Gas turbine

A gas turbine, cooling air technology, applied in the cooling of turbine/propulsion device, cooling of engine, engine function, etc., can solve the problems of low performance of gas turbine, axial deviation of bearing box and rotor, etc., and achieve uniform thermal expansion and contraction. , to avoid the effect of axial deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

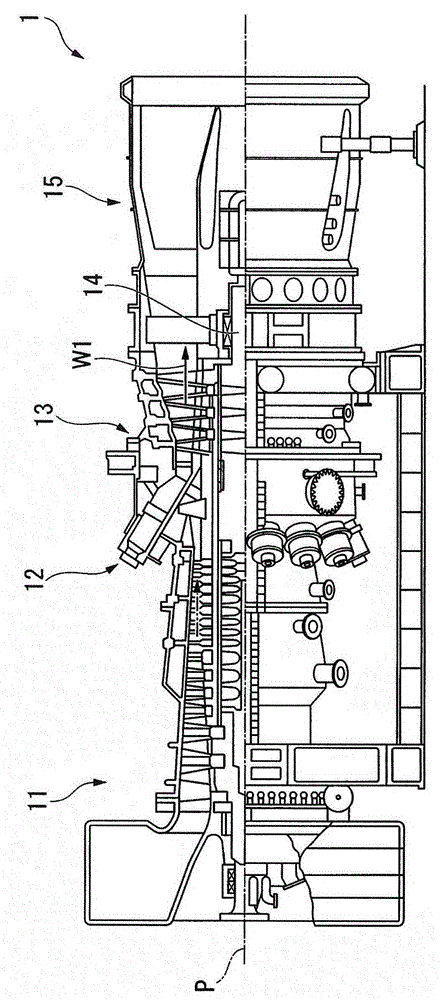

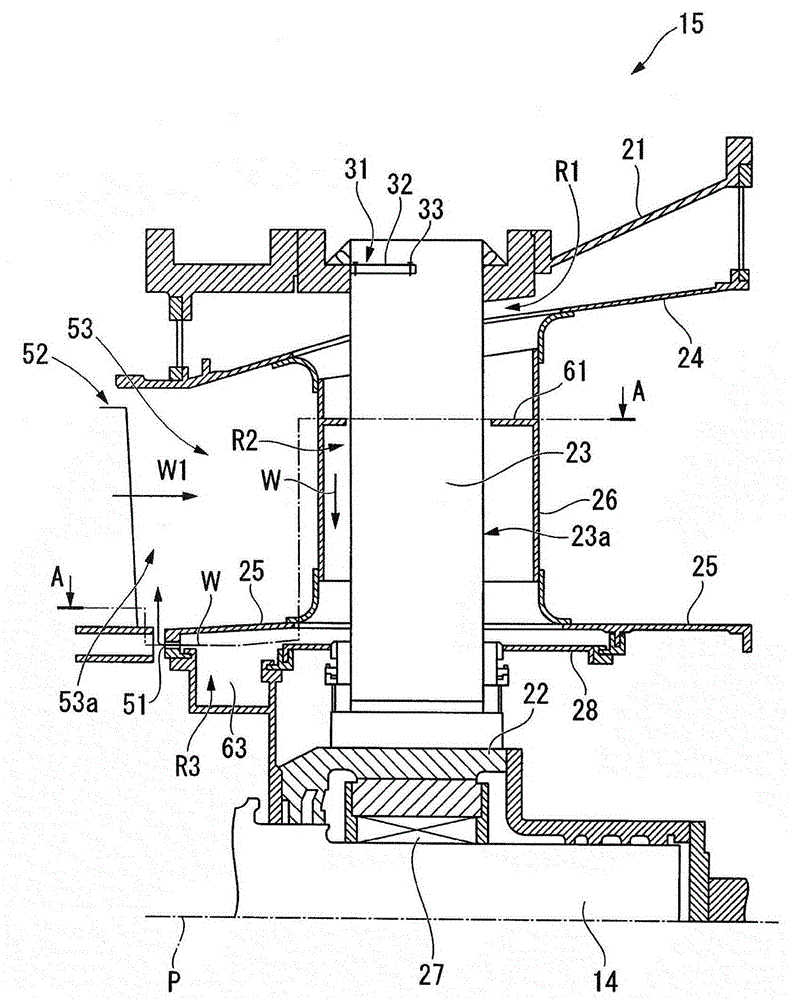

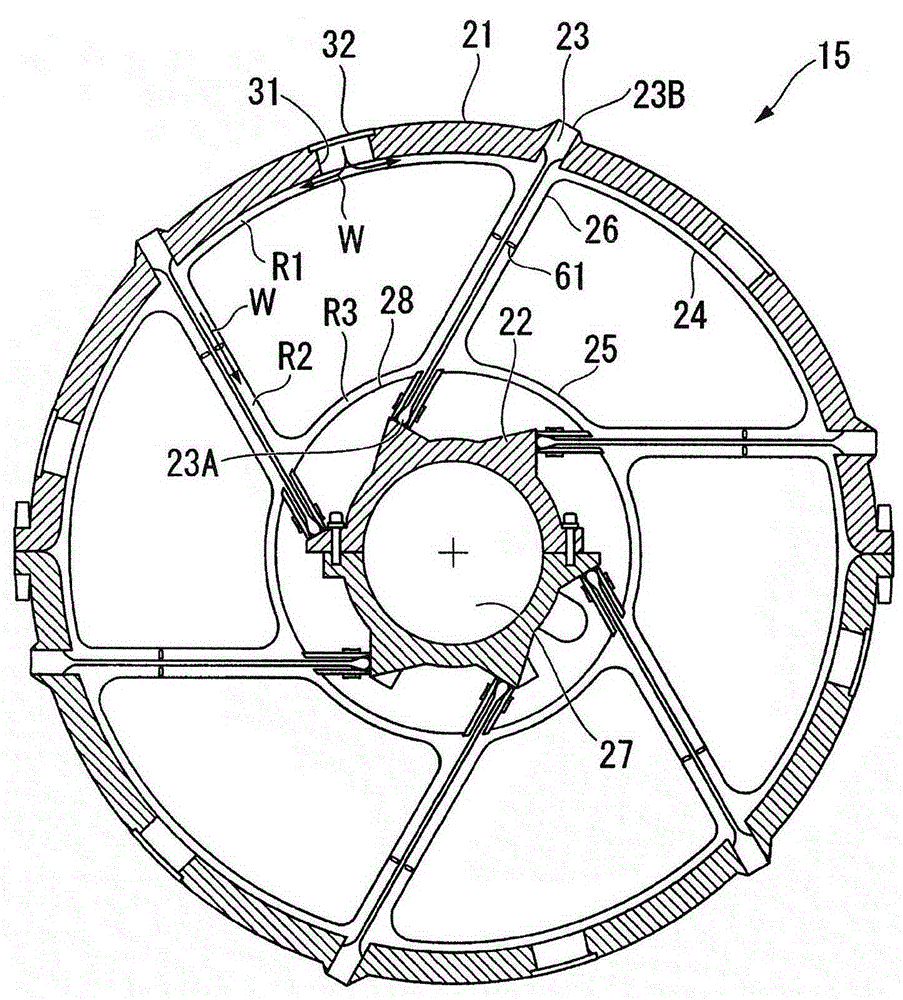

[0073] Hereinafter, the gas turbine 1 according to the first embodiment of the present invention will be described.

[0074] Such as figure 1 As shown, the gas turbine 1 is configured to mix compressed air generated by a compressor 11 with fuel through a combustor 12 and then combust it to generate high-temperature, high-pressure combustion gas W1. In addition, the gas turbine 1 obtains rotational power by causing the combustion gas W1 to flow into the turbine 13 to rotate the rotor 14 of the turbine 13 around the axis P. Furthermore, the turbine 13 is connected to, for example, an unillustrated generator, and generates electricity by the rotational power.

[0075] Then, the combustion gas W1 is exhausted through the exhaust chamber 15 after rotating the turbine 13 .

[0076] It should be noted that, in the following, the compressor 11 side of the gas turbine 1 ( figure 1 The left side of the paper) is referred to as the "upstream side of the axis P direction", and the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com