Magnetic push suspension bearing unit

A suspension bearing and magnetic repulsion technology, applied in the direction of bearing components, bearings, shafts and bearings, can solve problems such as short service life, poor impact resistance, and fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

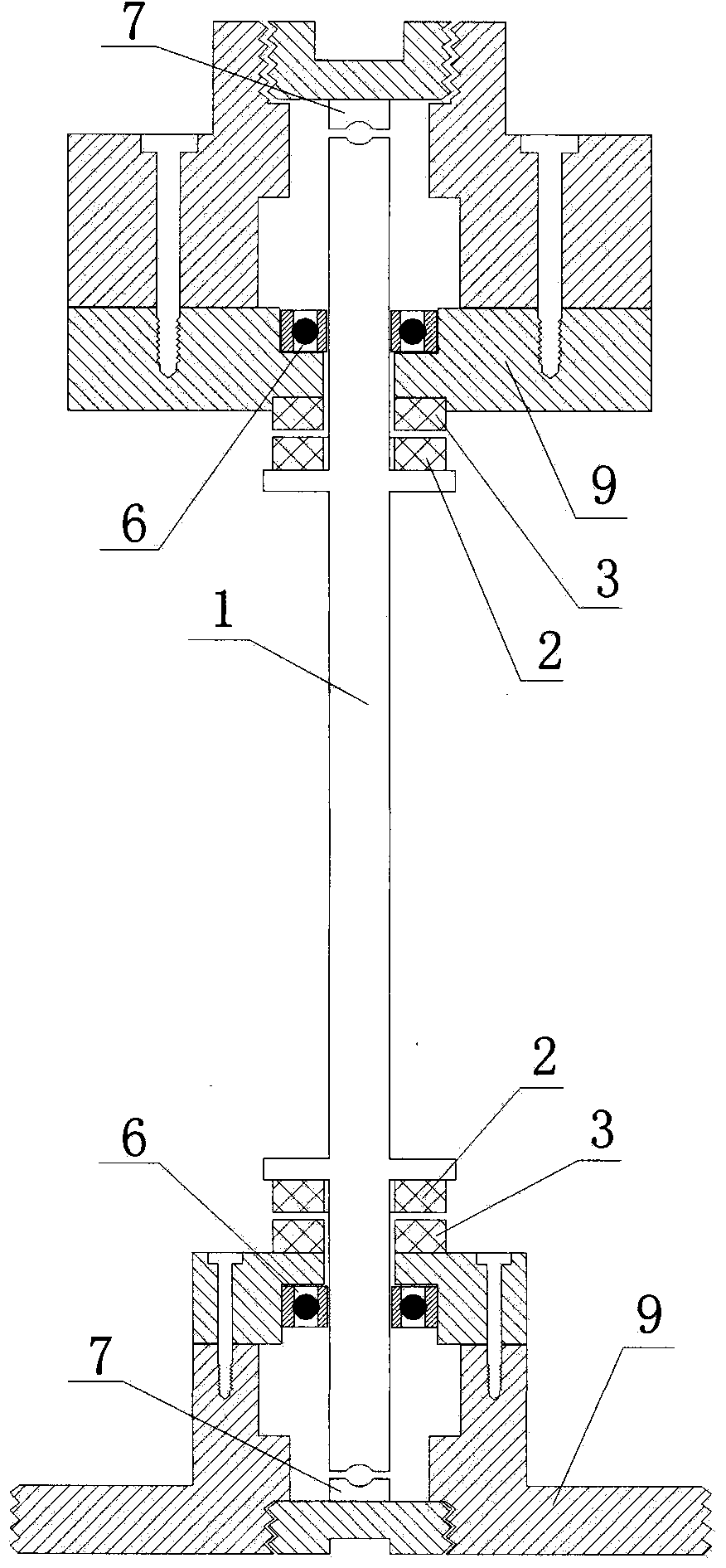

[0021] Embodiment 1 Axially suspended magnetic repulsion suspension bearing unit

[0022] see figure 1 , the magnetic repulsion suspension bearing unit mainly includes: shaft, inner magnetic ring, outer magnetic ring, auxiliary bearing, limit block and bracket; the inner magnetic ring is installed at the proximal end of the shaft, and the outer magnetic ring corresponding to the inner magnetic ring is installed On the bracket, the adjacent surfaces of the inner magnetic ring and the outer magnetic ring are of the same polarity, and the inner magnetic ring and the outer magnetic ring form an axial magnetic ring pair; the limit block corresponding to the shaft end is installed on the support, and the limit block The gap with the end of the shaft is smaller than the gap between the inner magnetic ring and the outer magnetic ring; an auxiliary bearing is arranged between the shaft and the bracket. Auxiliary bearings are ceramic bearings. The pair of axial magnetic rings can also...

Embodiment 2

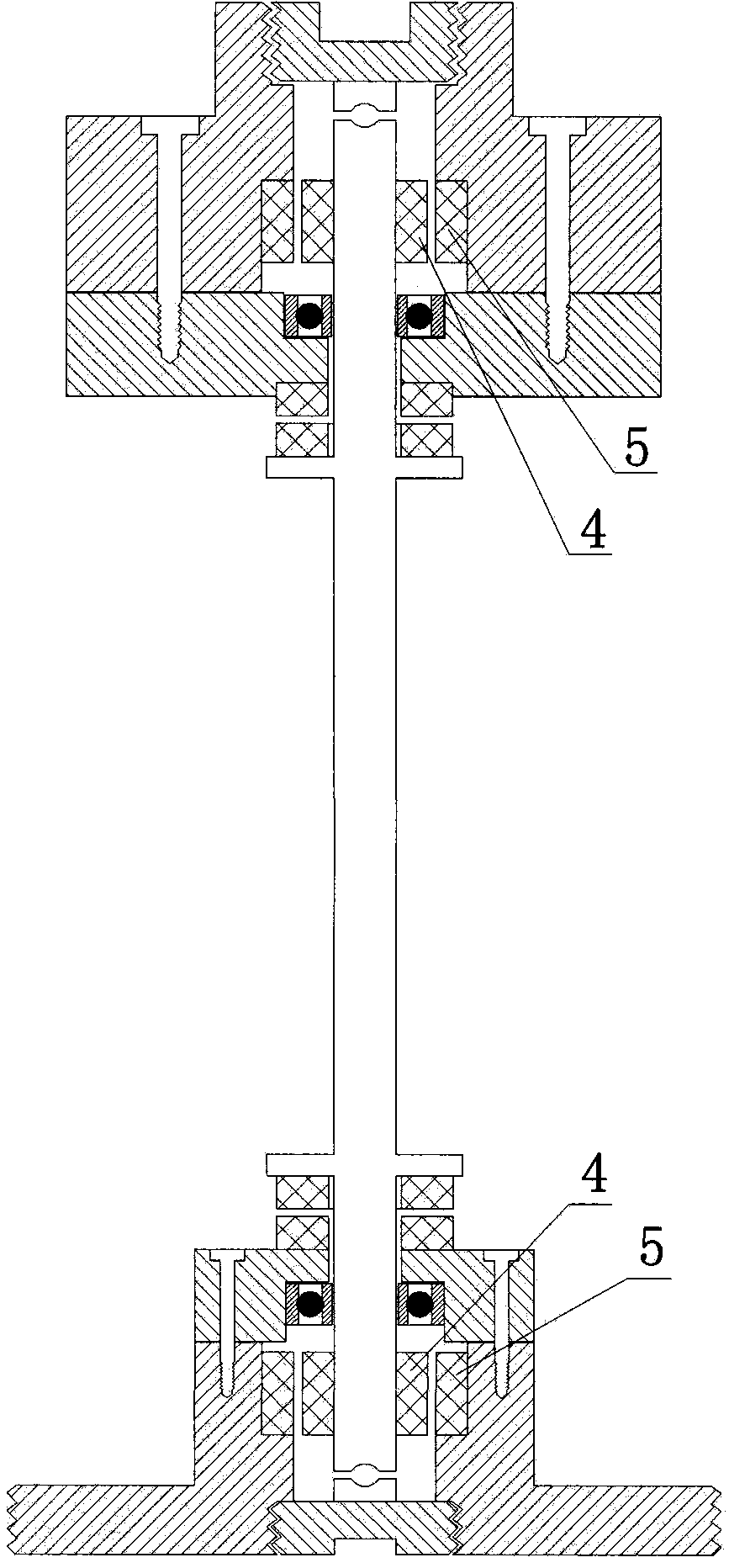

[0024] Embodiment 2 Axial and radial levitation magnetic repulsion levitation bearing unit

[0025] see figure 2 and 5 , on the basis of Embodiment 1, in addition, it also includes an inner magnetic cylinder and an outer magnetic cylinder, the inner magnetic cylinder is concentric with the shaft and fixedly installed at the proximal end of the shaft, and the outer magnetic cylinder is sleeved outside the inner magnetic cylinder and fixedly installed on the bracket Above, the inner diameter of the outer magnetic cylinder is slightly larger than the outer diameter of the inner magnetic cylinder. Both the inner magnetic cylinder and the outer magnetic cylinder are radially magnetized. The adjacent surfaces of the inner magnetic cylinder and the outer magnetic cylinder are of the same polarity. The inner magnetic cylinder and the outer magnetic cylinder are composed of Radial magnetic cylinder pair; the gap between the auxiliary bearing and the bracket or between the auxiliary b...

Embodiment 3

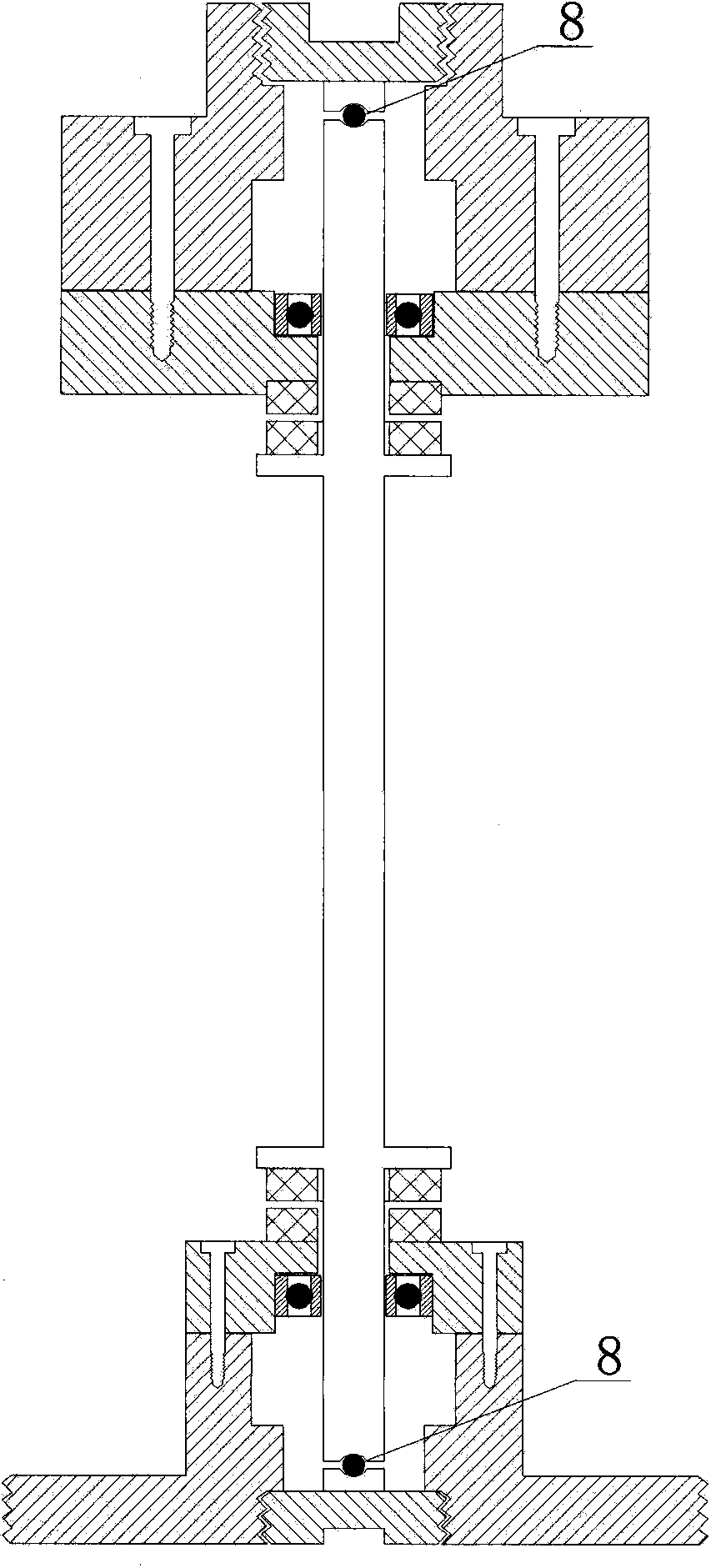

[0027] Embodiment 3 Adding a magnetic repulsion suspension bearing unit with limit ball axial suspension

[0028] see image 3 , On the basis of Embodiment 1, further, limit balls are installed between the limit block and the shaft end. The limit block can be a ceramic block, and the limit ball can be a ceramic ball.

[0029] The advantage of this embodiment is: this embodiment not only has the advantages of Embodiment 1, but when the shaft moves axially, the sliding friction between the limit block and the end of the shaft is converted into rolling friction. The use of ceramics improves the service life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com