Technology for applying duplex angle for contacting ball bearing of cutting part of board cutting machine

A contact ball and bearing technology, used in sawing equipment, circular saws, wood processing appliances, etc., can solve the problems of corrugated lines on the edge of the board, affecting the appearance quality of the finished board, product qualification rate, scorching, etc. shape lines, improve the appearance quality and product qualification rate, and solve the effect of the axial movement of the saw blade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

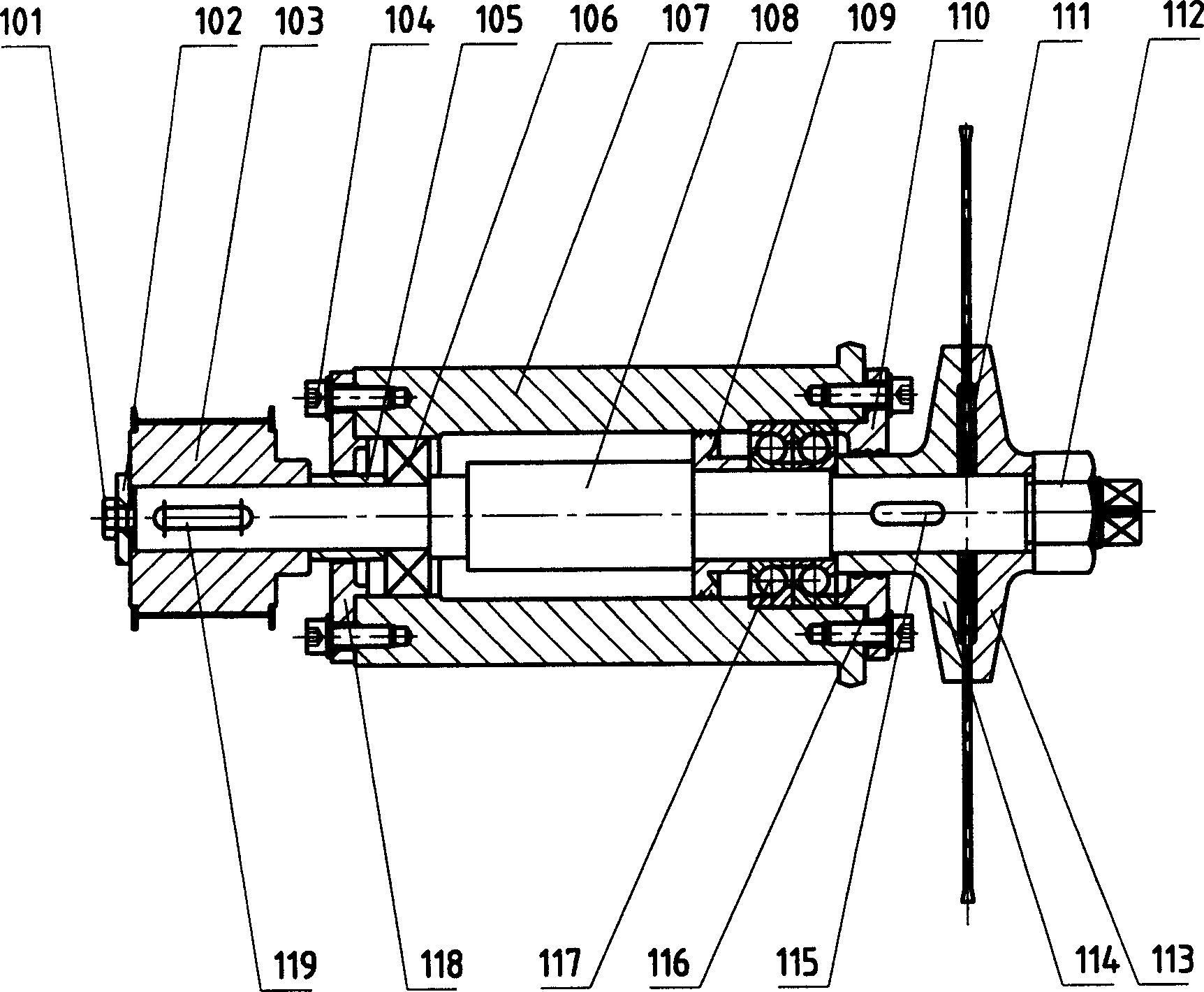

[0016] The embodiment of the present invention is a wood-based panel sawing machine in which paired angular contact ball bearings are installed on the fixed end of the bearing of the sawing part. , left bearing 106, bearing housing 107, main shaft 108, oil retaining ring 109, right transparent cover 110, saw blade 111, compression nut 112, outer pressure plate 113, inner pressure plate 114, flat key 115, gasket 116, right bearing 117 , The left transparent cover 118 and the pulley flat key 119 form (see accompanying drawing). Assemble according to the requirements shown in the figure, wherein: the material of the main shaft 108 is 45# steel, quenched and tempered, the hardness is HB240~280, the shaft diameter of the left end of the main shaft 108 is φ25mm, and the shaft diameter of the right end is φ35mm; the material of the bearing seat 107 is 20 #Steel, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com