Ferrule, method of manufacturing optical waveguide connector using the ferrule, and optical waveguide connector

A technology for optical waveguide and connectors, applied in the field of optical waveguide connectors, can solve the problems that the productivity of optical waveguide connectors cannot be improved, and achieve the effects of preventing axial deviation and suppressing connection loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Hereinafter, a ferrule of the present invention, a method of manufacturing an optical waveguide connector using the same, and preferred embodiments of the optical waveguide connector will be described in detail with reference to the accompanying drawings.

[0054] The term "optical waveguide" in this specification includes flat plate-type optical transmission devices having various rectangular cross-sections, such as optical waveguides, polymer waveguides, and optical fiber ribbons. In this embodiment, a case where a polymer waveguide is applied to an optical transmission path is described.

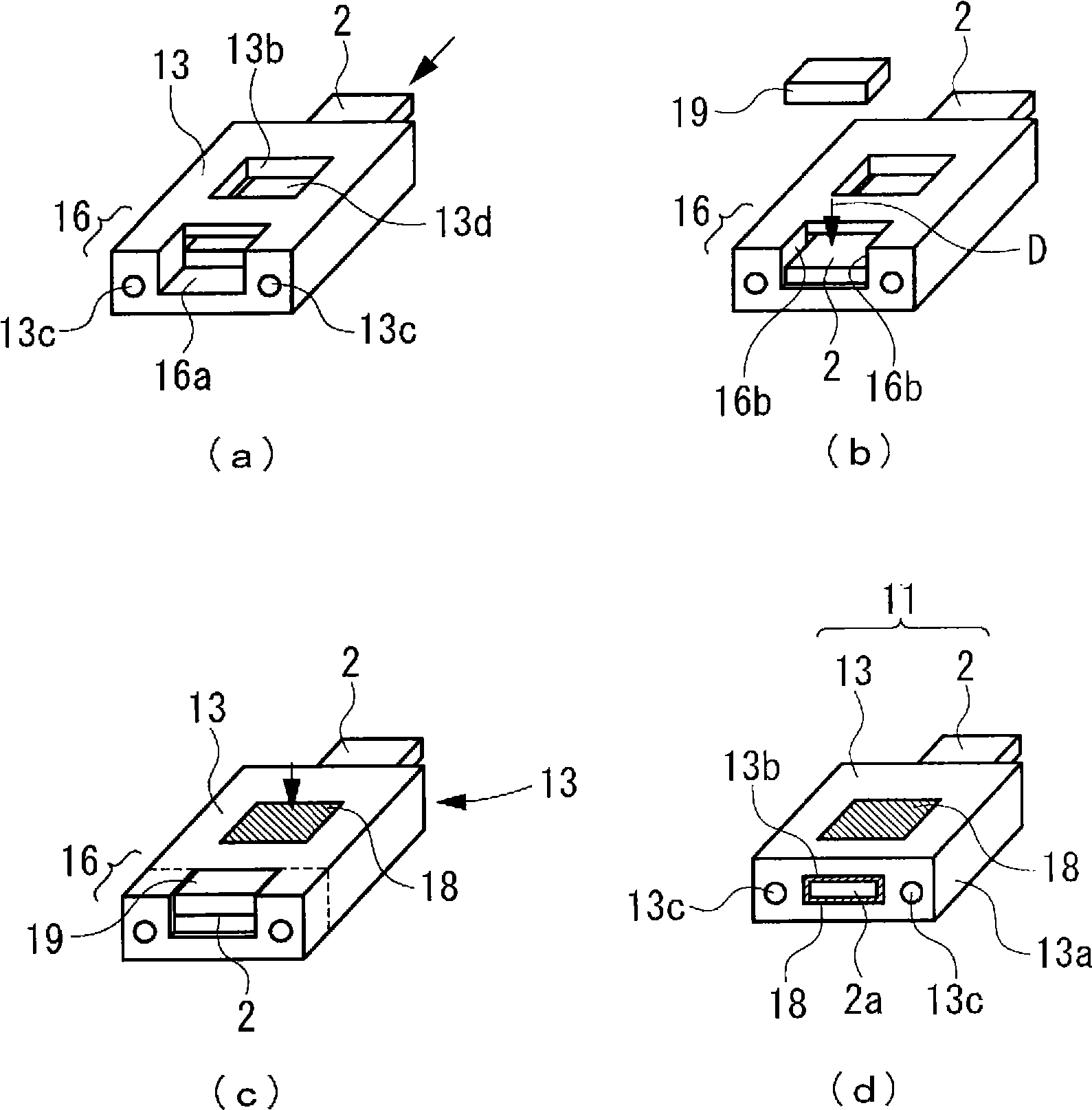

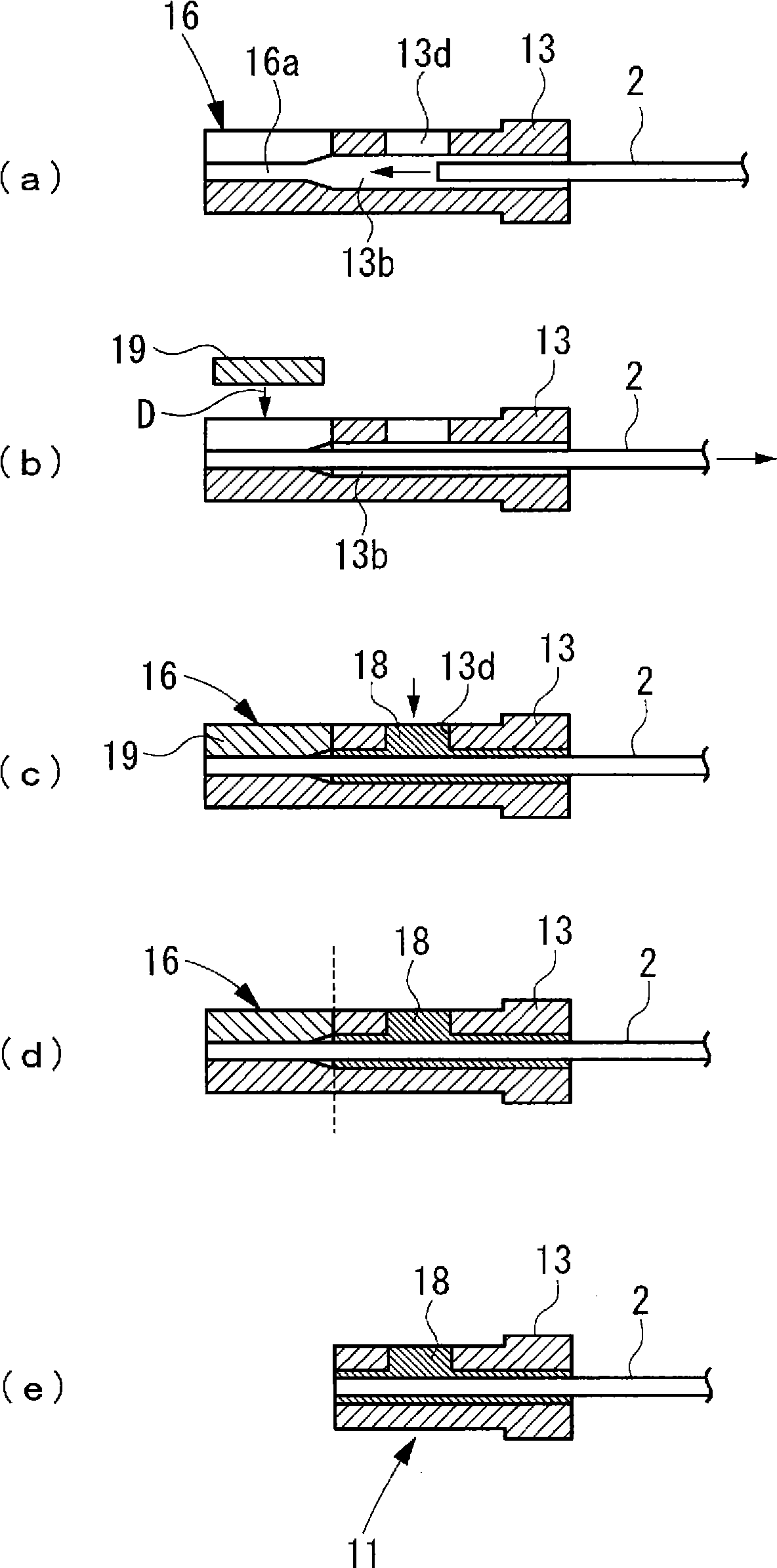

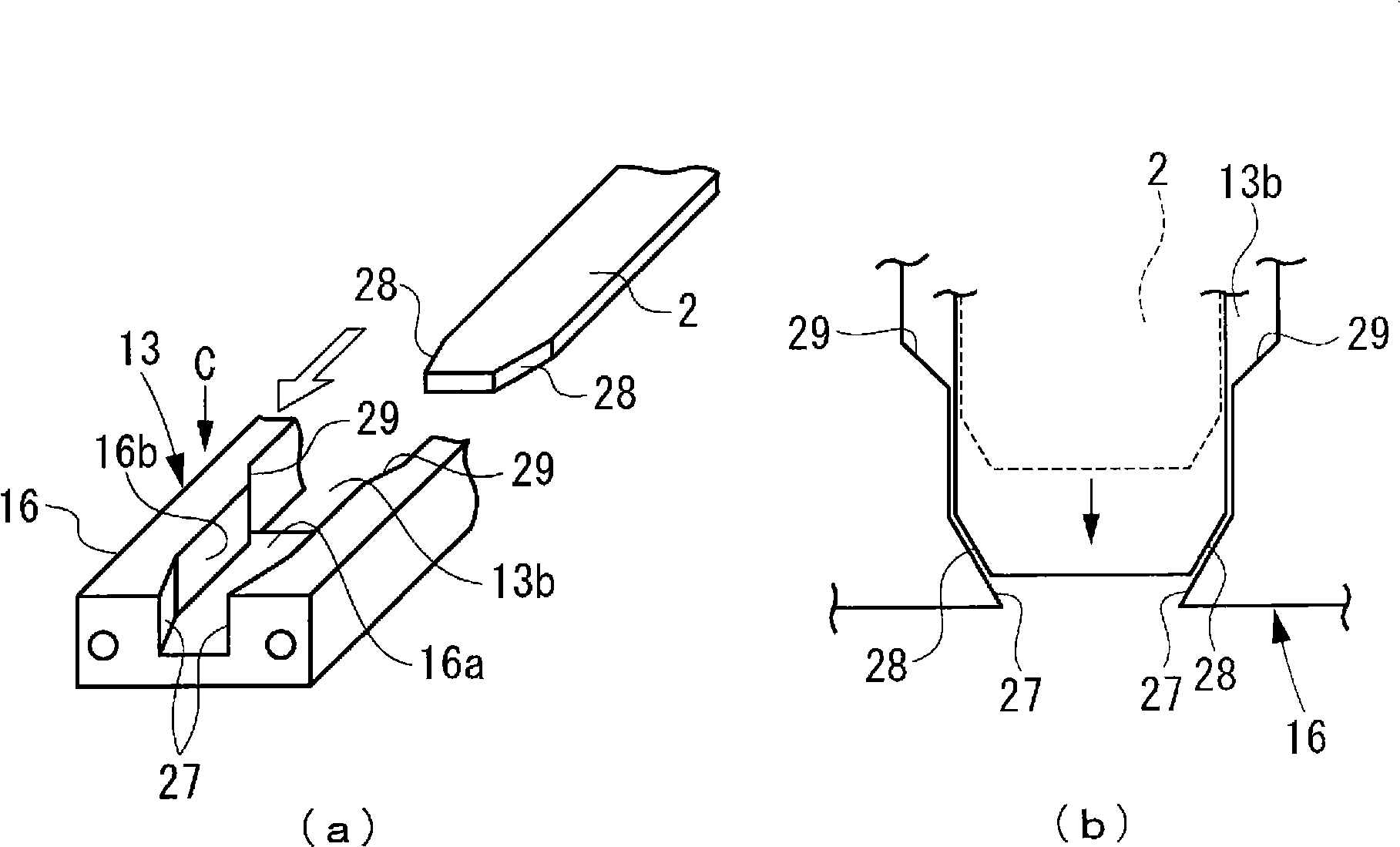

[0055] figure 1 is a perspective view showing a ferrule of the present invention and a first embodiment of a method of manufacturing an optical waveguide connector according to the present invention using the ferrule. In the drawings, (a) shows the state where the optical waveguide is passed through the insertion hole of the ferrule, (b) shows the state where the optical waveguid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com