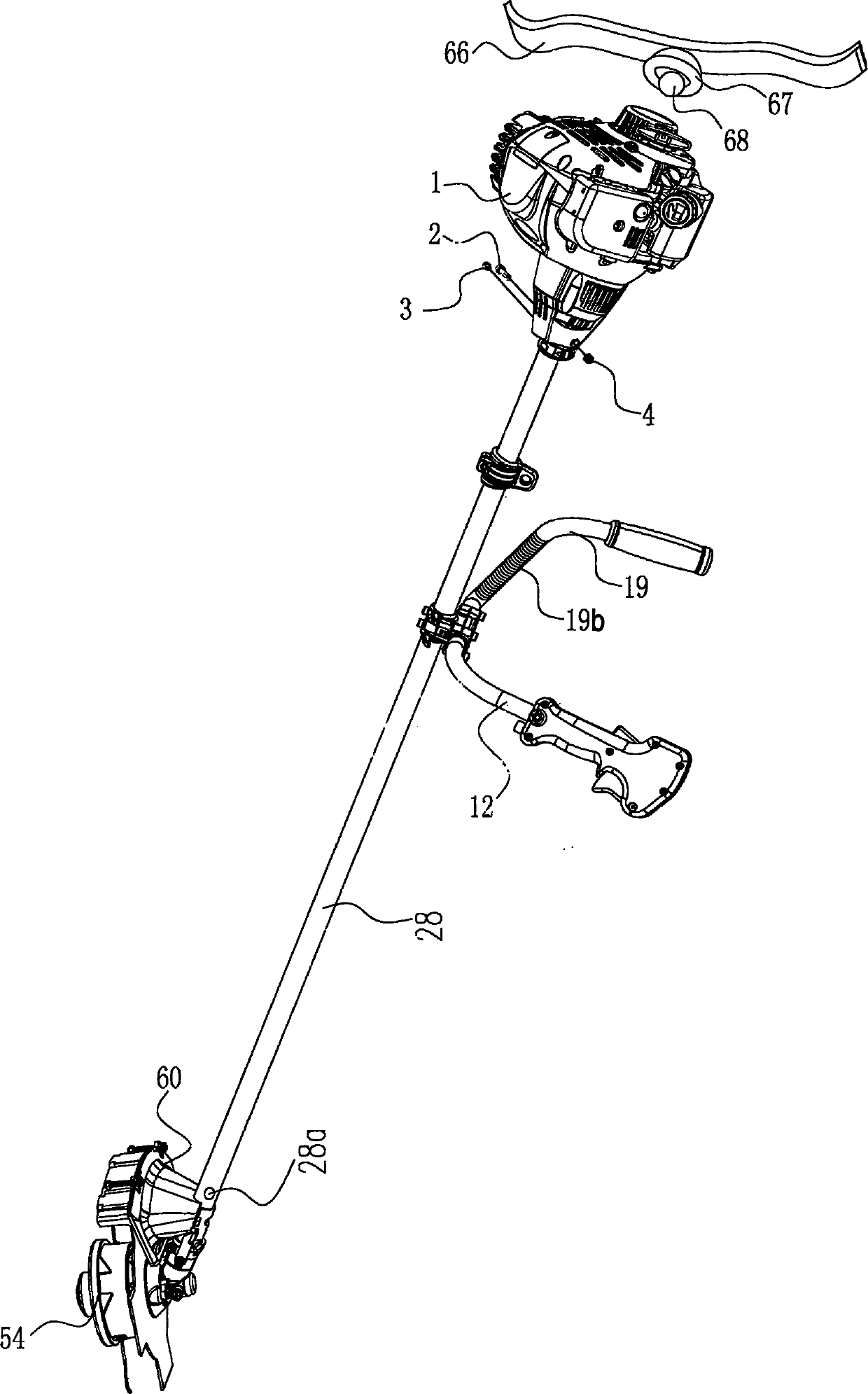

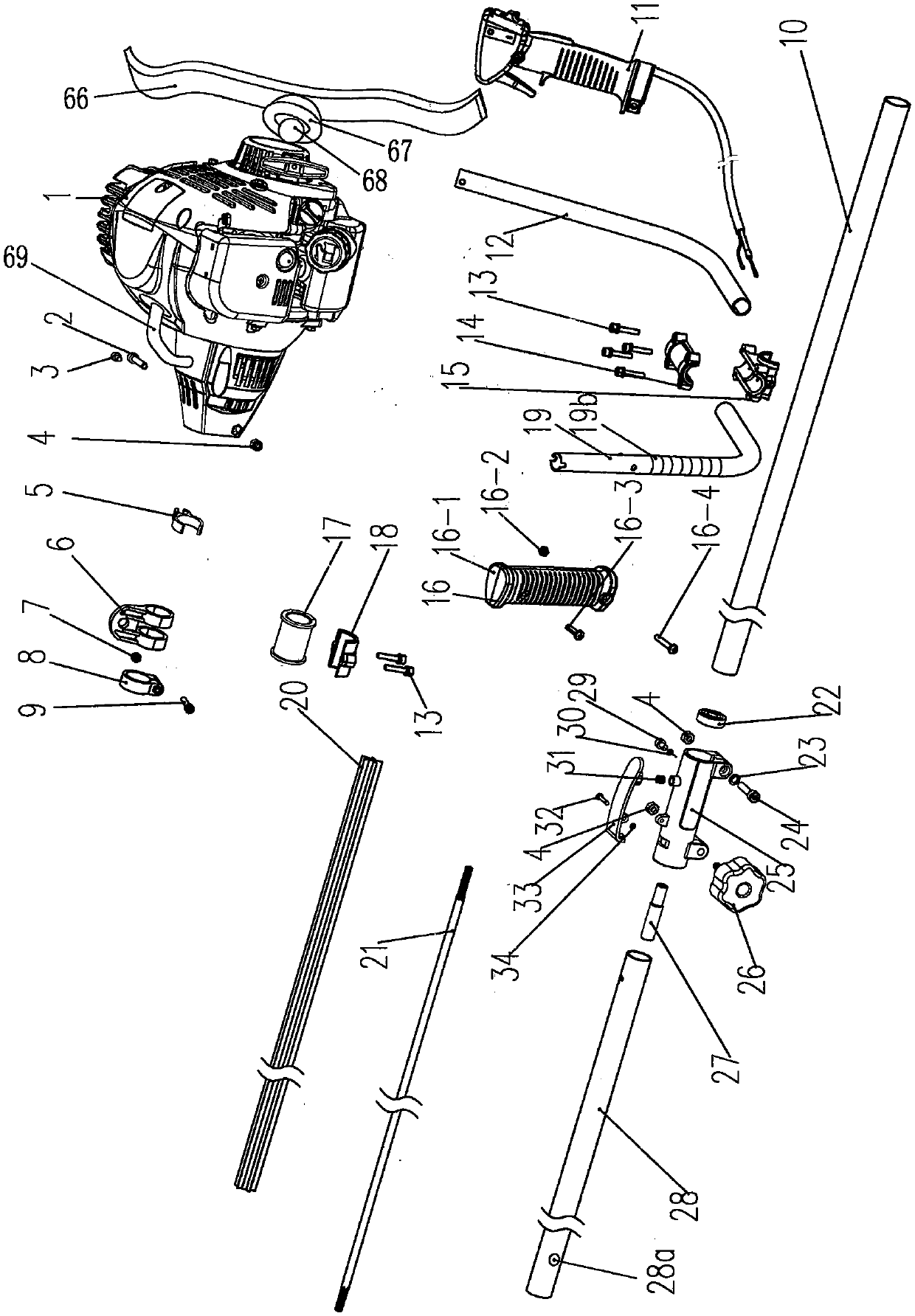

Grass trimmer having semi-balance deflection angle and provided with parabolic wing blade LPG (liquefied petroleum gas) engine

InactiveCN105626233AImprove qualitySolve the axial movementCasingsInternal combustion piston enginesLawnFlywheel

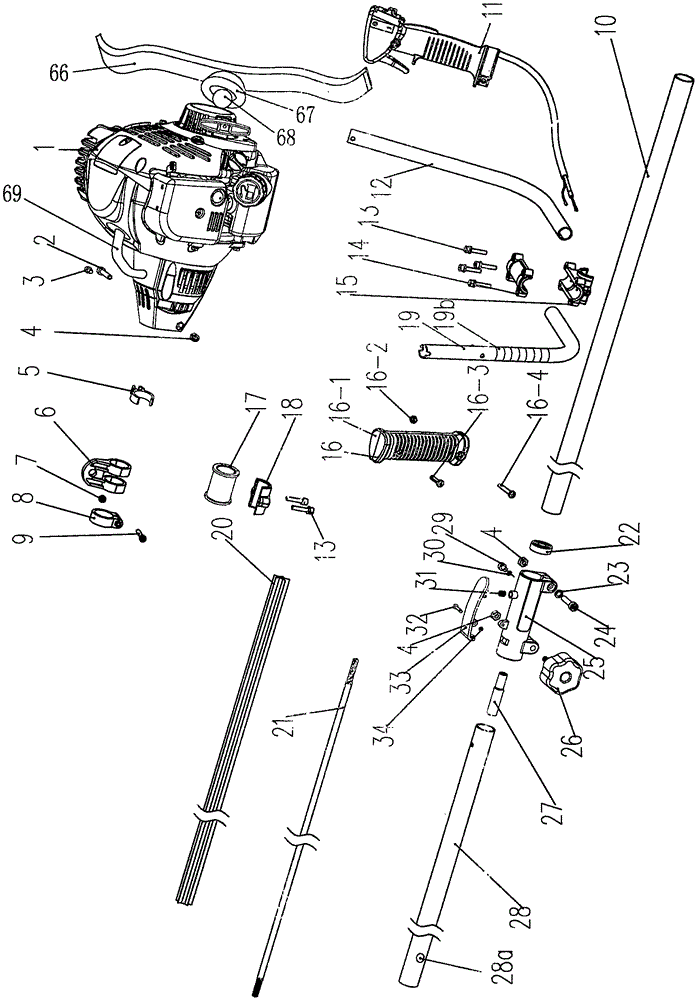

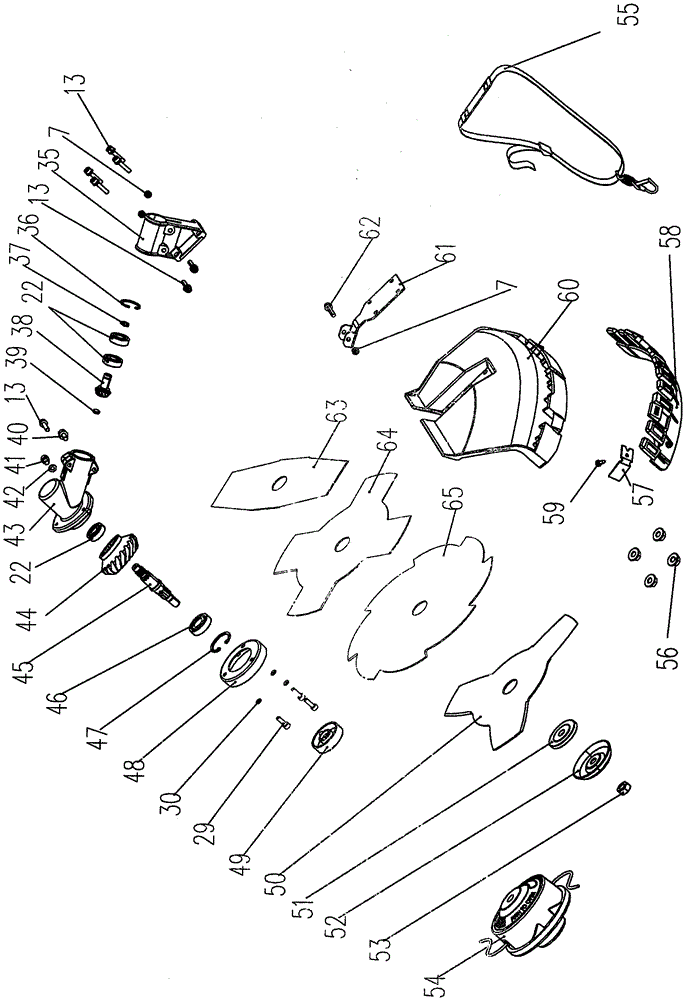

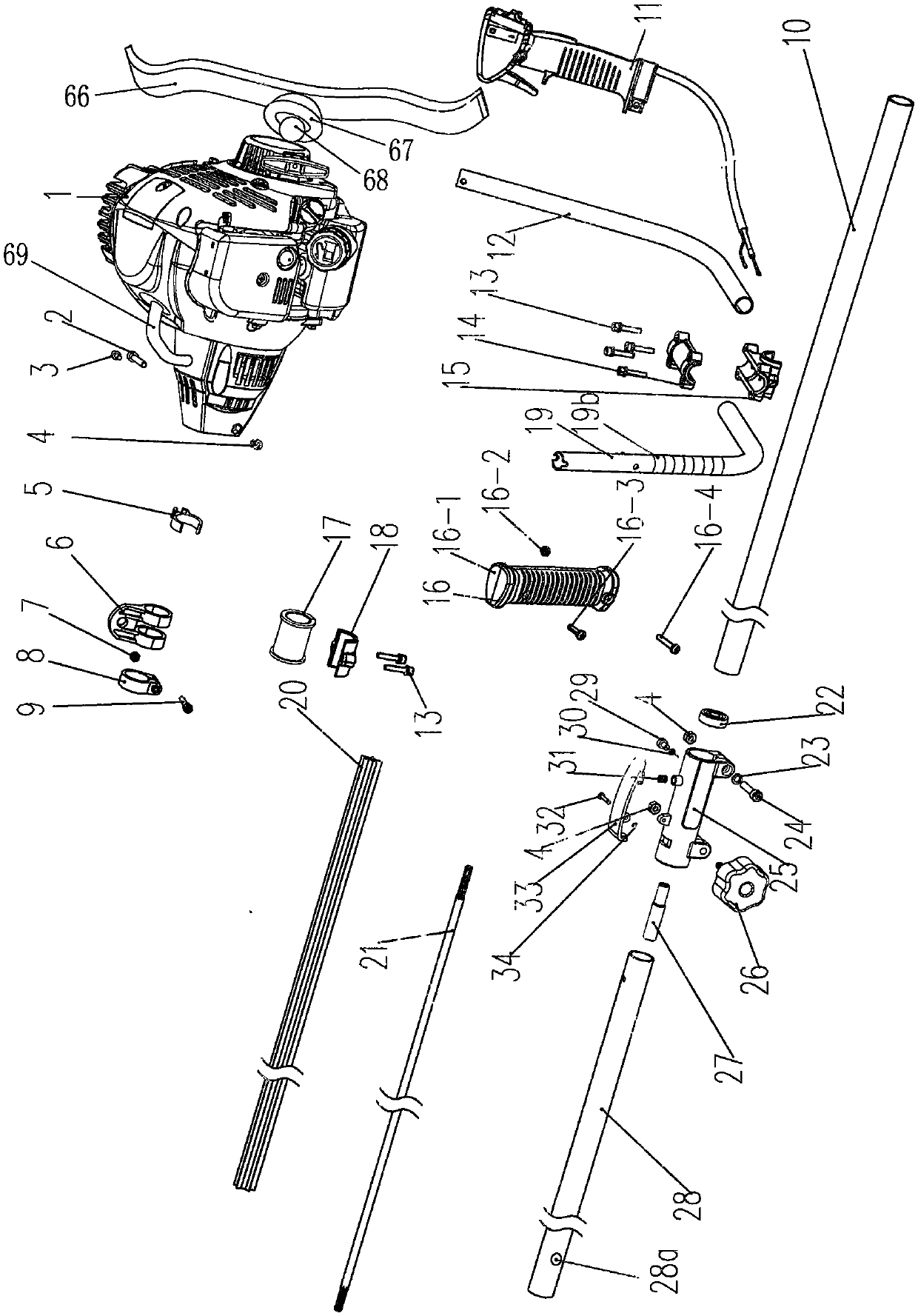

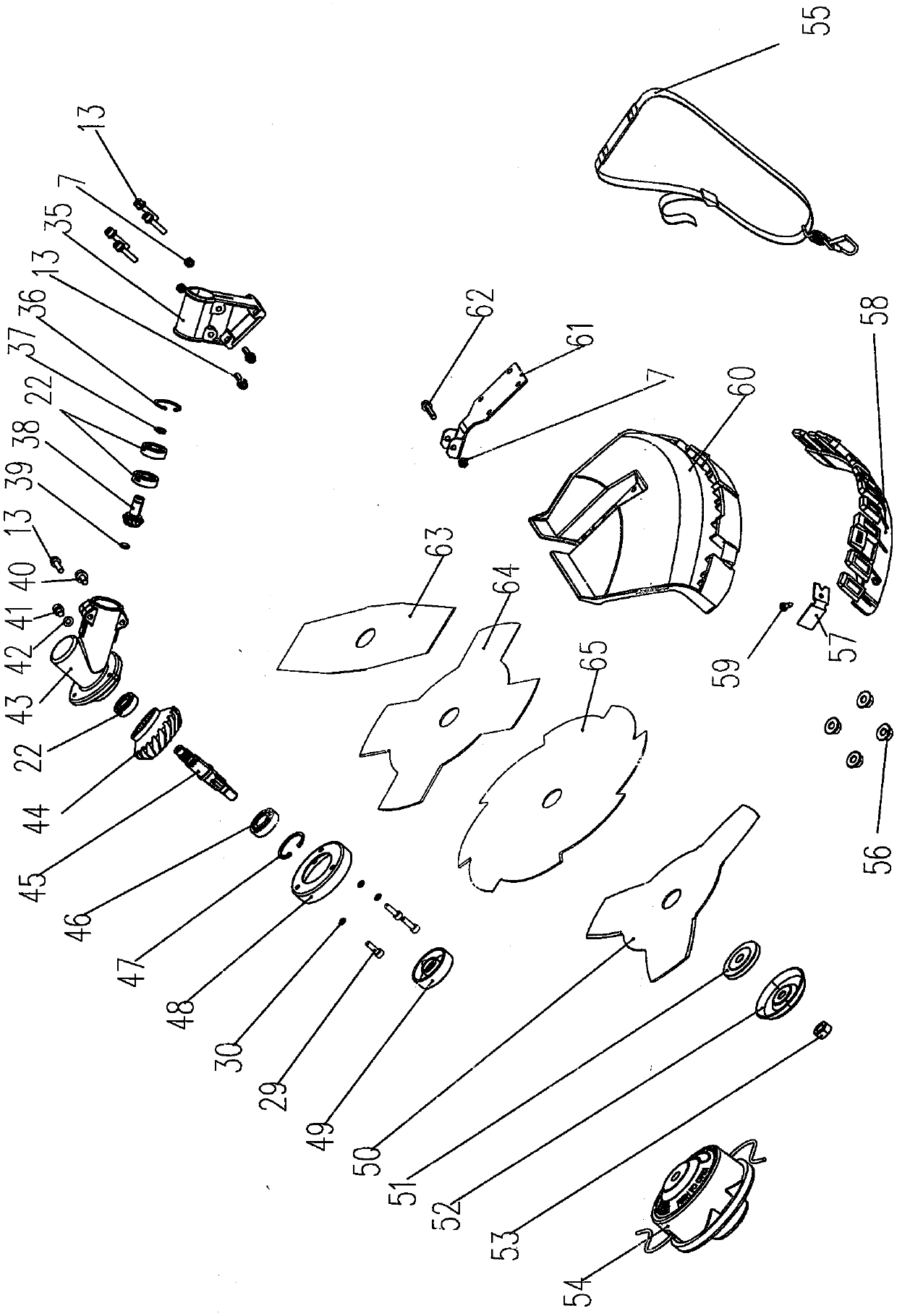

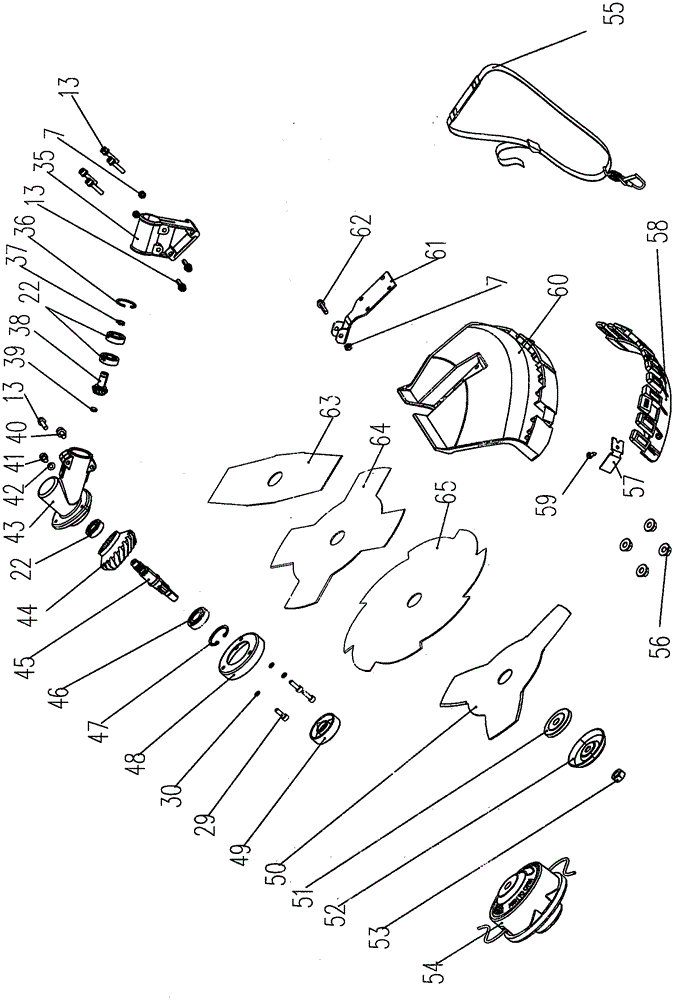

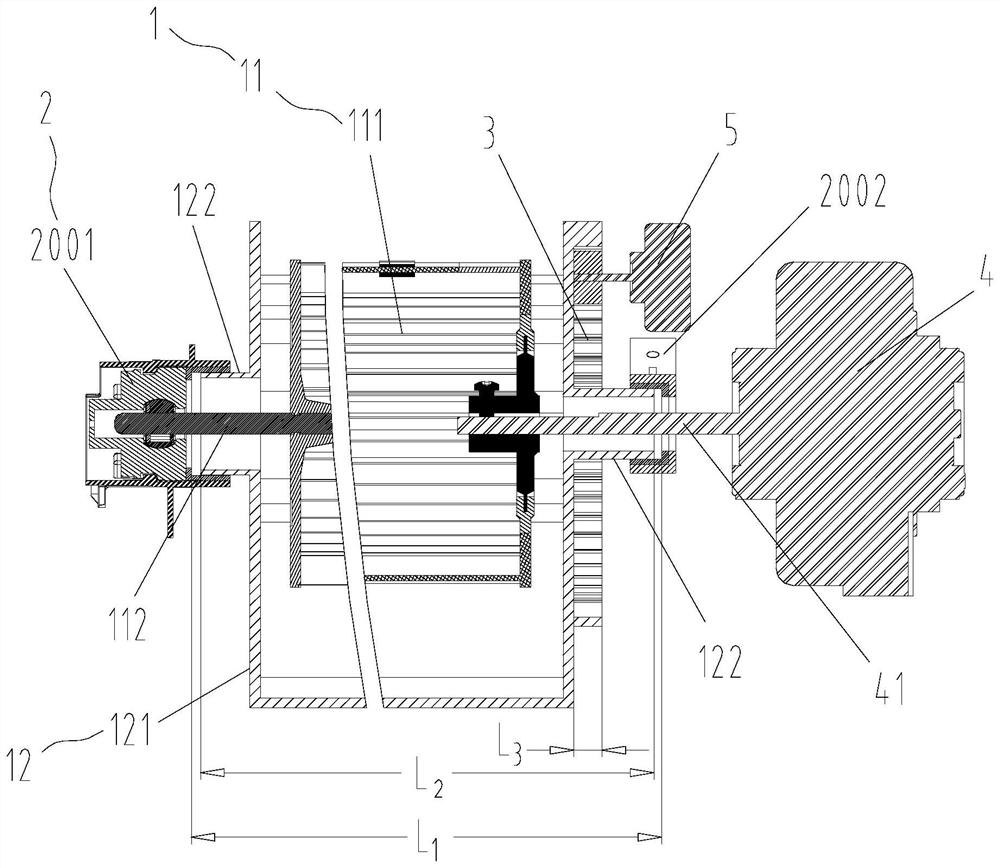

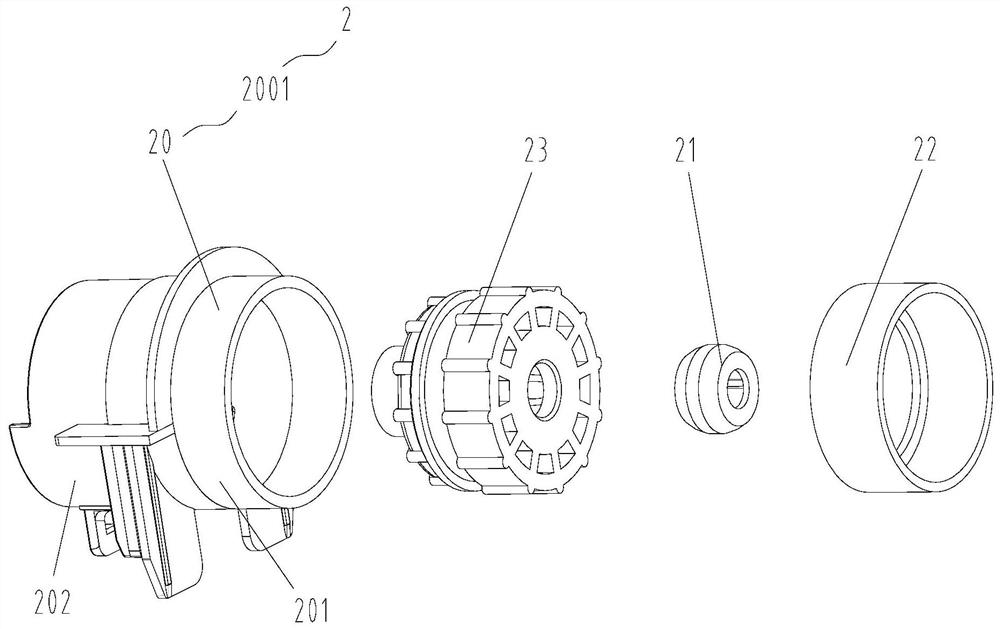

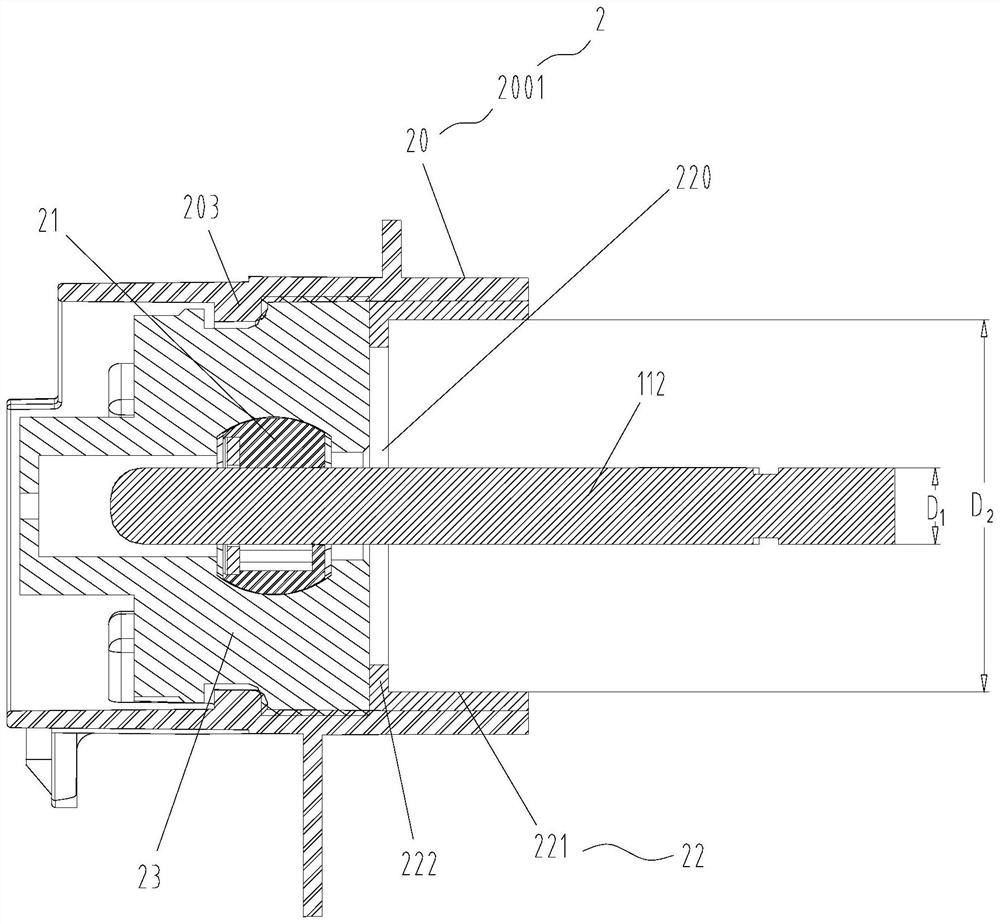

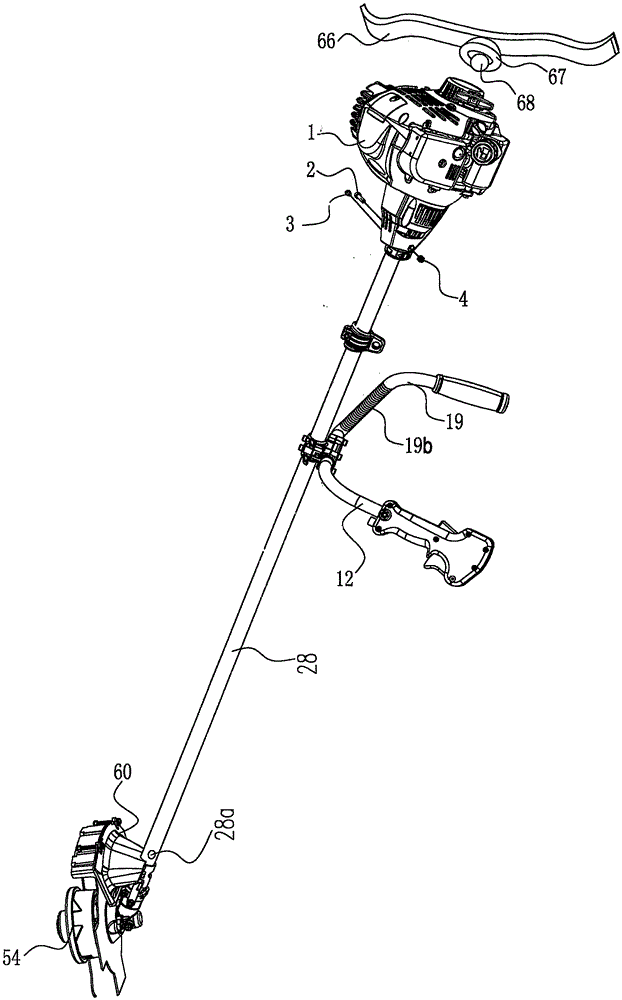

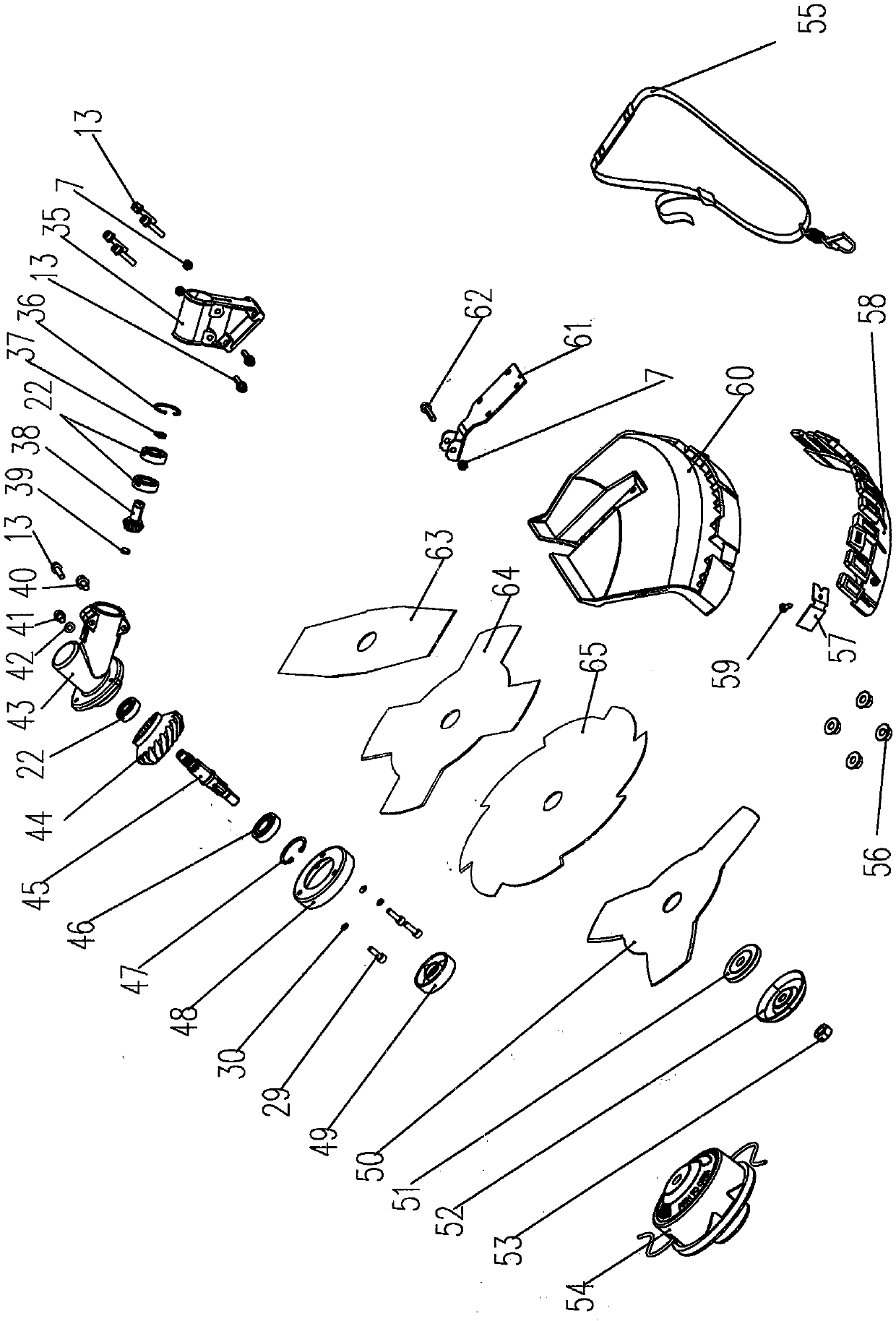

The invention discloses a grass trimmer having the semi-balance deflection angle and provided with a parabolic wing blade LPG (liquefied petroleum gas) engine and solves the problem of axial movement for the original taper of a magnetic flywheel. According to an equation for arcs of blades, the bending angle is 18 degrees, the chord length b is 20, the ratio of a to b is 0.45, and a refers to the maximum deflection point on the bow; an intermediate technician can make a mold module for the wing section contour line. Outer ends of the blades are sharp ends and have cutting edges, so that entangled materials can be cut off conveniently. The balance deflection angle (phi) exists between an angle bisector of the central angle from two sides of an opening, where a C-shaped ring (56a) of a crankshaft valve (56) is mounted, of a crankshaft (57) to a circle center of the crankshaft and a central connecting line from the circle center of the crankshaft to a large-end circle center of a connecting rod and is in the range of 2-22 degrees, and the single-cylinder semi-balance is improved. A cutter is provided with an outer protecting cover (73) mounted on an inner protecting cover (60), and a long grass pressing wheel (74) with the roller length equal to the grass trimming diameter is arranged on the outer protecting cover of the cutter, so that grass pressing water retention and grassland pattern pressing are facilitated; multiple sharp edges (54a) are arranged on a buttress cutting and grass trimming steel wire (54b) of a grass trimming head (54) of the cutter and cut out on the steel wire by a sharp flat-ended chisel under hammering.

Owner:NINGBO DAYE GARDEN EQUIP

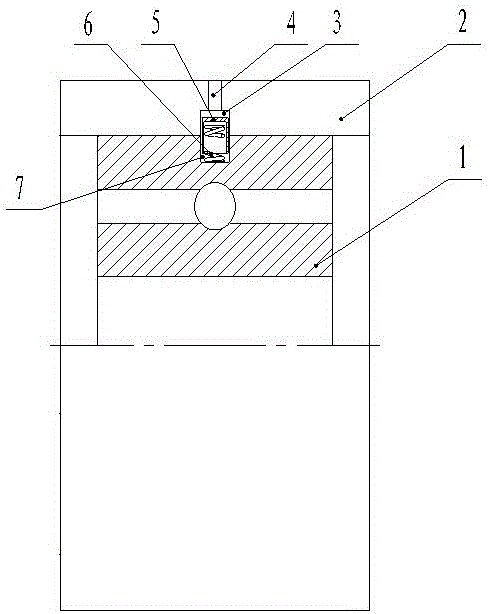

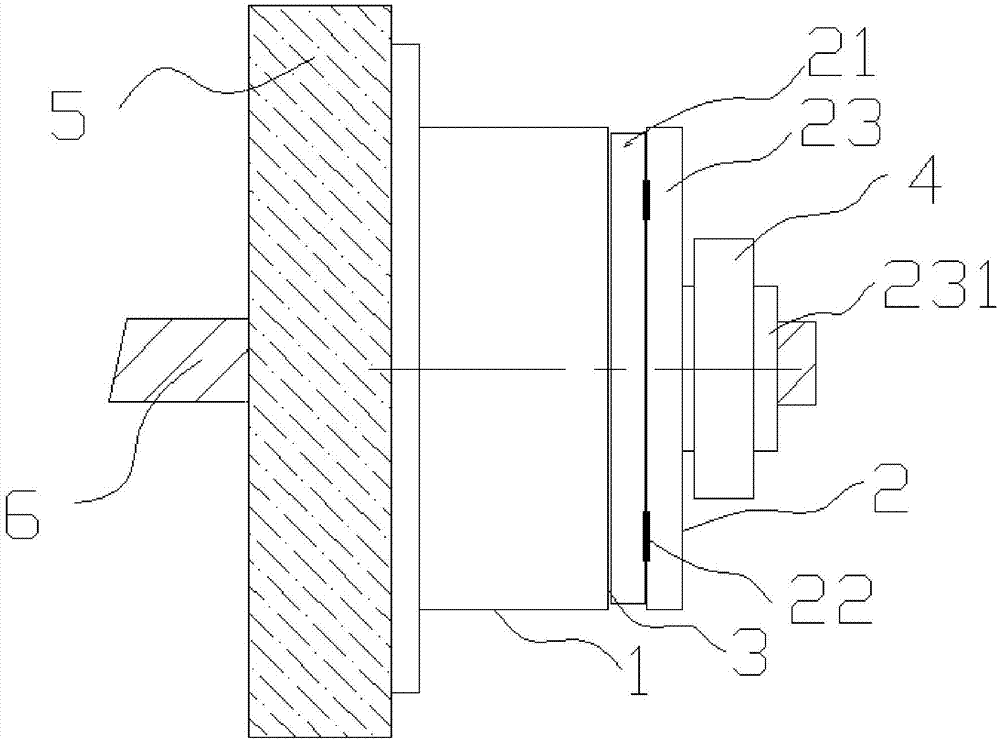

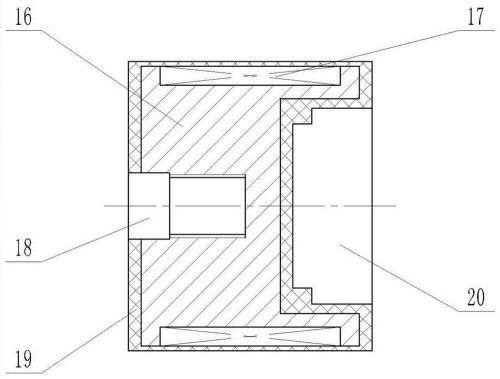

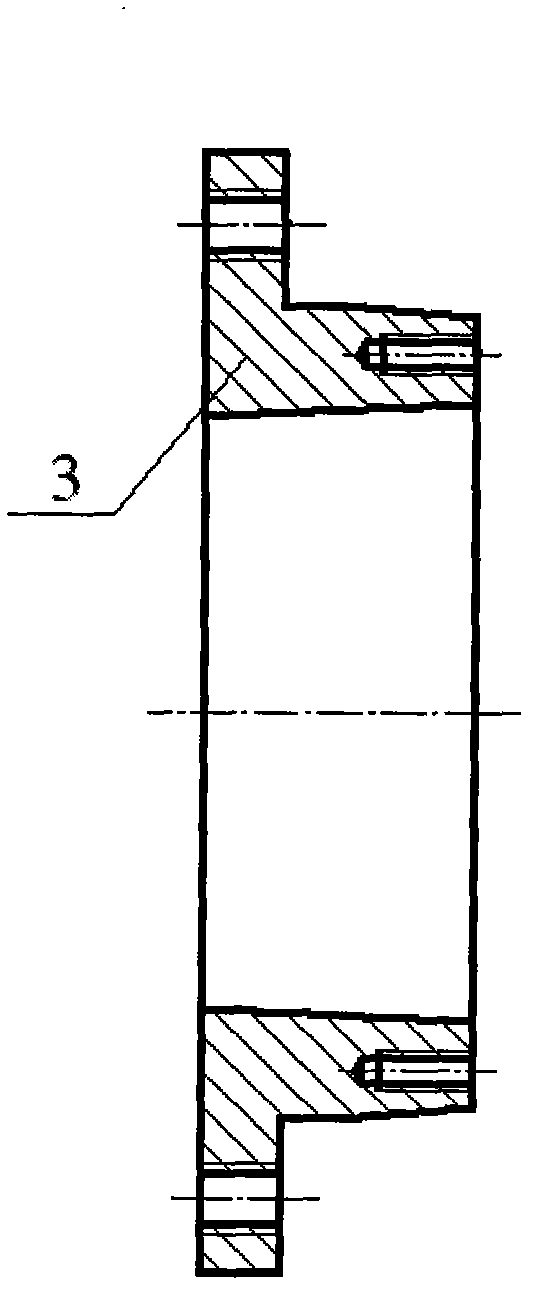

Bearing axial fixing device

The invention relates to a bearing axial fixing device. The fixing device comprises a bearing, a mounting body, an upper mounting hole, a loading / unloading hole, a sleeve, a spring and a lower mounting hole; the lower mounting hole is formed in the outer surface of the bearing; the upper mounting hole is formed in the inner surface of the mounting body; the mounting body coats the outer surface of the bearing; the sleeve is a cylindrical structure, and coats one end of the spring; the spring is a cylindrical spring, and is matched with an inner hole of the sleeve; the loading / unloading hole is formed in the corresponding position of the outer surface of the mounting body, and is communicated with the upper mounting hole; the axial height of the sleeve is smaller than the length of the lower mounting hole by 1-2 mm; and the length of the spring in the natural state is longer than the length of the lower mounting hole by 3-5 mm. The fixing device is designed by technicians according to problems generated in actual use of the bearing, is simple in structure and convenient for use, can be widely applied to bearings with different types, and solves the problem of axial movement of traditional bearings during working.

Owner:GUIZHOU HONGZHOU BEARING CO LTD

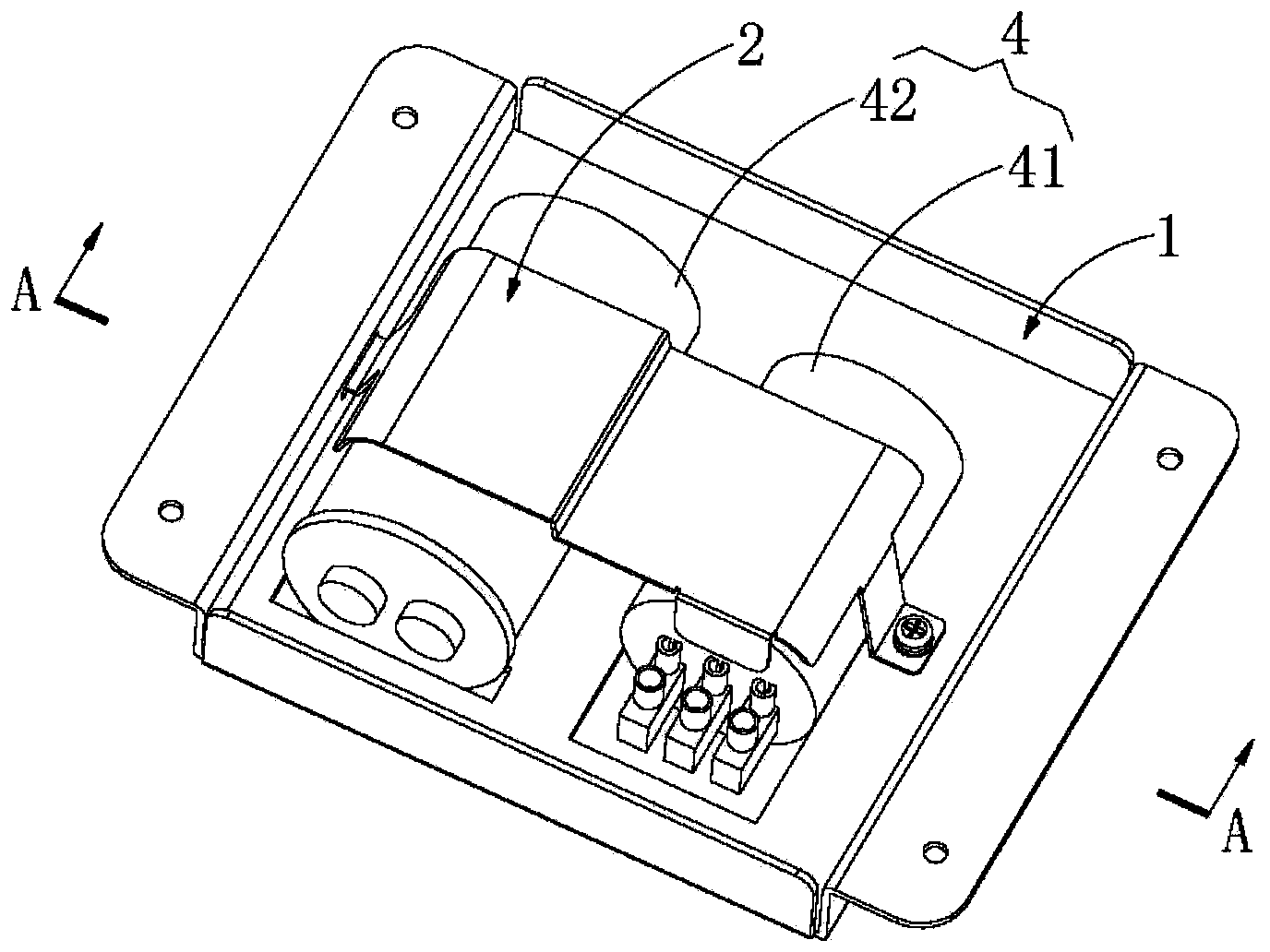

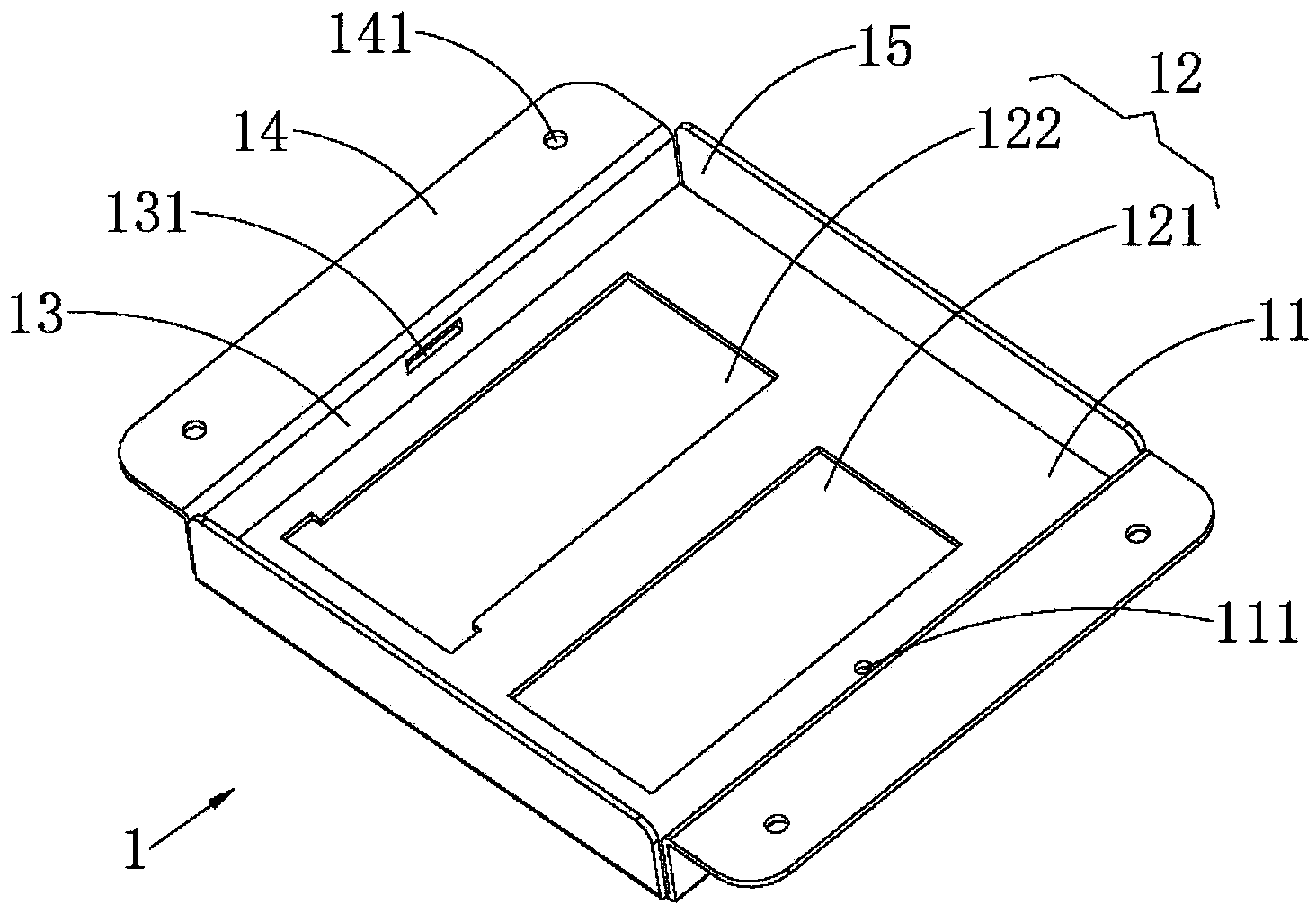

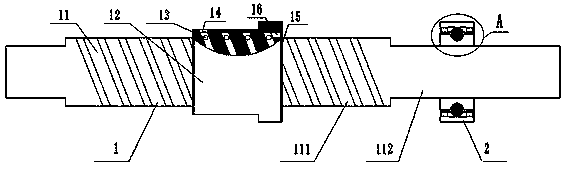

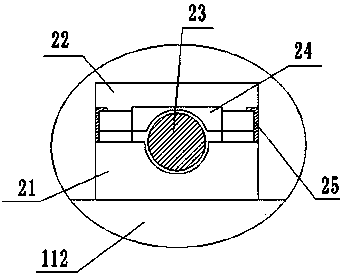

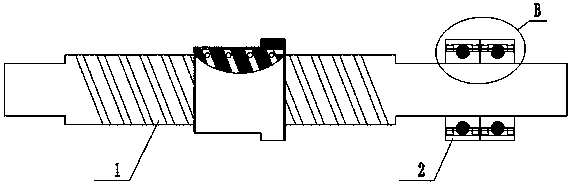

Photomultiplier installation protection structure

InactiveCN102110575ASolve the axial movementAvoid the problem of strong light damageElectron multiplier detailsLight irradiationPhotomultiplier

Owner:THE THIRD RES INST OF MIN OF PUBLIC SECURITY

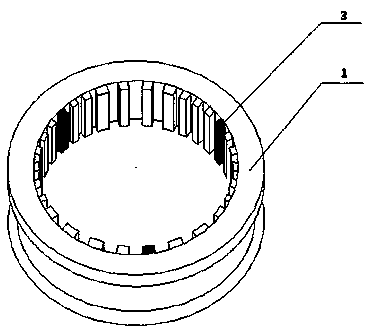

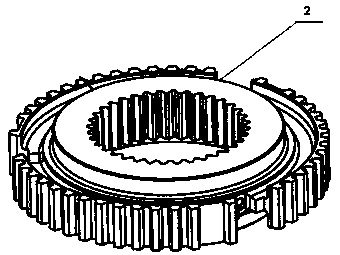

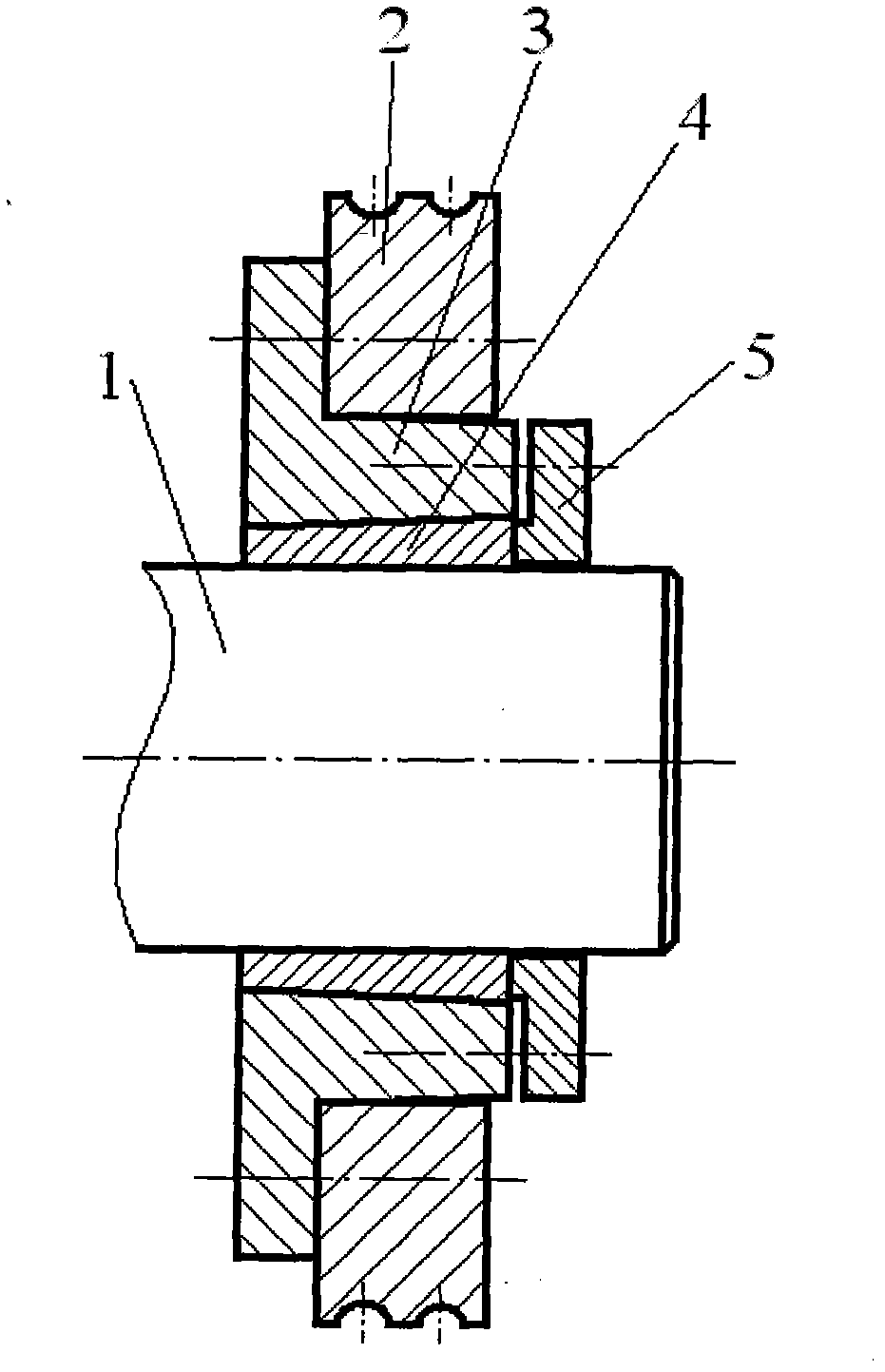

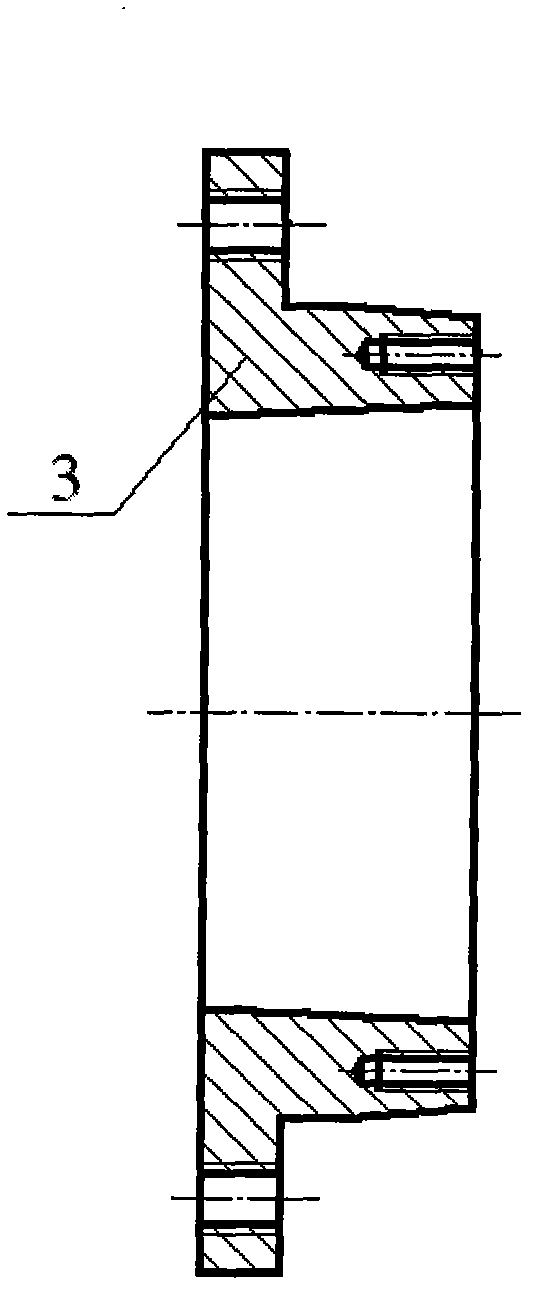

Synchronizer assembly for truck and machining technology thereof

InactiveCN109027035AImprove toughnessImprove wear resistanceMechanical actuated clutchesHobbingEngineering

The invention relates to a synchronizer assembly for a truck and a machining technology thereof, and belongs to the technical field of truck synchronizer and machining thereof. The synchronizer assembly comprises a gear sleeve and a gear core. The gear core is embedded in the gear sleeve, and the gear core and the gear sleeve are fixed and limited through a limiting device. The limiting device iscomposed of a sliding block, a sliding block mounting groove and an elastic element, and the sliding block is installed in the sliding block mounting groove through the elastic element. The sliding block mounting groove is formed in the gear sleeve. Gear teeth matched with the sliding block mounting groove are arranged on the outer surface of the sliding block. The machining technology comprises the following steps that the gear sleeve and the gear core are subjected to the processes such as normalizing, rough turning, finishing turning, gear hobbing, gear shaping and anti-rust oil applying, then are subjected to carburizing heat treatment, and then are subjected to polishing, ultrasonic cleaning, assembling, anti-rust oil applying and packaging, and a finished product is obtained. The prepared synchronizer assembly has the advantages that synchronize axial movement is not prone to occurring, the service life is long, abrasion is not prone to occurring, and the strength is high.

Owner:福建省真发齿轮股份有限公司

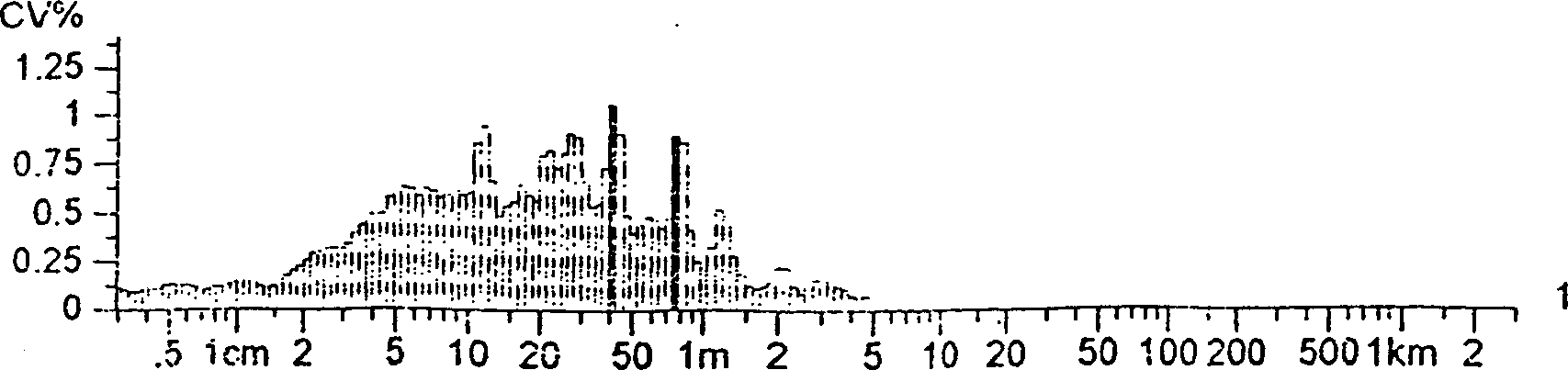

Technology for applying duplex angle for contacting ball bearing of cutting part of board cutting machine

InactiveCN1970253ASolve the axial movement of the saw bladeSolve the waviness patternCircular sawsPass rateEngineering

The match corner joint contact ball bearing for board cutting applies small axle direction lash 0.022-0.03mm match corner contact ball bearing as the bearing of the fastening end of the spanner cutting section to improve the appearance of the final product. It improves the sawing quality, with improved cosmetics and pass rate of the product.

Owner:SHANGHAI WOOD-BASED PANEL MASCH CO LTD

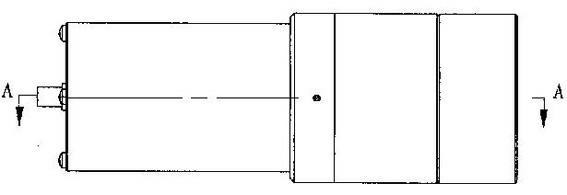

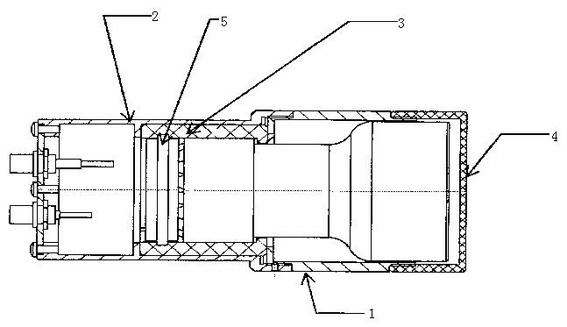

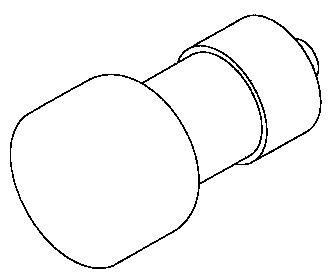

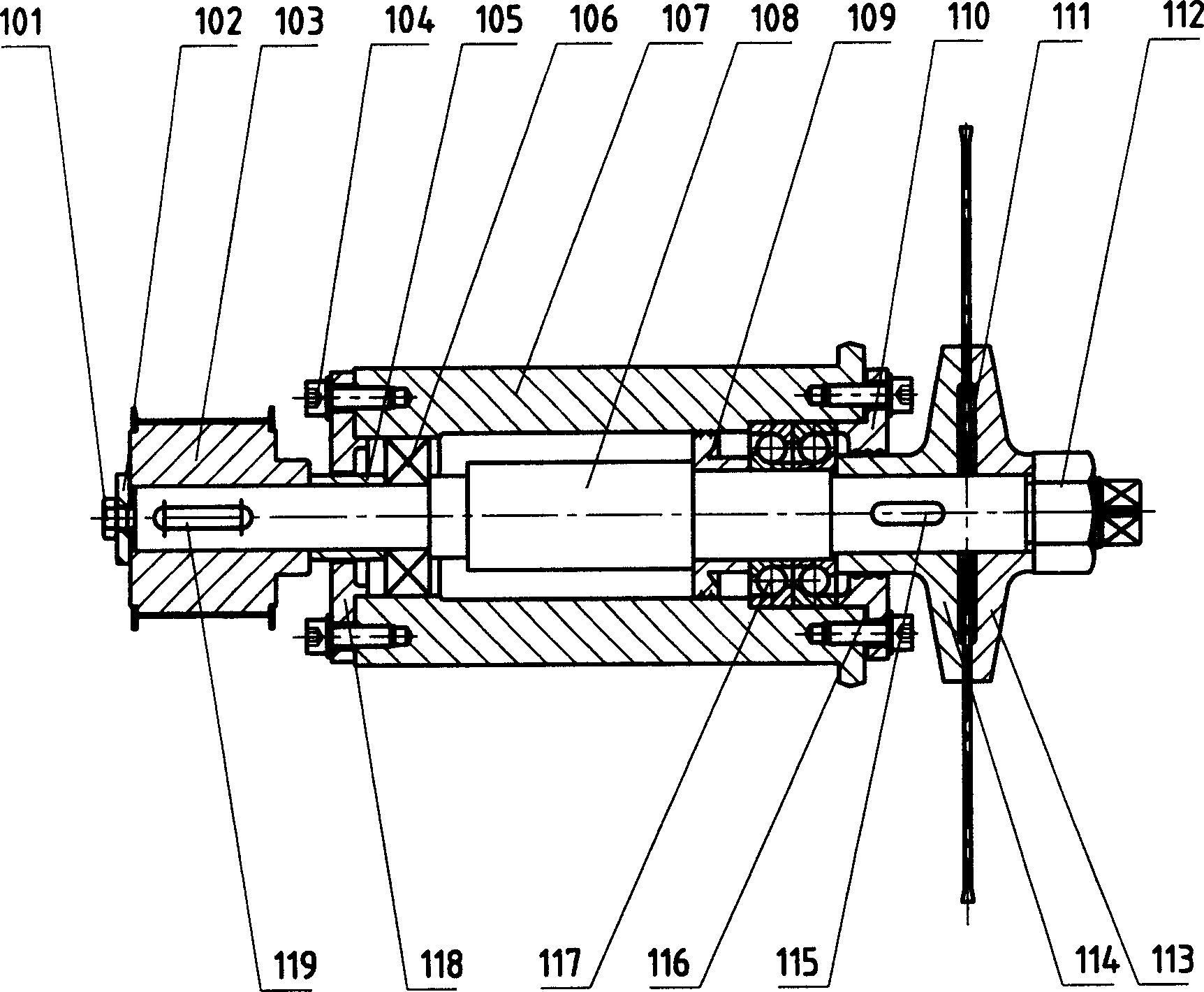

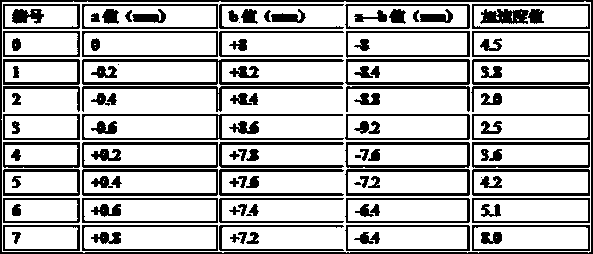

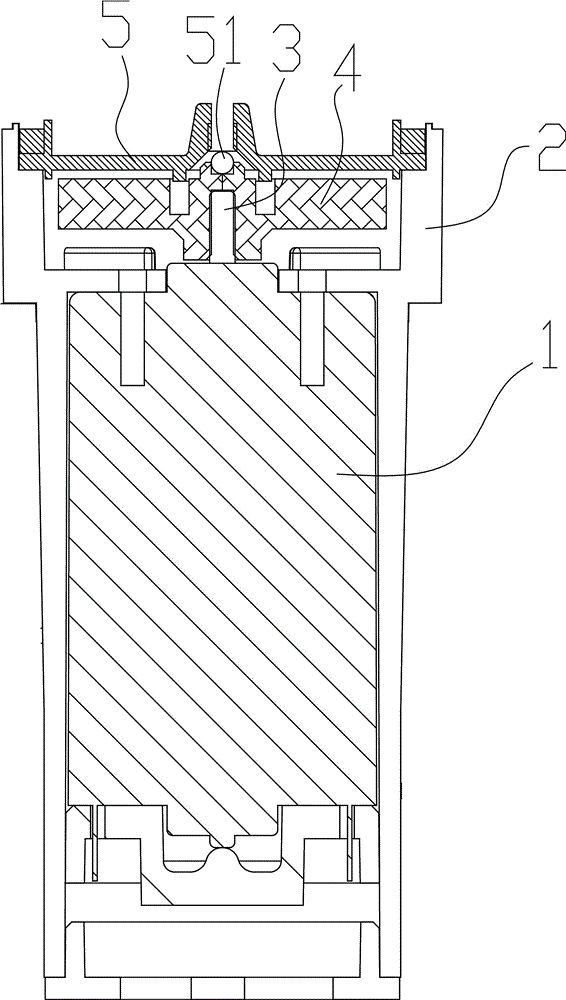

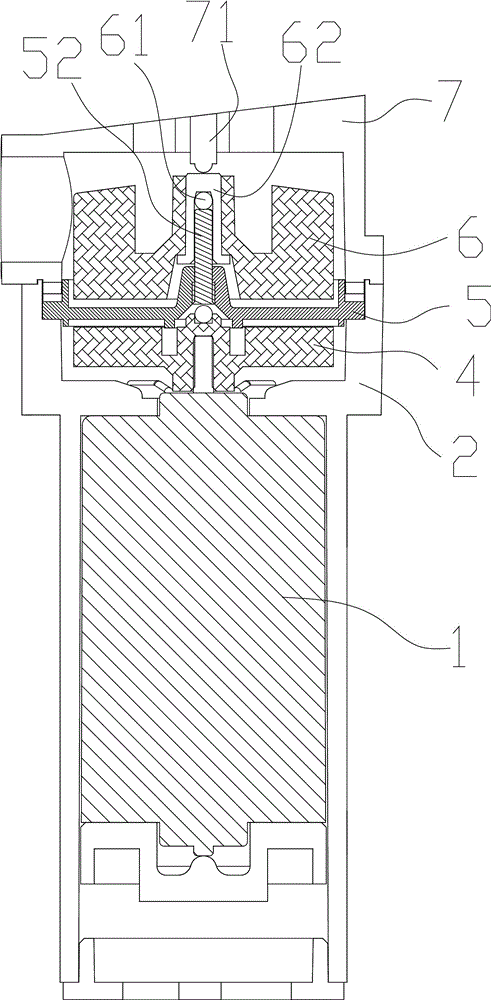

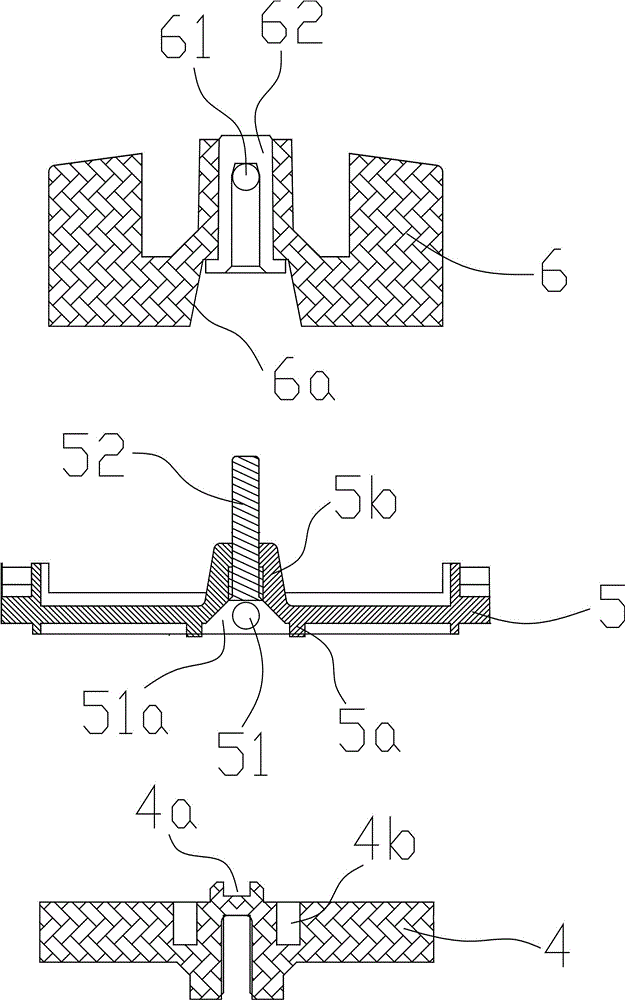

Gasoline engine of semibalance parabola-shaped mean camber line wing blade with single cylinder

InactiveCN105545460AImprove qualitySolve the axial movementSparking plugsCasingsDeflection angleEngineering

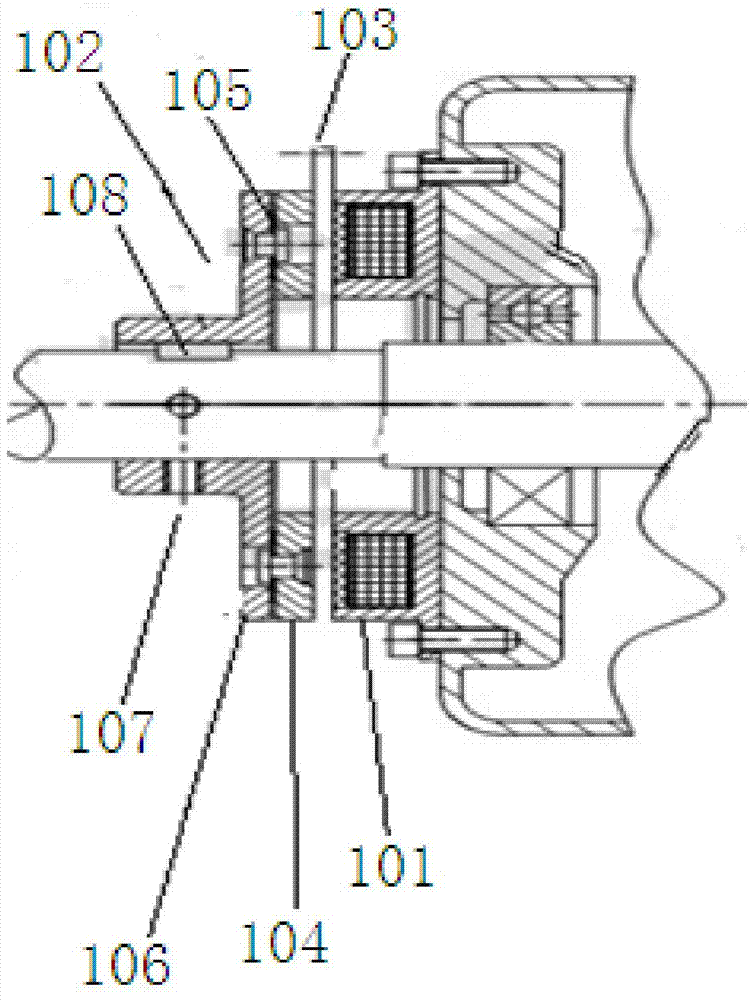

The invention discloses a gasoline engine of a semibalance parabola-shaped mean camber line wing blade with a single cylinder. A silencer assembly (F7) of a catalyst-contained silencing pipe (69) is installed on the two-stroke gasoline engine through a silencer pad (F8). An internal outlet (F7C2) of an internal metal cover (F7C1) is formed in an outlet of the silencer assembly (F7). An external outlet (F7j2) of an external resin cover (F7j1) and a logarithm flow channel (F7j3) are arranged in the outer position, so that double-layer cooling and silencing are facilitated. By the adoption of the gasoline engine, the problem of a magnetic fly wheel that the original taper floats axially is solved. An equation of the arc of the blade is determined; the bending angle is set to be 18 degrees, the chord length b is 20, and a / b=0.45; a is the maximum deflection point of the bow. A middle-rank technician can make a die module of the contour line of the wing-shaped section. The outer end of the blade is a point and is provided with a cutting edge so that entanglements can be cut easily. A balance deflection angle (phi) is formed between the angle bisector from the two side edges of an opening of a C-shaped ring (56a) to the central angle of the circle center of a crankshaft and a central connection line of the circle center of the larger end of a connecting rod, wherein the C-shaped ring of a crankshaft valve (56) is added on the crankshaft (57); the balance deflection angle (phi) ranges from 2 degrees to 22 degrees, and semibalance of the single cylinder is improved.

Owner:NINGBO DAYE GARDEN EQUIP

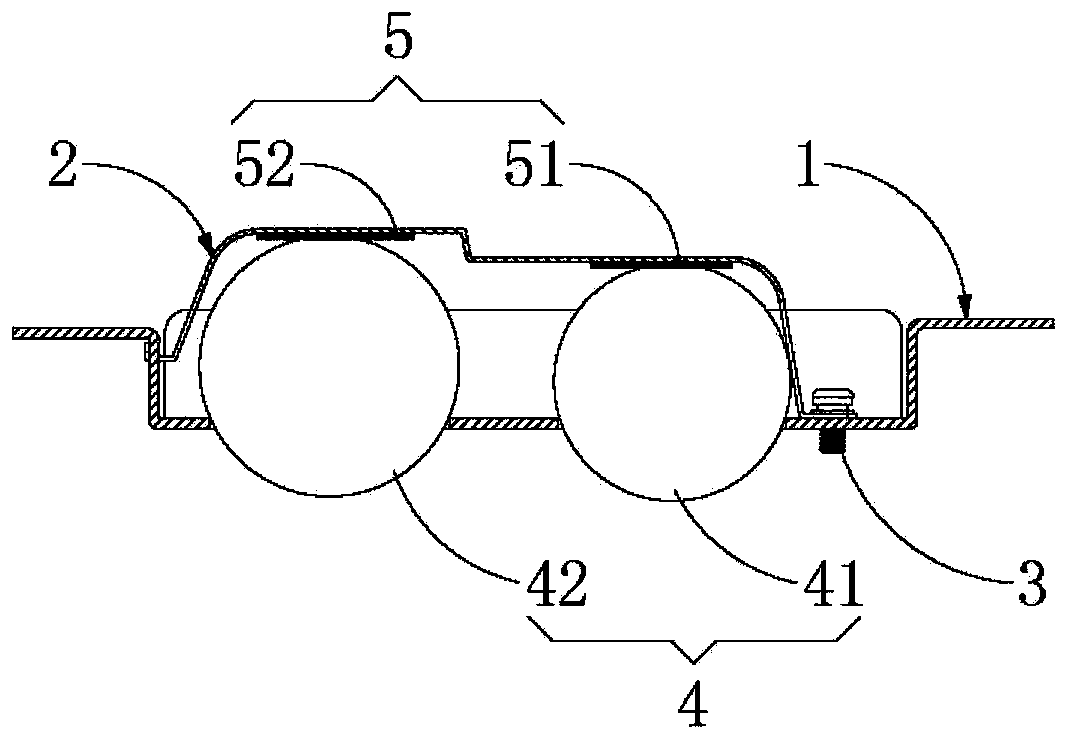

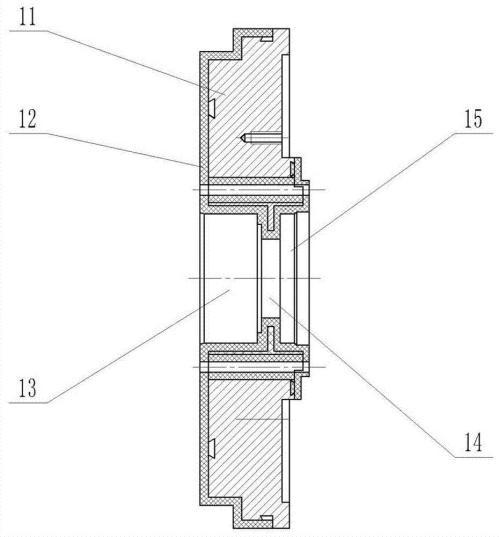

Brake rotor fixing mechanism and installation method thereof

InactiveCN104767320ASolve the axial movementSimple structureManufacturing dynamo-electric machinesBrake actuating mechanismsEngineeringMotor shaft

The invention discloses a brake rotor fixing mechanism and an installation method thereof. The mechanism comprises a stator fixed to an end cover of a motor through a bolt, and a rotor connected with a motor shaft in an integrally formed mode, wherein the stator and the rotor are coaxially installed, the rotor is located on the outer side of the stator, an axial gap is reserved between the stator and the rotor, the rotor comprises an armature, a leaf spring, a flange and a fastening ring, the armature is located on the outer side of the stator, the leaf spring is arranged between the outer side of the armature and the inner side of the flange, a flange boss on the outer side of the flange is connected with the motor shaft in a sleeving mode, an open groove is formed in the flange boss, and the fastening ring is connected to the flange boss in a sleeving mode to squeeze and deform the flange boss so as to clamp the motor shaft. According to the brake rotor fixing mechanism and the installation method thereof, axial movement is avoided, structure is simple, installation is easy, reliability is high, cost is low, the mechanism can be used under positive and negative impact and in a high-vibration environment, and application prospects are broad.

Owner:NANJING KANGNI MECHANICAL & ELECTRICAL

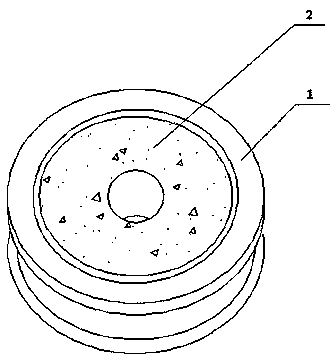

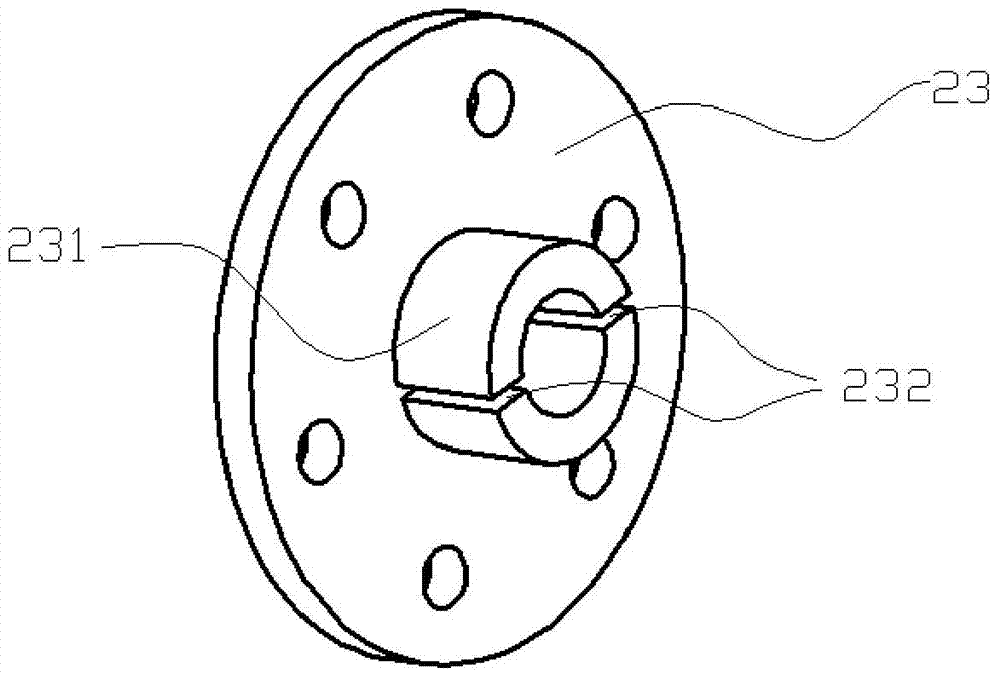

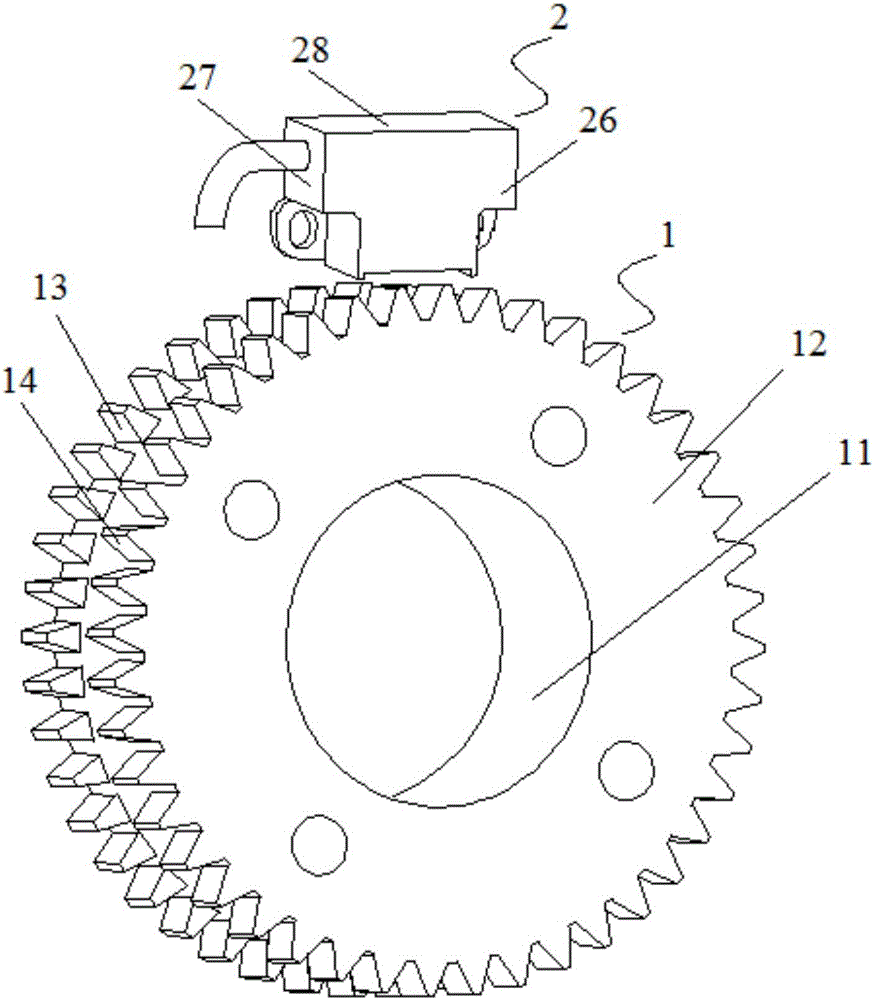

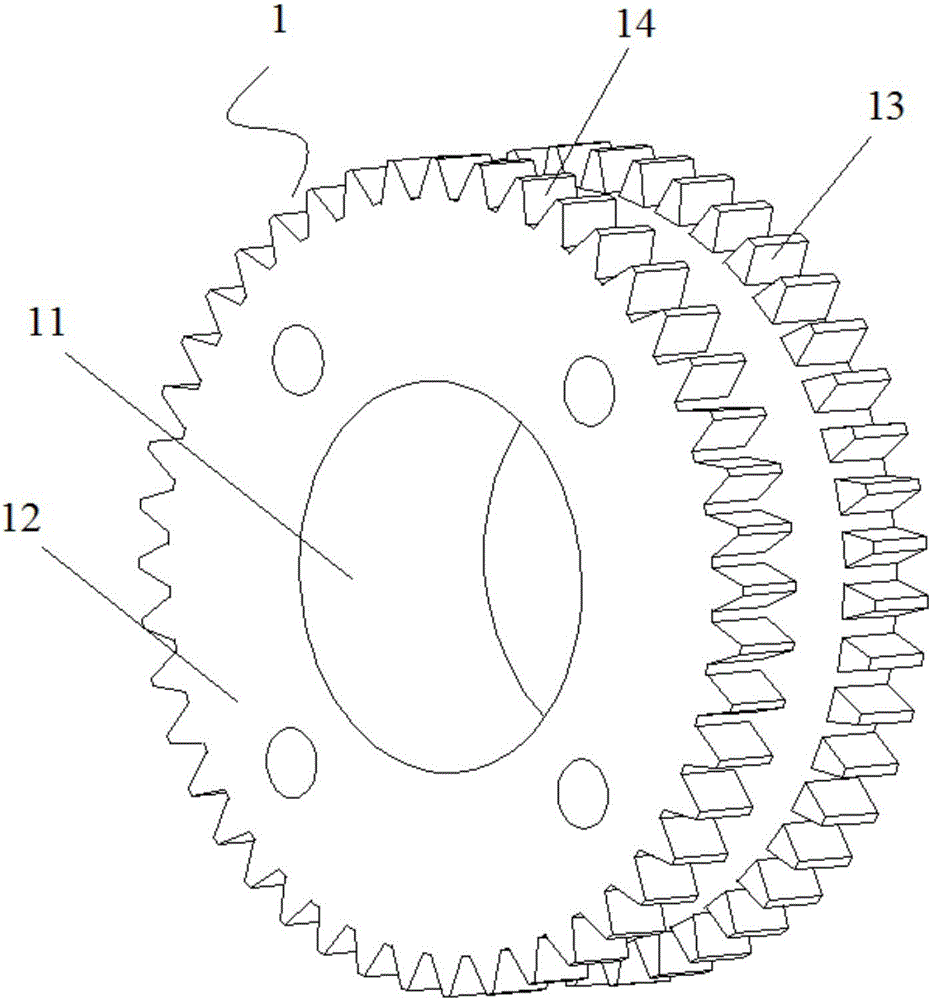

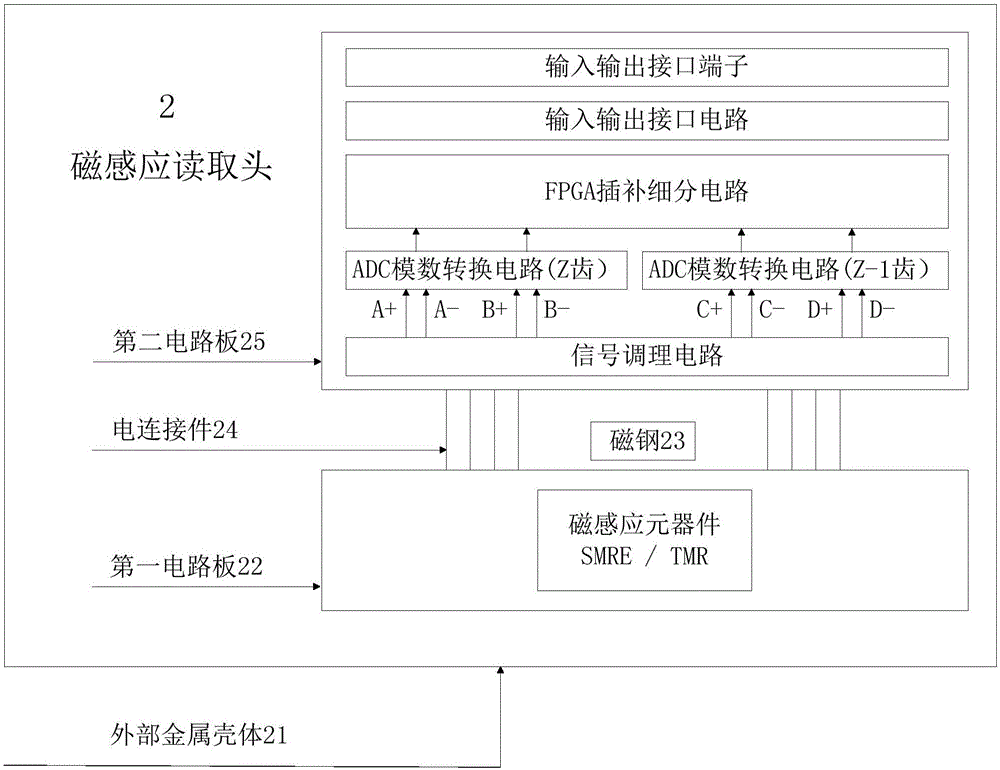

High-speed and high-precision magnetic induction absolute value encoder for machine tool spindle and measurement gear of absolute value encoder

ActiveCN106767956AHigh precisionImprove reliabilityProgramme controlComputer controlSignal conditioning circuitsTime error

The invention relates to a high-speed and high-precision magnetic induction absolute value encoder for a machine tool spindle and a measurement gear of the absolute value encoder. The measurement gear comprises an inner-circle major magnetic track and an outer-circle vernier magnetic track which are arranged in a mutual staggered manner, wherein the inner-circle major magnetic track contains Z teeth, and the outer-circle vernier magnetic track contains (Z-1) teeth; the absolute value encoder comprises the measurement gear and a magnetic induction reading head; a magnetic induction element, a signal conditioning circuit and an FPGA interpolation subdivision circuit are arranged in the magnetic induction reading head; Z and (Z-1) sine and cosine orthogonal differential signals are produced by the magnetic induction element through non-contact scanning of the measurement gear, the signals processed by the signal conditioning circuit are subjected to real-time error correction and compensation by the FPGA interpolation subdivision circuit, so that relative positional values of the number of angle lines are generated respectively for Z and (Z-1) tracks, and the absolute value of the current angle is calculated. The high-speed and high-precision magnetic induction absolute value encoder is simple in structure, high in precision, easy to mount and high in anti-shock capacity, positioning precision and repeated positioning precision of the machine tool spindle are improved remarkably, and the overall measurement precision and machining efficiency of a numerical control machine tool are improved.

Owner:张道勇

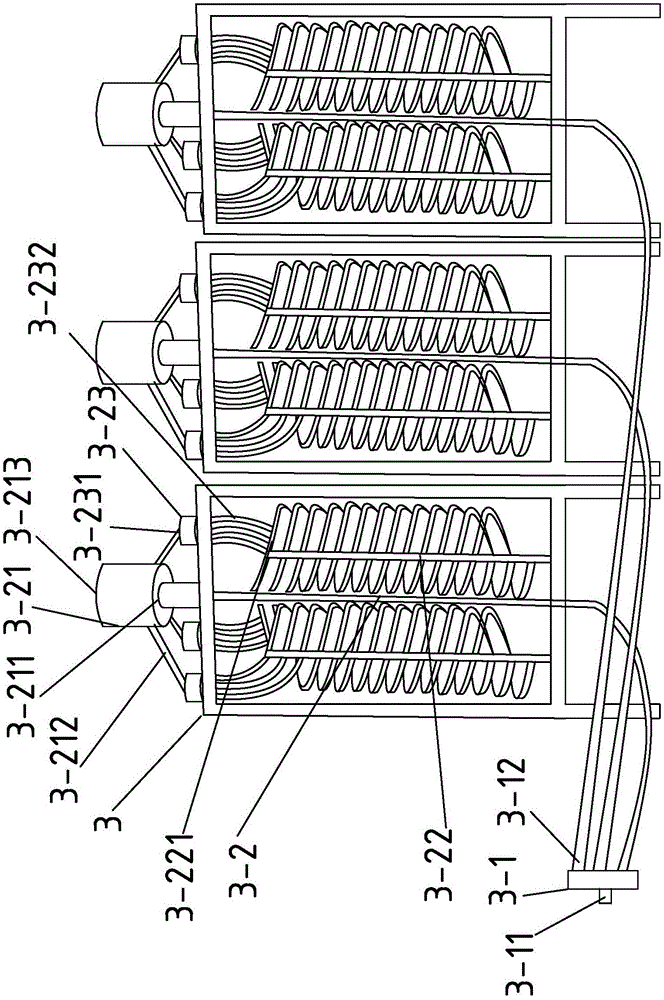

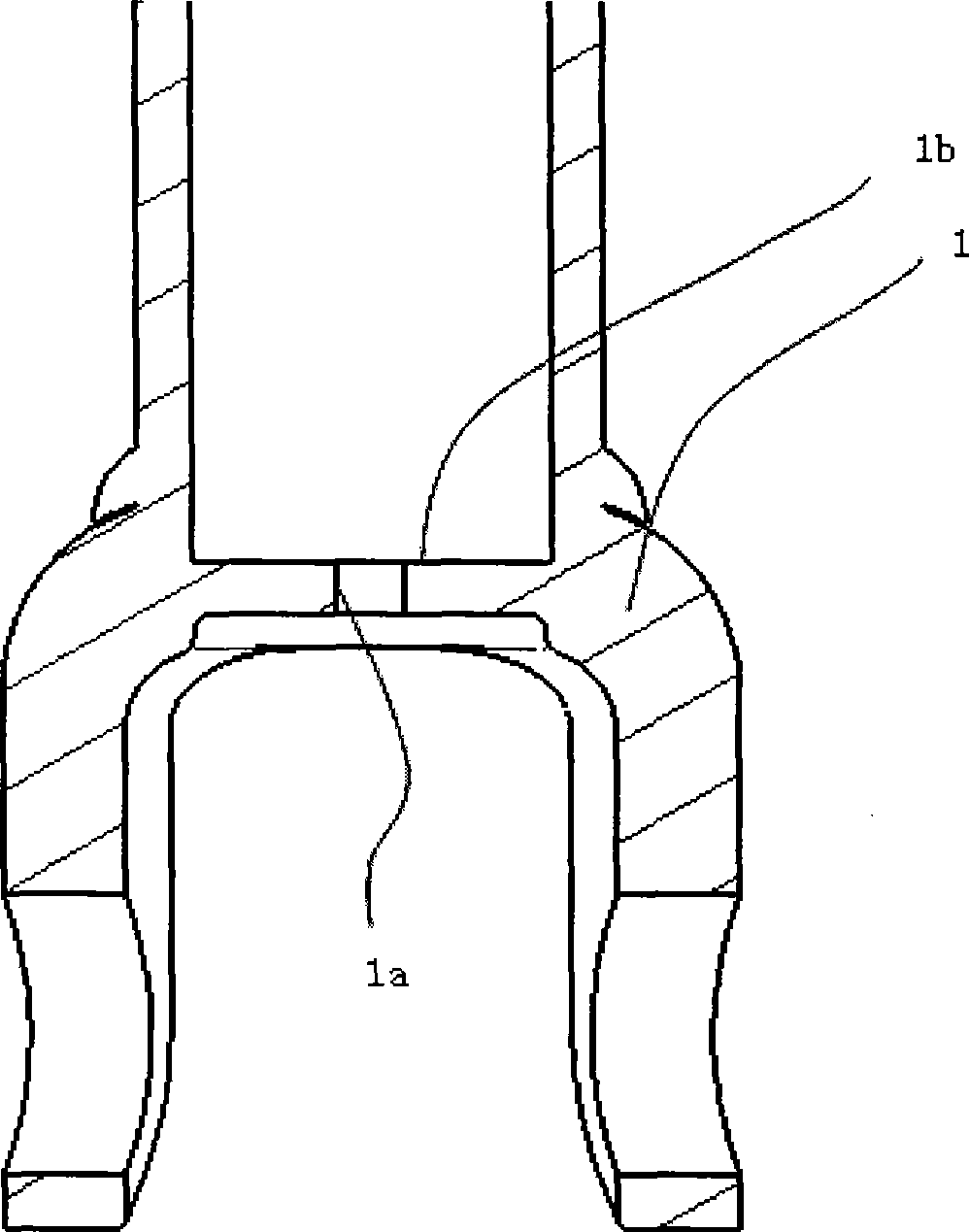

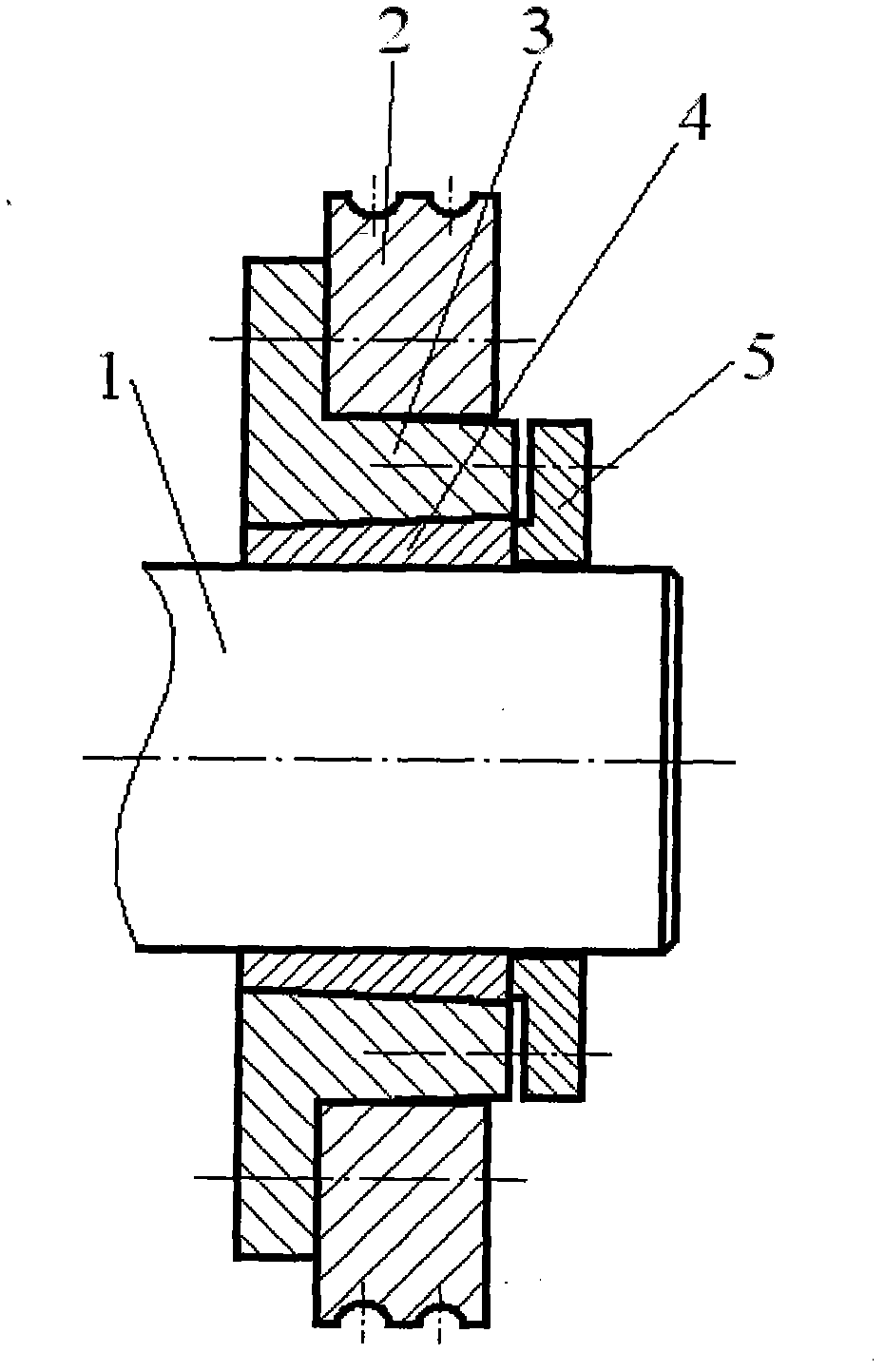

Feeding and positioning component of spring coiling machine

The invention relates to a feeding and positioning component of a spring coiling machine, which comprises a feeding wheel, a positioning shaft sleeve, an expansion taper sleeve and a pressing ring. The feeding wheel is only provided with two arc grooves equally spaced from end faces, the thickness of the feeding wheel is greatly decreased, and a positioning device comprises the positioning shaft sleeve, the expansion taper sleeve and the pressing ring and is used for axially and radially positioning and clamping the feeding wheel. Compared with the prior art, the feeding and positioning component solves the problem of axial deviation of an original feeding wheel in operation and leads feeding to be more stable and accurate, the overall weight of the feeding wheel and the positioning device is only 2 / 3 of that of an original structure, inertia is decreased, the driving burden of a machine tool is relieved, frequent speed change and reversing are facilitated, the structure of the feeding wheel is simplified, consumption of high-alloy steel is greatly reduced, and material cost and machining cost are saved.

Owner:SHANGHAI UNIV OF ENG SCI

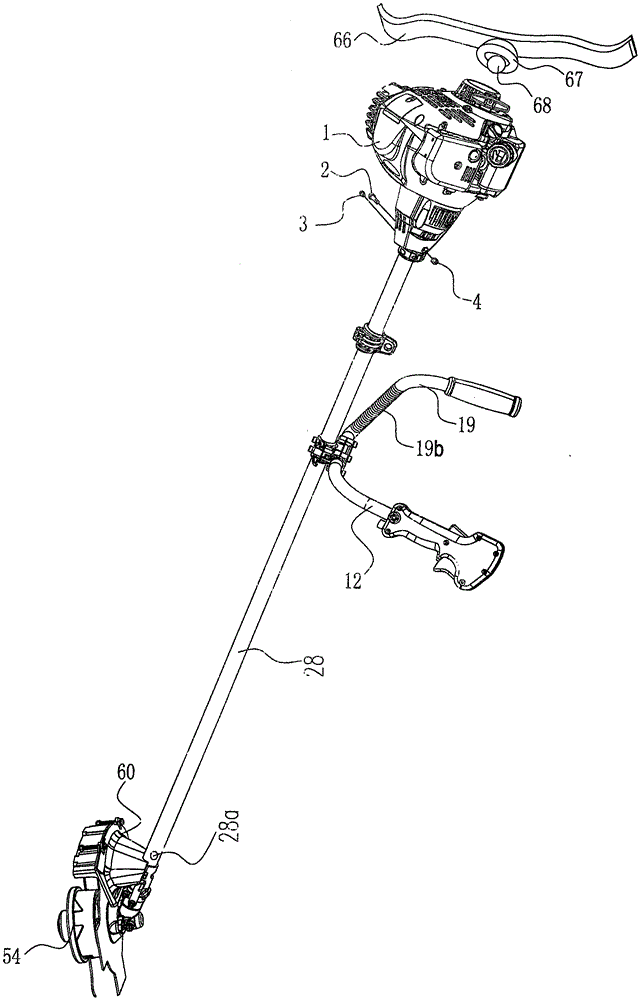

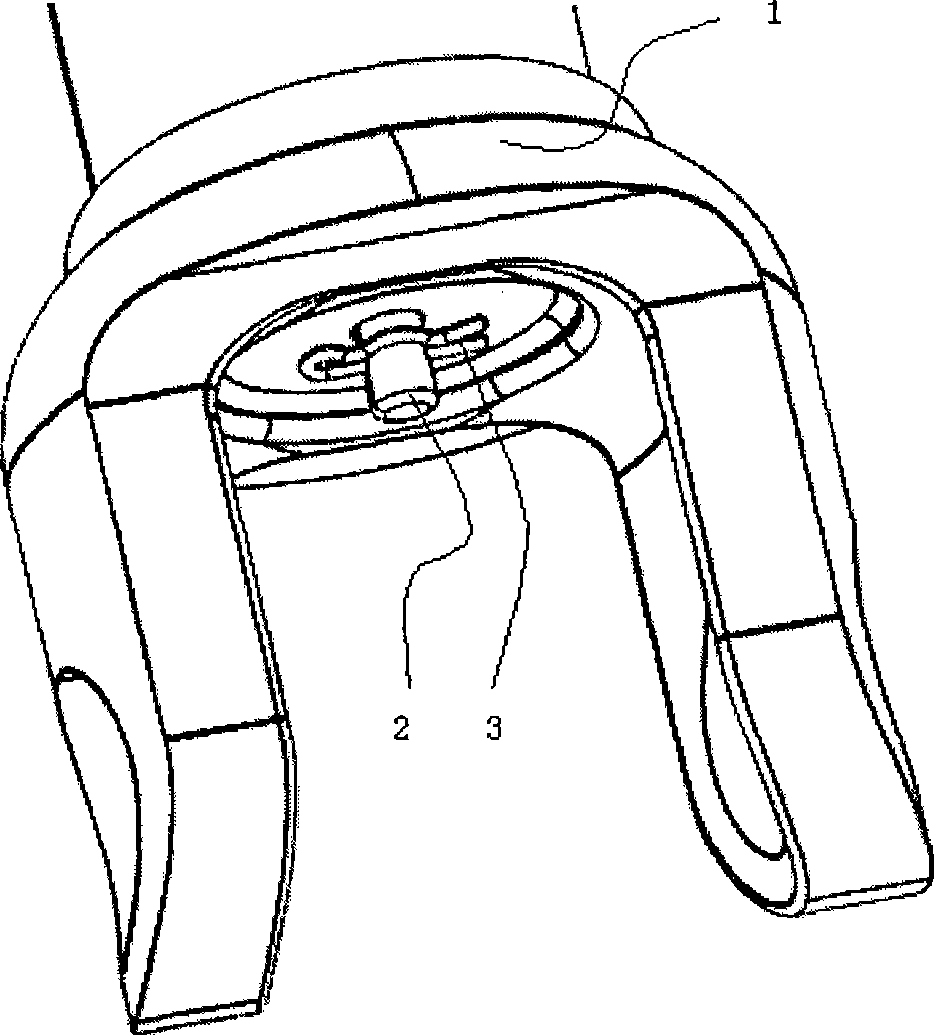

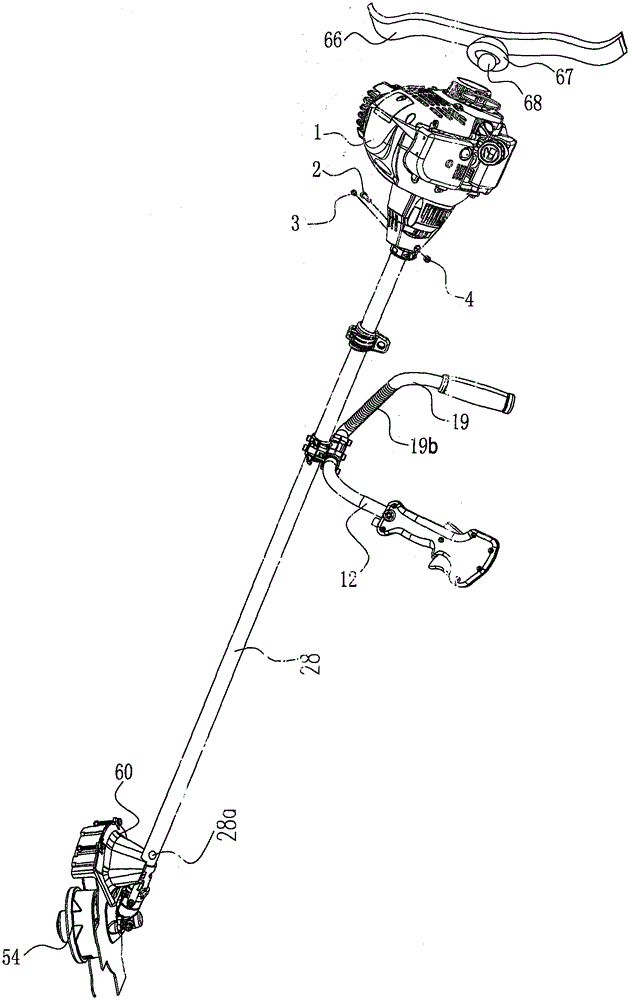

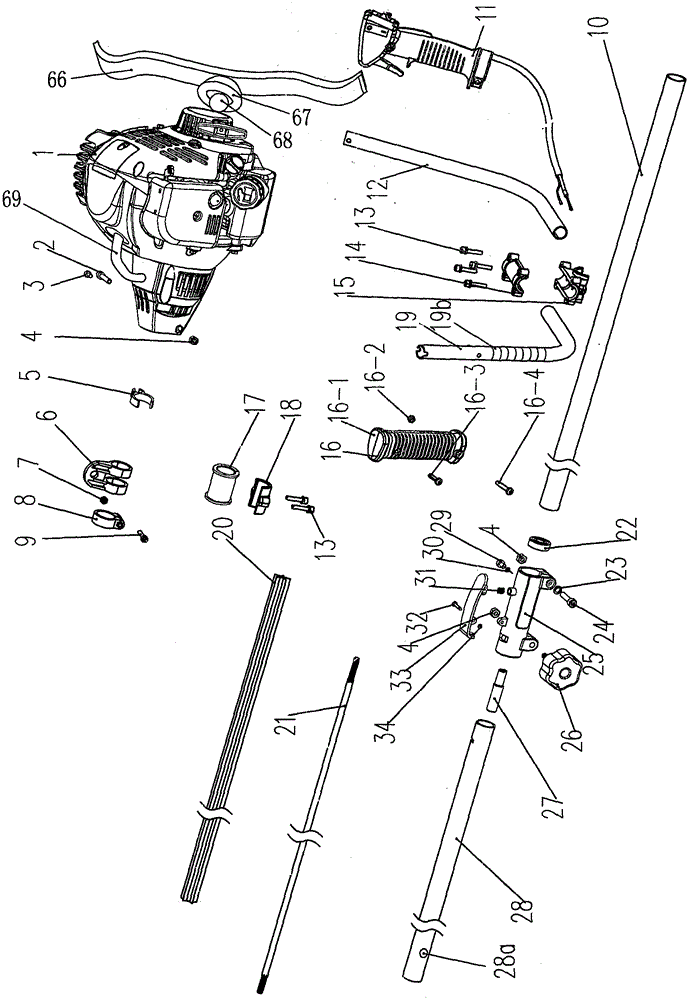

Brush cutter with single-cylinder half-balance and parabola wing-shaped blade gasoline engine

The invention discloses a brush cutter with a single-cylinder half-balance and parabola wing-shaped blade gasoline engine. A balance deflection angle phi is formed between the angle bisector of a central angle formed by the two lateral sides of an opening of a C-shaped ring (56a) for additionally arranging a crankshaft valve (56) on a crankshaft (57) of the brush cutter and the circle center of the crankshaft (57) and the center connecting line of the circle center of the crankshaft (57) and the circle center of the large end of a connecting rod, and the balance deflection angle is practically selected from 2 degrees to 22 degrees and now ranges from 10 degrees to 18 degrees. The half balance method of the single-cylinder engine is characterized in that the exciting force amplitude and the synthesis capsizing moment of a synthesis elliptic equation are reduced; the deflection angle substantially means that the balance gravity center is properly shifted, the condition that single-cylinder half balance can not be achieved is improved, and the mechanism is worthy of further detailed researching of people in the future. An inner metal cover, an outer resin cover and a logarithm runner (F7j3) are arranged in a silencer so that double-layer temperature reduction and noise reduction can be facilitated. Axial moving of the original taper of a magnetic flywheel is avoided. The equation of the arc shape of a blade is determined, the outer end of the blade is a sharp end and is provided with a blade opening, and winding objects can be cut off.

Owner:NINGBO DAYE GARDEN EQUIP

Casting-grade chrome ore dressing device and technology

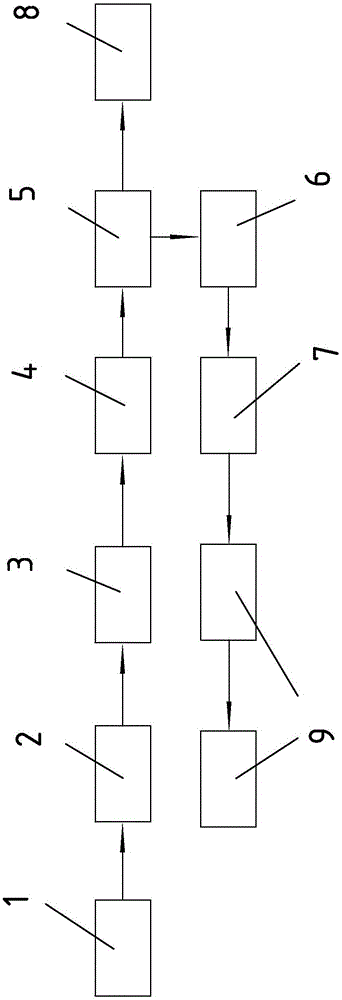

The invention discloses a casting-grade chrome ore dressing device. The casting-grade chrome ore dressing device comprises a feeding device used for feeding metallurgy-grade chrome ore, a drum screen used for screening the metallurgy-grade chrome ore, a spiral sluice system used for carrying out silicon removal on ore concentrate obtained through the drum screen, a dehydration unit used for carrying out dehydration on the ore concentrate obtained through the spiral sluice system, a drying device used for drying the dehydrated ore concentrate obtained through the dehydration unit, a cooling system used for cooling the dried ore concentrate obtained through the drying device, a rocker arm screen used for screening the cooled ore concentrate obtained through the cooling system and a dry type magnetic separation device used for carrying out magnetic separation on the on-screen ore obtained through the rocker arm screen. The invention further discloses a technology for carrying out ore dress of the casting-grade chrome ore through the casting-grade chrome ore dressing device. The casting-grade chrome ore dressing device and the technology are designed according to the feature of the casting-grade chrome ore, the ore dressing quality is improved, and the environment pollution is reduced.

Owner:DALIAN UNITED MINING CO LTD

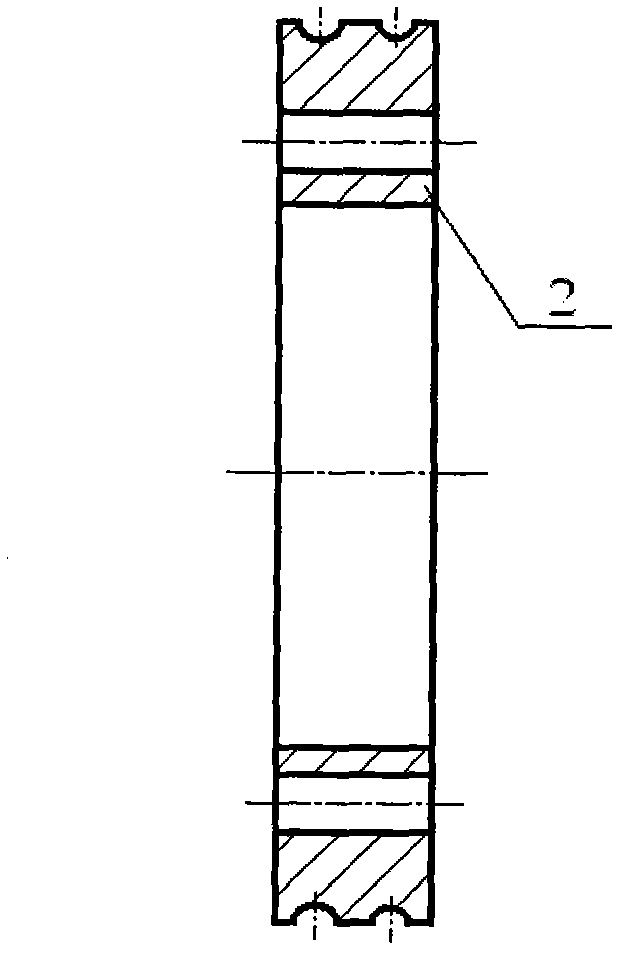

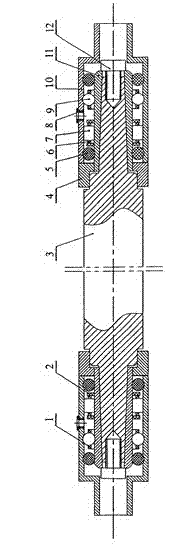

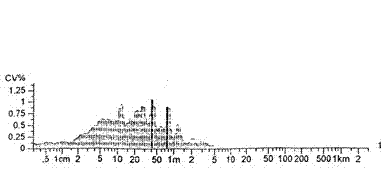

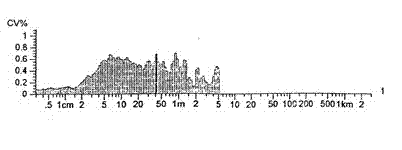

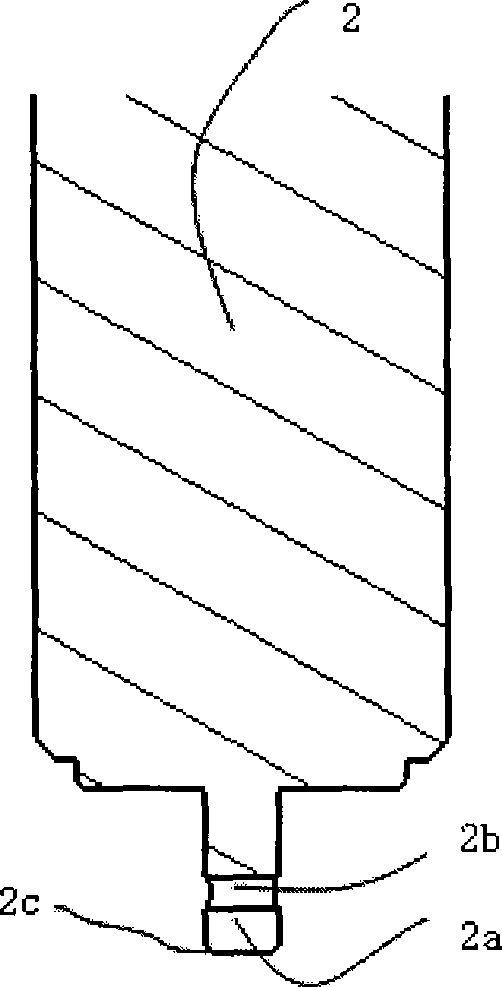

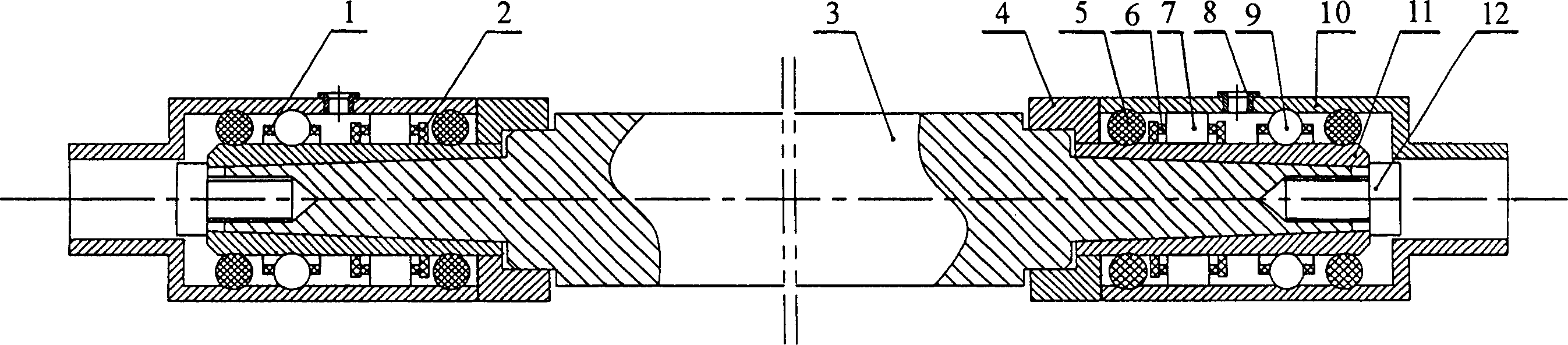

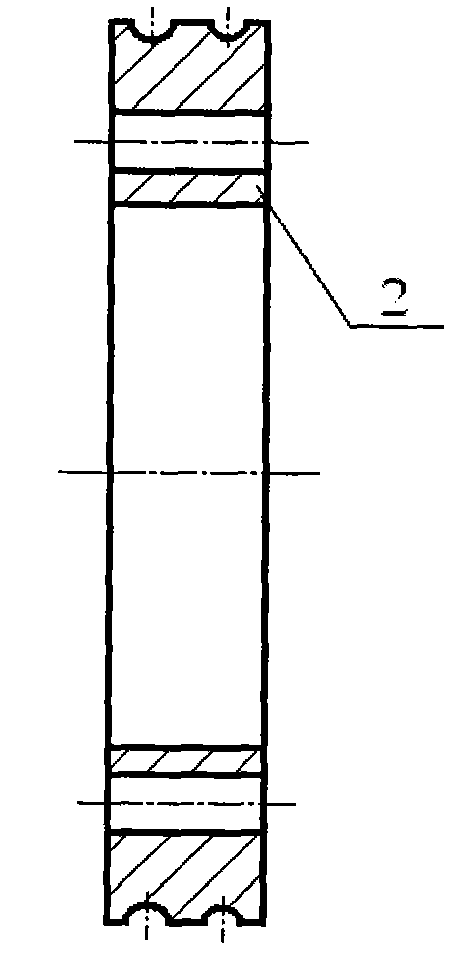

Novel shaft sleeve for textile machinery

InactiveCN102478078ASimple structureSolve the axial movementRoller bearingsCombing machinesInterference fitRadial stress

A novel shaft sleeve for textile machinery comprises a mandrel, a bearing shell, a conical inner ring, a stepped sleeve, a seal, a group of balls spaced and positioned by a retainer, another group of pin rollers axially positioned by a pin roller positioning ring, and the like. The group of balls and the group of pin rollers are used as a rolling part, an end of the mandrel close to the middle stress part of the mandrel is modified into a cylinder structure, the shaft end then extends to two ends to form cones, the conical inner ring is matched with the corresponding cone, the stepped sleeve outside the cylinder of the shaft end is in transition fit with the cylinder, and the stepped sleeve and the corresponding inner ring are in interference fit to form a fully closed structure. By means of the modification, the problem of axial endplay of the mandrel is solved, the problem of radial stress of the mandrel is also solved, tensile strength of the modified shaft end is improved, and bending formation is avoided. The balls and the pin rollers of the rolling part are constantly soaked into grease fully closed to rotate, and accordingly the problem of heat generated by the rolling part at high speed is solved, the novel shaft sleeve is applicable to drawing frames and combing machines for high-speed output, and thickness uniformity quality of cotton silvers is improved greatly.

Owner:DALIAN CHUANGDA TECH TRADE MARKET

Gasoline engine with three taper of magnetic flywheel and double0layer cooling of logarithmic spiral runner

InactiveCN105569814AImprove qualitySolve the axial movementSparking plugsCasingsGasolineEddy current

The invention discloses a gasoline engine with three taper of a magnetic flywheel and double0layer cooling of a logarithmic spiral runner. A silencer assembly (F7) including a catalyst silencing pipe (69) is mounted on a two-stroke gasoline engine through a silencer pad (F8); in an outlet of the silencer assembly (F7), an inner outlet (F7C2) of an inner metal cover (F7C1) is formed; and in an outer position, an outer outlet (F7j2) of an outer resin cover (F7j1) and a logarithmic runner (F7j3) are formed for double-layer cooling and silencing. A filter screen is arranged in a scavenging channel; another filter screen is arranged below the scavenging channel, and has a filter adjusting effect; and a catalyst is arranged. The gasoline engine is convenient for double-layer cooling and silencing, and is safe without scalding human hands. The gasoline engine solves the problem of axial movement of traditional taper of the magnetic flywheel. When a section shape of a wing-shaped blade with a parabola mean camber line equation is designed, the key is to determine an equation of a camber of the blade; a bending angle is 18 degrees, a chord length b is 20, and a / b is 0.45; a is a maximum deflection point on a bow; and the numbers are substituted into a general equation of a coordinate origin parabola of the analytic geometry for solution. Intermediate technicians can produce a mold module with a wing-shaped section outline. The outer end of the blade is a tip to facilitate smooth exhaust and to reduce disordered eddy currents, and has an edge to facilitate cutting of a winding object.

Owner:NINGBO DAYE GARDEN EQUIP

Steering transmission shaft with telescopic pre-limiting structure

The invention discloses a retractable steering transmission shaft which comprises an outer shaft with an internal pore, an internal shaft matched with the internal pore of the outer shaft and a resilient clip which is arranged on the internal shaft, wherein, the external shaft and the internal shaft can slide axially without rotation, a small pin roll is arranged on the end surface of the internal shaft which is vertical to the axial direction, and a small pinhole is arranged on the small pin roll; a pinhole is arranged on the round thin wall of the external shaft. When the internal shaft fully retracts into the external shaft, the small pin roll is inserted in the pinhole, the small pinhole on the small pin roll exposes out completely, the resilient clip is inserted in the small pinhole for confining the axial sliding of the internal and external shafts; and the internal and external shafts can axially slide after the resilient clip is removed. The invention solves the axial motion problem of the retractable steering transmission shaft during the assembling and transmission processes and ensures no accidental collisions of the steering transmission shaft with other articles, especially no sample collisions or accidental damages on installing personnel during the steering system assembling process of a turnover head stock.

Owner:CHERY AUTOMOBILE CO LTD

Electronic element fixing member

InactiveCN103687400ALow costThe solution steps are cumbersomeResilient/clamping meansEngineeringElectronic component

Owner:SHENZHEN OCEANS KING LIGHTING ENG CO LTD +1

Ball screw pair structure capable of improving positioning precision

InactiveCN109773548AExtended service lifeReasonable designGearingFeeding apparatusBall screwEngineering

The invention discloses a ball screw pair structure capable of improving the positioning precision. The ball screw pair structure comprises a ball screw body and a bearing. The ball screw body comprises a lead screw shaft, a nut, multiple steel balls, a reverser and a dustproof valve. The lead screw is composed of a rolling lead screw shaft and a bearing lever shaft. An outer roller bed is arranged on the outer circumferential face of the rolling lead screw shaft. An inner roller bed is arranged on the inner circumferential face of the nut. The multiple steel balls are arranged in a rolling channel formed by the outer roller bed and the inner roller bed and can freely roll in the channel. The bearing comprises an inner ring, an outer ring, a rolling body and a holding frame. The inner ringis integrally formed in the bearing lever shaft. The rolling body is arranged among the inner ring, the outer ring and the holding frame, and a sleeve ring roller bed is arranged in the holding frame. The rolling body can freely operate in the sleeve ring roller bed. By means of the ball screw pair structure, the integrated structural design is adopted, the positioning requirement of a high-speedprecision machine tool can be met, the beneficial effects of being good in assembling performance, high in bearing capacity and low in noise are achieved, and high popularization and utility value isachieved.

Owner:安顺虹特滚珠丝杠有限责任公司

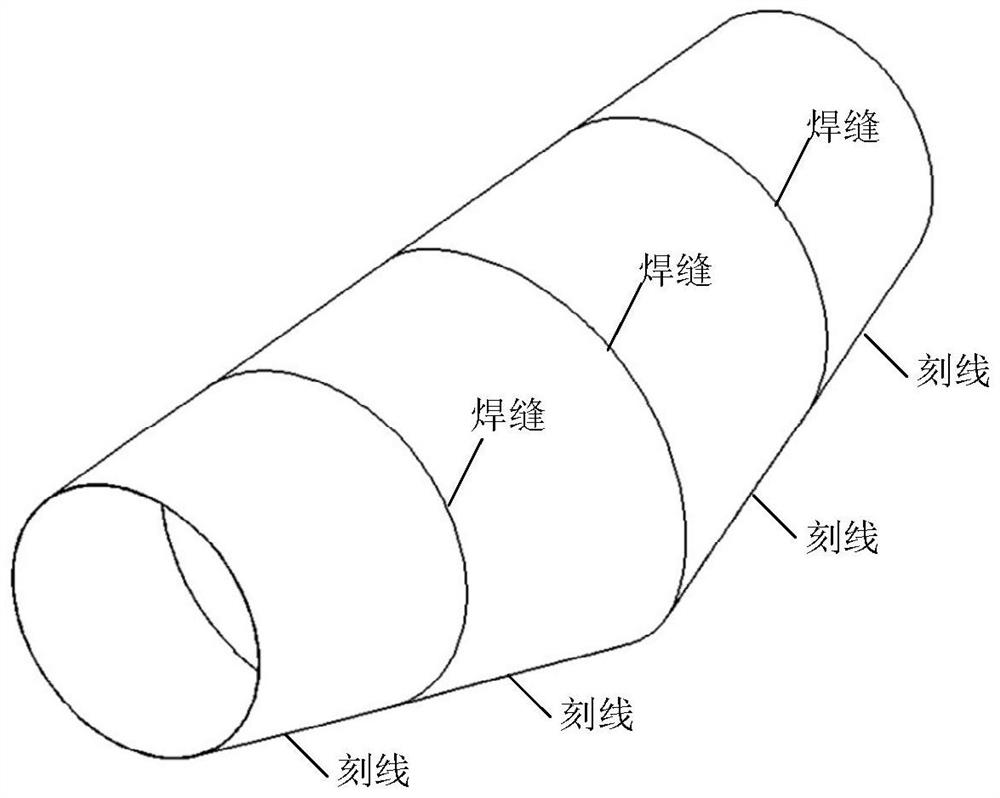

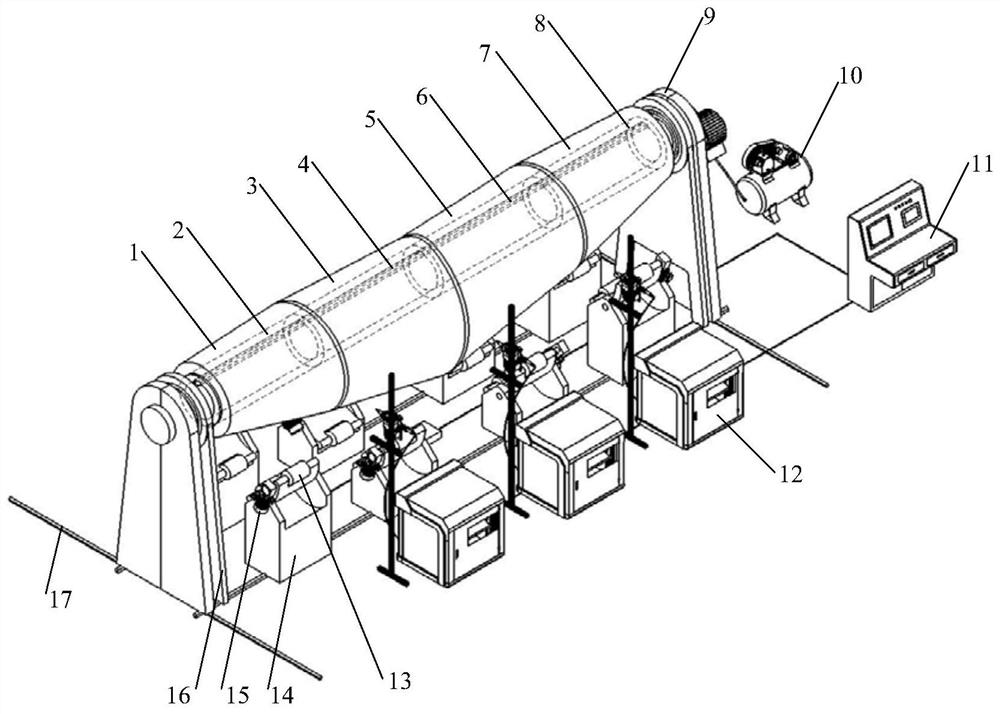

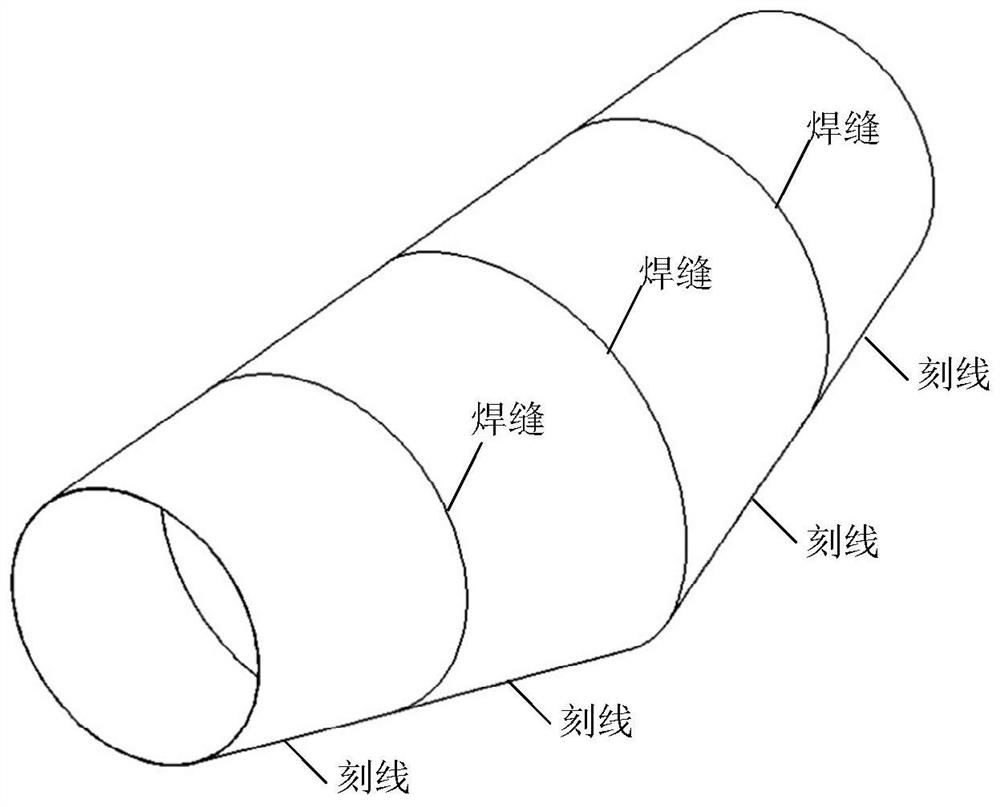

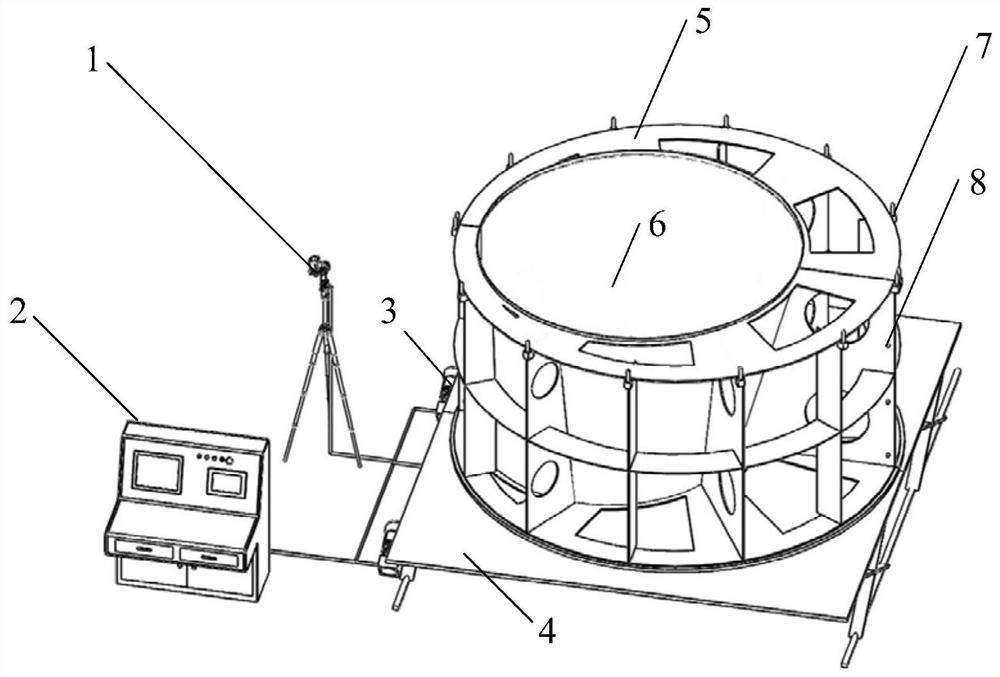

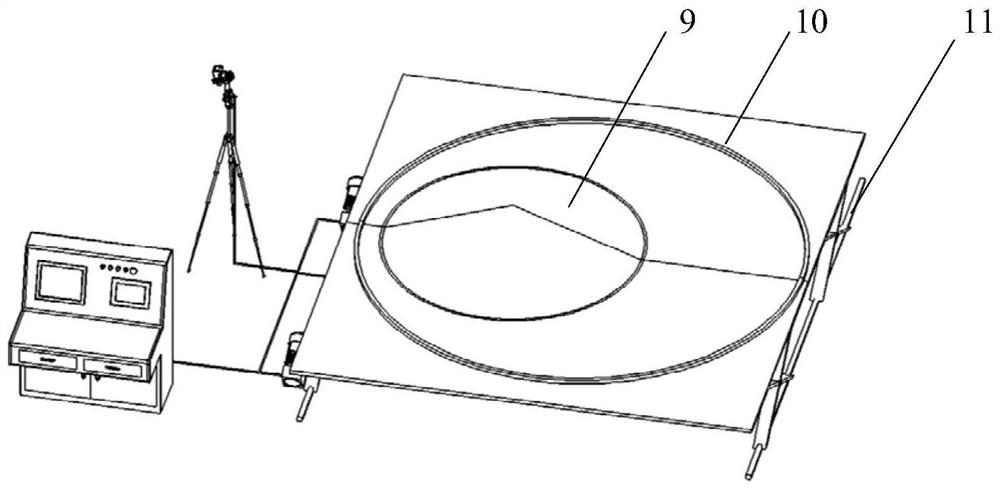

Automatic welding equipment and method for non-rotary tank cylinders of powder tank truck

ActiveCN113814595AReduce manual labor intensityReduce dependenceWelding/cutting auxillary devicesAuxillary welding devicesManufacturing engineeringButt joint

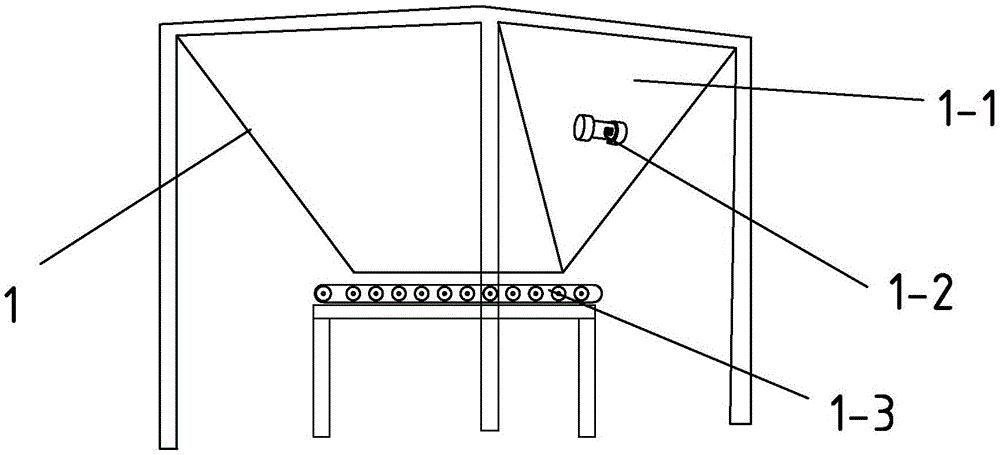

The invention provides automatic welding equipment and method for non-rotary tank cylinders of a powder tank truck. The automatic welding equipment comprises a conveying device, a shaping device, a welding device, an information acquisition device, a control device and a supporting device; the conveying device comprises a rail and the supporting device moving on the rail; the supporting device comprises a roller frame used for supporting the tank cylinders in the mounting and shaping processes, rollers and a mandrel used for supporting the shaping device; the tank cylinders to be welded are connected to the outer portion of the shaping device in a sleeving mode in the mounting process; the control device controls the roller frame to drive the tank cylinders to move to the mounting position of the shaping device based on information acquired by the information acquisition device and is further used for driving the shaping device to drive all the tank cylinders to complete axial butt joint and controlling the mandrel to rotate in the welding process; and the welding device is used for completing welding of the adjacent tank cylinders. Only a small amount of manual intervention is needed, the labor intensity of workers is relieved, dependence on the experience of the welding workers is reduced, and the welding efficiency and the welding quality are improved through automatic operation.

Owner:DALIAN UNIV OF TECH

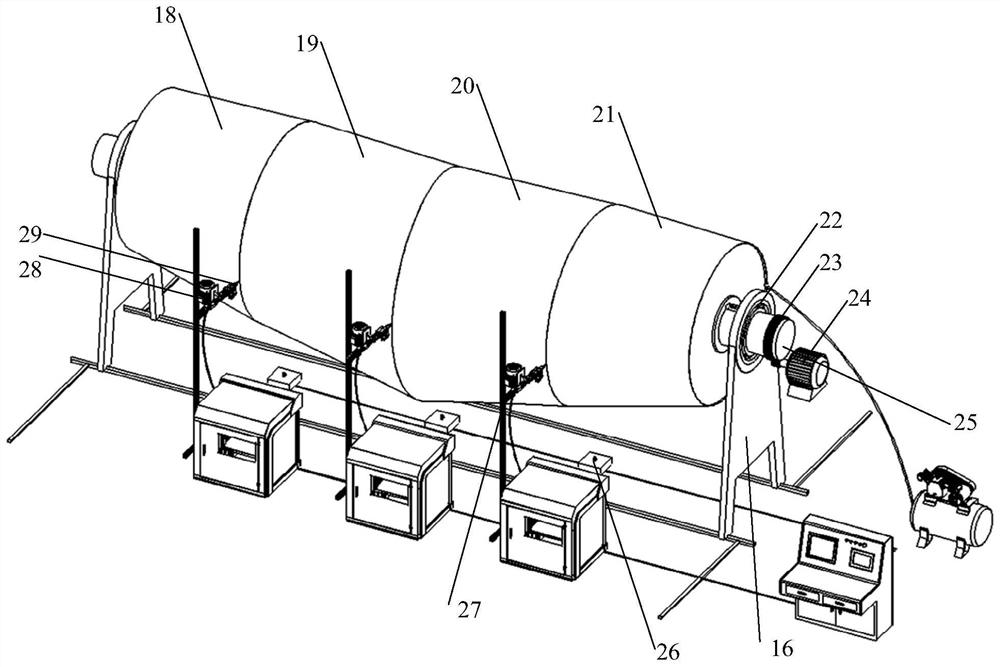

Automatic welding equipment and method for large-taper powder cylinder

ActiveCN113814568AReduce labor intensityReduce dependenceLaser beam welding apparatusButt jointManufacturing engineering

The invention provides automatic welding equipment and method for a large-taper powder cylinder. The automatic welding equipment comprises an annular clamp mounting device, a cylinder section automatic butt joint device and a cylinder section automatic welding device; the annular clamp mounting device is used for mounting all cylinder sections of the large-taper powder cylinder into corresponding annular clamps; the cylinder section automatic butt joint device is used for automatically adjusting the four large-taper cylinder sections to the welding positions in the axial direction and the circumferential direction; and the cylinder section automatic welding device is used for welding of a powder cylinder welding line after butt joint. All the devices are provided with information collecting feedback systems, only manual auxiliary transportation is needed, the labor intensity of workers is lowered, the dependence on the experience of the welding workers is reduced, and the welding efficiency and the welding quality are improved through automatic operation. The annular clamps are used for fixing the large-taper powder cylinder, a non-rotation body is converted into a rotation body, and the problem of axial movement on a roller frame during large-taper powder cylinder pairing butt joint is solved.

Owner:DALIAN UNIV OF TECH

Novel shaft sleeve of textile machinery

InactiveCN1821458ASimple structureSolve the axial movementRolling contact bearingsCombing machinesInterference fitRadial stress

The novel shaft sleeve for textile machinery consists of mandrel, bearing shell, conic inner ring, stepped sleeve, sealing part, balls separated and located with the holder, pin rollers located axially with pin roller locating ring, etc. The present invention has one group of balls and one group of pin rollers as the rolling bodies, cylindrical plus conic mandrel structure and the closed structure, so that it has less axial looseness, improved radial stress state of the mandrel, raised bending strength and less high speed heat release of rolling bodies. The novel shaft sleeve is suitable for use in high speed drawing frame and combing machine to result in raised cotton sliver quality.

Owner:陈兆南

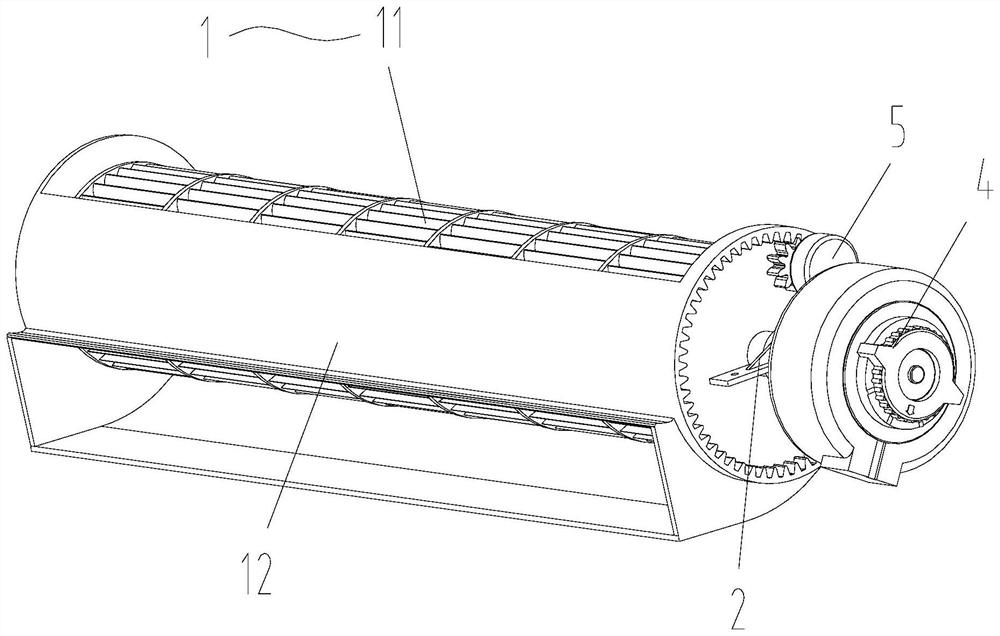

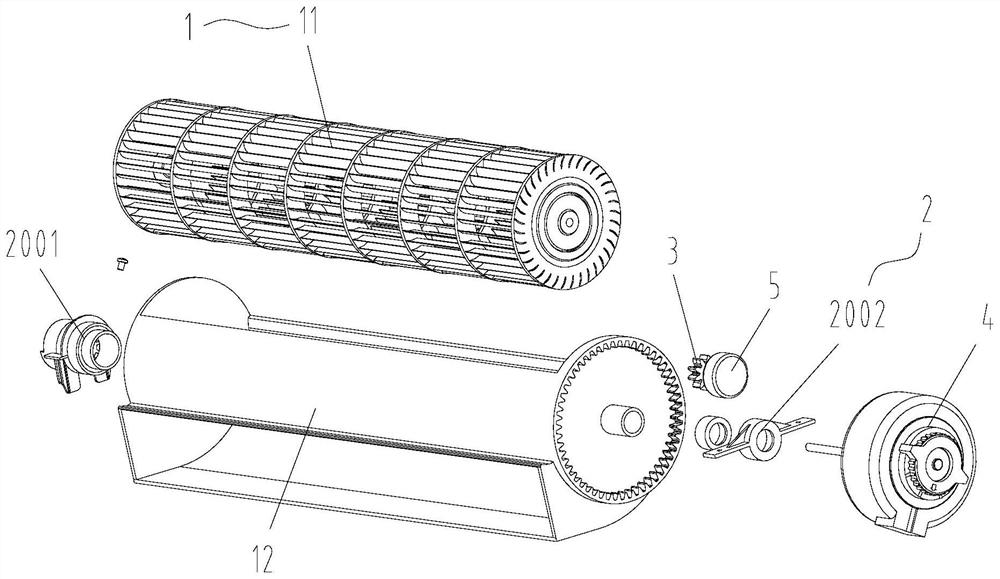

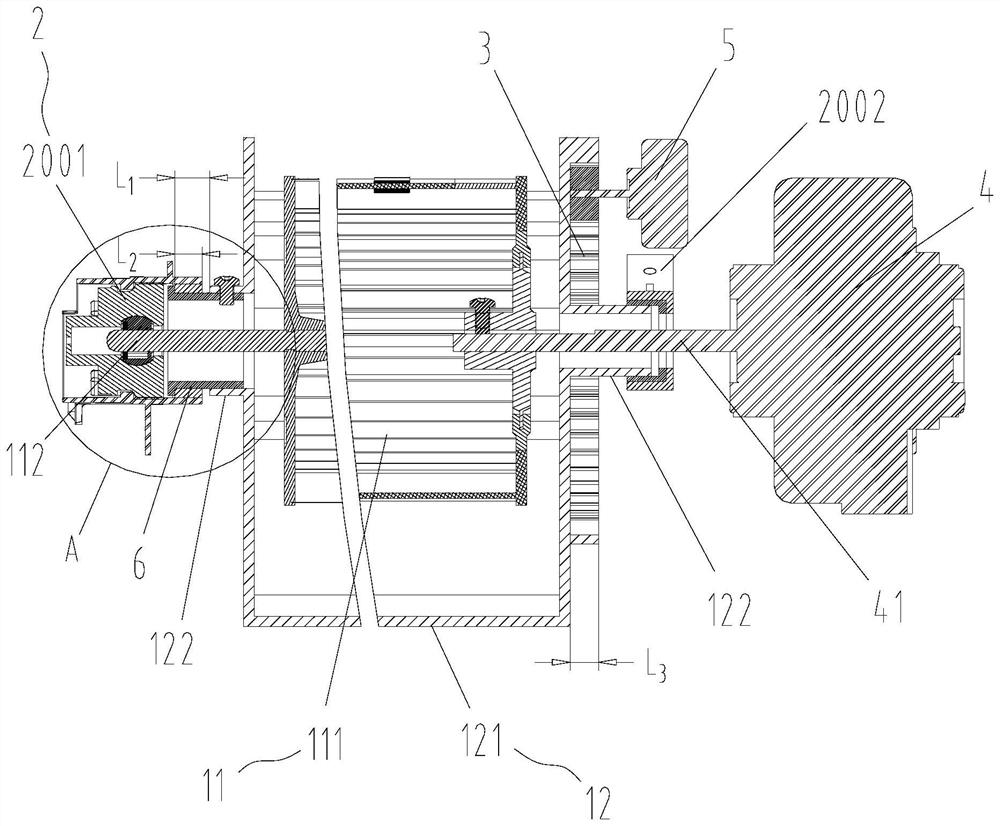

Air duct rotating mechanism, indoor unit and air conditioner

PendingCN114263625AGuaranteed stabilityGuaranteed reliabilityPump componentsLighting and heating apparatusEngineeringMachine

The invention provides an air duct rotating mechanism, an indoor unit and an air conditioner, the air duct rotating mechanism comprises a fan, the fan comprises fan blades and a fan shell, and the fan blades and the fan shell are rotatably arranged to supply air and change the air outlet angle; the two bearing assemblies are arranged on the two opposite sides of the draught fan in the axial direction of the draught fan and fixed to a machine body of an indoor unit of the air conditioner, and each bearing assembly comprises a shell bearing used for being connected with a shell rotating shaft of the draught fan shell so as to support the shell rotating shaft. The connecting shaft is used for connecting the shell bearing with the shell rotating shaft; the first stopping part is used for stopping the axial movement of the fan shell; wherein the first stop part is arranged on the connecting shaft and is used for being in contact with a shell bearing; or the first stop part is arranged on the shell bearing and is used for being in contact with the connecting shaft, so that the problem of axial movement of the fan shell of the air conditioner in the prior art is solved.

Owner:GREE ELECTRIC APPLIANCES INC

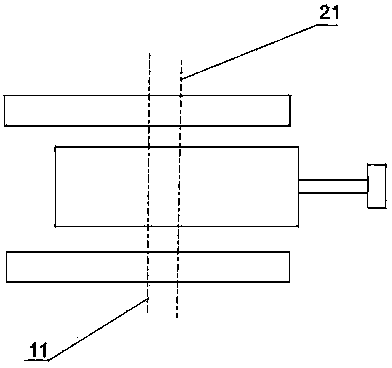

Method for adjusting center of magnetic field of high-voltage motor

The invention discloses a method for adjusting the center of a magnetic field of a high-voltage motor. The method includes selecting a testing point; finding static values a and b corresponding to minimum axial vibrating acceleration of a constraint end bearing seat; adjusting distance values between the circumferential end faces of stator iron cores at the front end and the rear end and the circumferential end face of a rotor iron core according to the static values a and b corresponding to the minimum acceleration. By the method, the problem of axial movement of the high-voltage motor can be solved; the method can be widely applied to magnetic field center adjusting of various high-voltage motors.

Owner:周建设

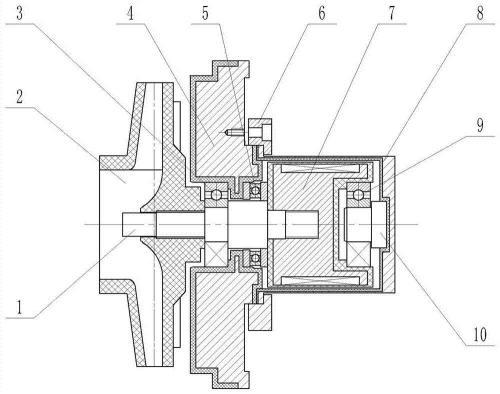

Ceramic bearing fluoroplastic magnetic drive pump

PendingCN114593070ABalance radial forceSolve the throwing eccentricityPump componentsPump installationsImpellerBall bearing

A fluoroplastic magnetic drive pump with a ceramic bearing solves the problems that an existing magnetic drive pump is complex in structure, large in vibration, high in noise, frequent in maintenance and large in application limitation. Which comprises a main pump shaft with an impeller at one end, and is characterized in that inner magnetic steel is arranged at the other end of the main pump shaft; a main ceramic ball bearing is arranged on the side, close to the impeller, of the middle of the main pump shaft, and a ceramic thrust bearing is arranged on the side, close to the inner magnetic steel, of the middle of the main pump shaft. A magnetic pump cover is arranged between the impeller and the inner magnetic steel and on the outer side of the middle part of the main pump shaft; a sealing cover seat arranged outside the inner magnetic steel is connected with a pump cover of the magnetic drive pump through a pressing plate; a secondary pump shaft is arranged on the inner side of the end of the sealing cover seat, and a secondary ceramic ball bearing is arranged between the secondary pump shaft and the inner magnetic steel. The motor is reasonable in design, compact in structure, stable in operation, free of vibration, low in noise, long in service life and low in maintenance cost, and can operate for a long time without lubrication.

Owner:虞淞

Feeding and positioning component of spring coiling machine

Owner:SHANGHAI UNIV OF ENG SCI

LPG engine with semi-balance drift angle and parabola mean camber line wing-shaped blade

InactiveCN105649753AImprove qualitySolve the axial movementCasingsInternal combustion piston enginesGravity centerEngineering

The invention discloses an LPG engine with a semi-balance drift angle and parabola mean camber line wing-shaped blade. A balance drift angle phi is formed between an angle bisector from the two side edges of an opening of a C-shaped ring (56a), additionally arranged on a crankshaft (57) of the LPG engine, of a crankshaft valve (56) to the circle center angle of the circle center of the crankshaft and a center connecting line from the circle center of the crankshaft to the circle center of a large head of a connecting rod, selecting is actually conducted in the range from 2 degrees to 22 degrees, and the value of 10 degrees is primarily used at present. According to a semi-balance method of a single-cylinder engine, the exciting force amplitude and compound upsetting moment of a resultant force elliptic equation are reduced, drift angle balancing is actually the appropriate offsetting of a balance gravity center, the inappropriate semi-balance of a single cylinder is improved, and the mechanism is worthy of being further explored in detail by people in the future. An inner metal cover, an outer resin cover and a logarithm runner (F7j3) are arranged on a silencer so that double-layer cooling and noise elimination can be facilitated. The problem that the original taper of a magnetic flywheel axially floats is solved. An arc equation of the blade is determined. The outer end of the blade is a sharp end and provided with a cutting edge, and an entanglement can be cut off easily.

Owner:NINGBO DAYE GARDEN EQUIP

Air duct rotating mechanism, indoor unit and air conditioner

PendingCN113982978AGuaranteed stabilityGuaranteed reliabilityPump componentsLighting and heating apparatusFan bladePhysics

The invention provides an air duct rotating mechanism, an indoor unit and an air conditioner. The air duct rotating mechanism comprises: a fan, wherein the fan comprises fan blades and a fan shell, and the fan blades and the fan shell are rotatably arranged to supply air and change the air outlet angle; and two bearing assemblies arranged on the two opposite sides of the fan in the axial direction of the fan and fixed to a machine body of an indoor unit of the air conditioner, wherein each bearing assembly comprises a shell bearing used for being connected with a fan shell so as to support the fan shell. Each shell bearing comprises a sleeving part and a stopping part, the sleeving part is used for being connected with the shell rotating shaft of the fan shell in a sleeving mode, and the stopping part is arranged at the end, away from the fan shell, of the sleeving part and used for stopping axial movement of the fan shell, so that the problem that in the prior art, axial movement exists in a fan shell of an air conditioner is solved.

Owner:GREE ELECTRIC APPLIANCES INC

Preparation method for corrosion-resistant spiral centrifugal impeller

InactiveCN107282913ALong-term reliabilityImprove yieldFireproof paintsMolten spray coatingManufacturing technologySurface roughness

The invention belongs to the technical field of centrifugal pump impeller manufacturing, and particularly relates to a preparation method for a corrosion-resistant spiral centrifugal impeller. A low pressure casting mode is adopted for pouring, so that the yield of spiral centrifugal impeller castings can be improved, the surface roughness conforms to the requirements of Ra3.2, and a good foundation is provided for subsequent cobalt-base alloy powder fusion treatment; a self-fusion alloy spray method for precipitating cobalt-base alloy powder enables a coating to be tightly adhered to the surface of a matrix without damaging substrate materials, the strength of the impeller is improved, and the higher corrosion resistance and abrasion resistance of the impeller can be improved; and dipping treatment for liquor dipping can further improve the strength and seepage resistance of the impeller and plays a sealing role in the surface of the impeller, meanwhile, the surface of the impeller is smooth and even, axial movement or bouncing of a pump is prevented in the use process, the problem of poor corrosion resistance of the impeller is effectively solved, the temperature resistance is good, the usage temperature can reach 120 DEG C, the pump can operate stably, and the service life of the pump is prolonged.

Owner:ANHUI LUYUAN PUMP&VALVE CO LTD

Gasoline engine with wing blade having one-fifth taper parabolic medial axis equation and magnetic fly wheel

InactiveCN105569817AImprove qualitySolve the axial movementSparking plugsCasingsMedial axisFiltration

The invention provides a gasoline engine with a wing blade having a one-fifth taper parabolic medial axis equation and a magnetic fly wheel. A muffler assembly (F7) of the gasoline engine, which comprises a catalytic agent silencer (69), is arranged on the two-stroke gasoline engine by a muffler pad (F8); and an internal outlet (F7C2) of an internal metal cover (F7C1) is formed at an outlet of the muffler assembly (F7), and an external outlet (F7j2) of an external resin cover (F7j1) and a logarithm flow channel (F7j3) are formed outside the outlet of the muffler assembly (F7), thereby facilitating double-layer temperature reduction and noise elimination. The gasoline engine with the wing blade having the one-fifth taper parabolic medial axis equation and the magnetic fly wheel is used for driving a garden machine. A filter screen is arranged in a scavenging channel; another filter screen is arranged below the scavenging channel; and the filter screens have filtration and regulation effects and also contain catalytic agents. The gasoline engine with the wing blade having the one-fifth taper parabolic medial axis equation and the magnetic fly wheel has the beneficial effects that the double-layer temperature reduction and noise elimination are facilitated; the gasoline engine does not scald hands and is safe; the problem of axial endplay caused by the original taper of the magnetic flywheel is solved; and the blade is also improved and is the wing blade having the one-fifth taper parabolic medial axis equation.

Owner:NINGBO DAYE GARDEN EQUIP

LPG (Liquefied Petroleum Gas) engine with wing blade having quartered taper parabolic medial camber line equation and magnetic fly wheel

InactiveCN105569816AImprove qualitySolve the problem of axial movement of the original taperSparking plugsCasingsFuel tankFlywheel

The invention provides an LPG (Liquefied Petroleum Gas) engine with a wing blade having a quartered taper parabolic medial camber line equation and a magnetic fly wheel. A muffler assembly (F7) of the PLG engine, which comprises a catalytic agent silencer (69), is arranged on the two-stroke LPG engine by a muffler pad (F8); and an internal outlet (F7C2) of an internal metal cover (F7C1) is formed at an outlet of the muffler assembly (F7), and an external outlet (F7j2) of an external resin cover (F7j1) and a logarithm flow channel (F7j3) are formed outside the outlet of the muffler assembly (F7), thereby facilitating double-layer temperature reduction and noise elimination. The LPG engine with the wing blade having the quartered taper parabolic medial camber line equation and the magnetic fly wheel is used for driving a garden machine. A pipe thread is arranged at the front of an LPG miniature propane fuel tank; fuel enters the engine for working by a gas mixing controller through a pipe joint; a safety valve is arranged at the front of the fuel tank; the diameter of the fuel tank is less than 100 millimeters; the fuel tank containing 465g of propane fuel is convenient to replace according to the standard; a filter screen is arranged in a scavenging channel; another filter screen is arranged below the scavenging channel; and the filter screens have filtration and regulation effects and also contain the catalytic agents. The LPG engine with the wing blade having the quartered taper parabolic medial camber line equation and the magnetic fly wheel has the beneficial effects that the double-layer temperature reduction and noise elimination of the LPG engine are facilitated; the LPG engine does not scald hands and is safe; the problem of axial endplay caused by the original taper of the magnetic flywheel is solved; and the blade is also improved.

Owner:NINGBO DAYE GARDEN EQUIP

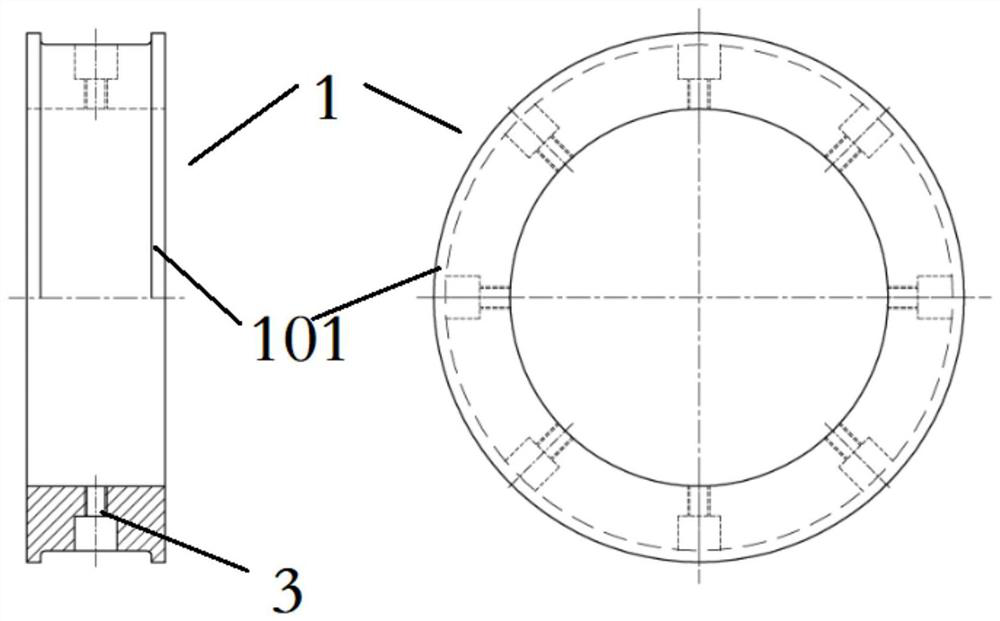

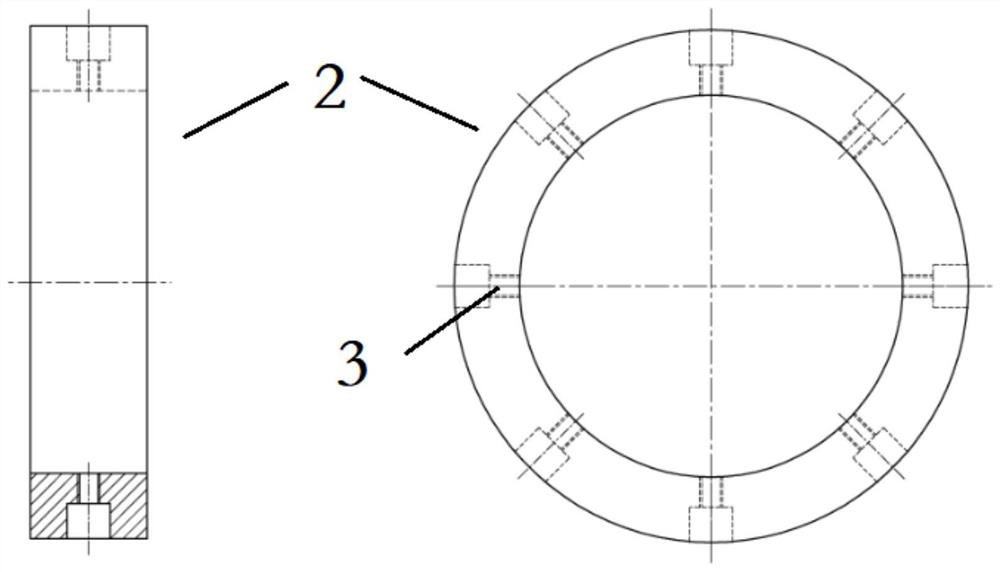

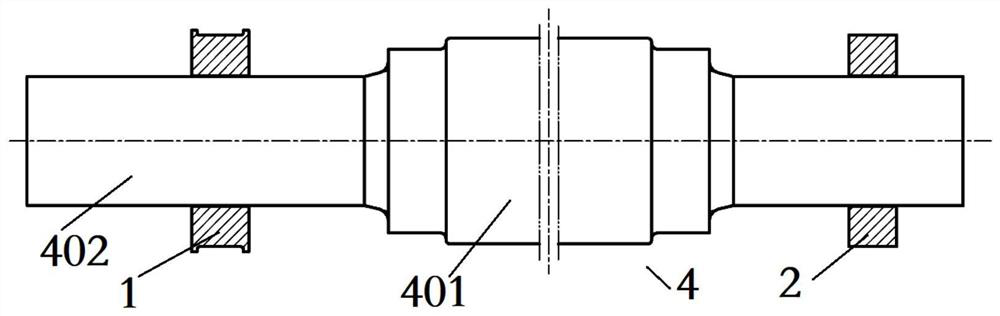

Anti-drifting device for differential heat treatment, differential temperature furnace and differential heat treatment method

ActiveCN112725607ASolve the axial movementEvenly heatedFurnace typesHeat treatment furnacesThermodynamicsEngineering

The invention discloses an anti-channeling device for differential heat treatment, a differential temperature furnace and a differential heat treatment method, belongs to the technical field of heat treatment, and solves the problems of difficulty in manufacturing a working roll of an aluminum plate rolling mill, poor hardness uniformity and the like in the prior art. The anti-drifting device for differential heat treatment comprises an anti-drifting sleeve and a supporting sleeve, wherein the anti-channeling sleeve and the supporting sleeve are each of a hollow cylindrical structure; the anti-channeling sleeve and the supporting sleeve are separately used for being arranged on roller necks at two ends of the working roll in a sleeving manner; and annular anti-drifting bulges are arranged at two ends of the anti-drifting sleeve and used for preventing the working roll from shifting in the axial direction in the rotating process. The device and the method are suitable for differential heat treatment of the working roll of the aluminum plate rolling mill.

Owner:TIANJIN HEAVY EQUIP ENG RES +1

Structure for preventing motor shaft from moving

ActiveCN105932826APrevent tamperingAvoid Axial MisalignmentMechanical energy handlingWork unitControl theory

The invention discloses a structure for preventing a motor shaft from moving. The structure comprises a motor fixed in a motor frame, wherein the motor comprises a motor shaft that is fixedly connected with a drive disc, a boundary plate is transversely arranged on the motor frame, the drive disc is positioned between the motor and the boundary plate, a first groove is formed in the axis of the drive disc, the boundary plate is provided with a second groove corresponding to the first groove, and a first ball is arranged in the first groove and second groove in a rolling manner. The drive disc serving as a work unit may generate axial deviation to drag the motor shaft, and the first ball pushes against the axis of the drive disc so as to be capable of preventing the drive disc from moving outwards, and thereby the axial deviation of the motor shaft is avoided. The structure has the advantages that the wearing of the motor and device caused by the axial deviation of the motor shaft generated under the action of long-term axial external force can be avoided, the problem about the axial deviation of the motor shaft generated after the traditional motor is aging is solved, and the structure has the advantages of reasonable structural layout, high mechanism fitting accuracy and stable operation.

Owner:HUAIAN PULEFEI INTELLIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com