Different load identifying dehydration control method

A control method and unified technology, applied to the control device of washing machine, washing device, textile and paper making, etc., can solve the problems of low passing rate, vibration, non-dehydration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

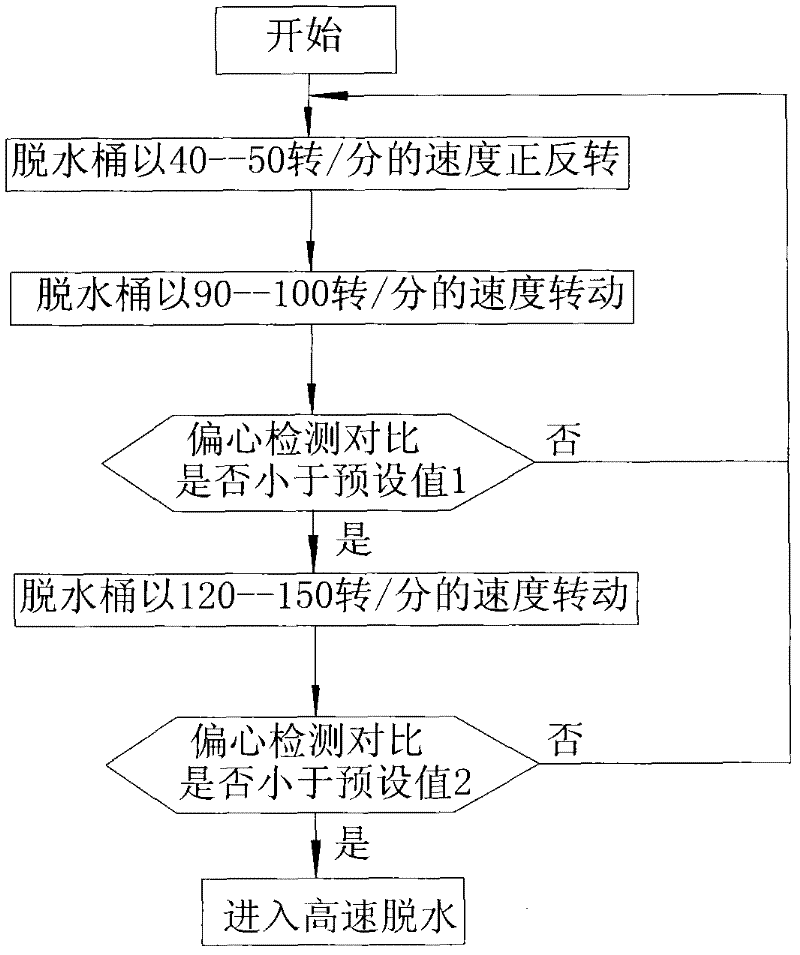

[0084] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0085] The present invention presets several preset parameter values to be used to deal with different clothes, and the preset parameter values are introduced before starting to describe specific examples.

[0086] (1) Acceleration time, the time for accelerating from the clothes shaking speed to the first eccentricity detection speed. The acceleration time is divided into long acceleration time and short acceleration time. The long acceleration time is suitable for small clothes, and the short acceleration time is suitable for large clothes. In this example, the long acceleration time is 15 seconds, and the short acceleration time is 5 seconds.

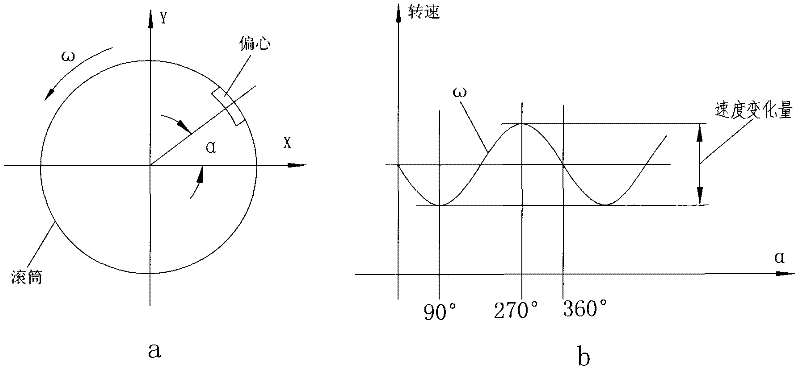

[0087](2) The first speed variable preset value and the second speed variable preset value, and the speed variation comparison value at the first eccentricity detection spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com