Intelligent automatic cooker

A cooking machine and intelligent technology, applied in the field of kitchen utensils, can solve the problems of producing large oil fume, being unable to be completely isolated, and not being perfect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

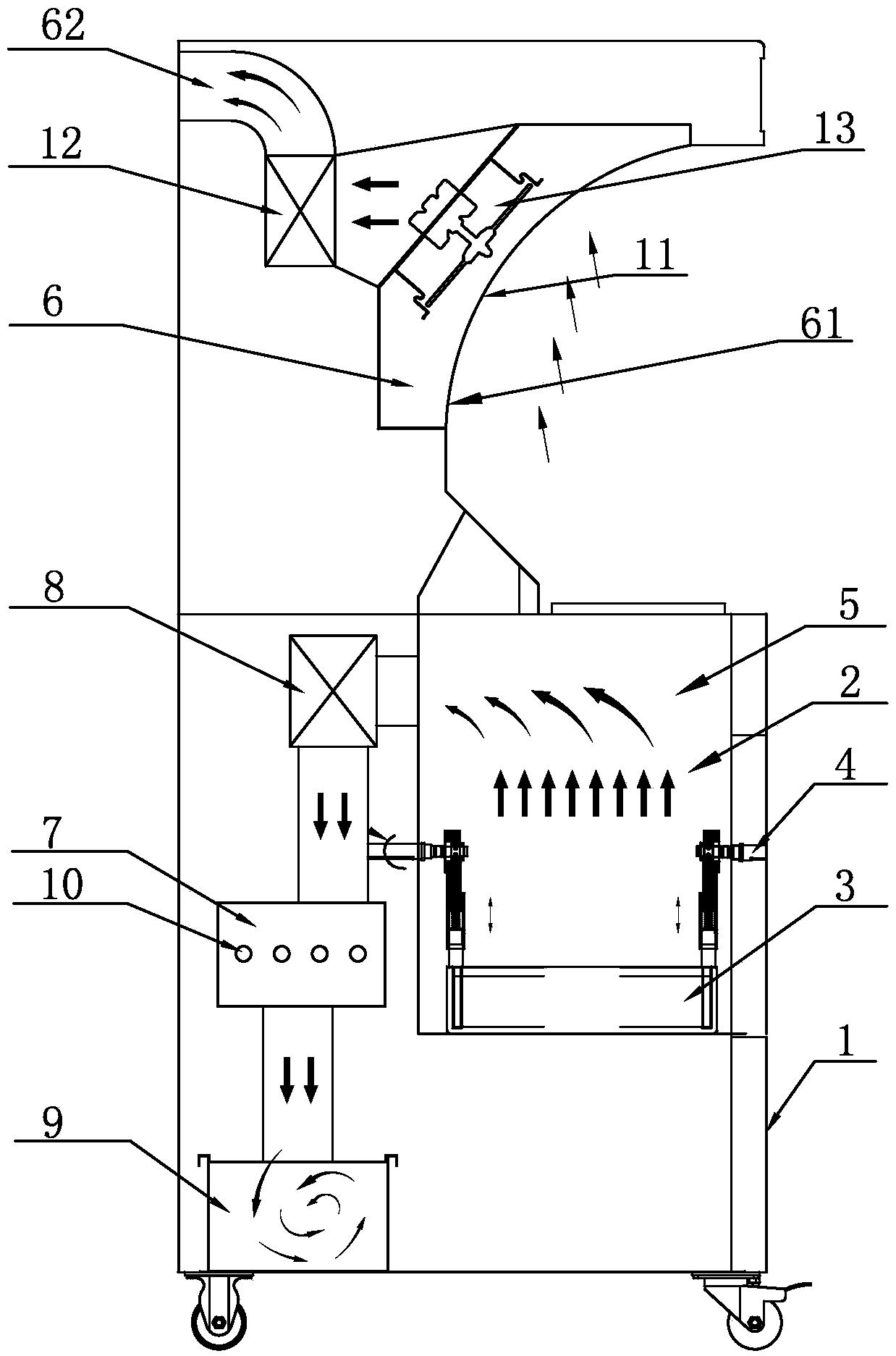

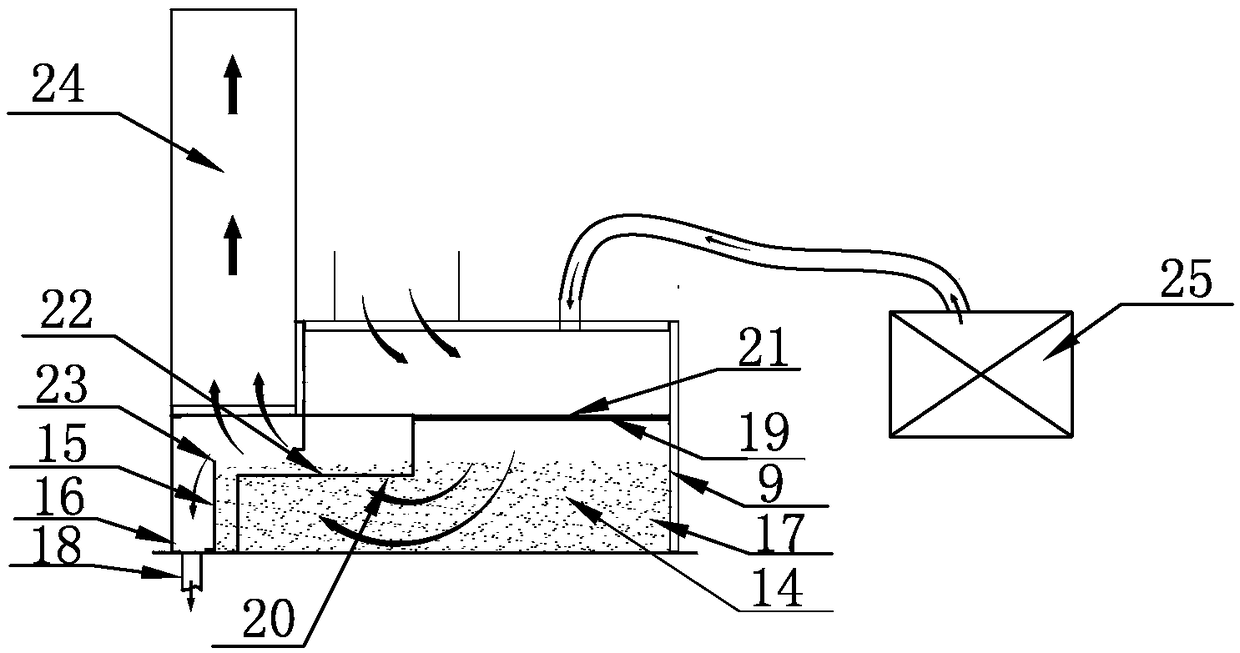

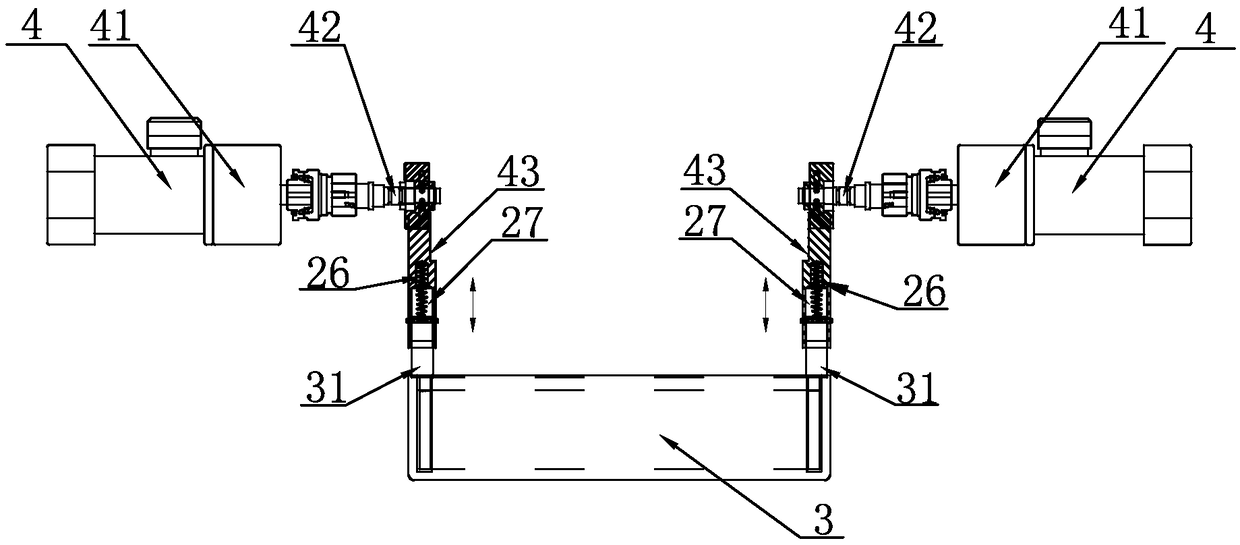

[0016] Such as Figure 1-3 As shown, an intelligent cooking machine of the present invention includes an organism (1) and a pot body (2) arranged in the body (1), and a spatula (3) is arranged inside the pot body (2), The body (1) is provided with a driving device (4) for driving the spatula (3) to swing, and the body (1) includes a frying area (5) and a smoking area (6) above the frying area (5) , the pot body (2) is set in the frying area (5), and the side of the frying area (5) is also equipped with a UV tube box (7), which sucks the oil fume of the pot body (2) into the UV tube The centrifugal fan (8) in the box (7), the oil fume treatment box (9) connected to the UV tube box (7), and the UV tube box (7) is equipped with a UV tube for oxidizing and separating the oil fume (10), one side of the smoking area (6) is a smoke inlet (61), the other side is a smoke exhaust port (62), a smoking hood (11) is provided at the smoke inlet (61), and the smoking area ( 6) A centrifuga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com