Free stopping mechanism

A stop-and-spin technology, applied in building structures, door/window fittings, hinges with pins, etc., can solve the problems of failing to pass 30,000 fatigue tests, difficulty in controlling dimensional accuracy, and excessively large diameter of friction discs. Improved coaxiality and stiffness, reduced critical parts, and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

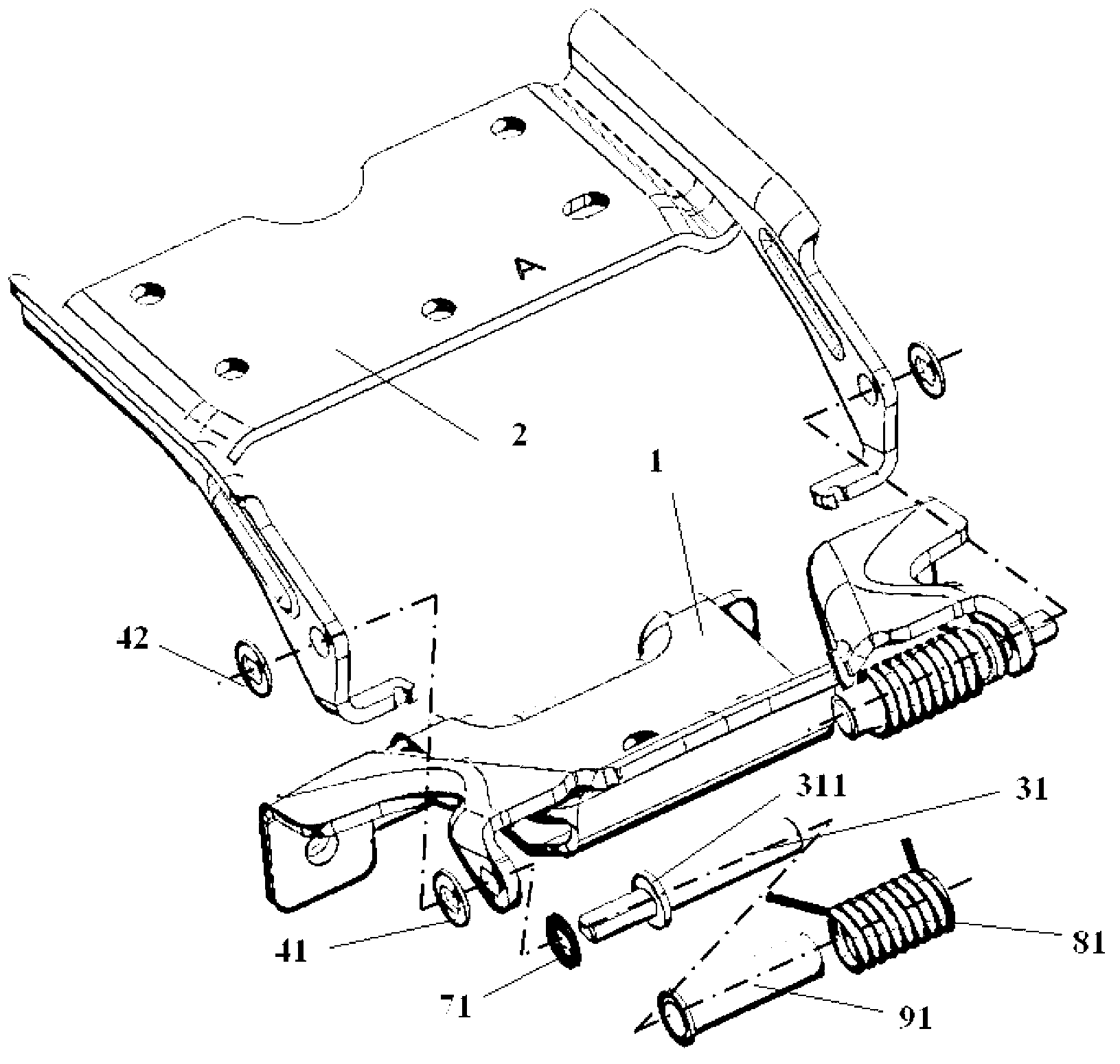

[0029] Below in conjunction with accompanying drawing, provide the preferred embodiment of the present invention, and describe in detail, make can better understand the function, characteristic of the follow-up mechanism of the present invention.

[0030] Such as Figure 3-5 Shown is a follow-up mechanism according to a preferred embodiment of the present invention. The mechanism includes a mechanism base 1 and a mechanism hinge 2 connected through two rotating shafts 31 on the left and right sides respectively. The left and right are completely symmetrical structures, wherein the rotating shaft 31 is divided into two sections, one section is a flat head section with a diameter of 6mm , the other section is a round head section with a diameter of 6mm, and the middle of the flat head section and the round head section is separated by a flange 311 with a diameter of 12mm. A flat hole is opened on the mechanism base 1, and a round hole is opened on the mechanism turning page 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com