Patents

Literature

72results about How to "Avoid Axial Misalignment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

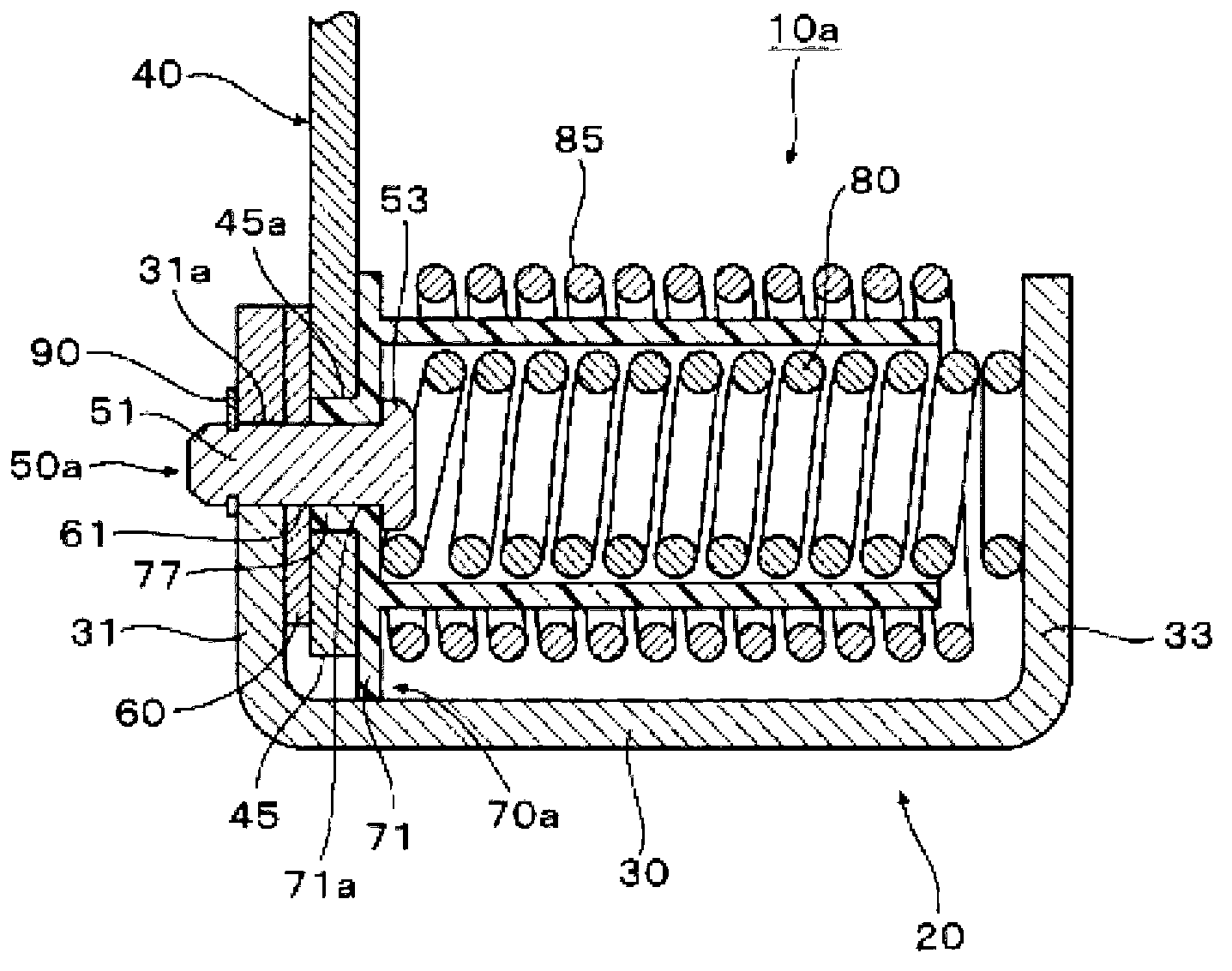

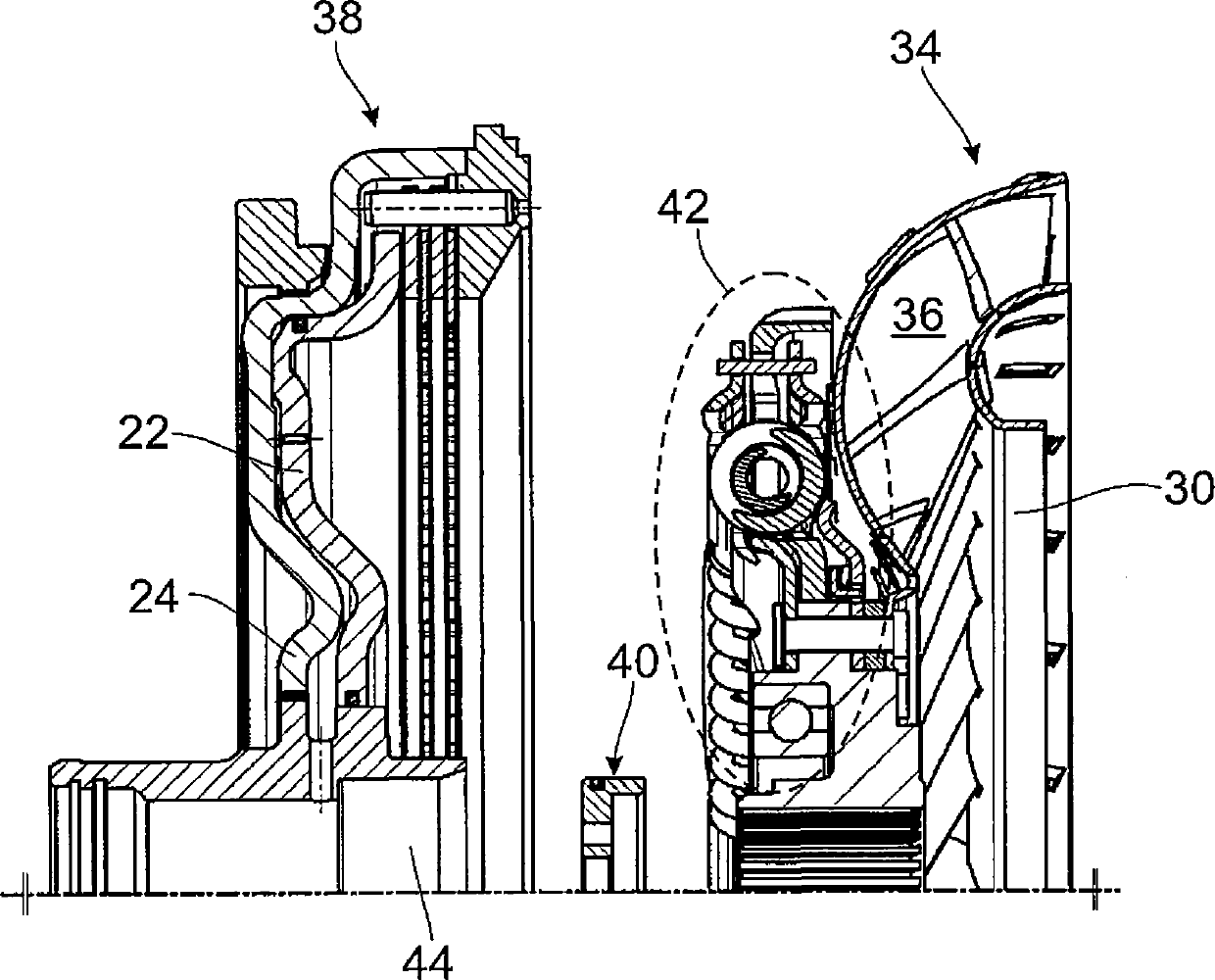

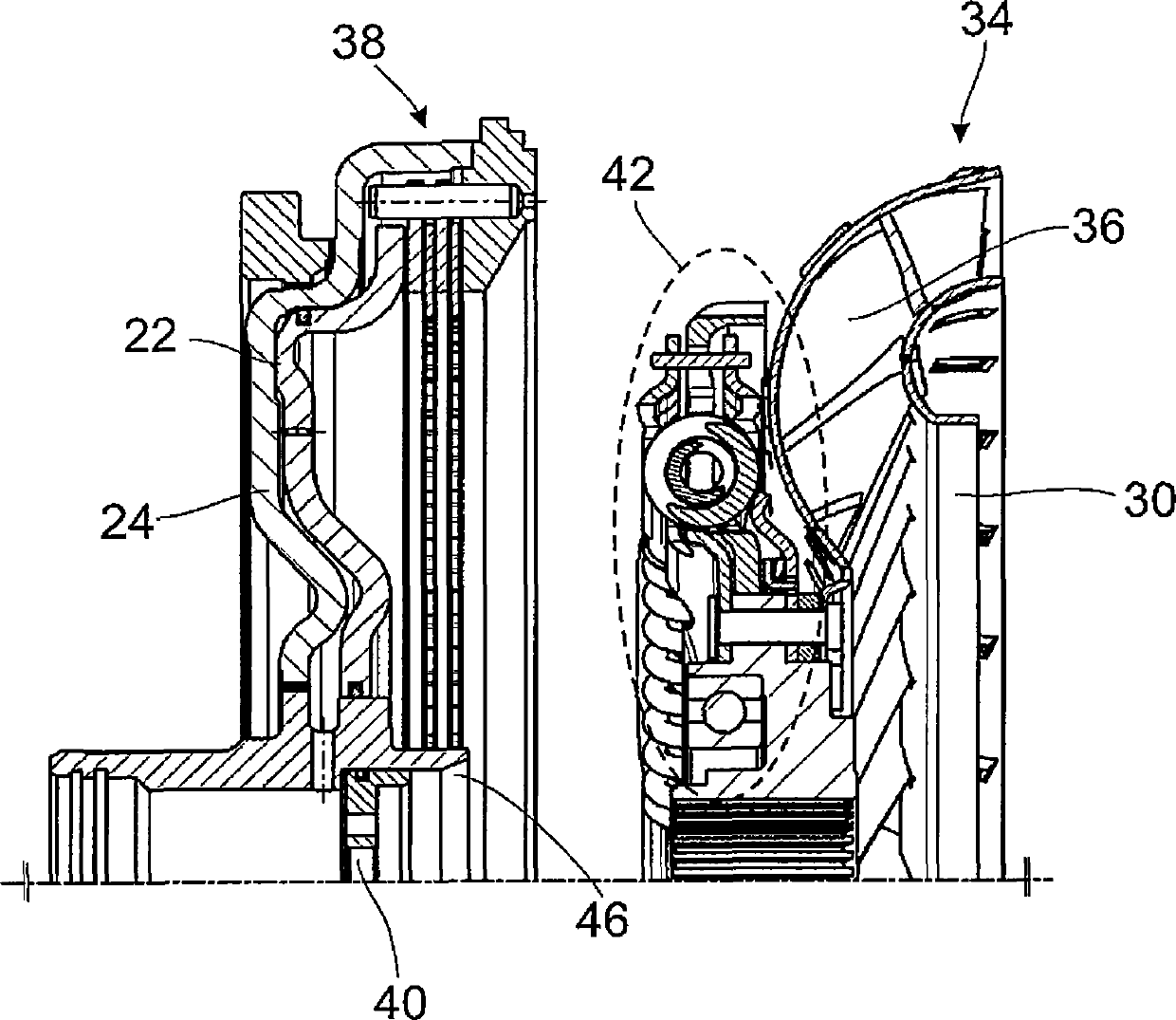

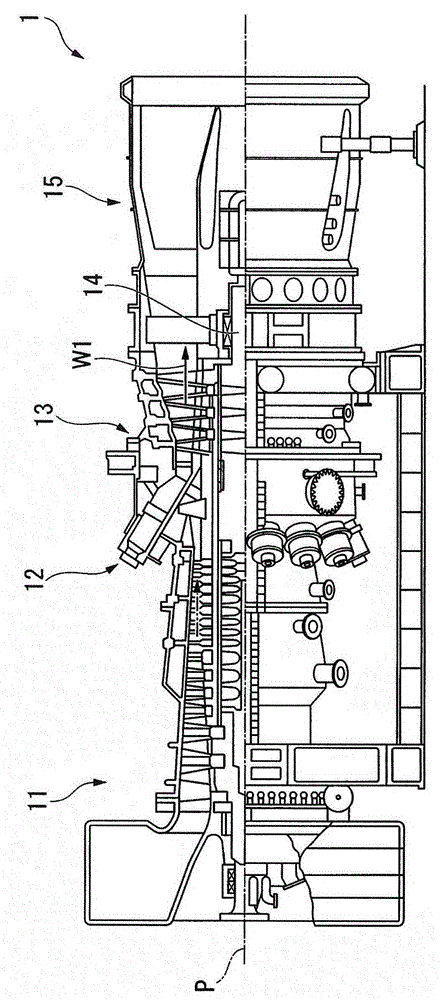

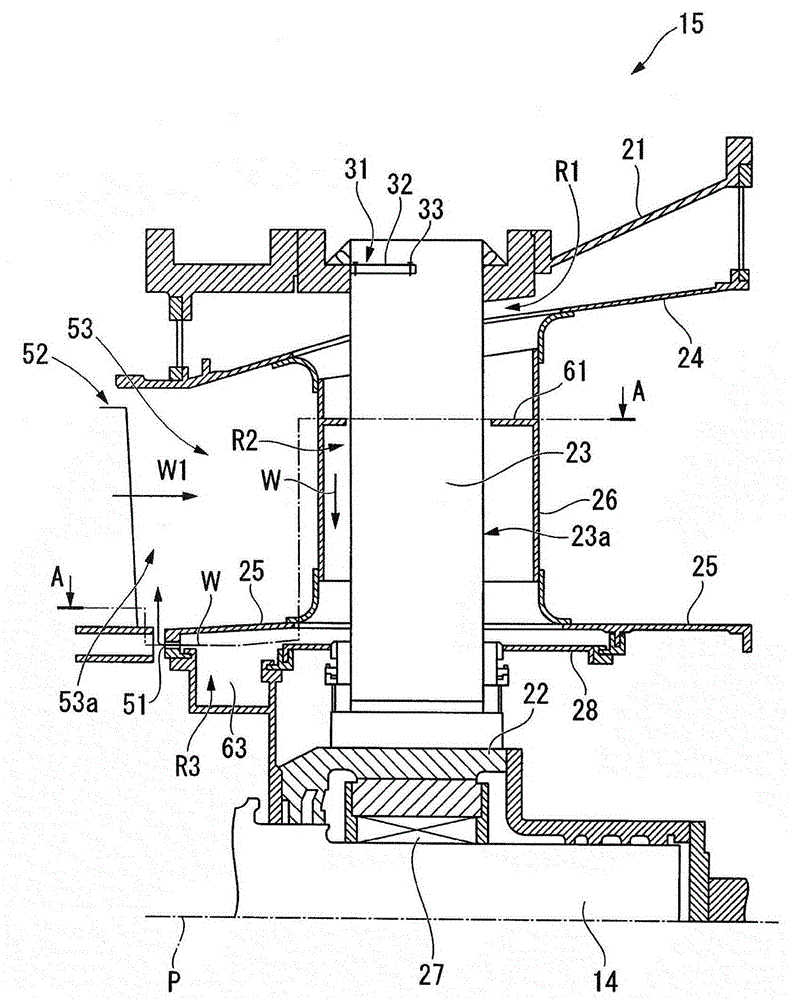

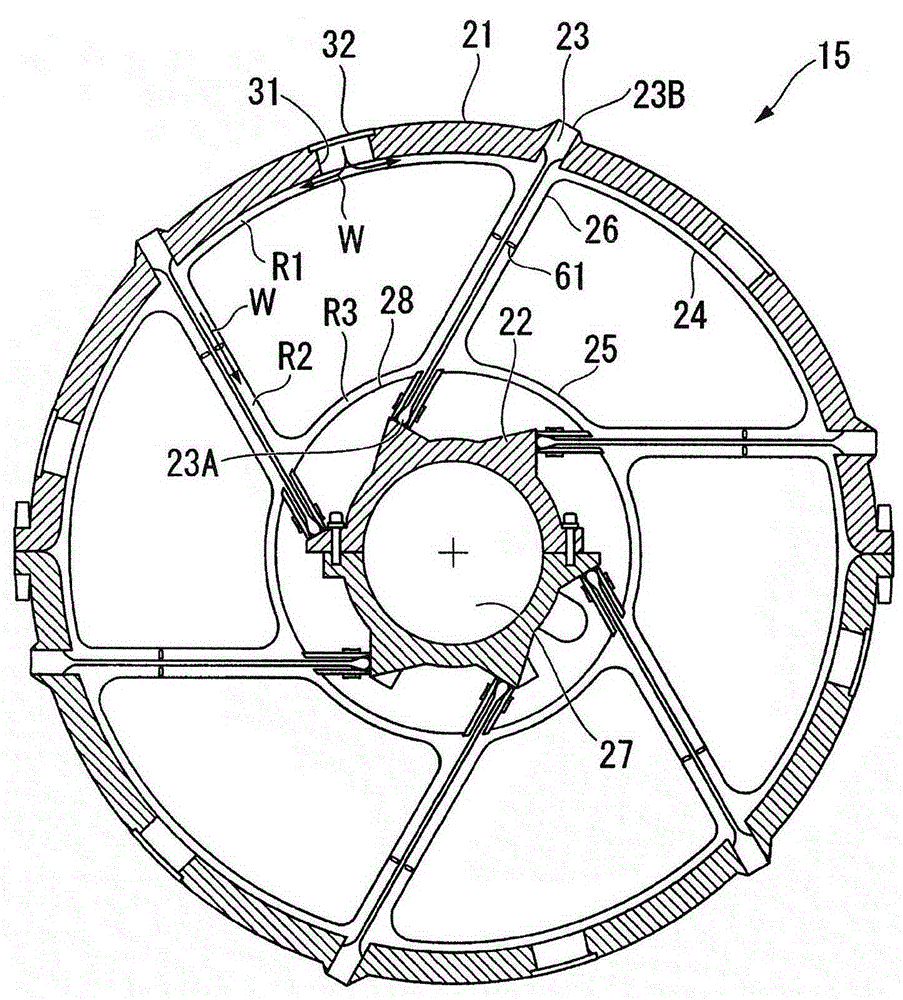

Gas turbine

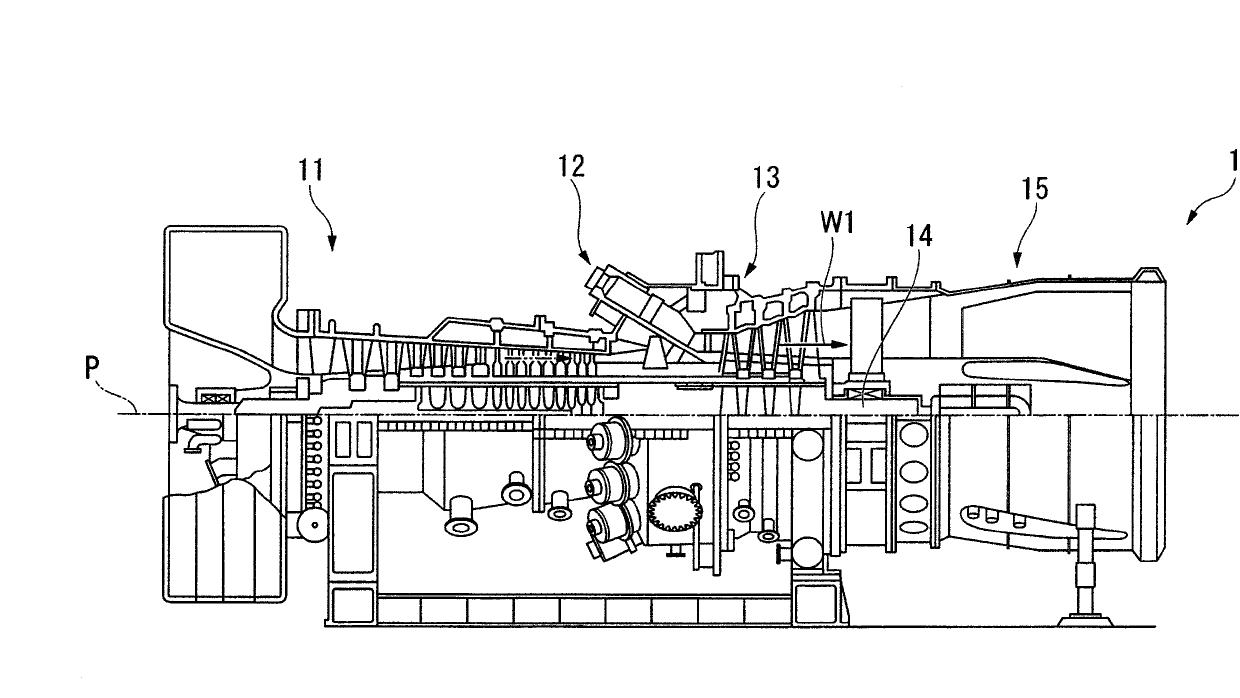

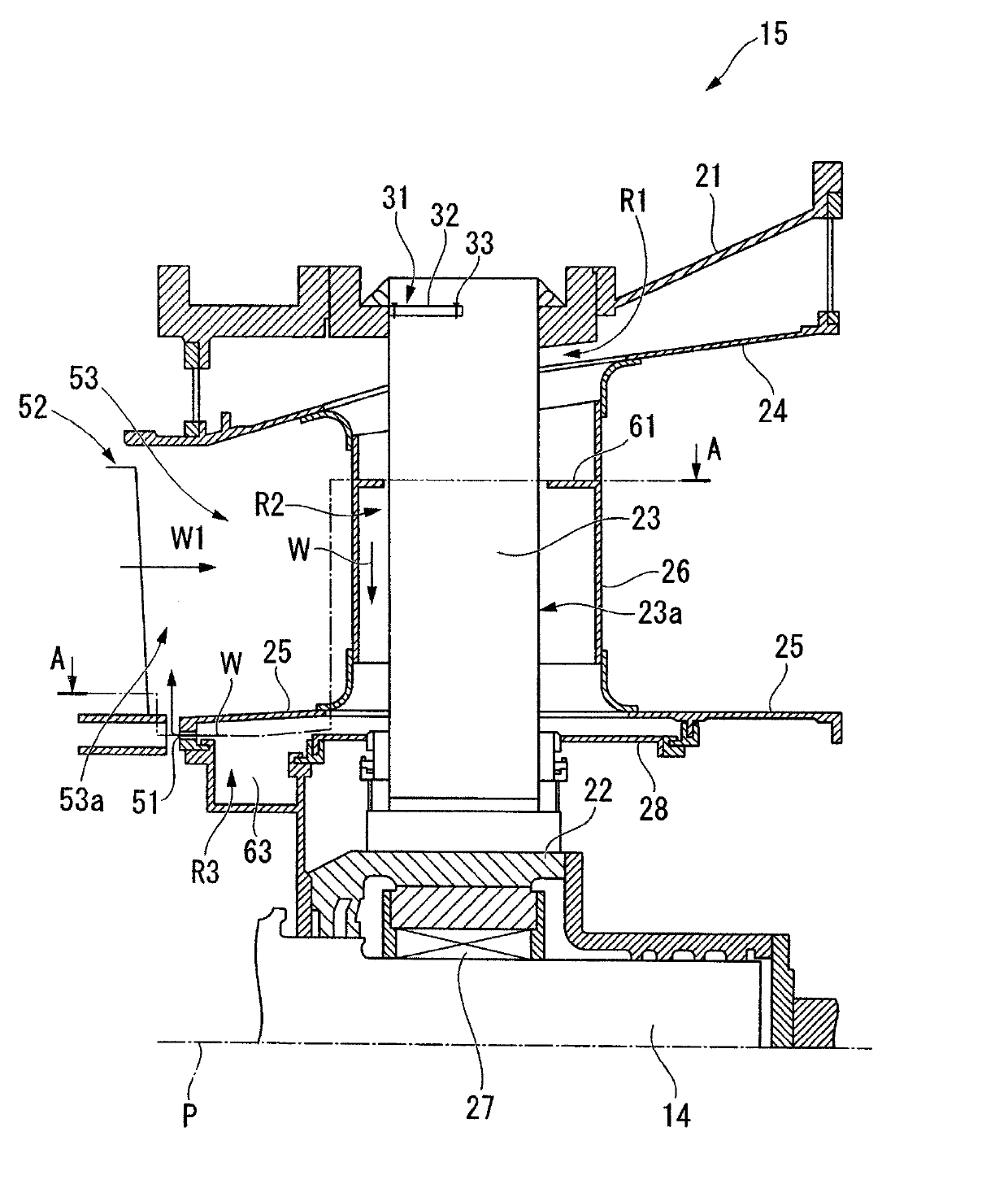

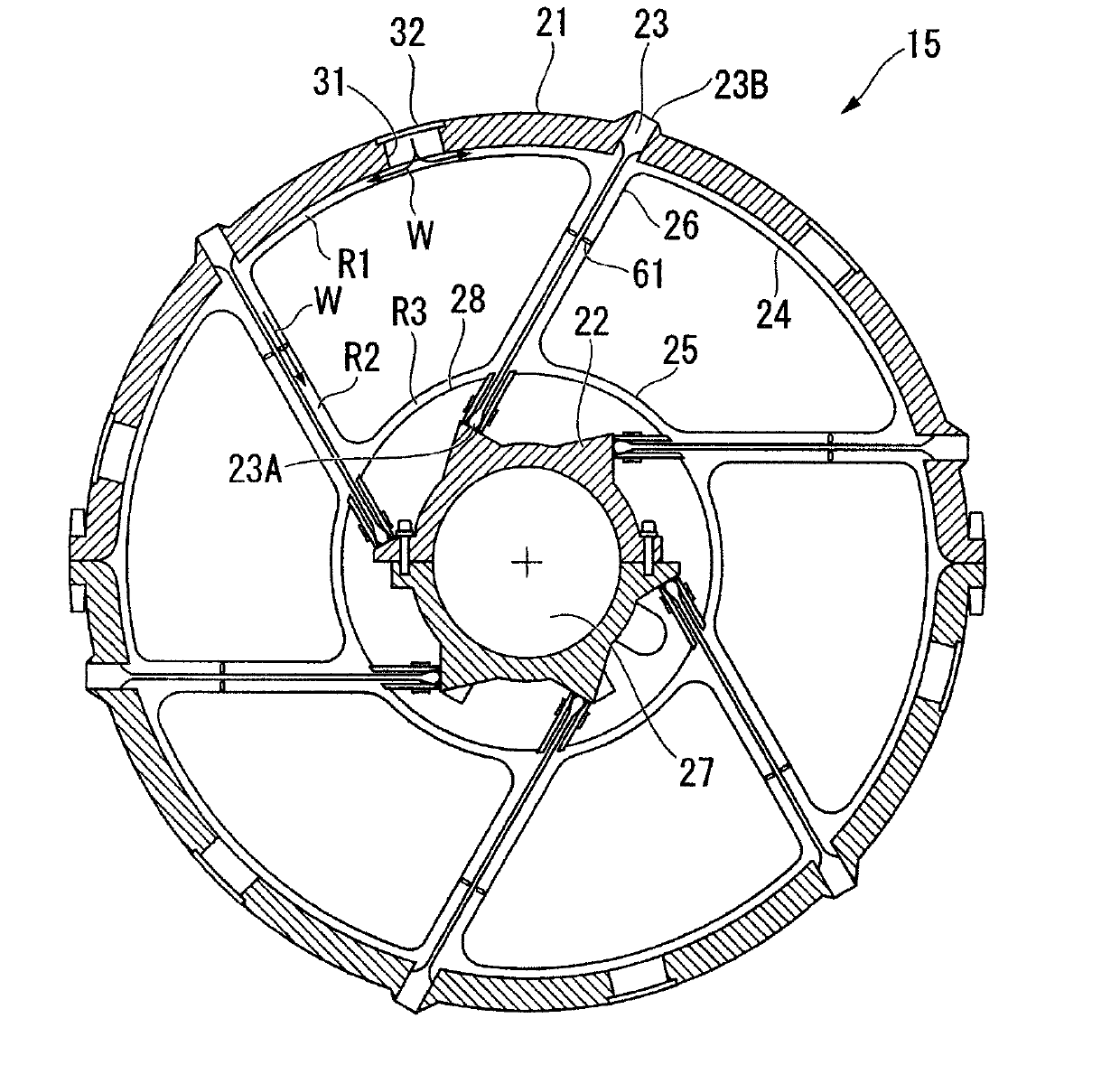

InactiveCN103109045AUniform thermal expansionAvoid Axial MisalignmentEngine manufactureTurbine/propulsion engine coolingGas turbinesAerospace engineering

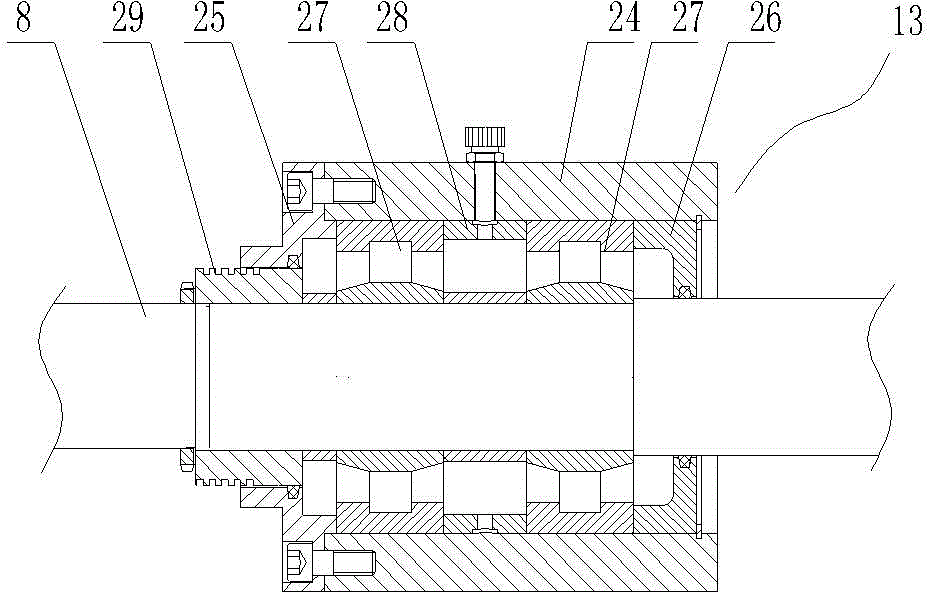

The present invention is a gas turbine that prevents heat-related axial misalignment of the rotary shaft of a rotor, said gas turbine being provided with: a strut (23); outer diffuser (24); an inner diffuser (25); a strut cover (26); and a partition wall (28). The gas turbine is provided with: an inflow port (31) through which cooling air (W) is drawn in; a first flow path (R1) formed between a casing wall (21) and the outer diffuser (24); a second flow path (R2) formed between the strut (23) and the strut cover (26); a third flow path (R3) formed between the inner diffuser (25) and the partition wall (28); and an outflow port (51) provided on the inner diffuser (25).

Owner:MITSUBISHI HITACHIPOWER SYST LTD

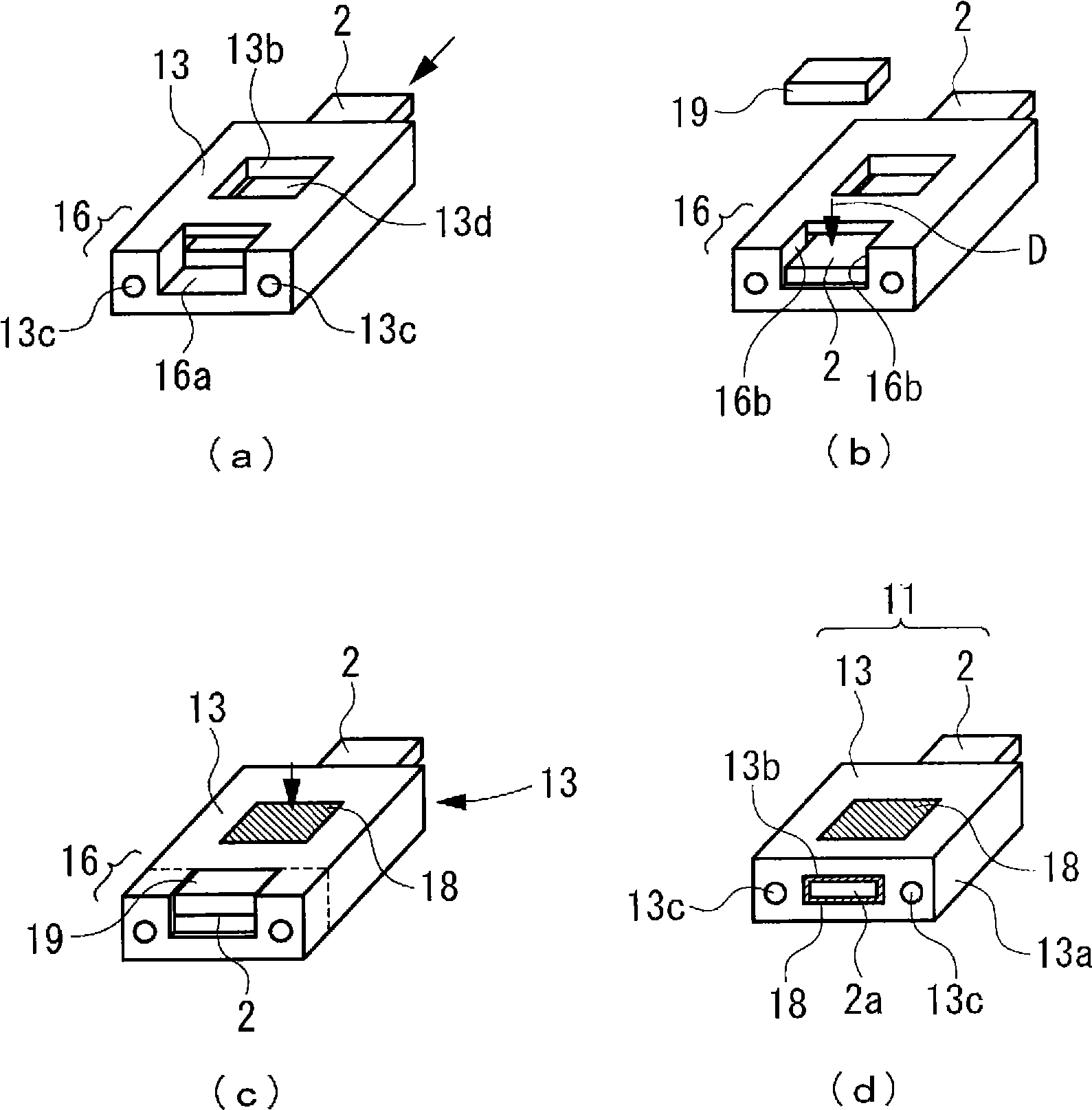

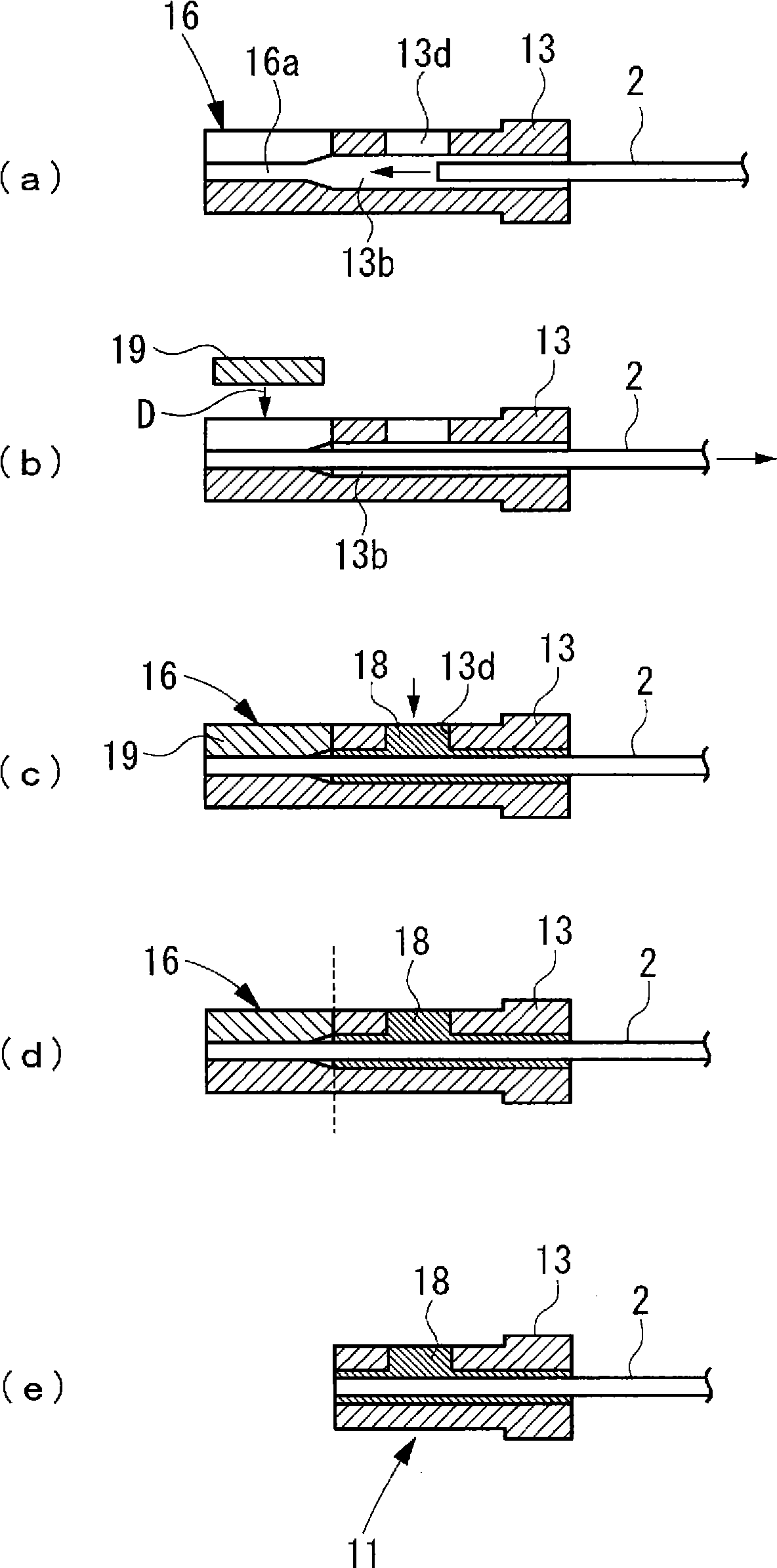

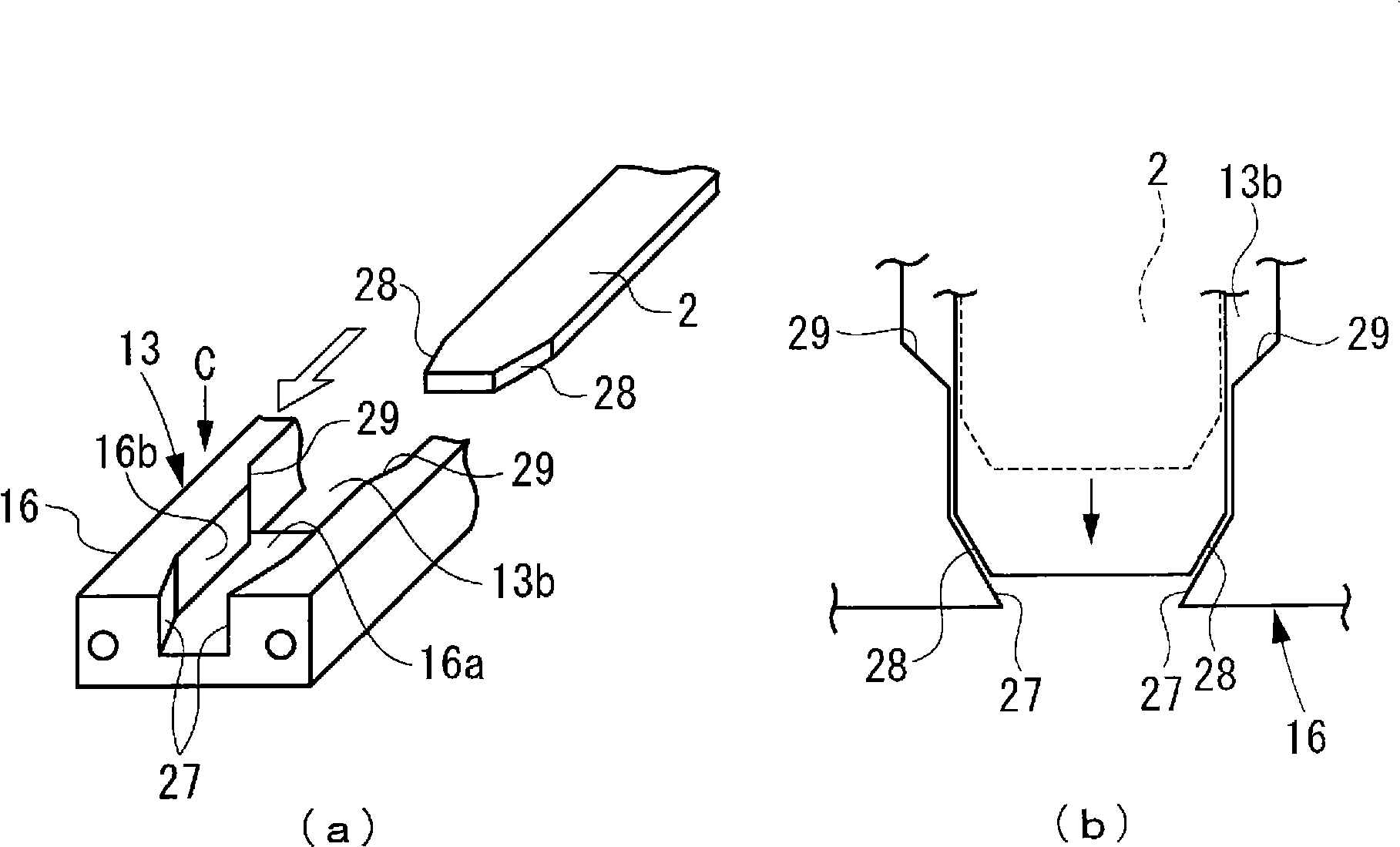

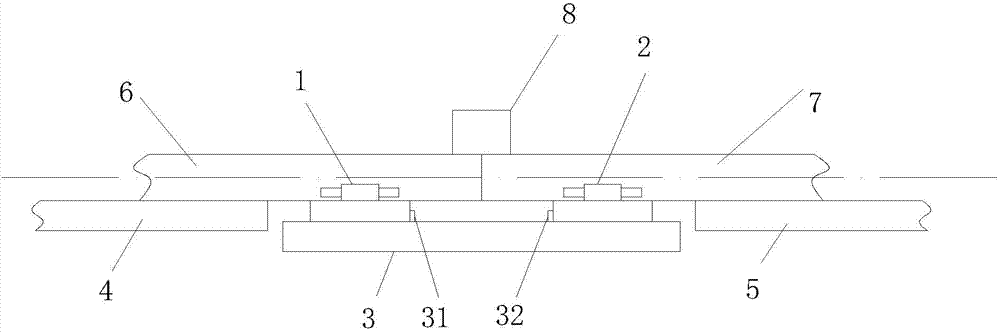

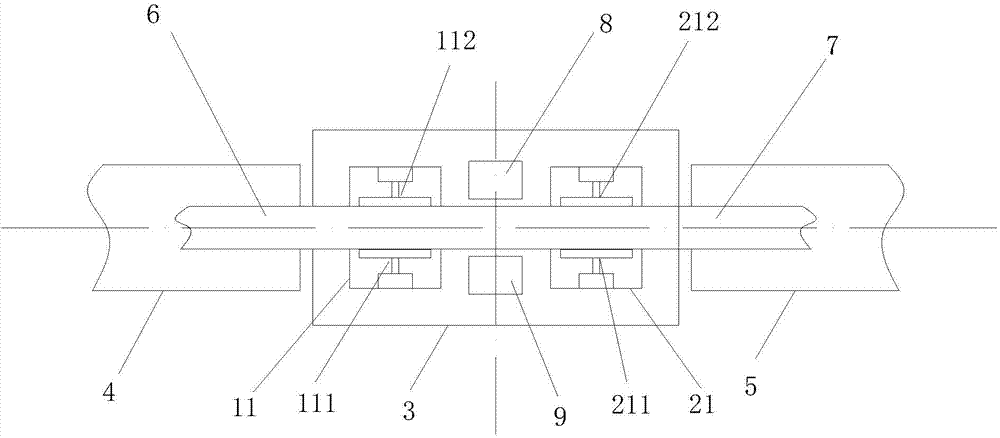

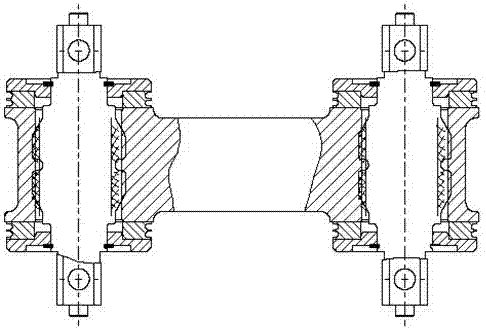

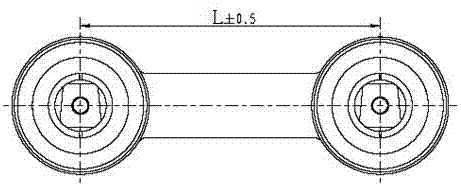

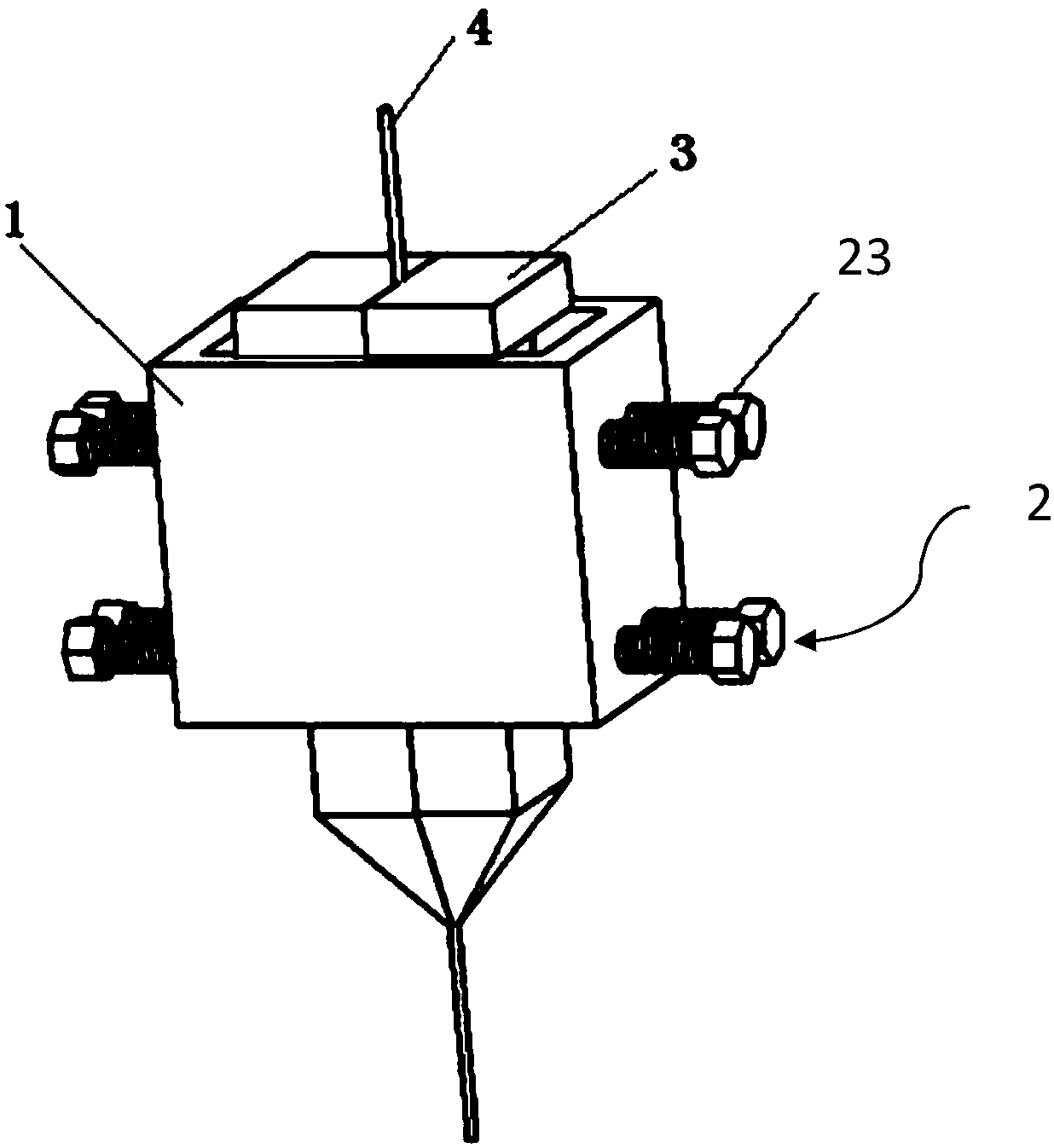

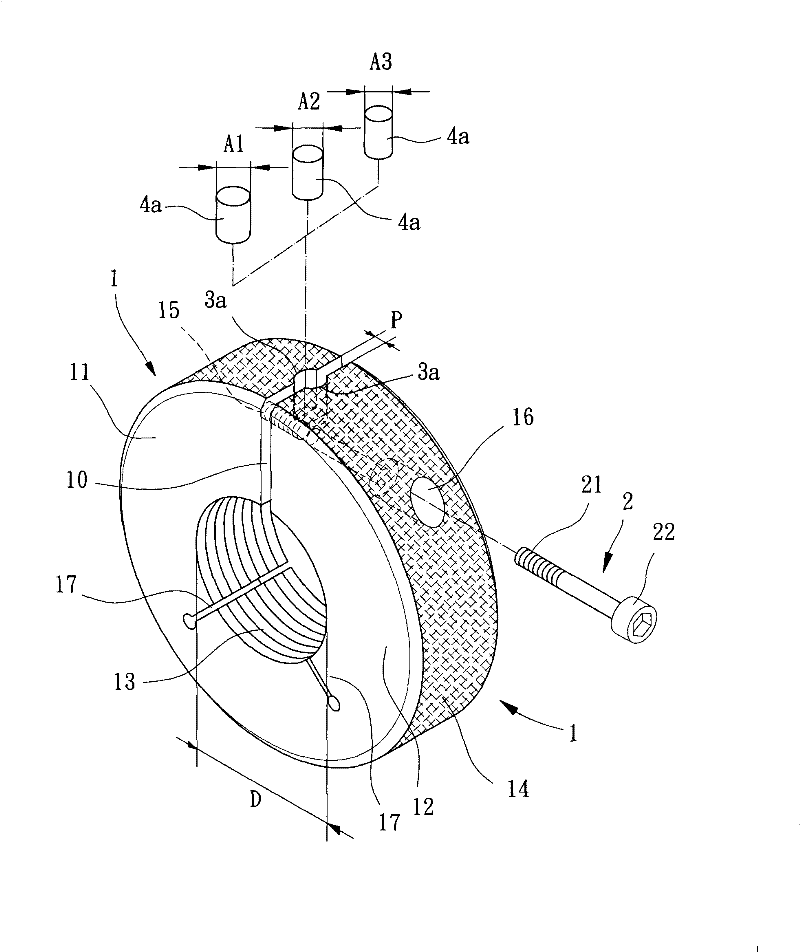

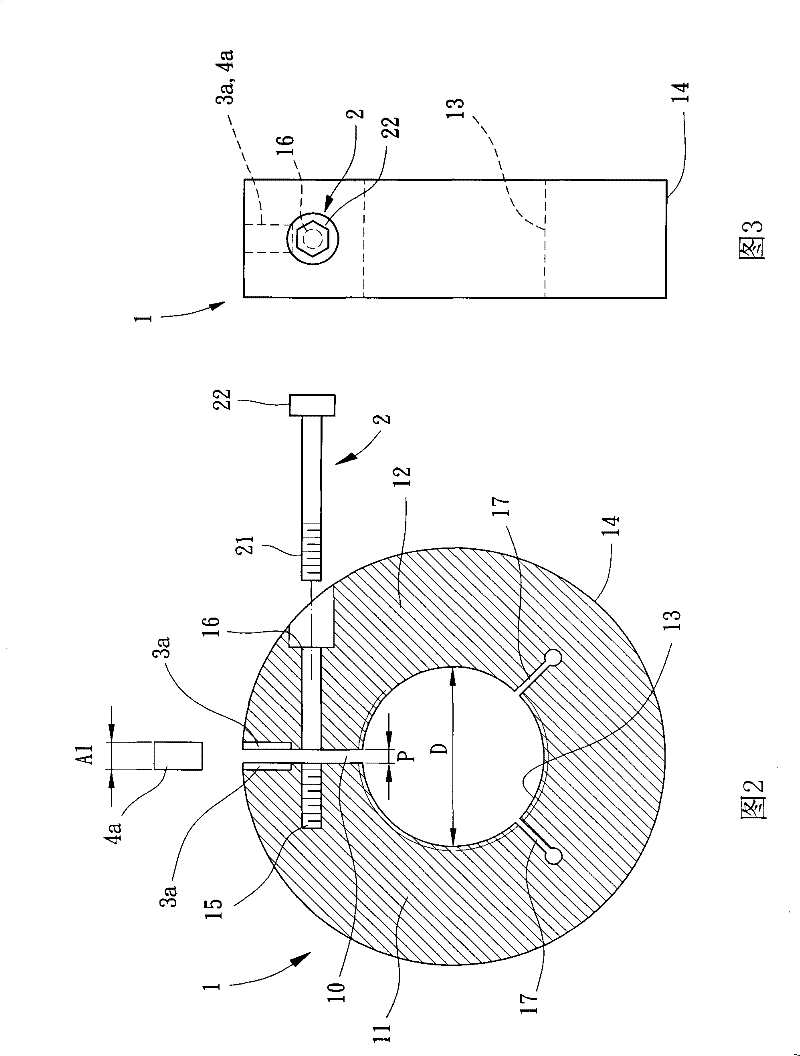

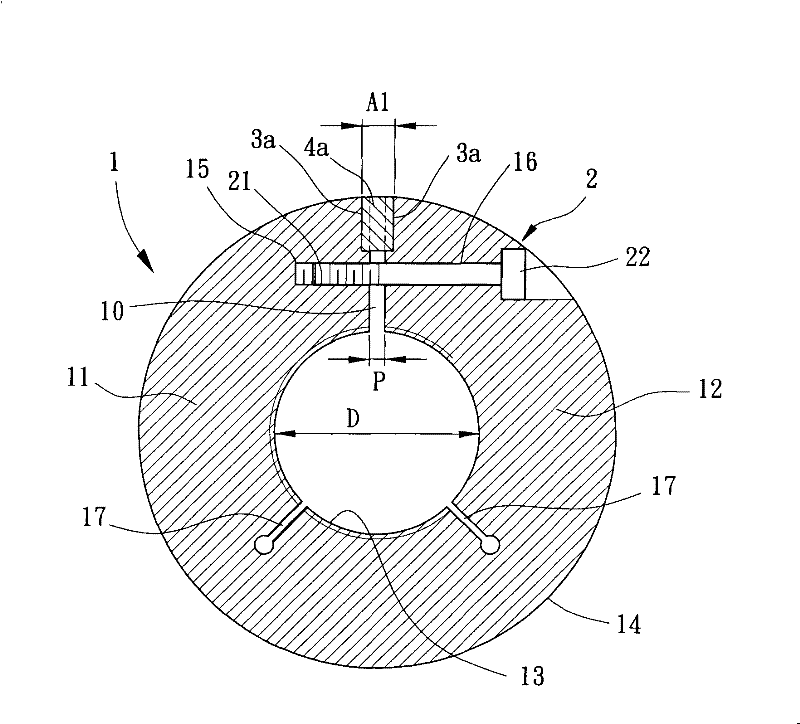

Ferrule, method of manufacturing optical waveguide connector using the ferrule, and optical waveguide connector

InactiveCN101523263ANo axial misalignmentImprove yieldCoupling light guidesOptical waveguide light guideProduction rateAdhesive

Provided is an optical waveguide connector manufacturing method capable of improving the productivity of a ferrule member and suppressing the connection loss of a partner connector. An optical waveguiProvided is an optical waveguide connector manufacturing method capable of improving the productivity of a ferrule member and suppressing the connection loss of a partner connector. An optical waveguide connector (11) is obtained by executing a centering step of position-regulating the leading end of an optical waveguide (2) inserted into the insert hole (13b) of a ferrule member (13), with the pode connector (11) is obtained by executing a centering step of position-regulating the leading end of an optical waveguide (2) inserted into the insert hole (13b) of a ferrule member (13), with the positioning portion of a positioning member (16) arranged to confront the leading end of the ferrule member (13), thereby to center the optical waveguide with respect to the ferrule member (13), an adhesitioning portion of a positioning member (16) arranged to confront the leading end of the ferrule member (13), thereby to center the optical waveguide with respect to the ferrule member (13), an adhering step of filling an adhesive (18) into the clearance between the optical waveguide (2) inserted into the insert hole (13b) and the insert hole (13b), thereby to fix the optical waveguide (2) in thring step of filling an adhesive (18) into the clearance between the optical waveguide (2) inserted into the insert hole (13b) and the insert hole (13b), thereby to fix the optical waveguide (2) in the ferrule member (13), and a cutting step of cutting off the leading end of the ferrule member (13) including the positioning member (16).e ferrule member (13), and a cutting step of cutting off the leading end of the ferrule member (13) including the positioning member (16).

Owner:SUMITOMO ELECTRIC IND LTD +1

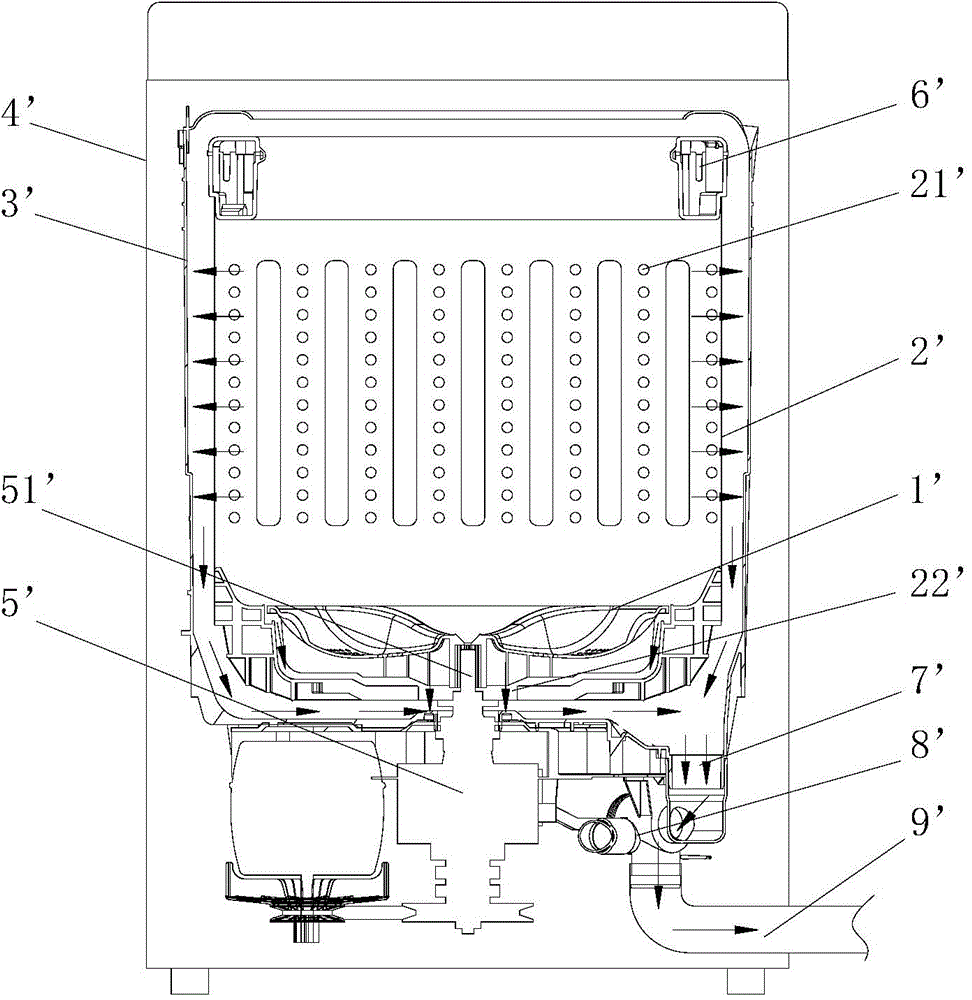

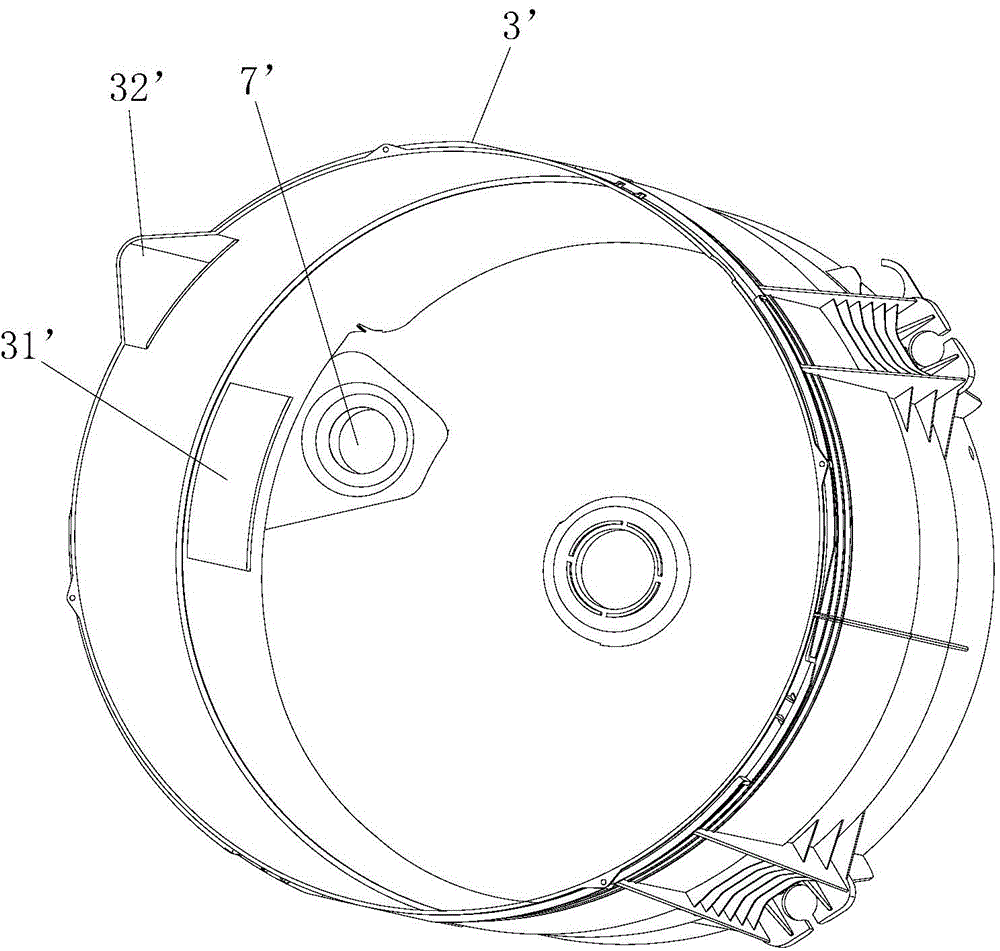

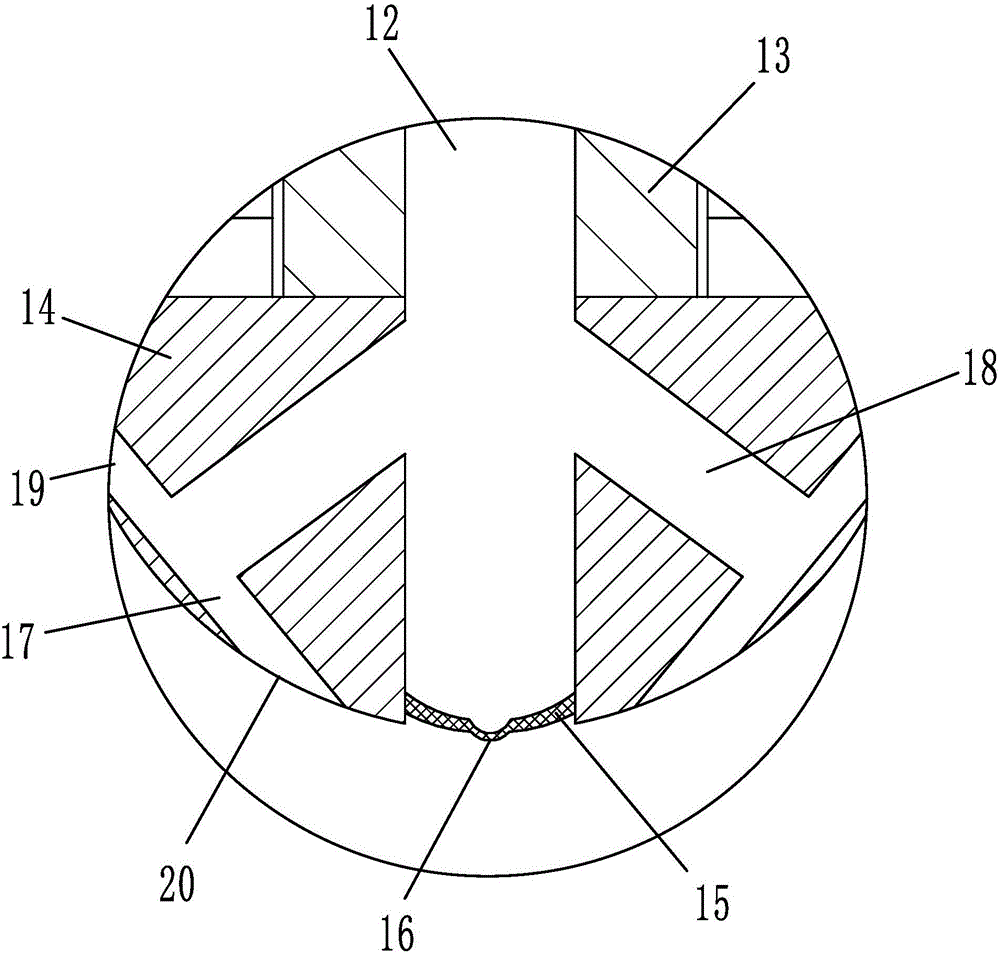

Washing machine inner barrel

PendingCN105624976AHygienic useEnvironmental protectionOther washing machinesTextiles and paperEngineeringWater holding

The invention discloses a washing machine inner barrel. The washing machine inner barrel comprises a barrel body, an inner barrel bottom arranged on the lower part of the barrel body, and a balancing ring arranged on the upper opening of the barrel body. The upper part of the inner barrel is provided with a water outlet, a water holding structure is arranged under the water outlet, and the barrel body is in seal connection with the inner barrel bottom. Specifically, the barrel body and the inner barrel bottom form an integral injection moulding structure; or the barrel body is provided with a loop of profiled part along the circumference, the profiled part is matched with the upper end face of the circumferential wall of the inner barrel bottom to form a blocking and supporting structure, a sealing ring is arranged between the profiled part and the inner barrel bottom, and end face seal is formed; or a sealing ring or a seal cartridge is arranged between the circumferential wall of the inner barrel bottom and the lower part of the barrel body, the inner wall of the seal cartridge is provided with at least two loops of convex ribs, and each loop of convex rib is correspondingly arranged in a mounting groove which is arranged in the external surface of the circumferential wall of the inner barrel bottom in the circumferential direction; or the lower part of the barrel body sleeves the outer surface of the circumferential wall of the inner barrel bottom, the lower edge of the barrel body is bent inwards to form a bound edge, the bound edge is connected with the inner barrel bottom, and the bound edge is inside provided with a sealing ring. The washing machine inner barrel is simple in structure and good in sealing effect, and can be installed conveniently, stably and firmly.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

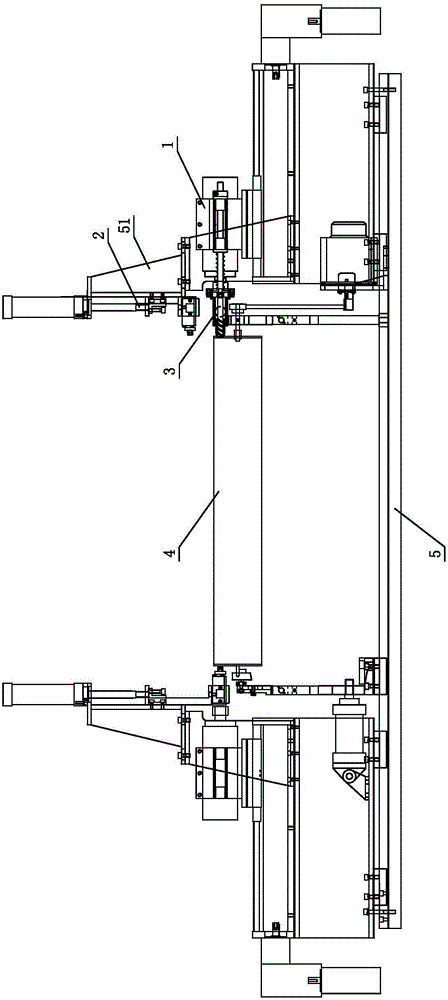

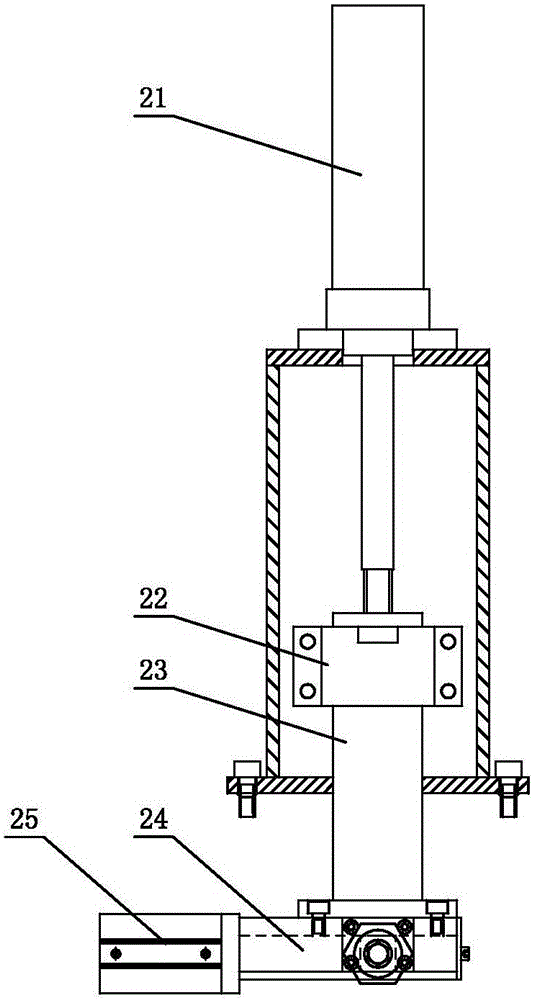

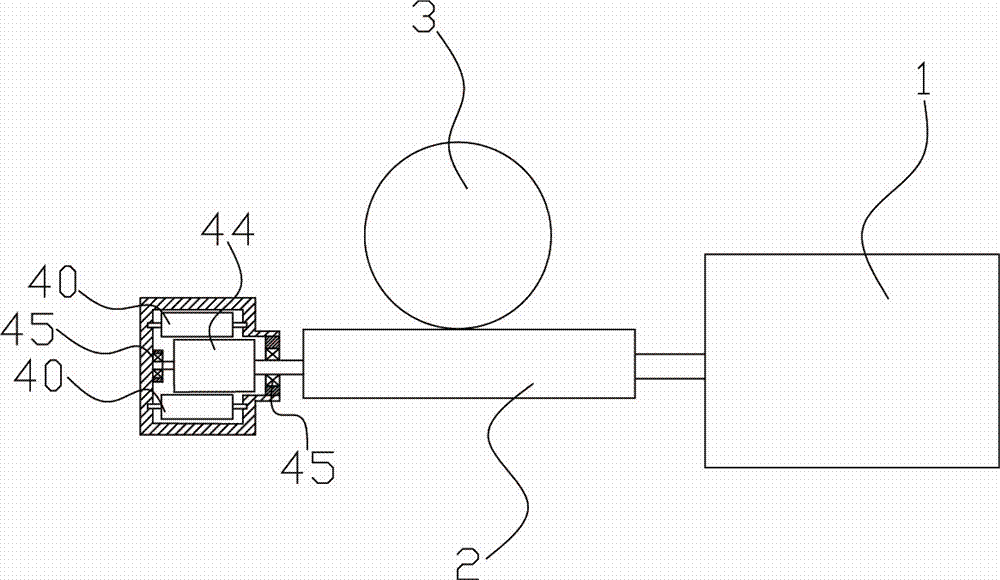

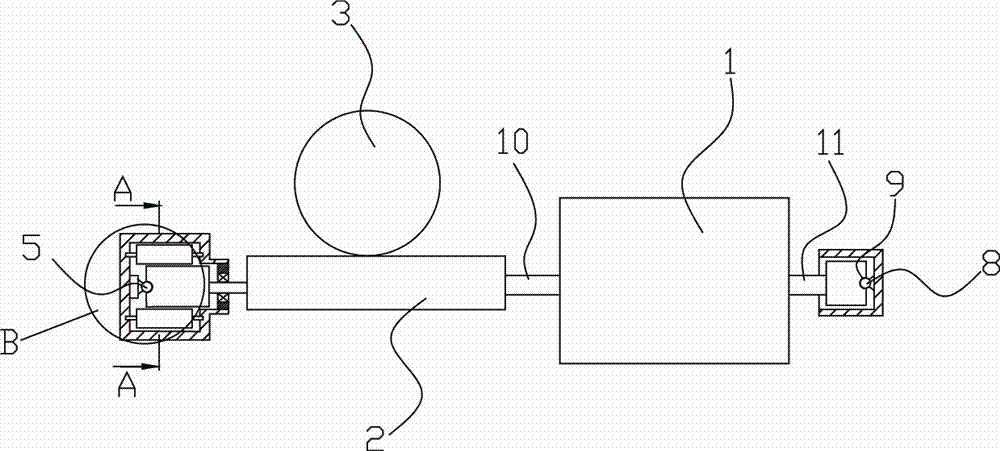

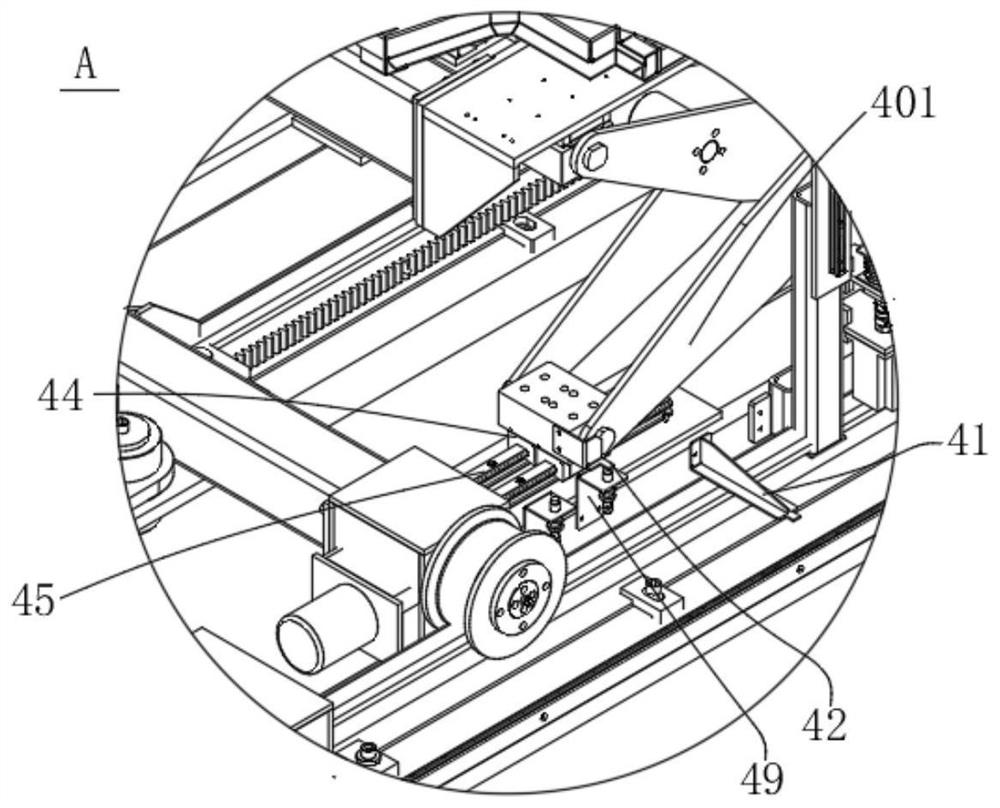

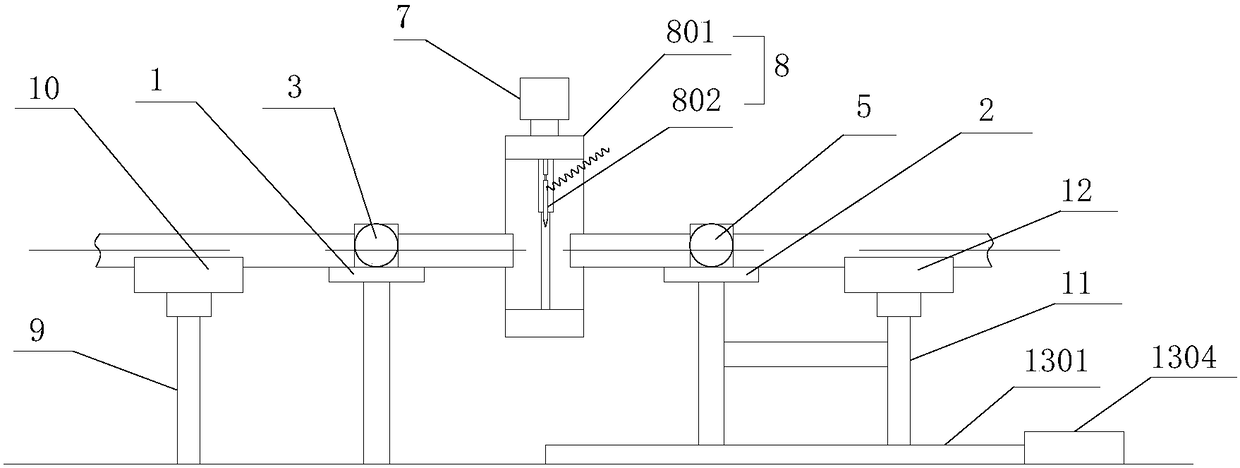

Pipe fitting automatic welding system

ActiveCN104708241AAvoid Axial MisalignmentImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesButt jointPipe fitting

The invention discloses a pipe fitting automatic welding system which comprises a first locating device, a second locating device, a workbench, a welding device, a control device, a first conveying device and a second conveying device. The first locating device is controlled by the control device and used for fixing a first pipe fitting and conveying the first pipe fitting to a welding station; the second locating device is controlled by the control device and used for fixing a second pipe fitting and conveying the second pipe fitting to the welding station to make the welding end face of the second pipe fitting and the welding end face of the first pipe fitting be in butt joint; the welding device is located at the welding station, controlled by the control device and used for conducting welding on a butt-jointed seam of the first pipe fitting and the second pipe fitting; the first conveying device is used for conveying the first pipe fitting to the first locating device, and the second conveying device is used for conveying the second pipe fitting to the second locating device. By means of the pipe fitting automatic welding system, the automation of welding the pipe fitting is achieved, the input of labor cost and requirements for artificial technical level are reduced, the efficiency is high, and the welding quality of the pipe fitting is improved.

Owner:WUHU JINGFENG GARDEN MACHINERY TECH

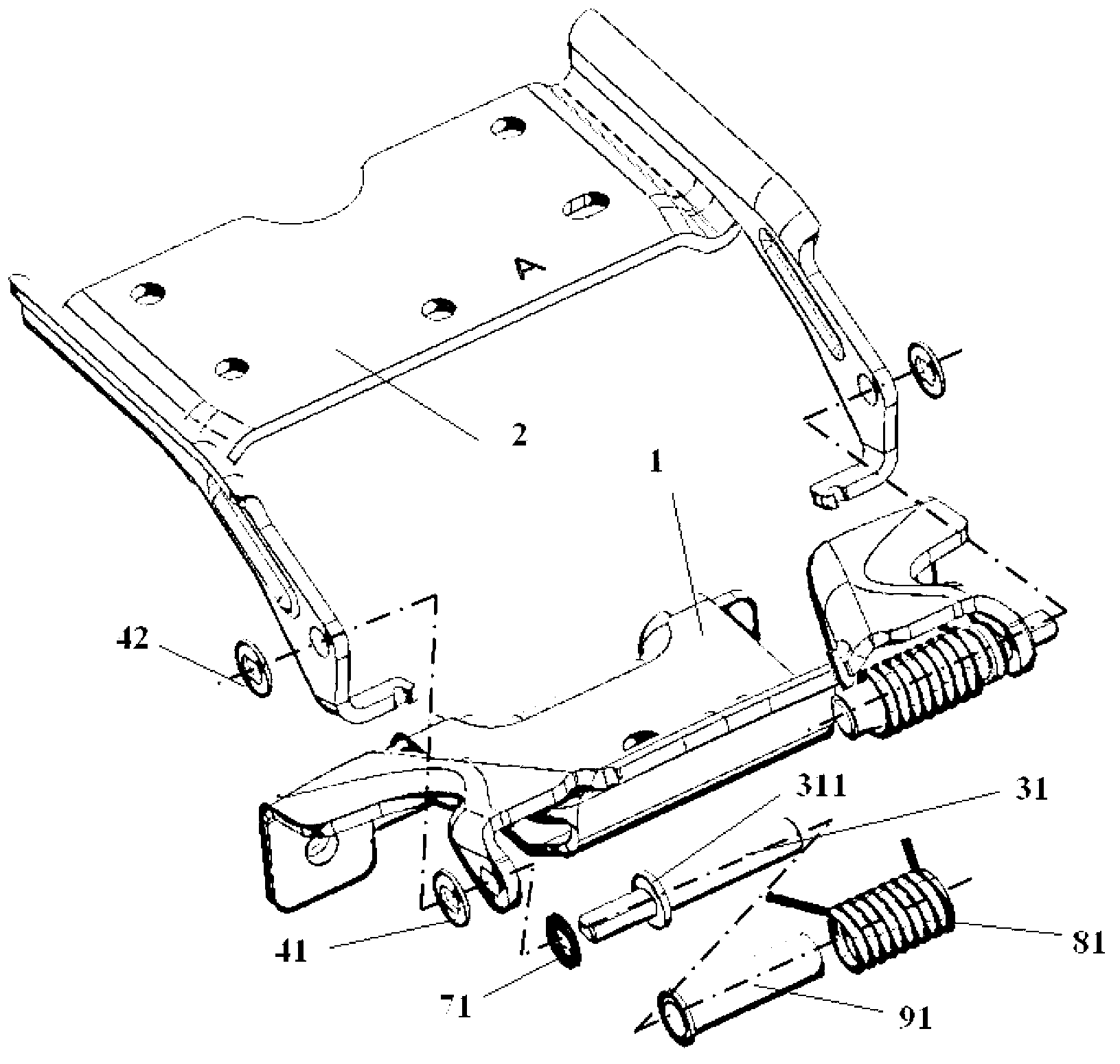

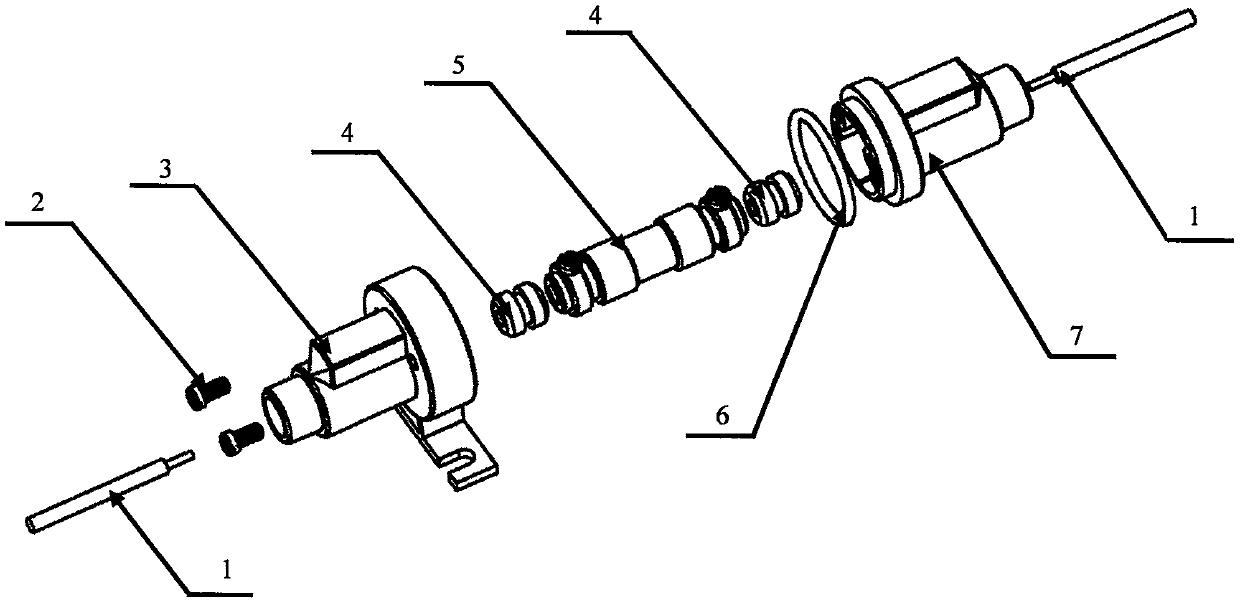

Free stopping mechanism

The invention provides a free stopping mechanism which comprises a mechanism base and a mechanism turning leaf, wherein the mechanism base and the mechanism turning leaf are connected on one side in a penetrating mode through a revolving shaft. A flange is arranged on the revolving shaft. A first friction piece, a second friction piece and a dish cushion piece are arranged among the mechanism base, the mechanism turning leaf and the flange at intervals. The mechanism base and the mechanism turning leaf are pressed through the flange. An opening-assisting spring is wound on the periphery of the revolving shaft and connected with the mechanism base at one end and connected with the mechanism turning leaf at the other end. The diameters of the friction pieces and the outer diameter of the opening-assisting spring can be controlled within 24mm and even can reach 12mm. Pressure on the friction pieces depends on pressure of riveting equipment or screwing torque of a nut so as to facilitate adjustment. Key parts are reduced. Coaxiality and rigidity are improved to prevent the revolving shaft from axially displacing. Attenuation of the friction pieces after a high temperature and low temperature fatigue alternating test is relieved and the friction pieces can undergo thirty thousand times of fatigue tests.

Owner:YANFENG AUTOMOTIVE TRIM SYST CO LTD

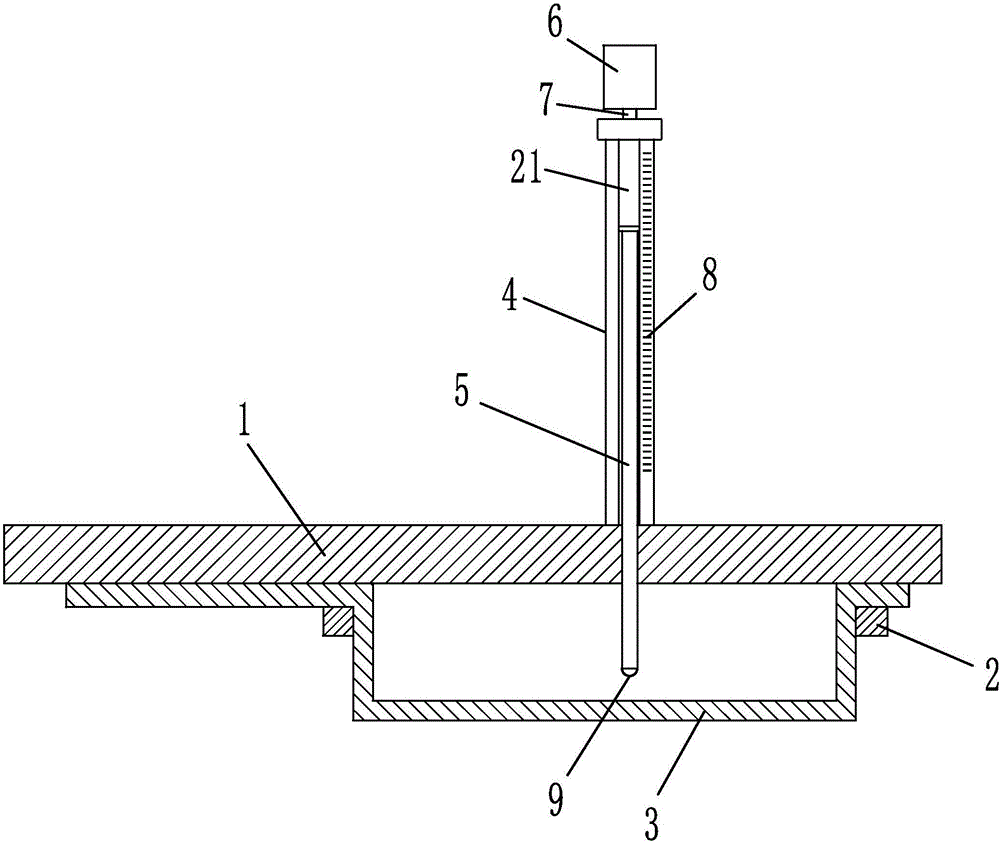

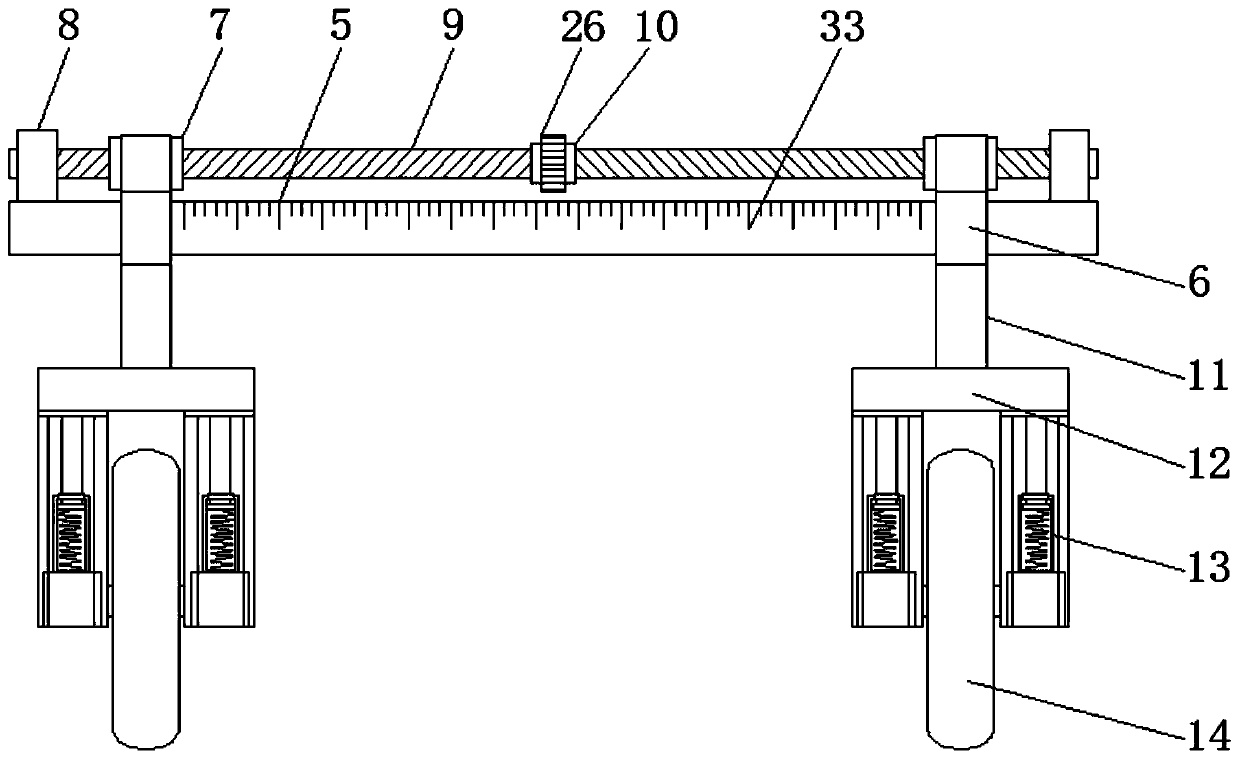

Aluminum plastic film scouring hole depth measuring device and measuring method thereof

ActiveCN106468532AAvoid pressure lossUniform force directionMechanical depth measurementsObservational errorAir pump

The invention relates to an aluminum plastic film hole-scouring technology of lithium batteries, and specifically relates to an aluminum plastic film scouring hole depth measuring device and a measuring method thereof. The aluminum plastic film scouring hole depth measuring device comprises a thickness gauge platform and a thickness ruler, the thickness gauge platform is provided with a die hole corresponding to an aluminum plastic film scouring hole, the bottom surface of the thickness gauge platform is connected with a positioning ruler used for fixing an aluminum plastic film in a sliding manner, the thickness ruler comprises a transparent main ruler fixed at an edge of the die hole, the axis of the transparent main ruler is provided with a containing chamber, an auxiliary ruler is connected in the containing chamber in a sliding manner, the top of the transparent main ruler is provided with an air pump, the air pump communicates with the containing chamber through an air pipe, the bottom of the auxiliary ruler is provided with a contact head, an airway is arranged at the axes of the auxiliary ruler and the contact head in a penetrating manner, the airway, close to the bottom edge of the contact head, is provided with an air cushion, a side surface of the contact head is provided with a plurality of vent holes, and the vent holes communicate with the airway. The beneficial effects of the device are that multipoint measurement can be realized, the measuring precision is improved, and measuring errors are reduced.

Owner:ZHEJIANG CHAOWEI CHUANGYUAN INDUSTRAIAL

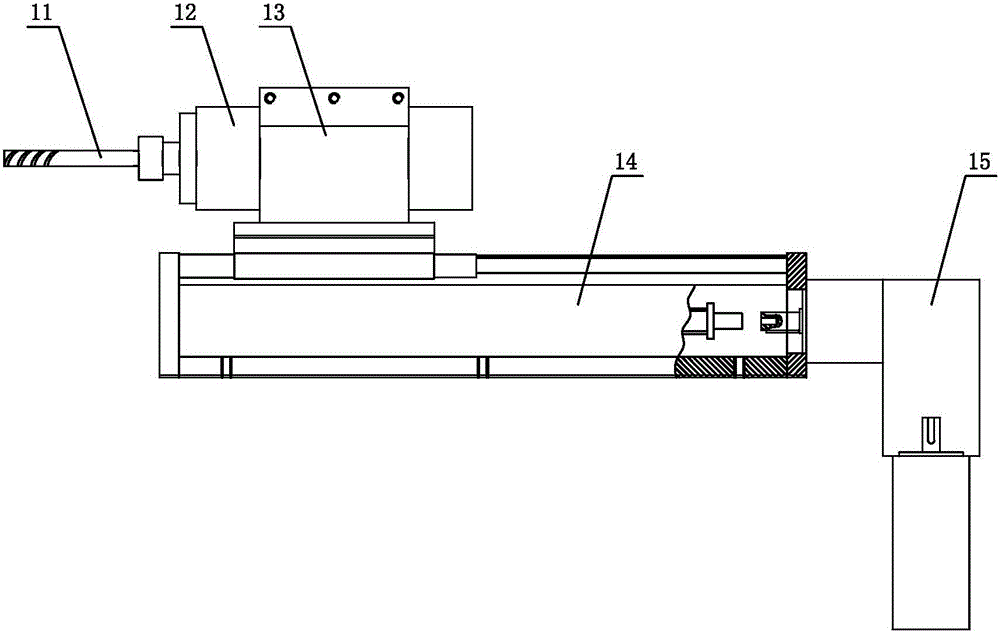

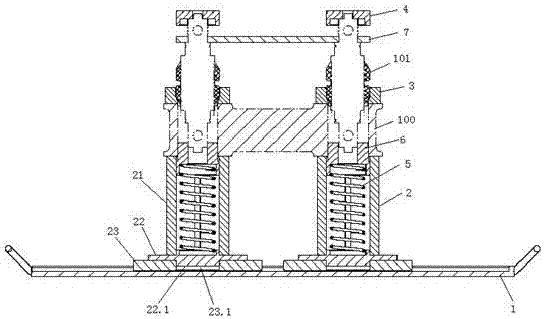

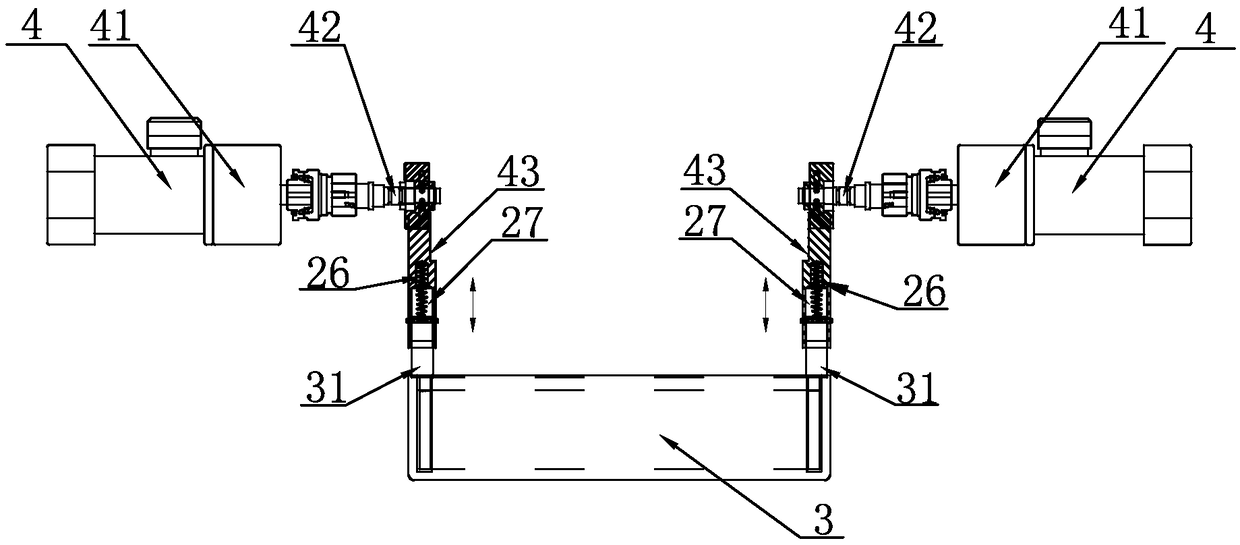

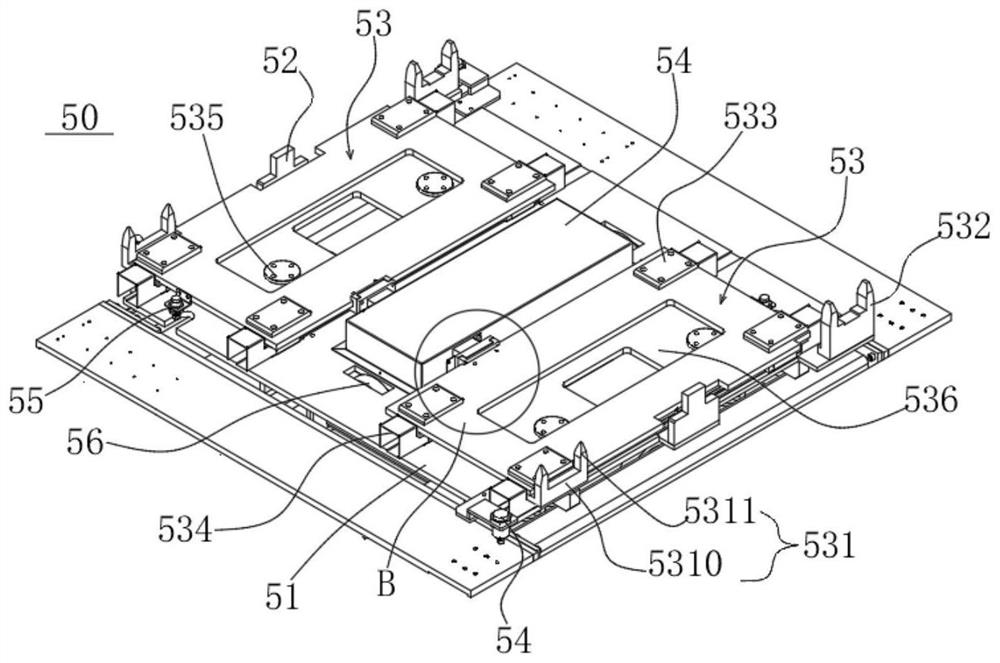

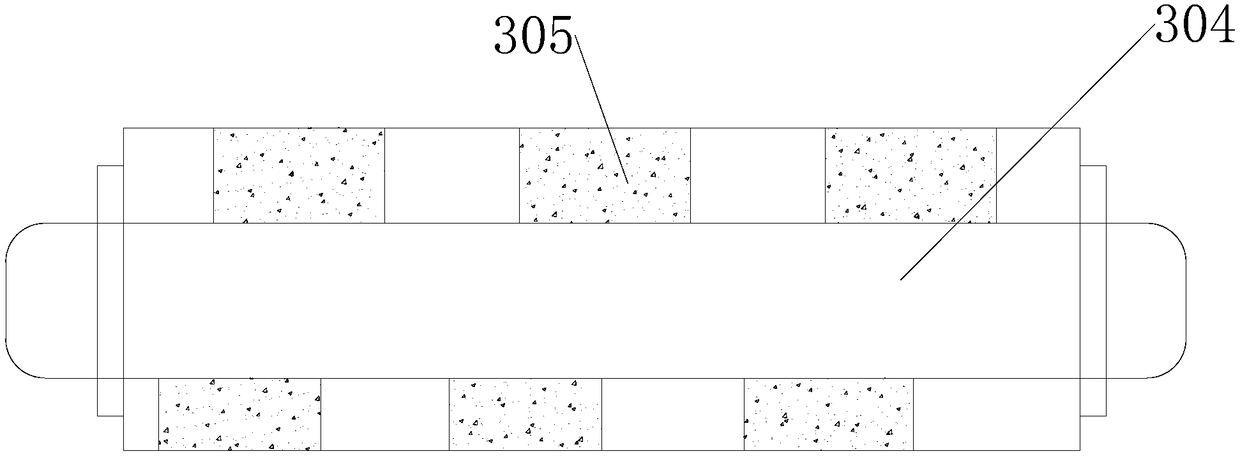

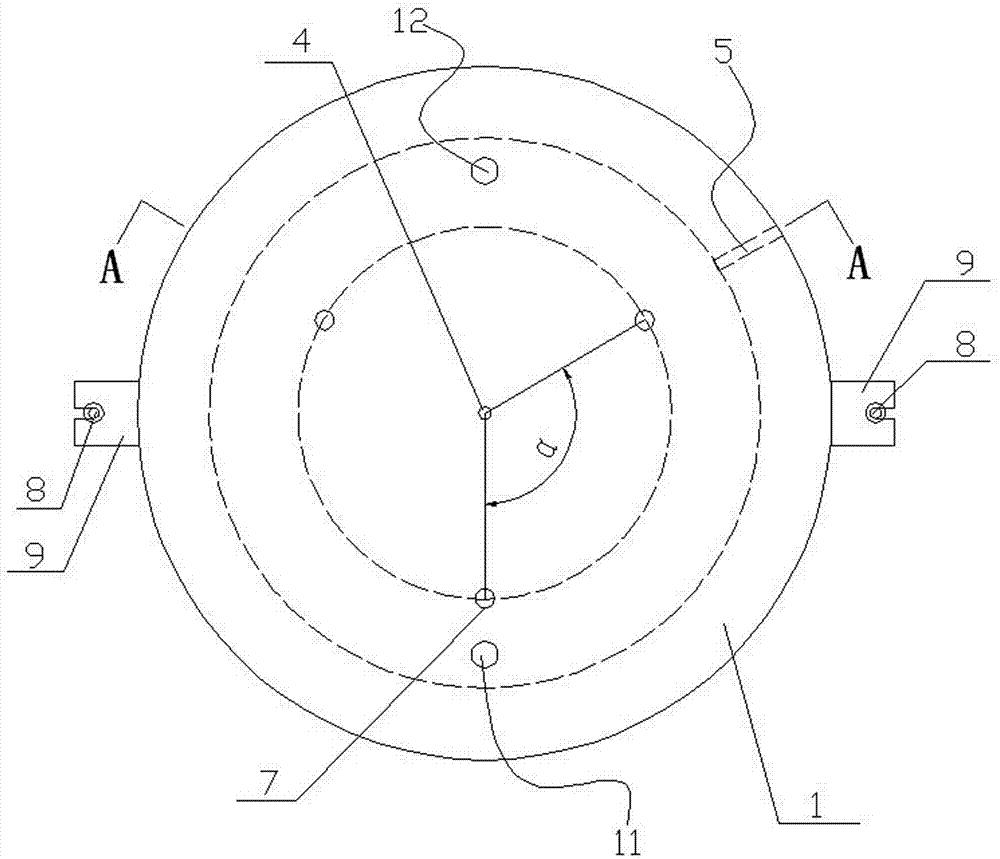

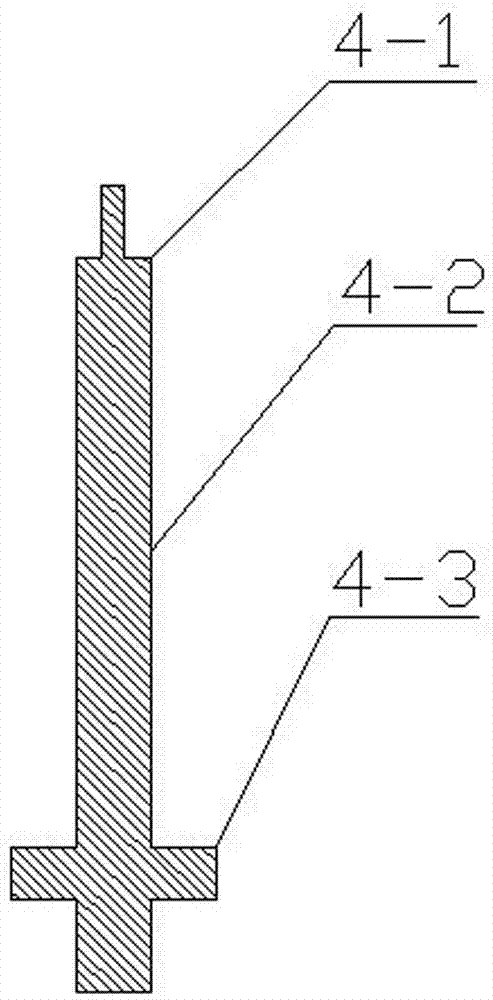

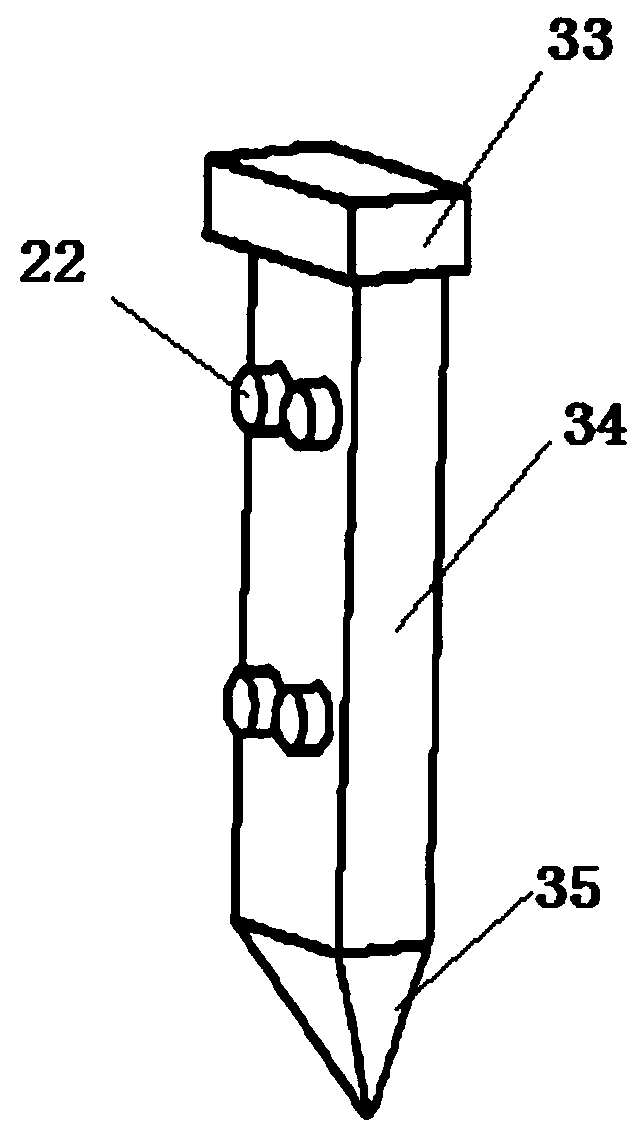

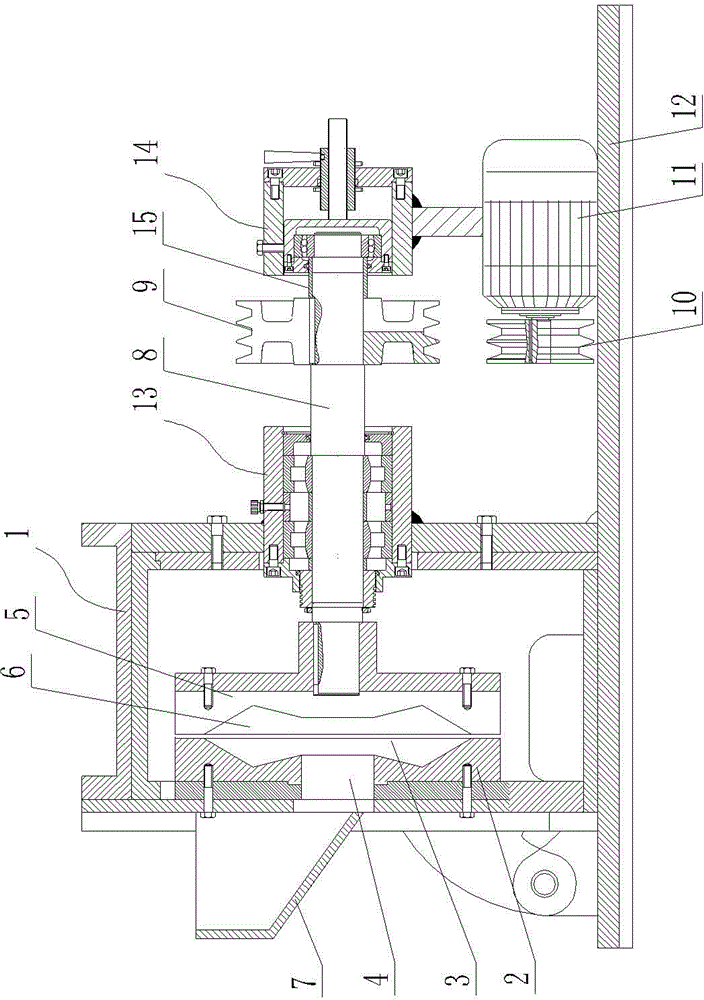

Unbalance ridding mechanism for cross-flow fan dynamic balance emendation

ActiveCN105784278AAvoid Axial MisalignmentGuaranteed accuracyStatic/dynamic balance measurementDynamic balanceMilling cutter

The invention discloses an unbalance ridding mechanism for cross-flow fan dynamic balance emendation, which comprises a base. A cross-flow fan is clamped on the base; the base is provided with two sets of drilling unbalance ridding assemblies for drilling unbalance ridding and two sets of end surface top tight assemblies for cancelling the drilling force; the two sets of the drilling unbalance ridding assemblies and / or the two sets of the end surface top tight assemblies are respectively arranged at two ends of the cross-flow fan; and when a drilling milling cutter on the drilling unbalance ridding assembly performs drilling processing, the end surface top tight assemblies at the same side do not act on the cross-flow fan, and the end surface top tight assemblies at the opposite side act on the cross-flow fan to cancel the drilling force. Two sets of the drilling unbalance ridding assemblies and the two sets of the end surface top tight assemblies are arranged symmetrically, a uniform stress layout with drilling unbalance ridding at one end and top tight at the other end is adopted, axial offset of the cross-flow fan caused by the drilling force can be effectively avoided, the precision of an unbalance test system is ensured on one hand, and on the other hand, the drilling depth precision can be ensured; and in addition, as a debris absorption assembly is arranged, debris generated by drilling can be timely cleaned, and cleanness of the working environment can be effectively ensured.

Owner:GUANGDONG SUNWILL PRECISING PLASITC CO LTD

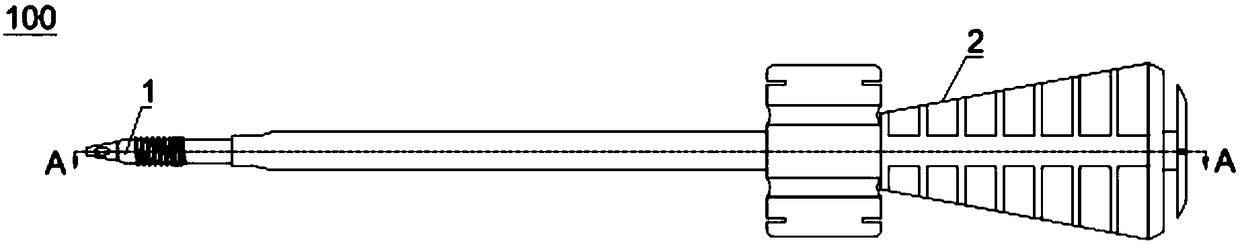

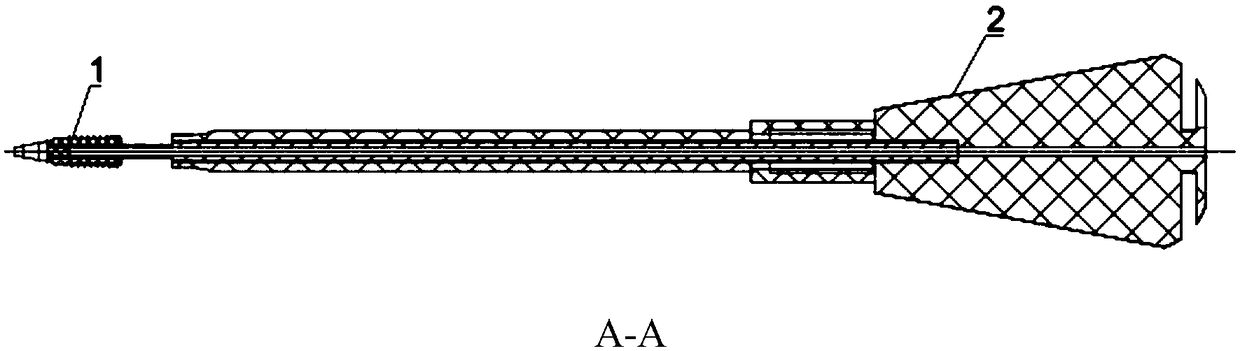

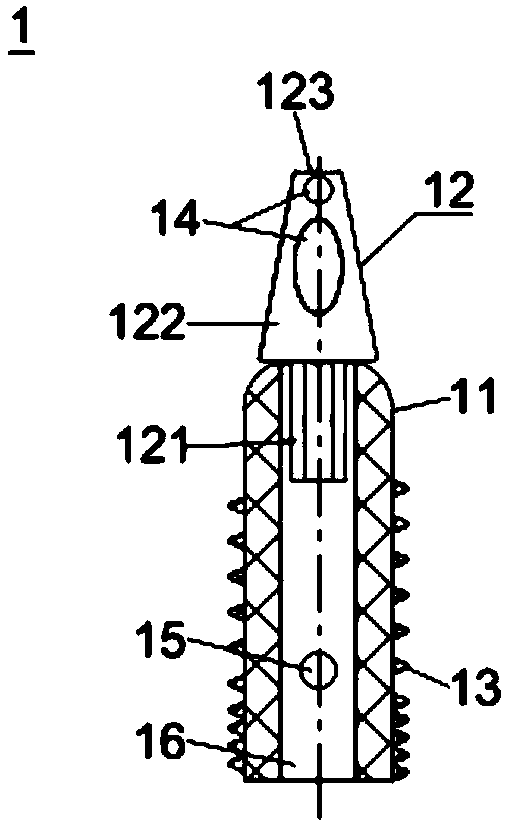

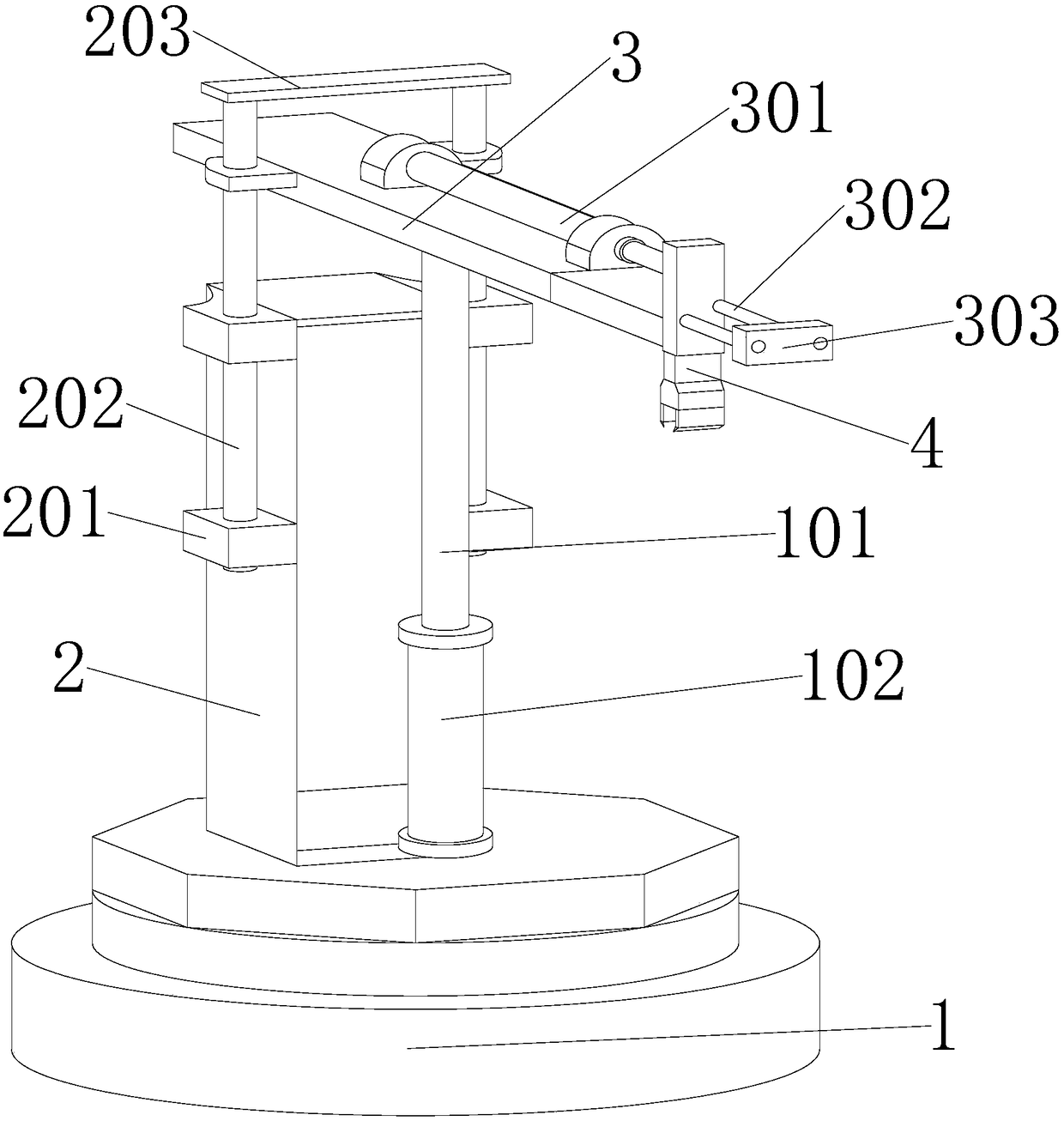

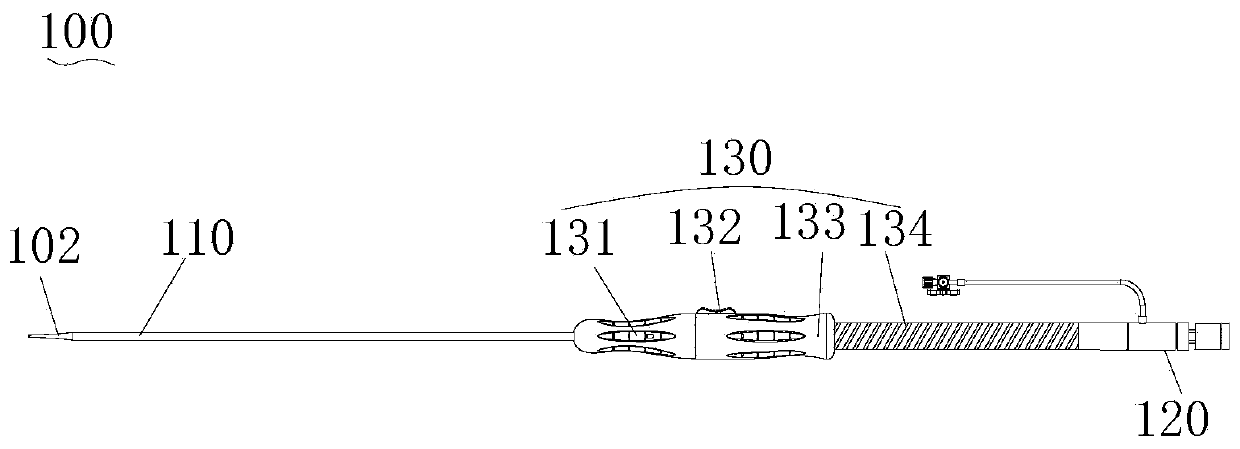

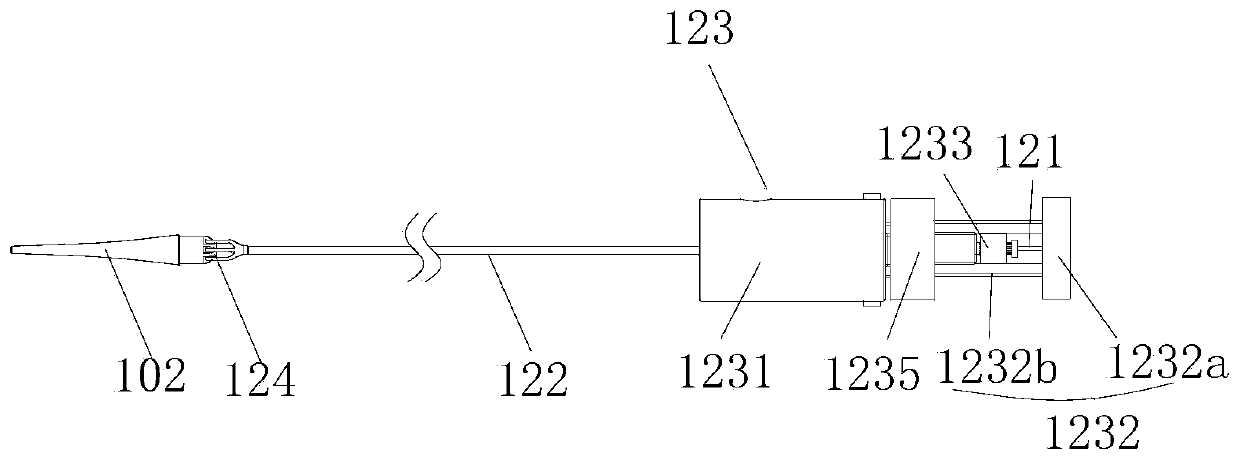

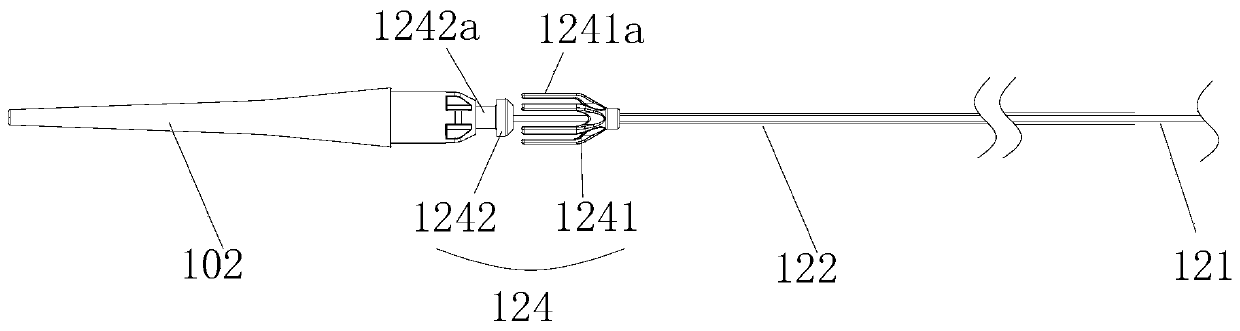

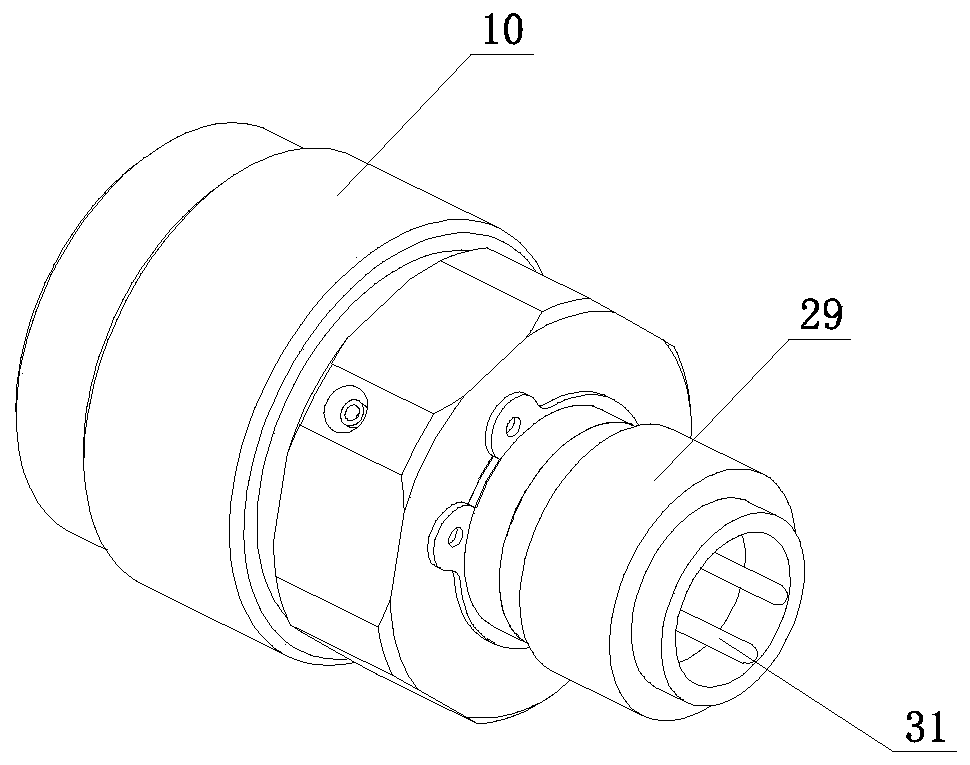

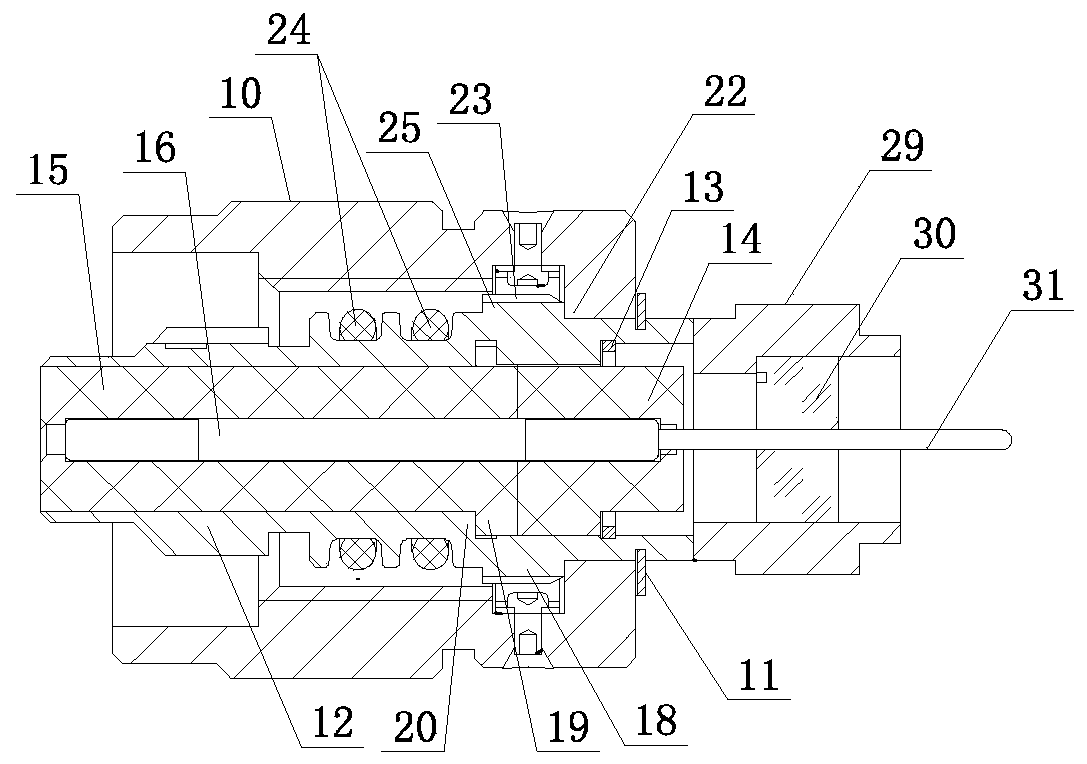

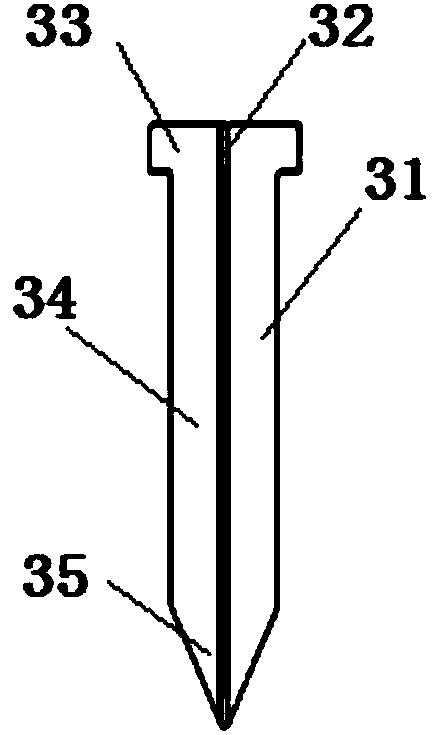

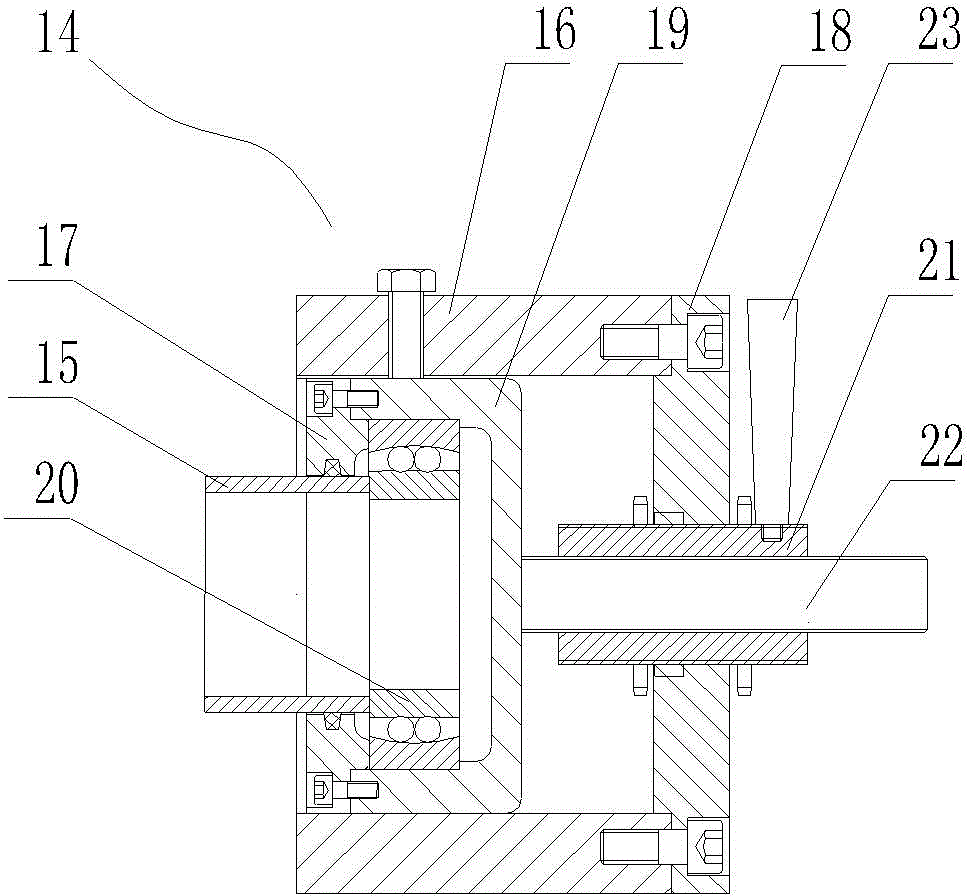

Knot-free anchor and implantation device thereof

InactiveCN109223076AAvoid axial misalignmentImproving Implantation EfficiencySuture equipmentsImplantable rodMedical device

The invention relates to the field of medical devices, and discloses a knot-free anchor and an implantation device thereof. The knot-free anchor comprises an anchor body and a threading portion located at a top end position of the anchor body, a first external thread is formed on an outer peripheral wall of the anchor body, and a threading hole is formed on the threading portion. The structure ofthe implantation device comprises: a rotary handle including an implantation rod for connecting with a knot-free anchor and an implantation handle coaxially connected with the implantation rod; And asupport handle including a support sleeve and a grip handle coaxially connected to the support sleeve. The knot-free anchor of the invention can make the fixation effect of the suture better, so thatthe knot-free anchor can more stably and effectively fix the soft tissue on the bone, thereby promoting the rapid repair and reconstruction of the soft tissue. The knot-free anchor of the invention can make the fixation effect of the suture better, so that the knot-free anchor can more stably and effectively fix the soft tissue on the bone, thereby promoting the rapid repair and reconstruction ofthe soft tissue.

Owner:BEIJING CHUNLIZHENGDA MEDICAL INSTR

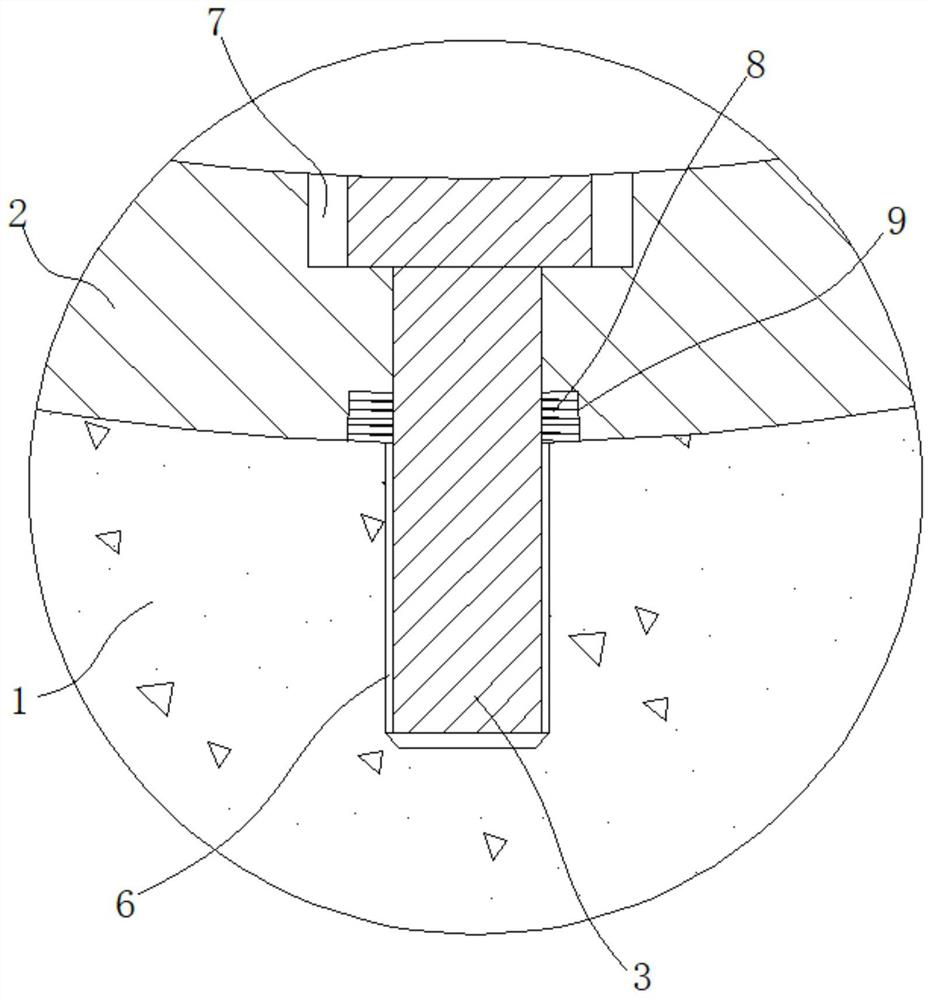

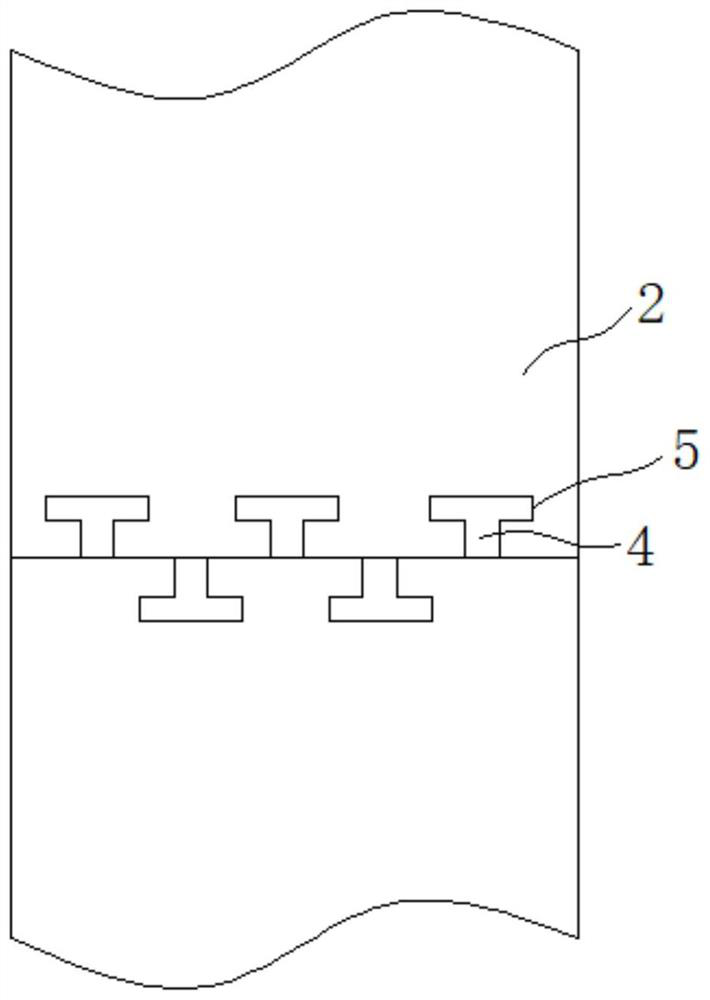

Shield interval tunnel connection channel segment supporting structure

ActiveCN111894636ADoes not hinder accessShorten the construction periodUnderground chambersTunnel liningEngineeringScrew thread

Owner:CHINA CREC RAILWAY ELECTRIFICATION BUREAU GRP

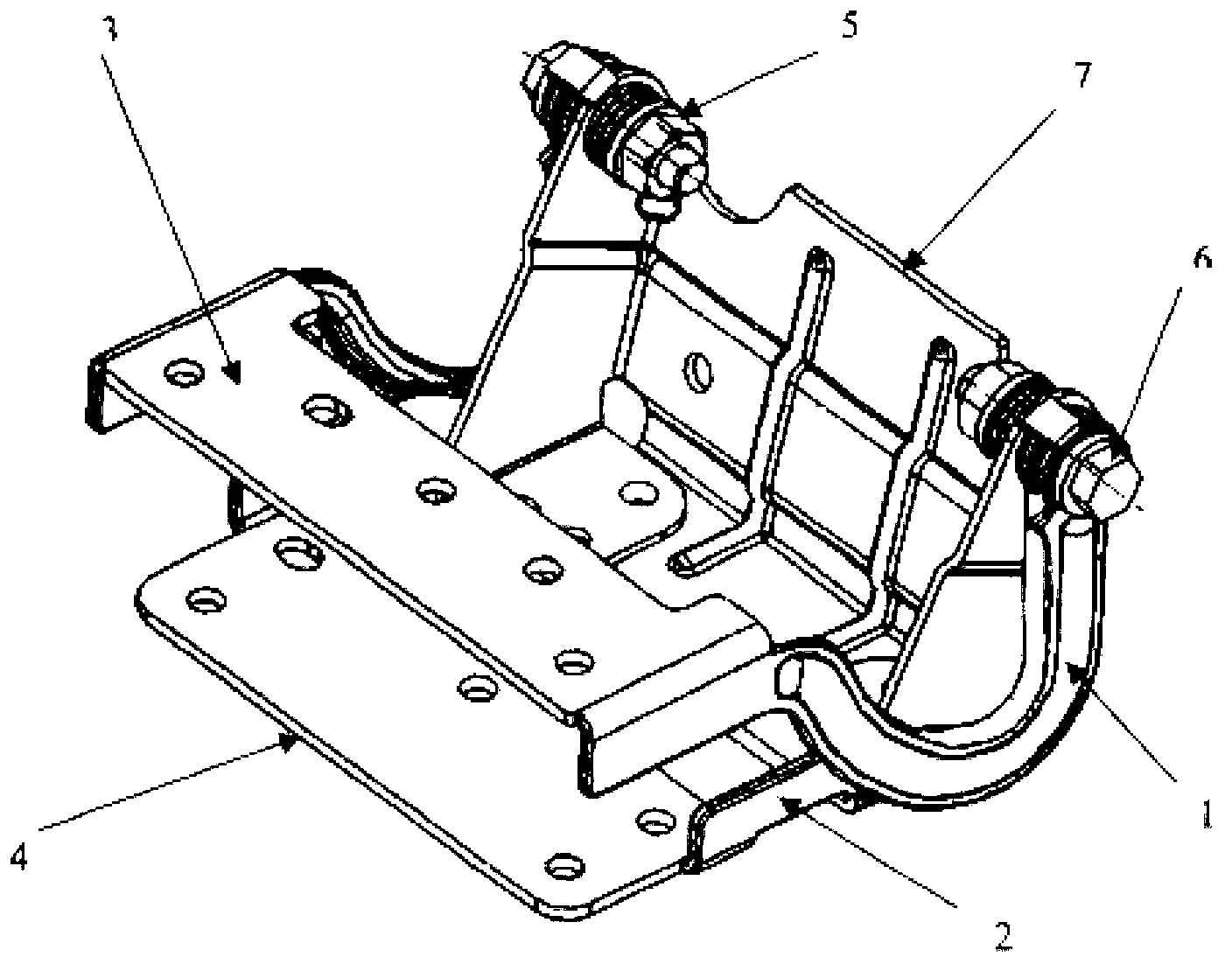

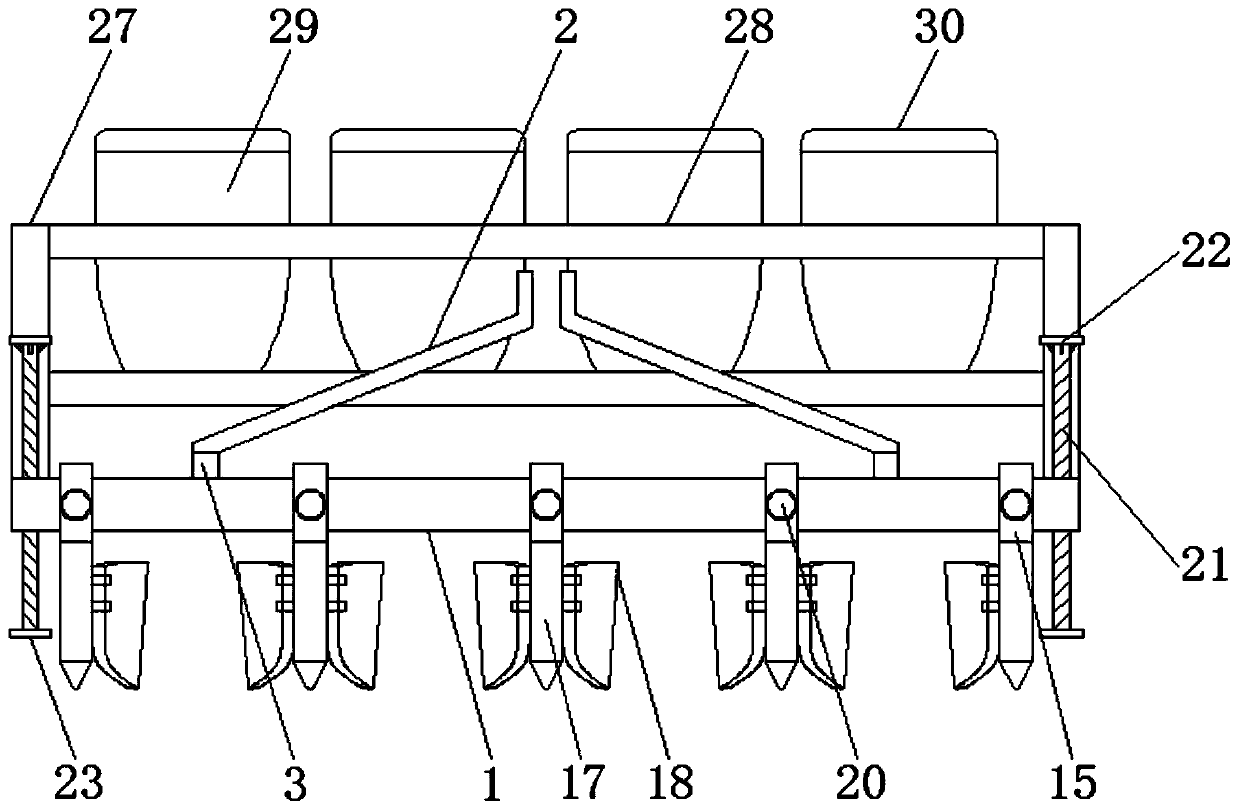

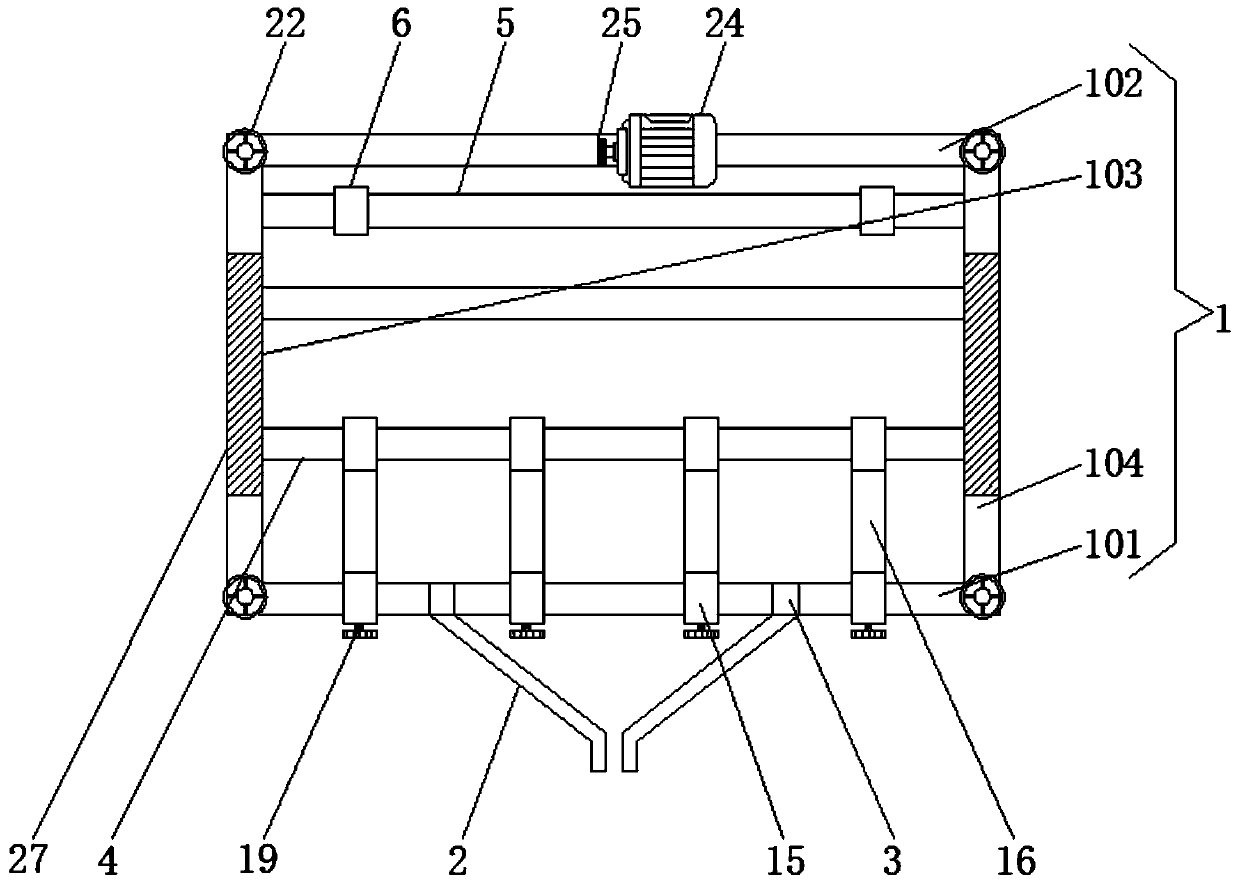

Pulling rack for agricultural sowing

InactiveCN109906701AEasy to adjustAdapt to seeding operationsAgricultural machinesAdjusting devicesAgricultural engineeringChassis

The invention discloses a pulling rack for agricultural sowing and relates to the technical field of pulling racks. The pulling rack comprises a bottom rack and a connection rack, the bottom rack comprises a first horizontal plate and a second horizontal plate, and a first vertical plate is fixedly connected between one side of the first horizontal plate and one side of the second horizontal plate; a second vertical plate is fixedly connected between the other side of the first horizontal plate and the other side of the second horizontal plate. According to the pulling rack for agricultural sowing, a third horizontal plate is fixedly connected between the sides, opposite to each other, of the first vertical plate and the second vertical plate and is close to one side of the first horizontal plate, a mounting plate is fixedly connected between the sides, opposite to each other, of the first vertical plate and the second vertical plate and is close to one side of the second horizontal plate, and first connection blocks are slidingly connected to the two sides of the surface of the mounting plate; the distance between every two walking wheels can be conveniently adjusted, so that therack better adapts to sowing operation of the crops according to different ridge spacing demands, the application range of the pulling rack for sowing is enlarged, and the use limitation is lowered.

Owner:肥西县堰丰农业农民专业合作社

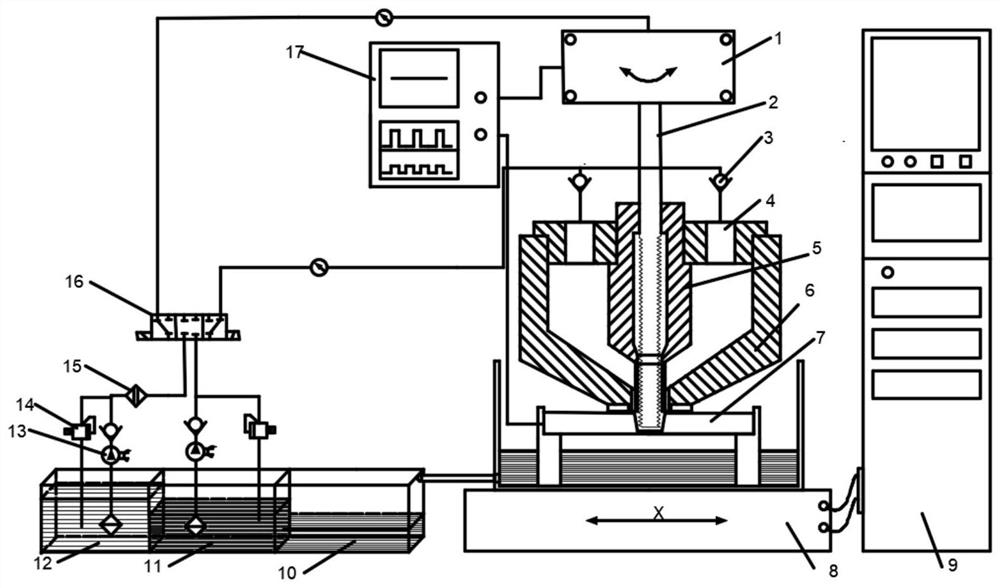

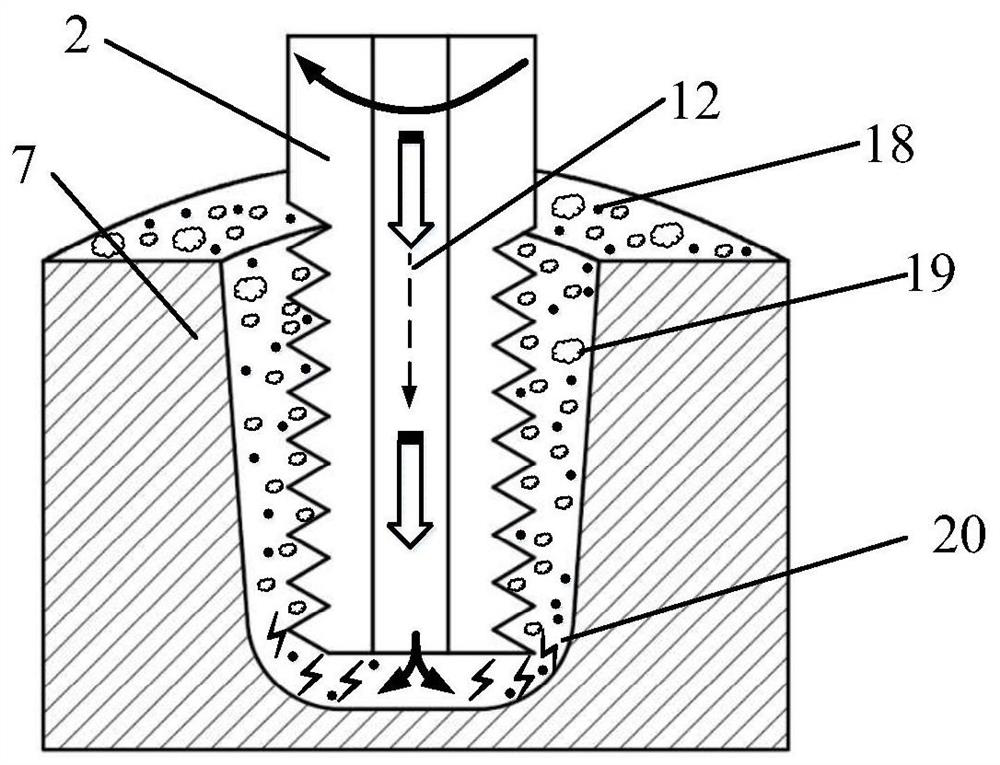

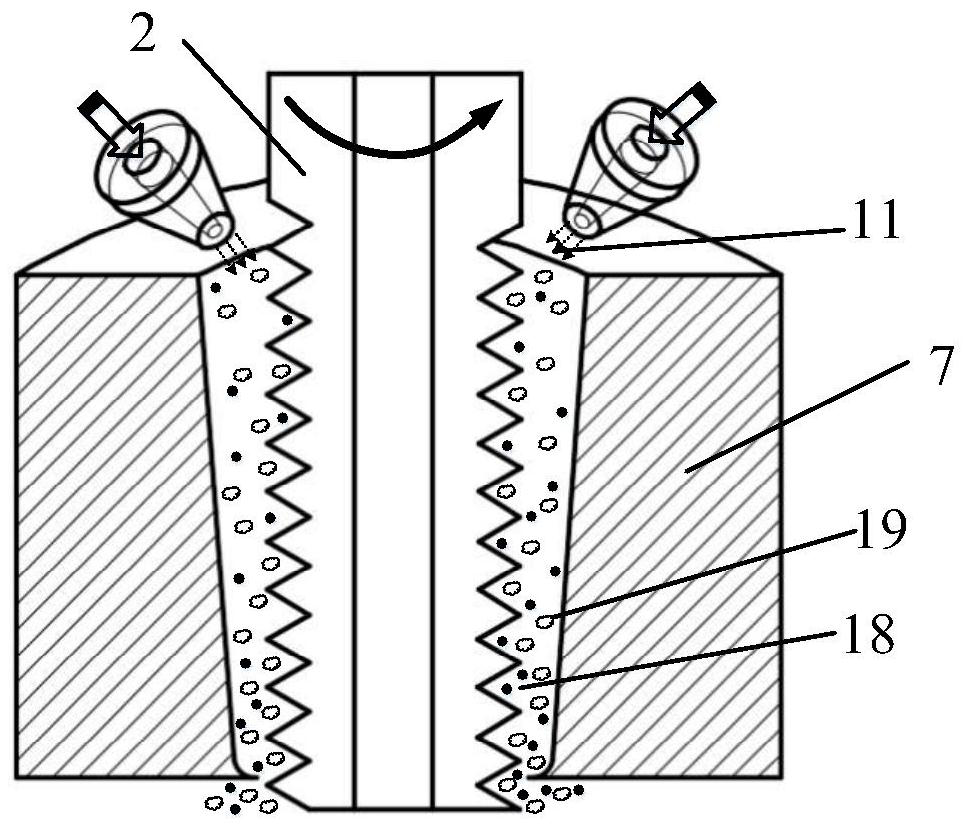

Method for making holes through electric spark-electrolysis combination via matching of thread pipe electrode with inner and outer liquid flushing

The invention provides a method for making holes through electric spark-electrolysis combination via matching of thread pipe electrode with inner and outer liquid flushing. At the electric spark high-speed hole making machining stage, an electric spark pulse power source is connected, the inner liquid flushing manner is adopted for leading in of deionized water, in cooperation with rotation of thethread pipe electrode, meanwhile, downward feeding is carried out, when the interpolar distance is up to the electric spark discharge gap, a pulse electric spark is generated, a workpiece material issubjected to corrosion removing, through thread rotation disturbance and upward action force of a thread groove on electric corrosion solid small particles, the electric corrosion solid small particles can be rapidly and upwards discharged, when a workpiece is subjected to breakdown, the electrode station is kept unchangeable, an electrolysis power source is connected, outer liquid flushing is replaced, an outer nozzle is aligned with the gap to spray an electrolyte, in cooperation with reverse rotation of the thread pipe electrode, the thread groove can contain more electrolyte to enter thenarrow and small gap, the workpiece has the anodic dissolution reaction, electrolytic flocs can be rapidly and downwards discharged under extrusion of the thread groove, micro hole manufacturing highprecision and high efficiency can be ensured, and the hole wall non-micro-crack and non-recast-layer machining needs can be achieved.

Owner:NANJING UNIV OF TECH

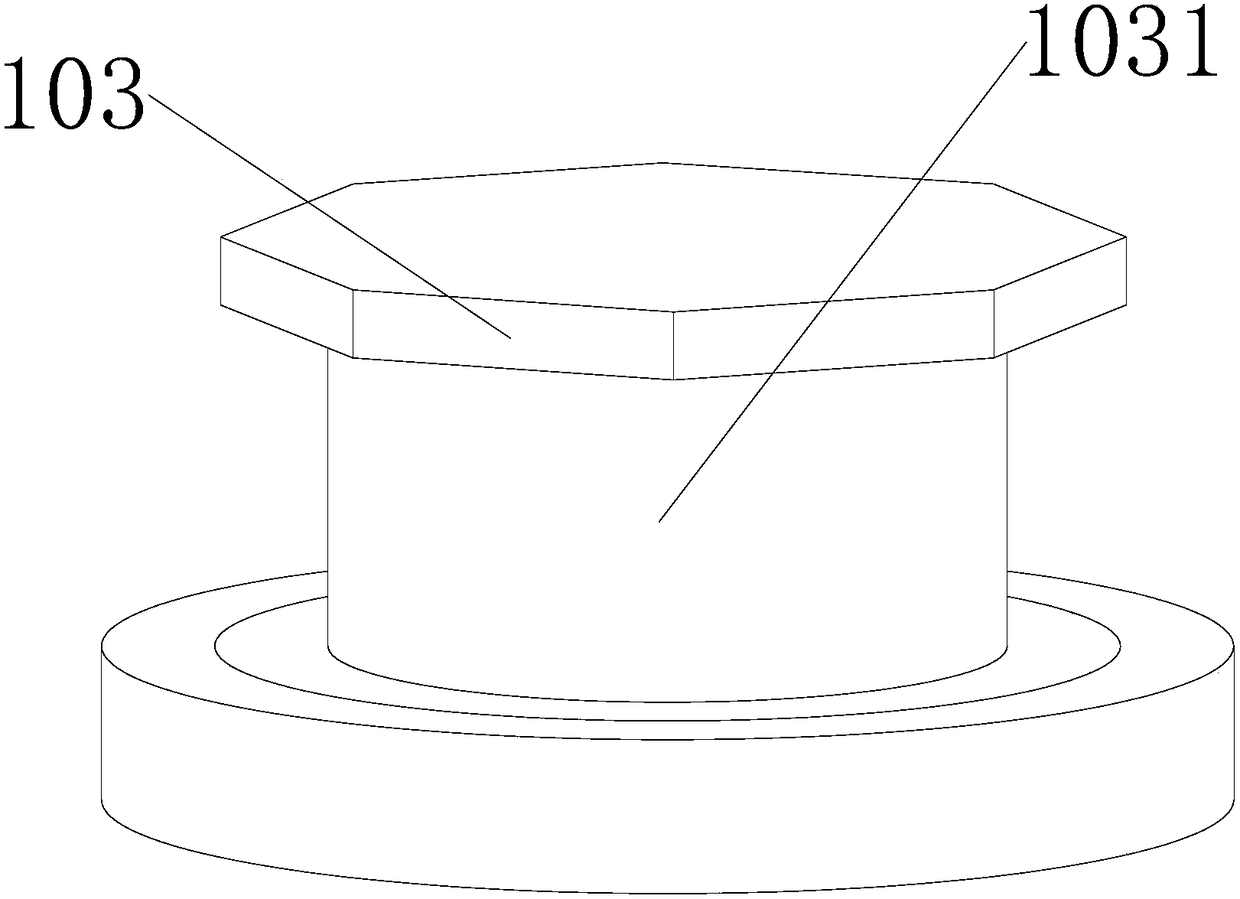

Press-mounting tool and press-mounting method for axle-box pull rod

PendingCN107350774AAvoid Axial MisalignmentRealize high-precision pressingVehicle componentsMetal working apparatusEngineeringStructural engineering

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Securing element for fixing hub of turbine wheel and method of assembling hydraulic starting torque converter

ActiveCN103307247AReduced possibility of sealingReduce complexityHybrid vehiclesClutchesTurbine wheelPiston

The invention relates to a securing element for fixing a hub of a turbine wheel and a method of assembling a hydraulic starting torque converter. The securing element (40) used for fixing a hub of the turbine wheel (6) of a hydraulic starting torque to an input shaft (2) of a gear box is provided with a sealing element (16) at an outer circumferential surface (12). The sealing element (16) extends to a housing (20) of the hydrodynamic starting converter in a mounted state such that a piston volume (26) of a piston (22) of a converter lockup clutch is sealed relative to a converter volume (30) by the seal element.

Owner:ZF FRIEDRICHSHAFEN AG

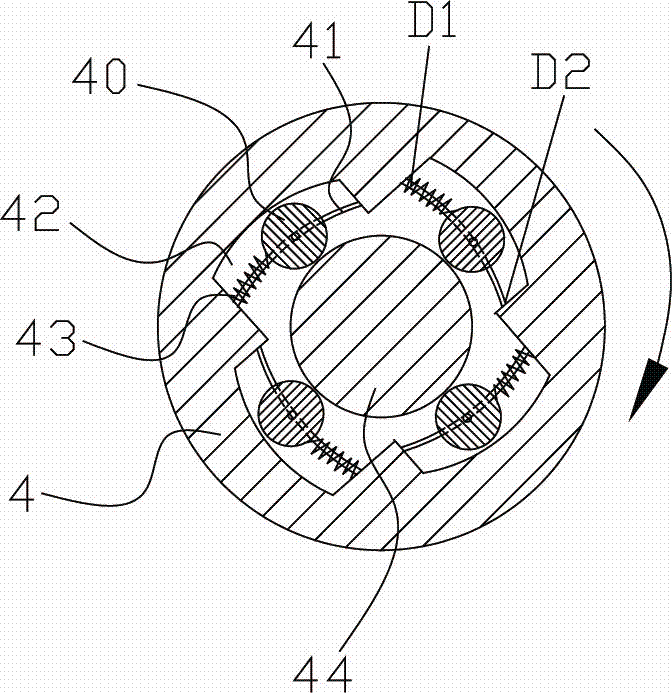

Elevator motor structure

ActiveCN104499862AReduce frictionIncreased self-locking strengthMan-operated mechanismPower-operated mechanismEngineeringTurbine

The invention discloses an elevator motor structure. The elevator motor structure comprises a motor, a worm, a turbine and a sleeve, wherein the turbine is meshed with the worm; a rotary roller is arranged at one end of the worm and is positioned in the sleeve; an extrusion element is arranged in the sleeve and propped against the rotary roller; a groove for accommodating the extrusion element is formed in the sleeve; a sliding rail is arranged in the groove; the extrusion element is slidably arranged on the sliding rail; an elastic piece propped against the extrusion element is arranged on the sliding rail; a first ball is arranged on the inner wall of the sleeve; a first ball seat matched with the first ball is arranged on one side of the rotary roller; a second roller is arranged on one side of a second output shaft; a second ball seat matched with the second ball is arranged on one side of the second output shaft. By the first ball and the second ball which are axially arranged on the worm, the worm can be fixed at the axial position, so that the axial offset of the worm is prevented, and the service life is greatly prolonged.

Owner:宁波世通汽车零部件有限公司

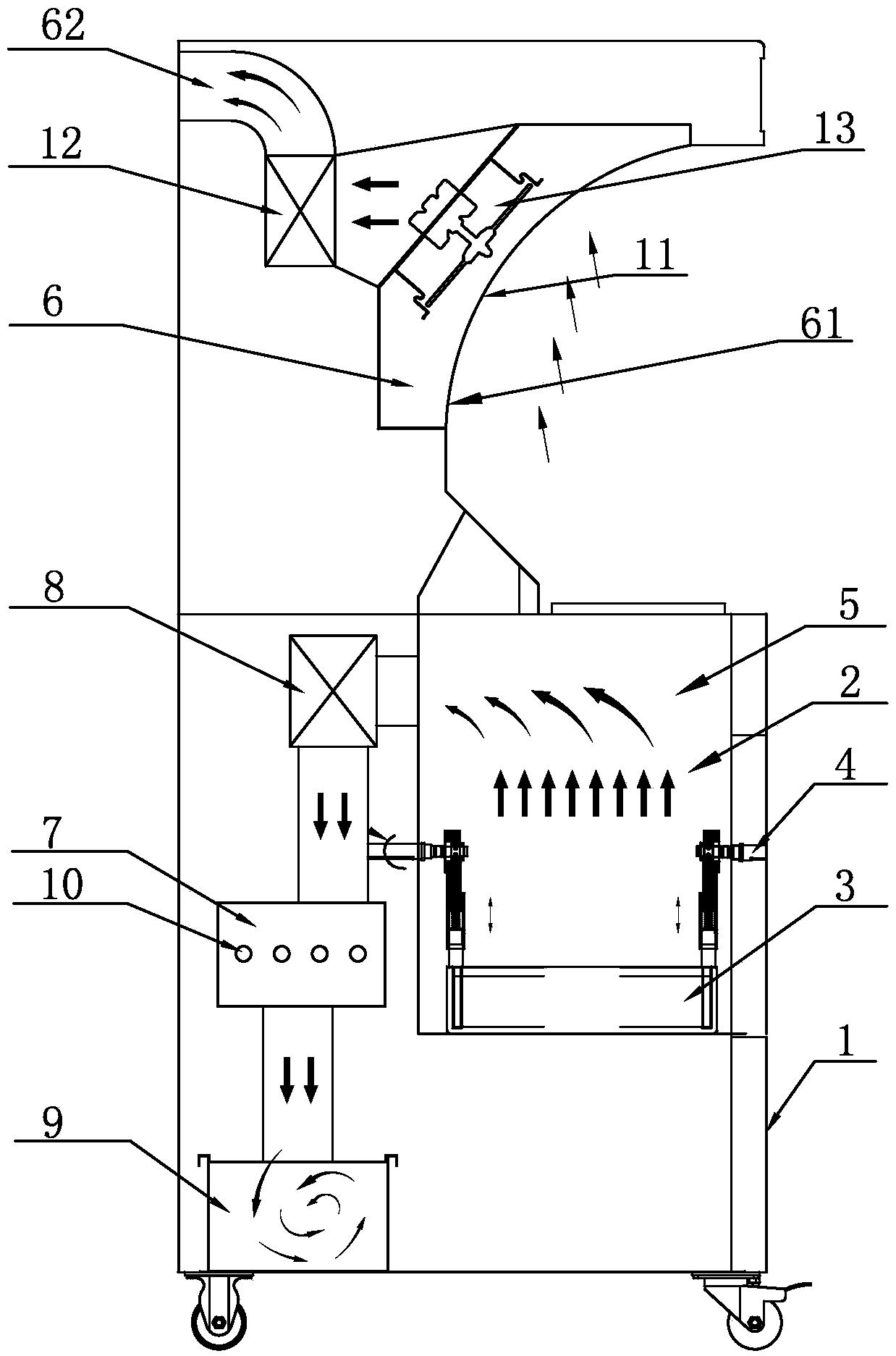

Intelligent automatic cooker

PendingCN108652426APlay a role in radial positioningAvoid Axial MisalignmentDomestic stoves or rangesLighting and heating apparatusDeep fryingEngineering

The invention relates to an intelligent automatic cooker which comprises a machine body and a cooker body arranged in the organic body. A turner is arranged in the cooker body, and the machine body isprovided with a driving device for driving the turner to swing. The intelligent automatic cooker is characterized in that the machine body comprises a deep-frying zone and a smoke sucking zone abovethe deep-frying zone, the cooker body is arranged in the deep-frying zone, a UV tube box, a centrifugal fan sucking smoke from the cooker body into the UV tube box and an oil-smoke treating box communicated with the UV tube box are also arranged on one side of the deep-frying zone, a UV tube for oxidizing and separating oil and smoke is arranged in the UV tube box, a smoke inlet is formed in one side of the smoke sucking zone, a smoke discharging port is formed in the other side, a smoke sucking cover is arranged at the smoke inlet, a centrifugal fan is arranged in the smoke sucking zone, andan oil-smoke separator is arranged between the centrifugal fan and the smoke sucking cover. By adopting the technical scheme, the intelligent automatic cooker is more perfect in function, achieves complete oil and smoke separation, is healthy, is friendly to the environment and keeps kitchen air clean.

Owner:唐山安米智能科技有限公司

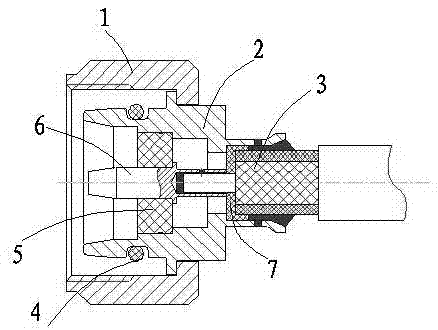

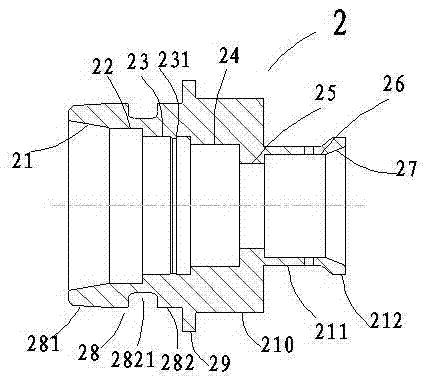

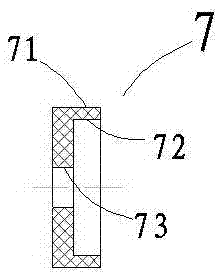

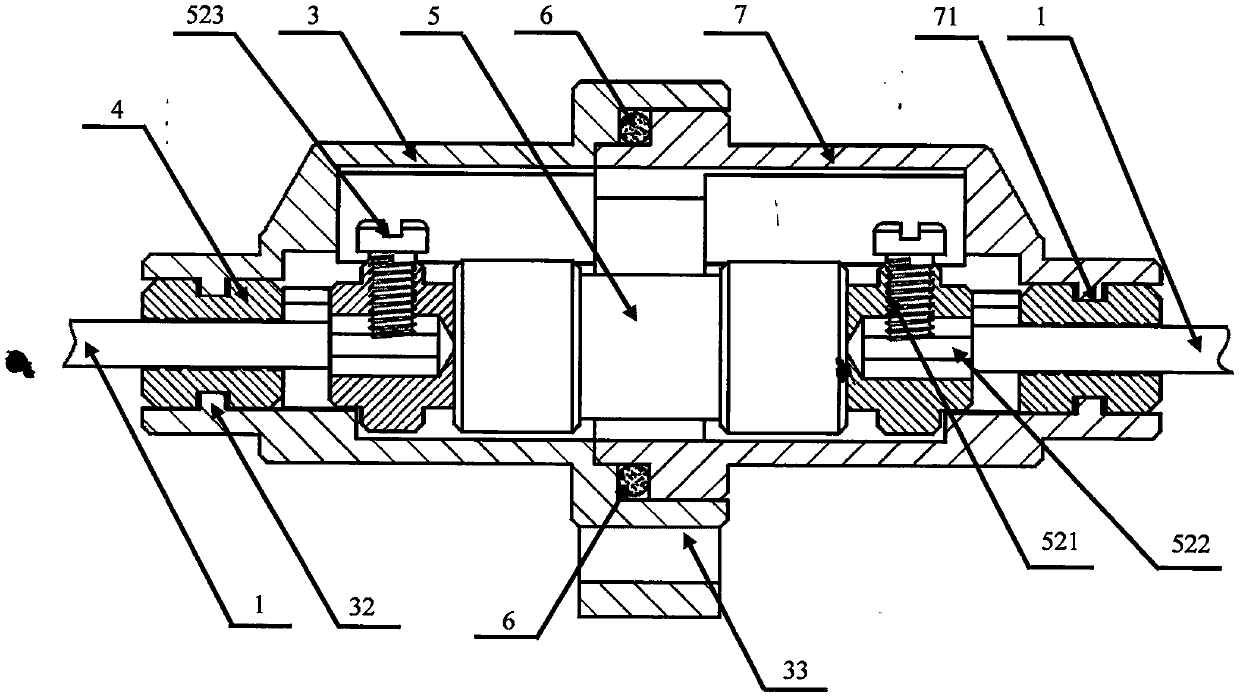

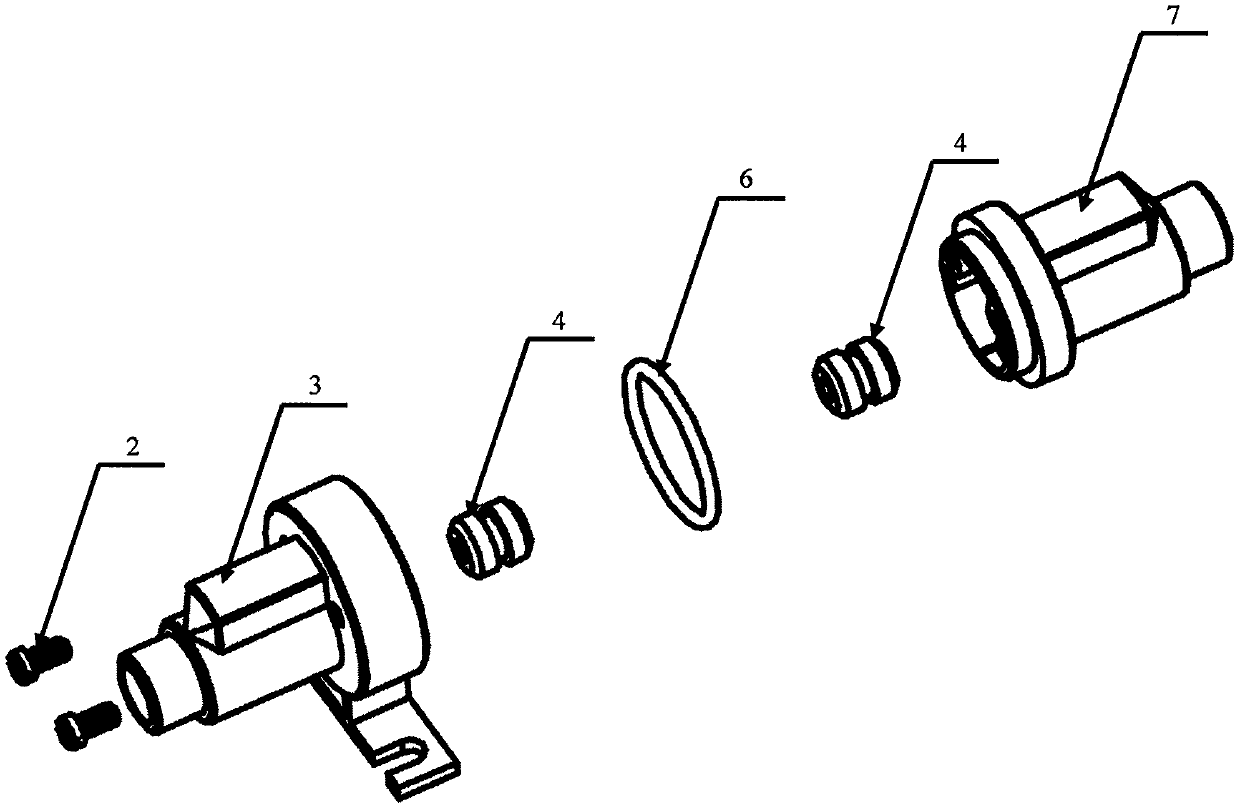

Mode of realizing high performance of electric connector with tail end wire welding

InactiveCN106935990AAvoid short circuitAvoid Axial MisalignmentElectrically conductive connectionsSecuring/insulating coupling contact membersInterference fitElectrical conductor

A high-performance method for realizing a tail-end welding wire electrical connector, the tail end of the electrical connector includes an outer conductor (2), a cable (3), a support body (7), and an inner conductor (6), and is characterized in that : the support body (7) is provided with an outer cylindrical surface (71), and the first inner cavity (72) and the second inner cavity (73) are respectively arranged inside, and the inner diameter of the first inner cavity (72) of the support body is larger than that of the support The inner diameter of the second inner cavity (73) of the support body, the first inner cavity (72) of the support body and the cable shielding layer (33) are set to an interference fit or clearance fit, the second inner cavity (73) of the support body and the cable inner cavity The conductor (31) is interference fit, and the cylindrical surface (71) outside the support body is interference fit with the sixth inner cavity (26) of the outer conductor. According to the high-performance method of realizing the electrical connector with welding wire at the tail end of the present invention, the axial deviation can be prevented, and the flow range of solder can be fixed at the same time, so as to prevent the solder from short-circuiting the tail end of the electrical connector.

Owner:SHANGHAI AEROSPACE SCI & IND ELECTRIC APPLIANCE RES INST

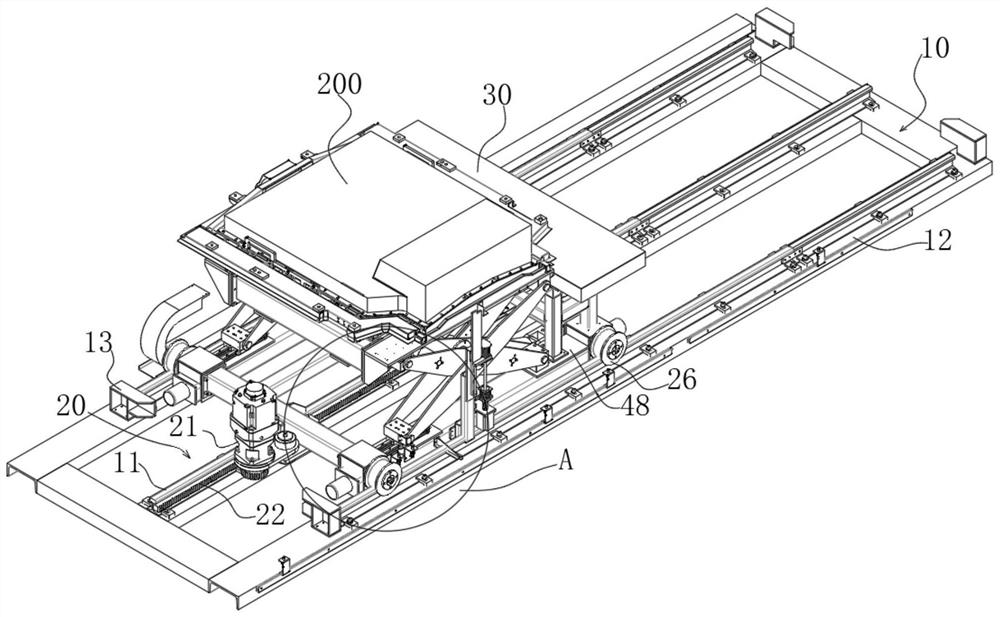

Battery replacing and charging system for an electric automobile

PendingCN112455280AQuick changeImprove experienceCharging stationsElectric vehicle charging technologyElectrical batteryElectric vehicle

The invention discloses a battery replacing and charging system for an electric automobile, and belongs to the technical field of charging and battery replacing for electric automobiles. The battery replacing and charging system for the electric automobile comprises a battery replacing platform, wherein a walking mechanism and a battery locking and unlocking mechanism lifting mechanism are arranged on the battery replacing platform; the battery locking and unlocking mechanism is mounted on the vehicle body through a lifting mechanism, and the lifting mechanism is used for lifting the battery locking and unlocking mechanism to a battery replacing position; the battery locking and unlocking mechanism is used for locking and unlocking the battery assembly; the battery storage rack is mountedon a motion path of the walking mechanism, and a charging platform is arranged on the battery storage rack; and the battery grabbing mechanism is mounted on one side of the battery storage rack and used for placing the unlocked battery assembly on the charging platform. Through cooperative movement of the battery replacing platform, the charging platform and the battery storage rack, automatic unloading, automatic charging and automatic mounting of the battery assembly are realized, the labor intensity of personnel can be reduced, the battery replacement efficiency of the electric vehicle is improved, and the user experience is improved.

Owner:泽清新能源科技有限公司

Grabbing mechanical arm

InactiveCN108481314AImprove gripQuality improvementProgramme-controlled manipulatorGripping headsHydraulic cylinderEngineering

Owner:清远市天勤电子科技有限公司

Fuse for protecting two-wheeled and three-wheeled electric vehicles

PendingCN111161986AImprove sealingWith waterproof functionEmergency protective devicesElectric carsElectric vehicle

The present invention relates to a fuse for protecting two-wheeled and three-wheeled electric vehicles. The fuse comprises a fuse body and a protective seat sleeve, a protective seat is provided witha fixed seat and has a waterproof function, and the fuse body is provided with a wire connecting hole. An insulator or a mounting base does not need to be additionally arranged on a circuit system, the fuse can be connected and installed on a line directly, and positioning columns and positioning grooves are arranged between the front and rear protective seat sleeves and in an inner cavity of theprotective seat sleeve, so that the axial dislocation between the front and rear protective seat sleeves and the axial rotation of the fuse body in the protective seat can be prevented. The fuse is more stable to combine, is novel in design, compact in structure, good in sealing performance and stability and reliable in circuit connection, is resistant to impact and vibration, and is a necessary safety protection device for the two-wheeled and three-wheeled electric vehicles. Meanwhile the fuse can be applied to the circuit safety protection systems of the small and low-speed electric vehicles, such as four-wheeled electric vehicles (elderly scooters), garden landscape vehicles, etc.

Owner:赫森电气(无锡)有限公司

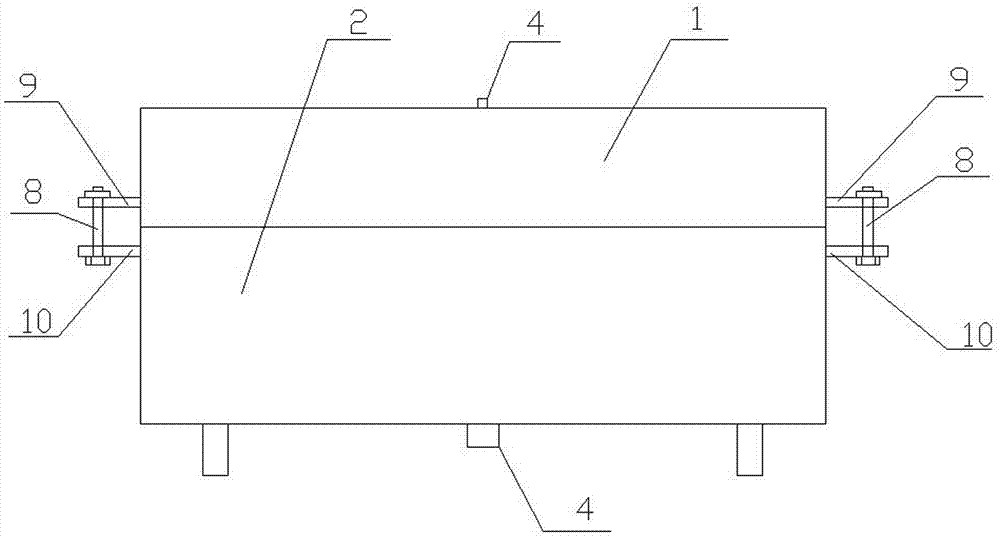

Conveying device and control assembly thereof

ActiveCN110916862AImprove release precisionAvoid Axial MisalignmentStentsMechanical engineeringCovered stent

The invention relates to a conveying device and a control assembly thereof. The control assembly comprises a handle main body, a first moving part and a second moving part, and an inner sheath core tube and an outer sheath core tube can axially and movably penetrate through the handle main body; the first moving part is used for being connected to the inner sheath core tube and controlling the inner sheath core tube to axially move relative to the handle main body, and the first moving part has a locking state or an unlocking state relative to the handle main body; and the second moving part is used for being connected to the outer sheath core tube and controlling the outer sheath core tube to move axially relative to the handle body. According to the conveying device and the control assembly thereof, the inner sheath core tube and the outer sheath core tube are controllably controlled by the control assembly to move in the axial direction. Under the condition that a covered stent is anchored by an anchoring assembly, the far end of the covered stent is synchronously pulled to move towards the near end, so that the far end of the membrane of the covered stent is attached to the blood vessel wall, axial deviation of the far end of the membrane of the covered stent before and after released is avoided, and then the release precision of the covered stent is improved.

Owner:LIFETECH SCIENTIFIC (SHENZHEN) CO LTD

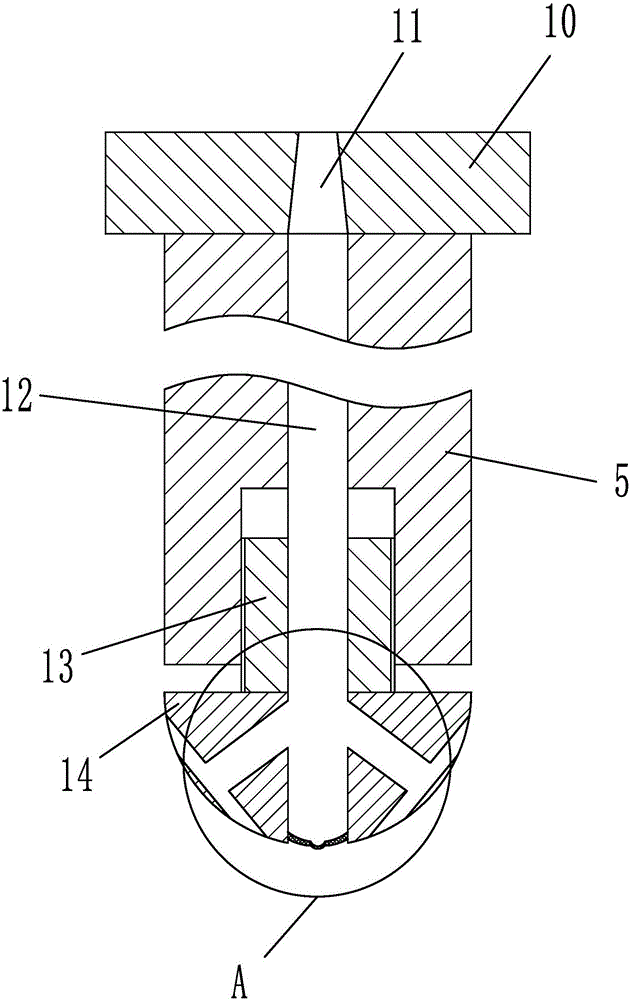

Forming mold of indoor mutual inductor and pouring sealing method of forming mold

InactiveCN104723485AReduce investmentThreats to personal safetyInductances/transformers/magnets manufactureChinese charactersInductor

The invention discloses a forming mold of an indoor mutual inductor and a pouring sealing method of the forming mold. The forming mold comprises an upper mold and a lower mold which defines a mold die cavity, wherein the upper mold is provided with a pouring hole and an exhaust hole which are communicated with the mold die cavity; a mold core is arranged in the mold die cavity, the upper end of the mold core is in the shape of Chinese character 'tu', the lower end of the mold core is in a crossed shape, and the part, positioned in the mold die cavity, of the mold core is cylindrical; a group of insulating supporting columns for supporting a mutual inductor coil is arranged around the mold core in the mold die cavity and is movably connected with the lower mold; the upper end of each insulating supporting column is provided with a step-shaped buckling platform for being buckled with the lower edge of the mutual inductor coil; and a wire outlet hole is formed in a connection position between the upper mold and the lower mold. The forming mold disclosed by the invention has the advantages that the resin pouring sealing efficiency of the indoor mutual inductor can be improved, the unit energy consumption and the rejection rate of the indoor mutual inductor are reduced, the insulating degree of the indoor mutual inductor is improved, and the indoor mutual inductor can be prevented from threatening personal safety when being broken down by high voltage.

Owner:XUCHANG YONGXIN ELECTRIC

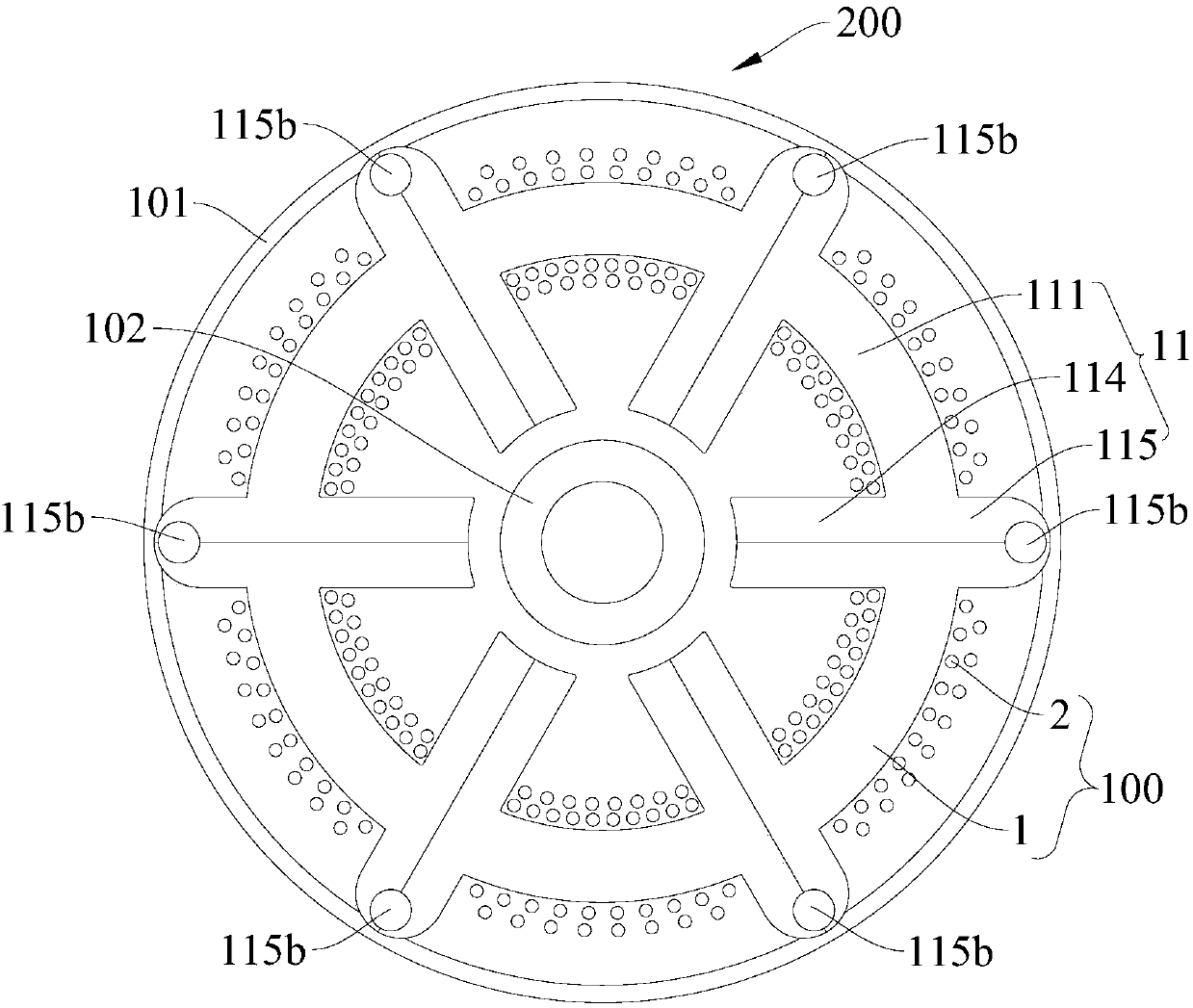

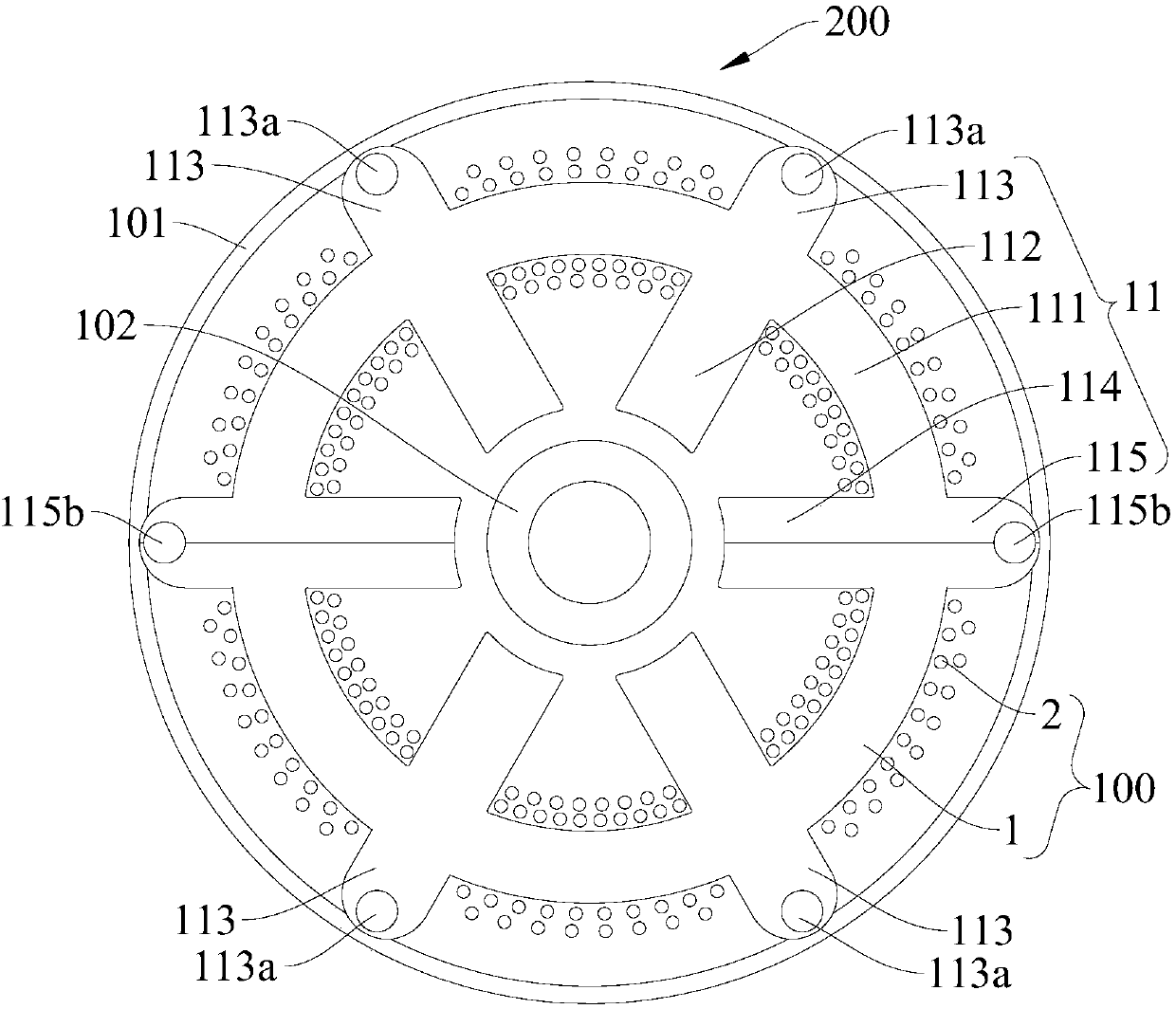

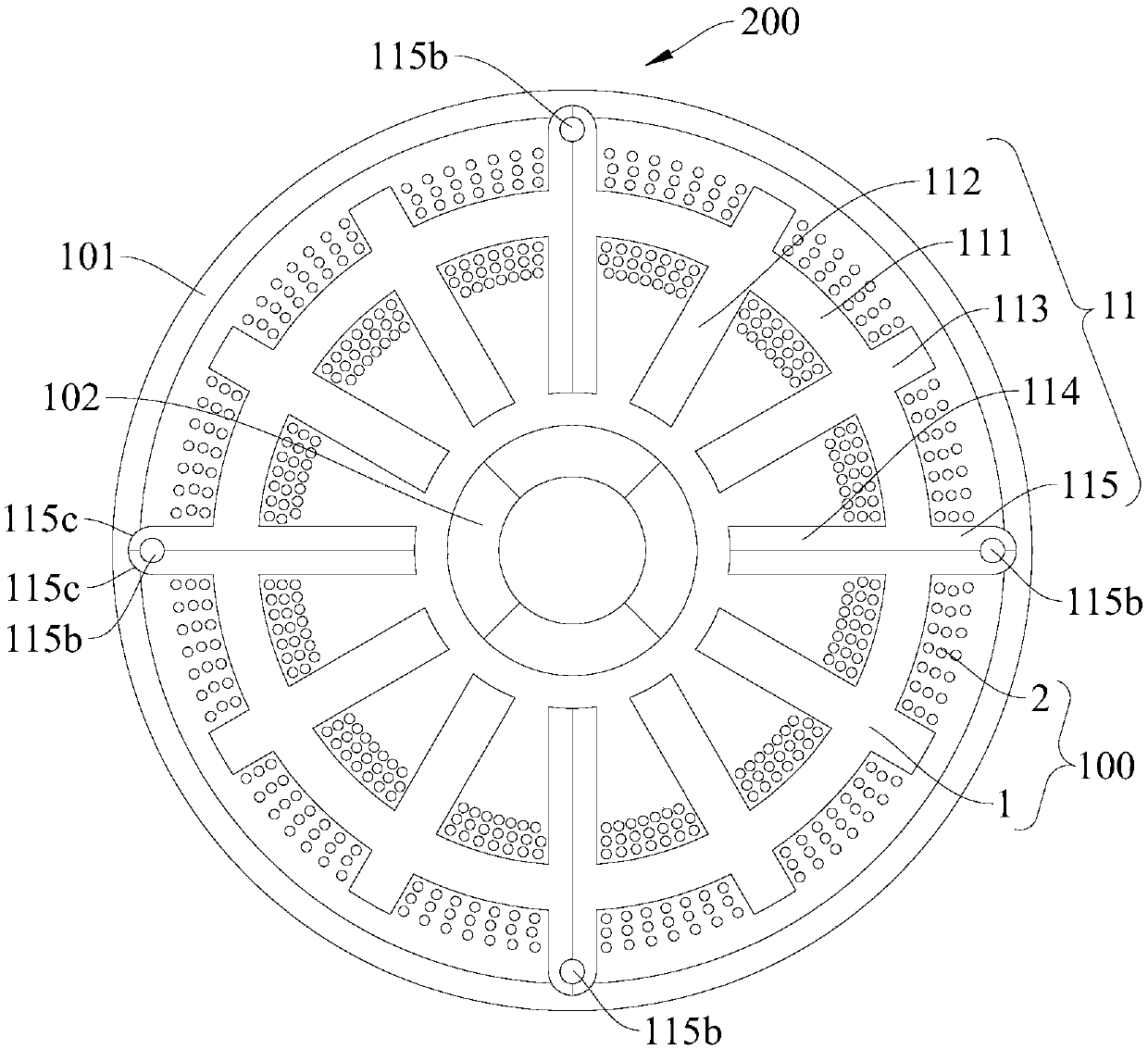

Motor stator and motor with same

PendingCN107834721AEasy to assembleIncrease productivityMagnetic circuit stationary partsSupports/enclosures/casingsElectric machineControl theory

The invention discloses a motor stator and a motor with the motor stator. The motor stator comprises a stator core and a stator winding, wherein the stator core comprises a plurality of sub stator cores; each sub stator core comprises a stator yoke part, two sub stator tooth parts and two connecting outer end parts; the stator winding is wound on the stator yoke parts; the two sub stator tooth parts are arranged on the inner side of the corresponding stator yoke part respectively and are positioned at two ends of the corresponding stator yoke part in the peripheral direction respectively; thetwo connecting outer end parts are arranged on the outer side of the corresponding stator yoke part respectively and are opposite to the two corresponding sub stator tooth parts respectively; a grooveis formed in each connecting outer end part; two grooves of the connecting outer end parts in contact with the two adjacent sub stator cores form a mounting hole; and each mounting groove is internally matched with a connecting piece so as to realize connection and mounting positioning of every two adjacent sub stator cores. According to the motor stator disclosed by the invention, the motor stator is convenient to manufacture, small in assembling difficulty and high in production efficiency, and axial positioning between every two adjacent sub stator cores is easily guaranteed.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG +1

K1-type electrical connector assembly of mineral insulated cable for nuclear power

ActiveCN110380252AImprove corrosion resistanceNo maintenanceSoldered/welded conductive connectionsSecuring/insulating coupling contact membersNuclear powerButt joint

The invention relates to a K1-type electrical connector assembly of a mineral insulated cable for nuclear power, and the assembly comprises a cable assembly, and a plug and a socket which are respectively spliced with two ends of the cable assembly. The cable assembly is characterized in that the cable assembly comprises a mineral cable, a corrugated pipe wrapped outside the mineral cable, a positioning plate for fixing the mineral cable, and a stainless steel pipe welded with the positioning plate; the stainless steel pipe is internally provided with a glue pouring area and a switching jack contact piece; the switching jack contact piece is of a double-end jack structure, one end of the switching jack contact piece is electrically connected with the mineral cable core wire through a barewire, and the other end is plugged with the plug or the socket; the plug comprises a connecting nut, a spline housing, an insulator part, and a glass sintering part which is in butt joint with the double-end jack contact part; the socket is of an integrated structure formed by sintering a socket shell, a glass cake II and a double-end contact pin contact piece II through glass. The assembly provided by the invention is resistant to irradiation and aging and long in service life, and it is guaranteed that the product can still be used after being subjected to severe accident working conditionswhile the using requirements of a nuclear-grade K1-type electrical connector are met.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

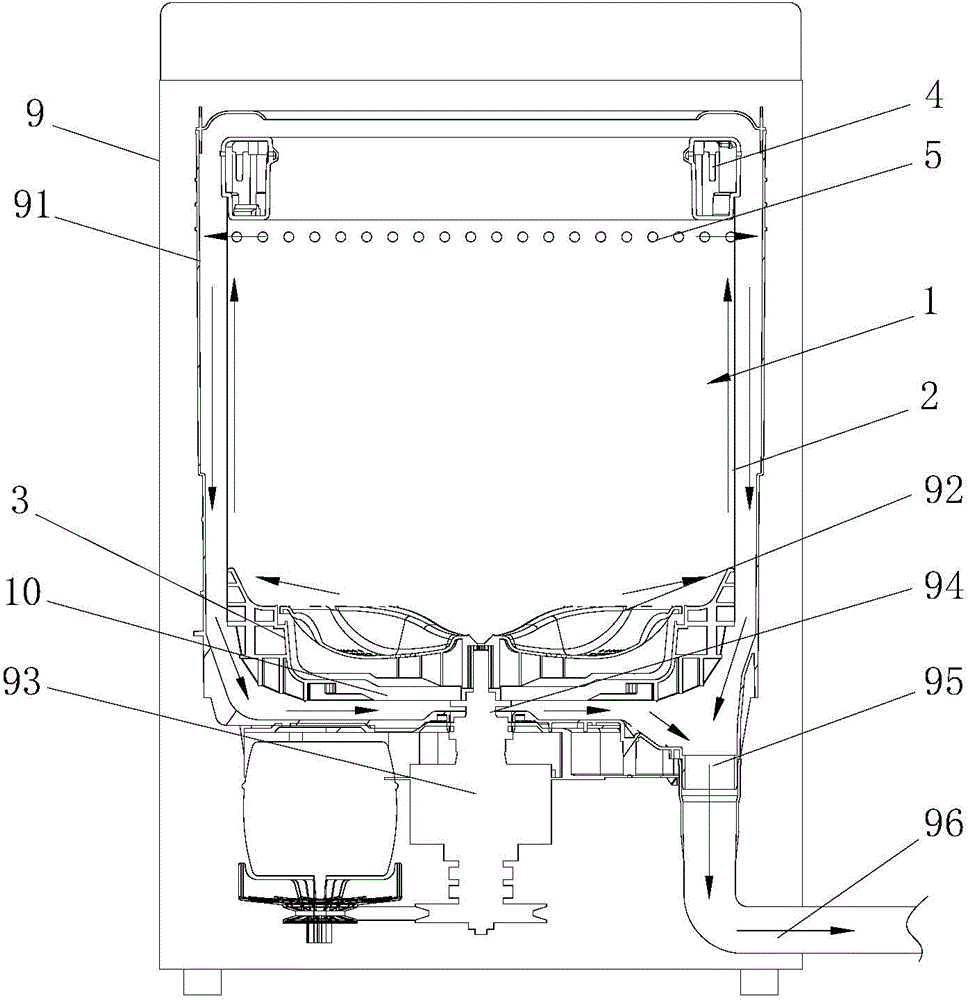

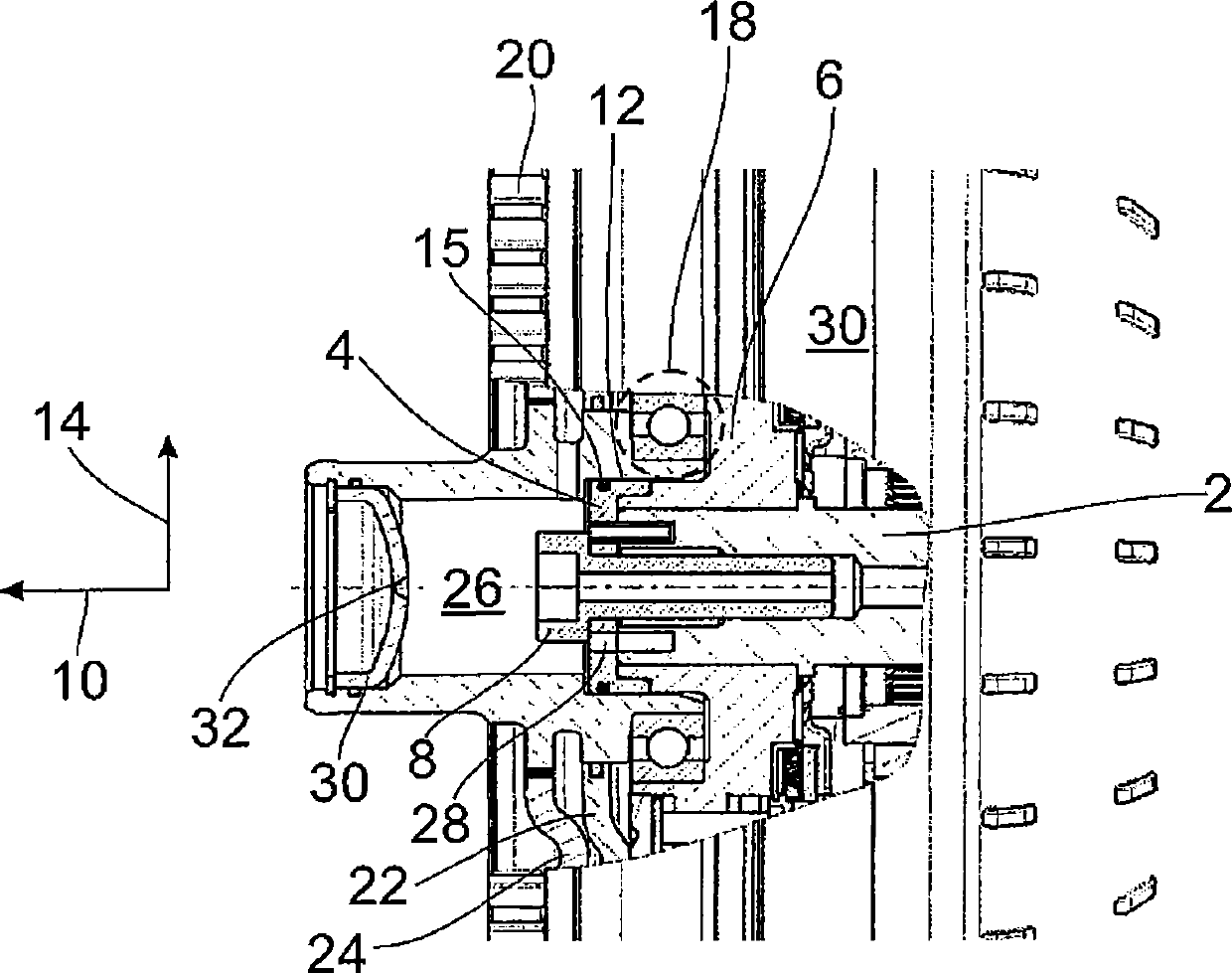

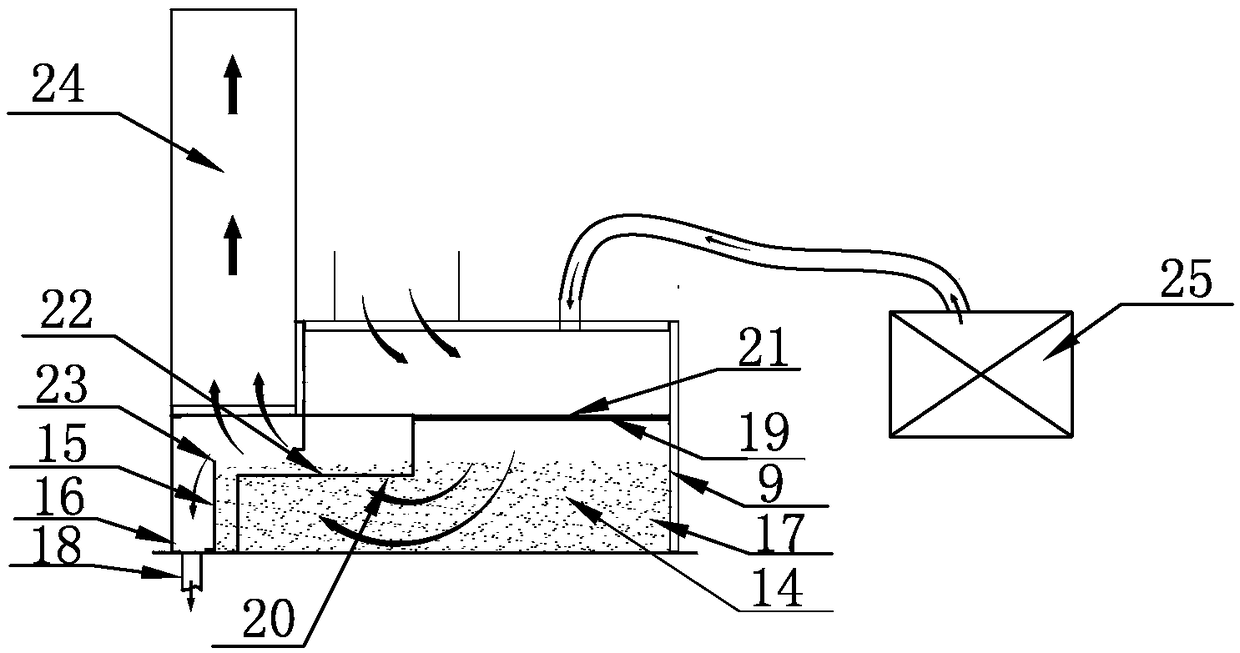

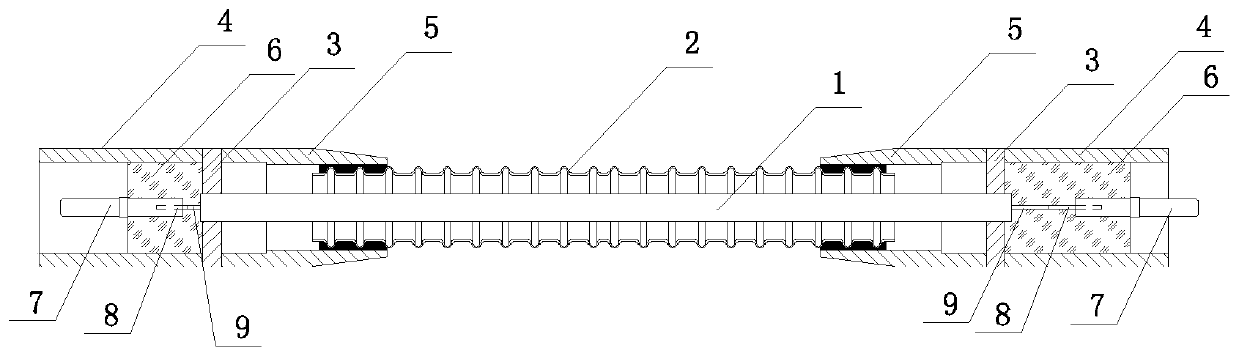

Gas turbine

InactiveCN105179029AUniform thermal expansionAvoid Axial MisalignmentEngine manufactureTurbine/propulsion engine coolingEngineeringGas turbines

A gas turbine configured to prevent eccentricity of a rotor (14) due to heat is installed with a strut (23), an outer diffuser (24), an inner diffuser (25), a strut cover (26), and a partition wall (28), wherein the gas turbine includes an inflow hole (31) for cooling air (W), a first flow passage (R1) formed between a casing wall (21) and the outer diffuser (24), a second flow passage (R2) formed between the strut (23) and the strut cover (26), a third flow passage (R3) formed between the inner diffuser (25) and the partition wall (28), and an outflow hole (51) installed in the inner diffuser (25).

Owner:MITSUBISHI HITACHIPOWER SYST LTD

Current conduction nozzle

The invention relates to a current conduction nozzle which comprises a current conduction nozzle body, a shell and a spring adjusting device. The shell is provided with a current conduction nozzle body installing hole, and a plurality of threaded installing holes are formed in the shell wall and are symmetrically arranged around the current conduction nozzle body installing hole; the spring adjusting device comprises springs, bosses and threaded connecting pieces which correspond to the threaded installing holes in a one-to-one manner; the current conduction nozzle body is formed by two matching bodies, the matching faces of the two matching bodies are each provided with a semi-groove, and the two semi-grooves are combined to form a wire penetrating hole; each matching body sequentially comprises an axial positioning section, a matching section and an extending-out section from the wire inlet end and the wire outlet end; the current conduction nozzle body and the shell are installed ina matched manner, the axial positioning sections are located outside the shell, the matching sections are located inside the shell, and the extending-out sections extend out of the shell. The currentconduction nozzle solves the problem that an existing current conduction nozzle inner hole is difficult to machine, and the matching precision of the diameter of the current conduction nozzle inner hole and the wire diameter is low; and the current conduction nozzle has the beneficial effects that machining is easy, the matching accuracy is high, adjustment is facilitated, efficiency is high, andthe service life is long.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

Frictional regenerator

InactiveCN104668452ASimple structureReduce energy consumptionMould handling/dressing devicesDrive shaftEngineering

The invention provides a frictional regenerator which can be used for treating used sands by virtue of dry reclamation. The frictional regenerator is simple in structure, low in energy consumption, low in cost and good in regeneration effect. The equipment provided by the invention comprises a housing, wherein a sand feeding hopper is mounted on the housing. The frictional regenerator is characterized by further comprising a refiner plate, a transmission shaft and a driving device, wherein the refiner plate comprises a fixed refiner plate and a movable refiner plate which are arranged in the housing; the fixed refiner plate is fixedly arranged on the inner wall of the housing, sand guide holes communicated with the sand feeding hopper are formed, the movable refiner plate is mounted on the end part at one side of a transmission shaft and is parallel to the fixed refiner plate; the end part at the other side of the transmission shaft is supported on the support device, and the transmission shaft is driven by the driving device.

Owner:WUXI SHUANGQUAN MECHANICAL FACTORY

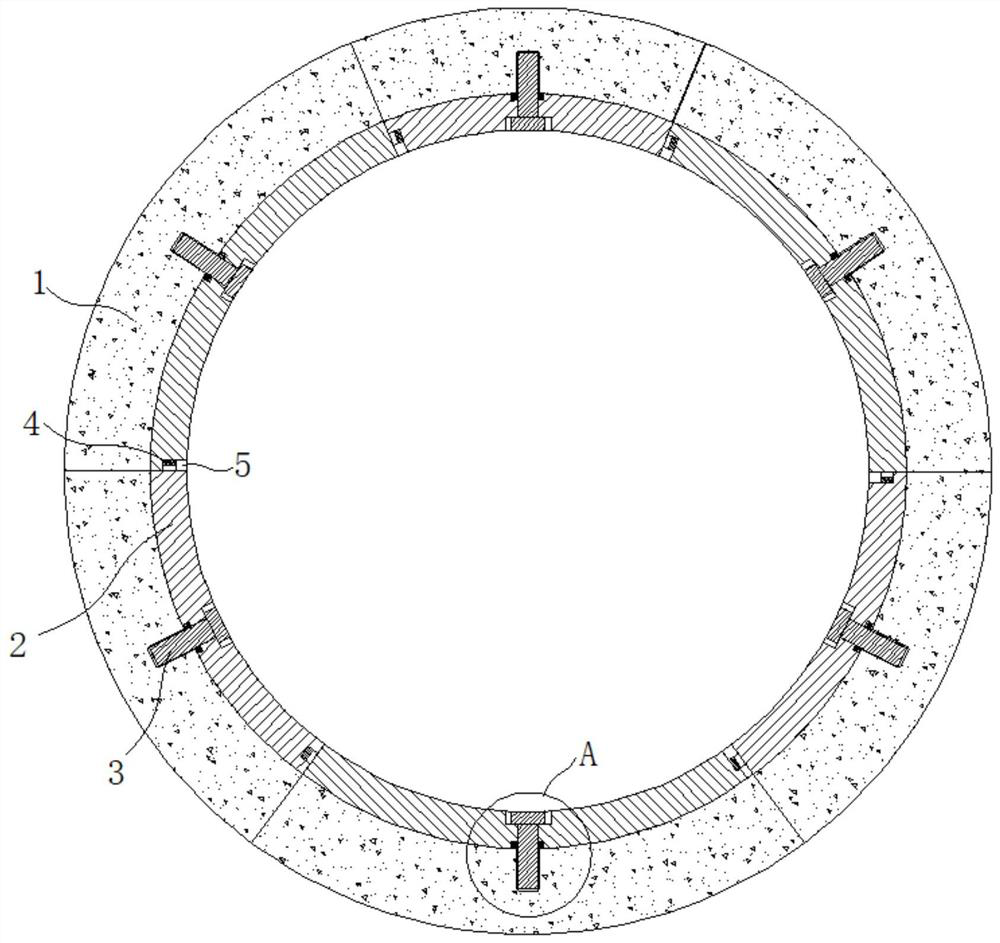

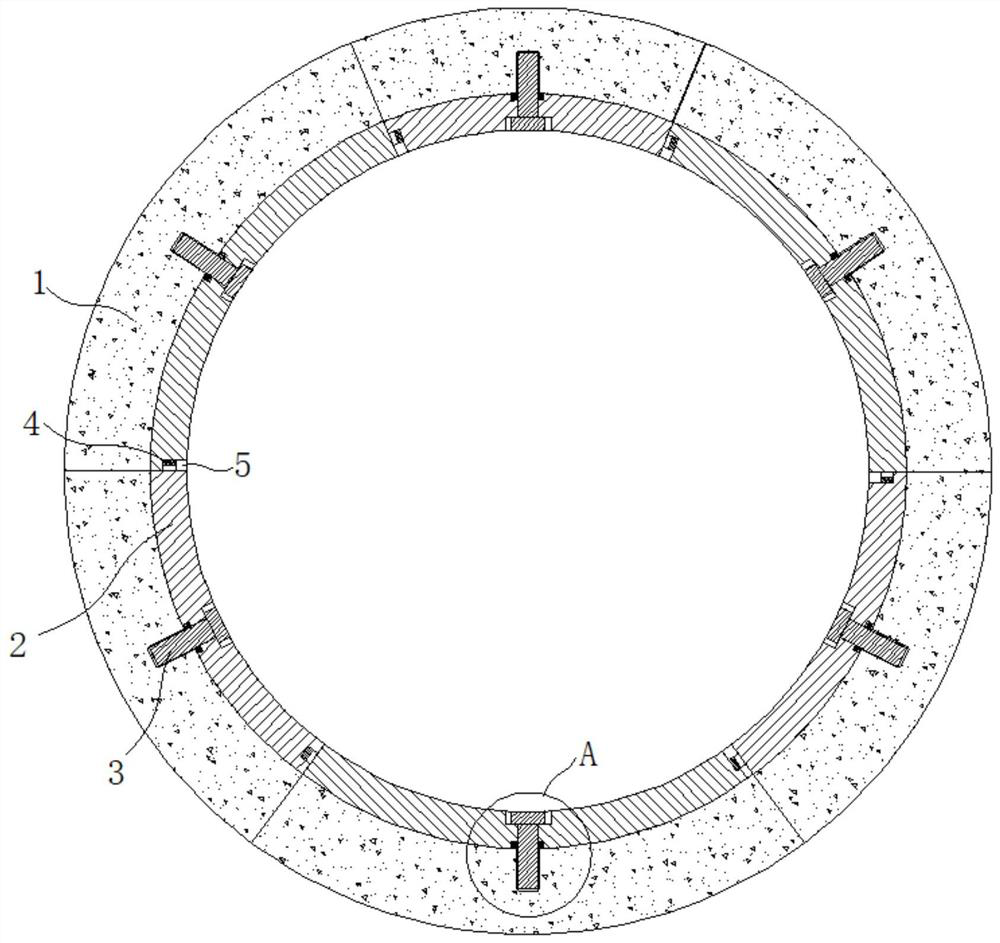

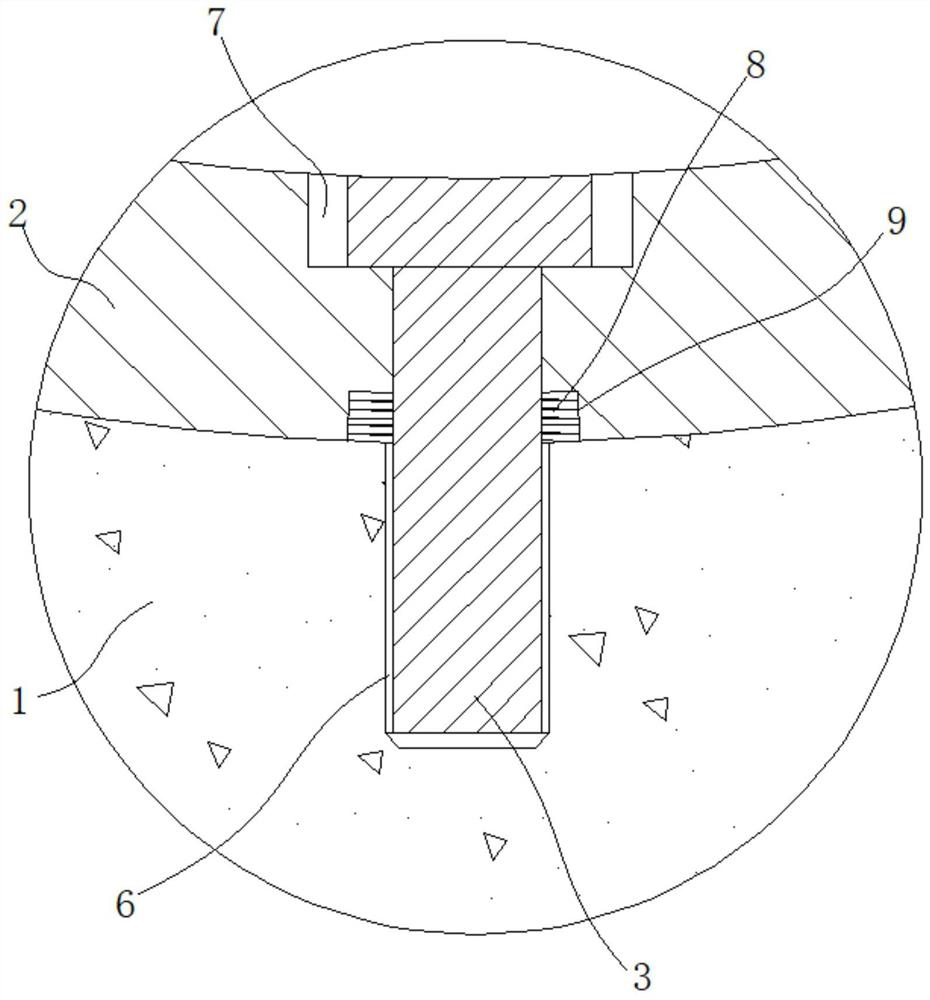

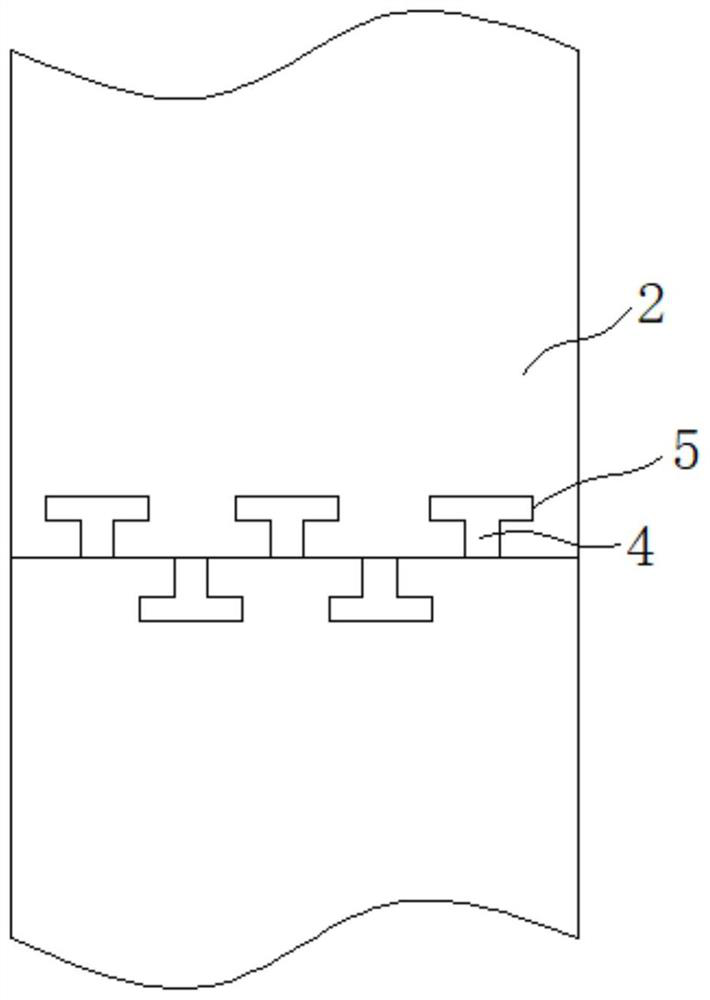

Segment support structure of shield section tunnel communication channel

ActiveCN111894636BDoes not hinder accessShorten the construction periodUnderground chambersTunnel liningScrew thread

The invention discloses a segment support structure of a connecting channel in a tunnel in a shield tunnel, which comprises a segment ring assembled from a plurality of segments and a ring-shaped steel support structure circumferentially surrounding the inner side of the segment ring; There is an assembly screw hole in the middle part of the inner side of the segment, and an assembly bolt threaded with it is provided corresponding to the assembly screw hole; the annular steel support structure includes arched steel support pieces consistent with the number of the segment, two by two The adjacent arched steel support pieces are detachably connected; the middle of each piece of said arched steel support piece is provided with a via hole corresponding to the assembly bolt, and the arched steel support piece passes through the assembly bolt The through holes are screwed into the corresponding assembly screw holes to detachably connect with the corresponding segments; a telescopic mechanism is arranged between each arched steel support piece and the corresponding segment; The invention has simple structure, convenient assembly and disassembly, convenient entry and exit of construction personnel and materials, and effectively shortens the construction period of the shield communication channel.

Owner:CHINA CREC RAILWAY ELECTRIFICATION BUREAU GRP

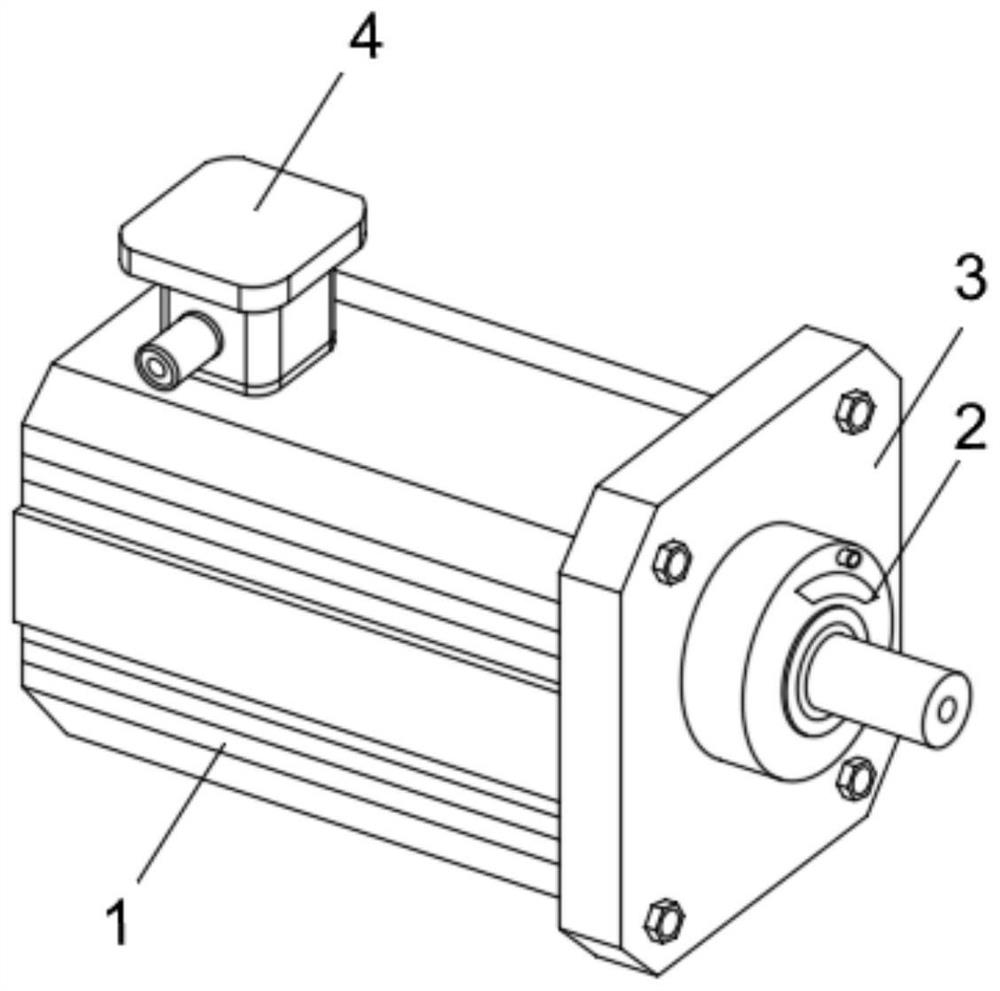

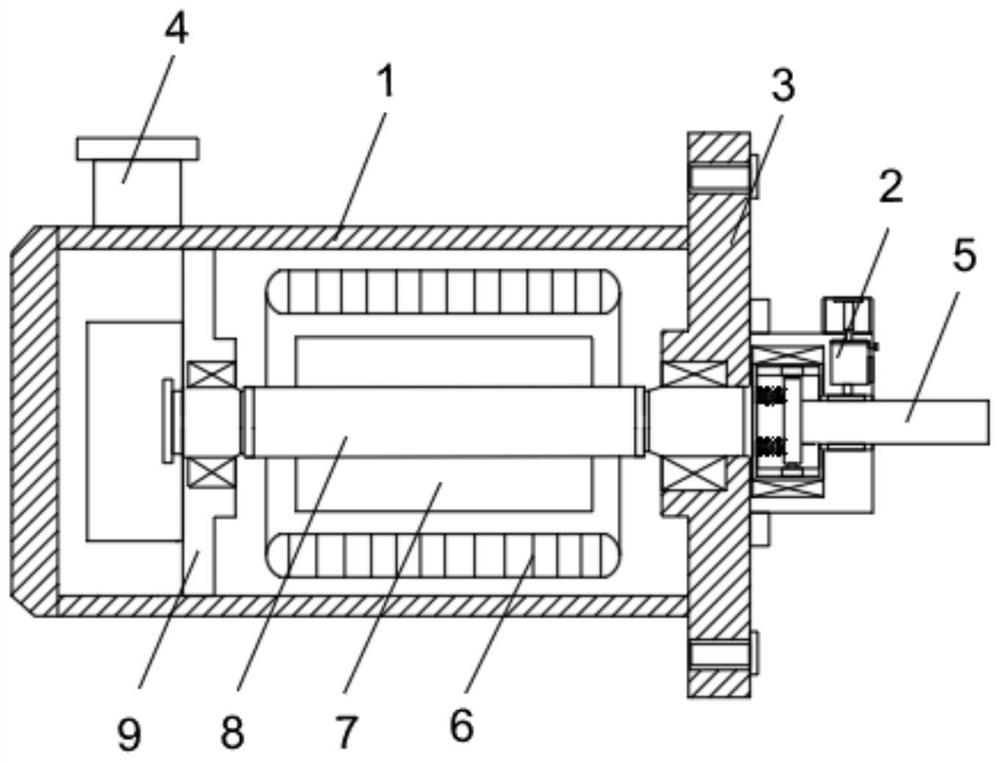

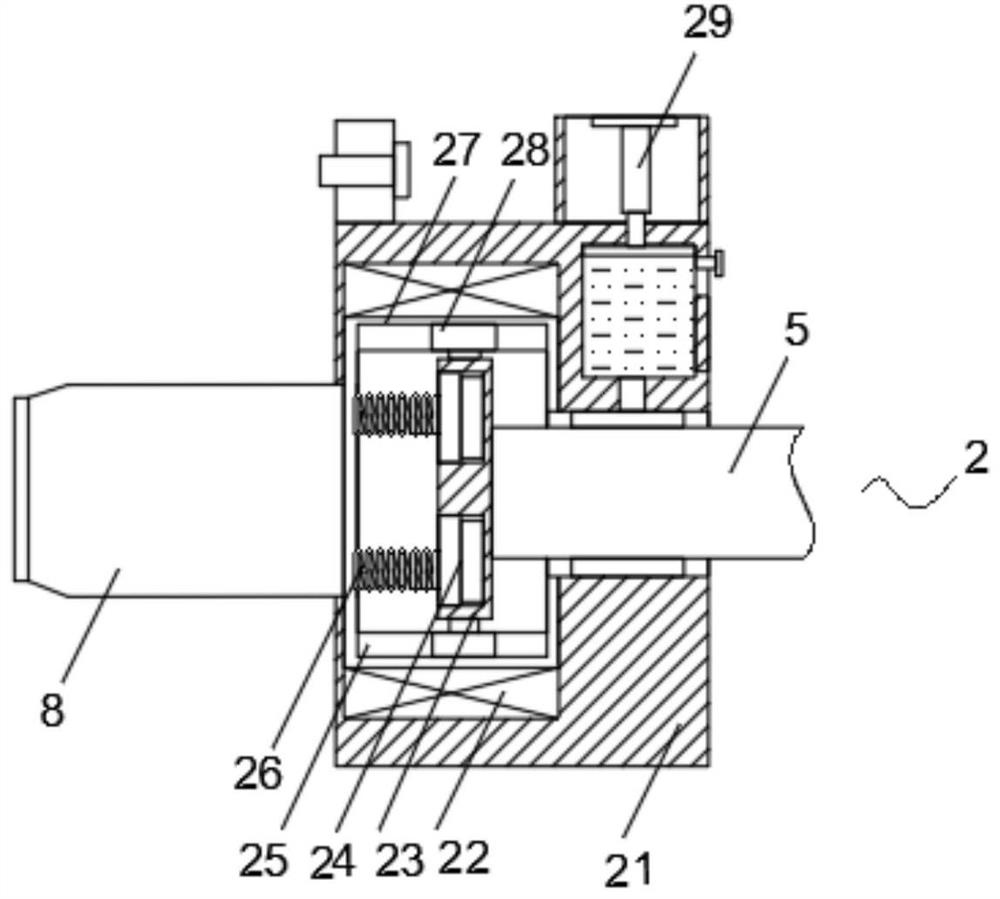

Motor and motor shaft thereof

InactiveCN112610656AGuaranteed uptimeImprove structural strengthRotating vibration suppressionLubrication elementsBall bearingElectric machine

The invention discloses a motor and a motor shaft thereof. The motor comprises a housing which is provided with a working mechanism. An axial stabilizing mechanism is fixedly installed in the middle of the side surface of one end of the shell. The working mechanism comprises a mounting plate, a photoelectric encoder, a shaft end, an armature coil, a permanent magnet, a main shaft and a fixed plate. The mounting plate is fixedly mounted on the side surface of one end of the shell. According to the motor and the motor shaft thereof, by arranging the axial stabilizing mechanism, the axial impact force of a load is buffered, axial dislocation is avoided, meanwhile, a connecting shaft can be limited through a fixing shell and a ball bearing, then the structural strength of the connecting position of the shaft end and the main shaft is improved, and normal operation of the motor is guaranteed; and meanwhile, a protection mechanism is arranged, dust and impurities in the external environment can be prevented from entering the connecting position of the shaft end and the main shaft to cause abrasion of the shaft, and the service life of the shaft end is prolonged.

Owner:陈艳红

Threaded ring

Owner:CHUAN HONG PRECISION TOOL MFG

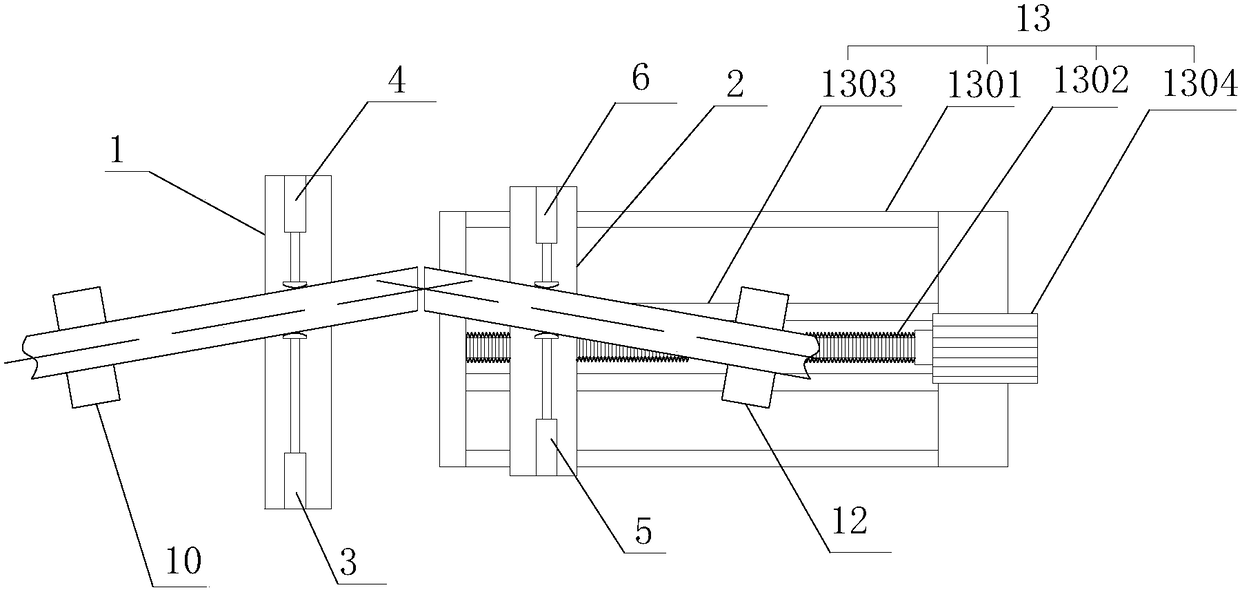

A pipe fitting angle welding equipment

ActiveCN105945501BAvoid Axial MisalignmentImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesPipe weldingWelding process

The invention discloses a pipe angle welding device which comprises a first workbench, a second workbench, a first push device, a second push device, a third push device, a fourth push device, a slide rail, a welding unit and a drive unit. The first workbench and the second workbench are both used for supporting pipes; the first push device, the second push device, the third push device and the fourth push device are all used for pushing the pipes to skew; the drive unit and the slide rail are mutually matched for driving the welding unit to move; and a drive mechanism in the welding unit is matched with a ring sleeve for enabling a welding gun to rotate by 360 degrees. The pipe angle welding device achieves automatic adjustment of pipe welding angles, and rotation of the pipes in the welding process is not needed.

Owner:WUHU JINGFENG GARDEN MACHINERY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com