Sealing device of blast furnace planetary reducer

A planetary reducer and sealing device technology, which is applied in the direction of engine sealing, transmission parts, mechanical equipment, etc., can solve the problems of ignorance and misunderstanding of the transmission principle, so as to improve the anti-deformation ability, reduce bending, prevent deformation or The effect of destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

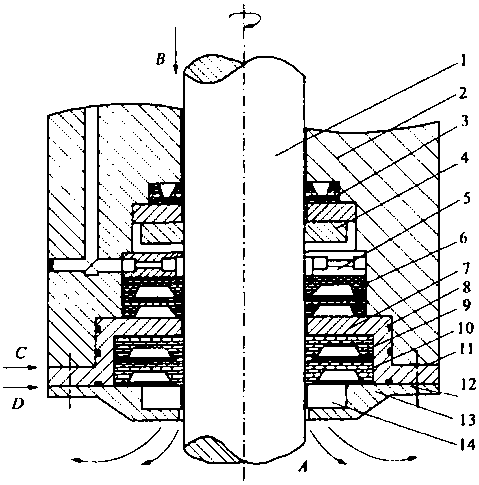

[0011] Such as figure 1 As shown, the sealing device of the blast furnace planetary reducer of the present invention includes a rotating arm shaft 1; a rotating arm support 2 is provided on the outside of the rotating arm shaft 1; a gland 13 is installed at the end of the rotating arm support 2; The boom frame 2 is sequentially installed on the outer side of the boom shaft 1 with a J-type oil seal 3, a magnetic oil seal 4, an oil guide ring 5, a composite oil seal 6, a sealing sleeve 7, a high pressure oil seal 9 and a packing 10 from top to bottom; An O-shaped sealing ring 8 is provided on the sealing sleeve 7; an asbestos gasket 11 is provided on the outside of the sealing sleeve 7; a sealing ring 12 is installed between the boom bracket 2 and the gland 13.

[0012] An oil bearing or copper sleeve 14 is installed on the gland 13.

[0013] A steel gasket (not shown) is installed between the high pressure resistant oil seal 9 and the packing 10.

[0014] The inner diameter of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com