Forming mold of indoor mutual inductor and pouring sealing method of forming mold

A technology for forming molds and transformers, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of secondary equipment damage to personal safety, decreased insulation, and more casting or injection abrasives, etc., to prevent Threat to personal safety, reduce unit energy consumption, and reduce the effect of mold investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

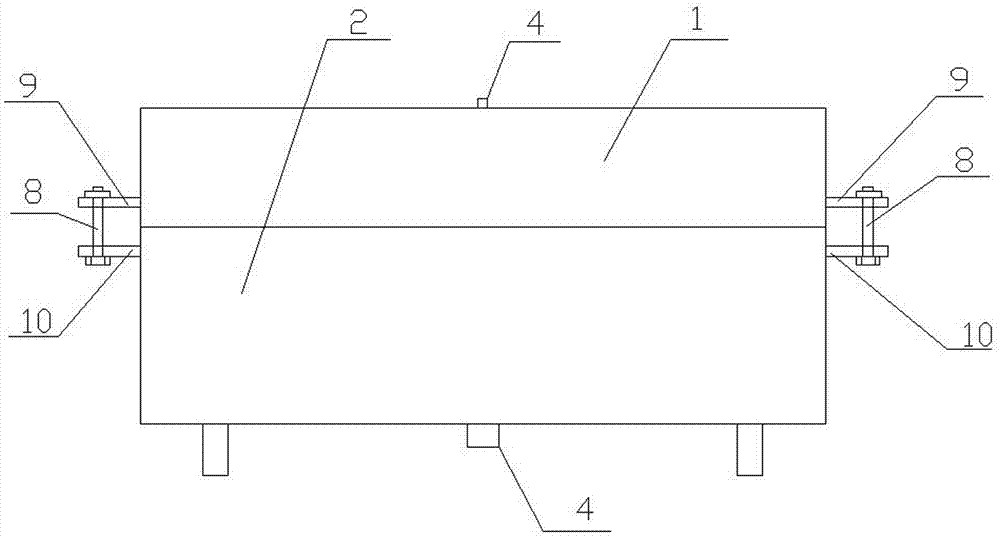

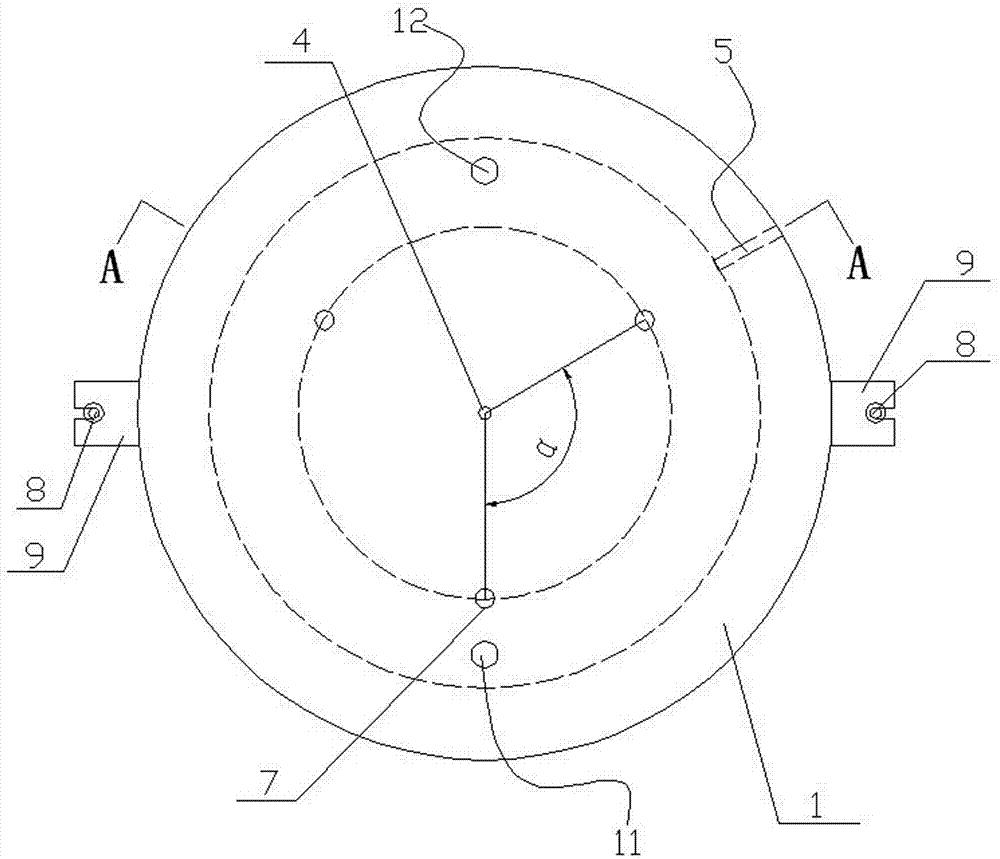

[0022] Combine below Figure 1 to Figure 5 The structure and working process of the present invention are further described.

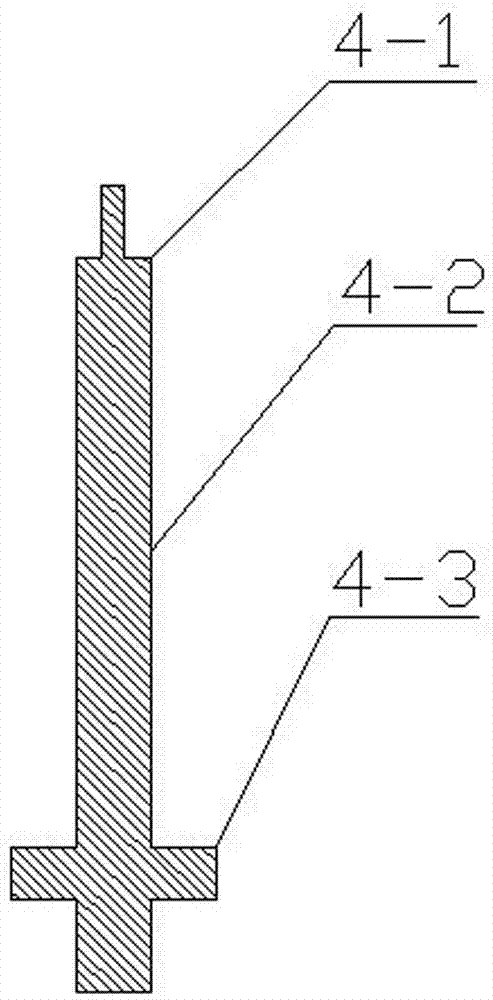

[0023] The forming mold of the indoor transformer of the present invention includes an upper mold 1 and a lower mold 2 for surrounding a mold cavity 15, and a position where the upper mold 1 and the lower mold 2 are connected is provided with a coil outlet 6 for placing the transformer. The outlet hole 5 of the upper mold 1 is provided with a pouring hole 11 and an exhaust hole 12 communicating with the mold cavity, and a mold core 4 is arranged in the mold cavity 15, and the upper and lower sides of the mold core 1 The two ends are respectively connected with the upper mold 1 and the lower mold 2, the upper end 4-1 of the mold core 4 is set in a convex shape, and the upper mold 1 is provided with a hole that matches the upper end 4-1 of the convex mold core. Upper groove 16, which is designed to separate from the mold core 4 when the upper mold 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com