Main shielding case of vacuum arc-extinguishing chamber and vacuum arc-extinguishing chamber

A technology of vacuum interrupter and shielding cover, which is applied in the direction of high-voltage air circuit breakers, electrical components, electric switches, etc., can solve the problems of unfavorable miniaturization and great influence of metal vapor on insulation performance, so as to improve the fixing reliability and benefit Effects of miniaturization and reduction in axial dimension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

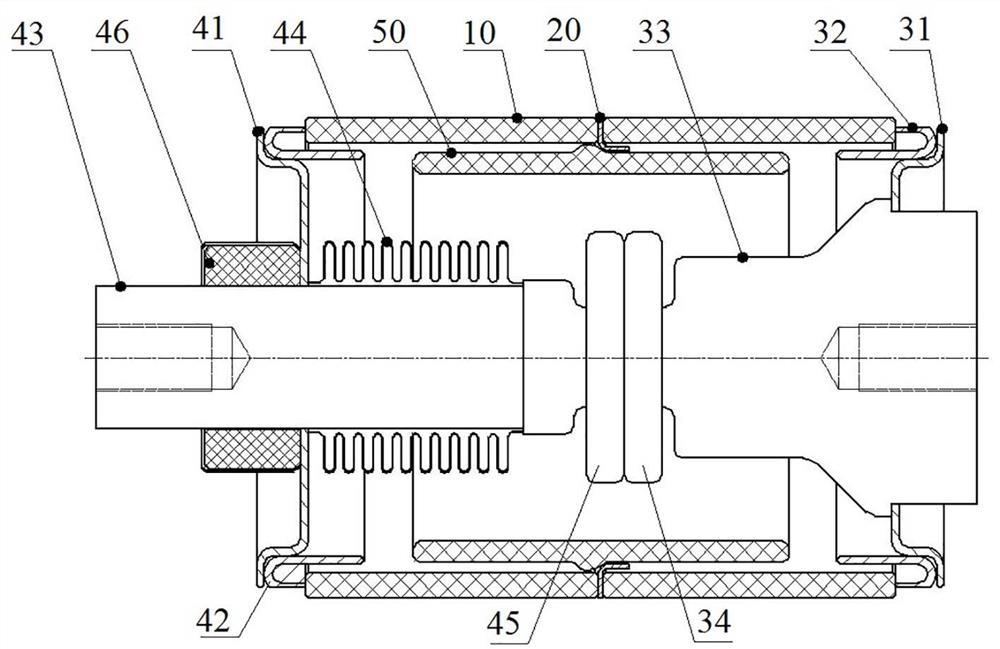

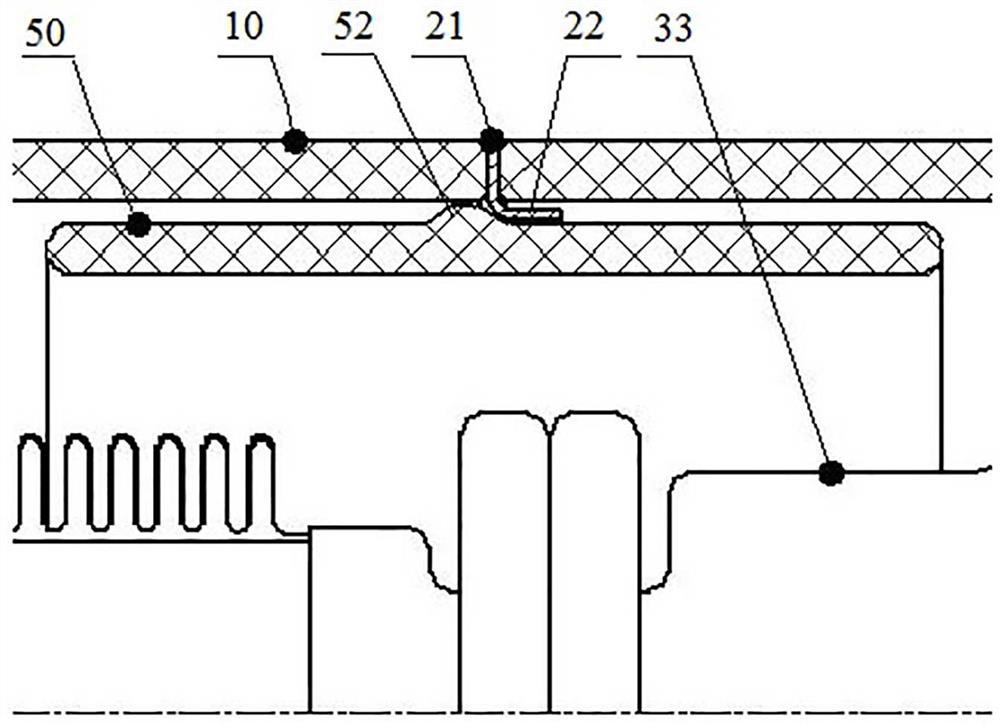

[0052] Such as figure 1 As shown, the vacuum interrupter is a 126kv vacuum interrupter, including a hollow shell 10, the shell 10 is an existing structure, made of ceramic material, the shell 10 is a two-stage structure spliced with each other, the two-stage shell 10 They are fixedly connected by a metal intermediate sealing ring 20. The two axial ends of the casing 10 are respectively provided with a static contact 34 assembly and a moving contact 45 assembly, and the casing 10 is provided with a main shield 50 in the axial middle.

[0053] The static contact 34 assembly includes a static cover 31, a static end shield 32, and also includes a static conductive rod 33 and a static contact 34. The static cover 31, the static end shield 32 and the static conductive rod 33 are welded and fixed together. The contact 34 is fixed on the static conductive rod 33 .

[0054] The moving contact 45 assembly includes a moving cover plate 41, a moving end shield 42, and also includes a ...

Embodiment 2

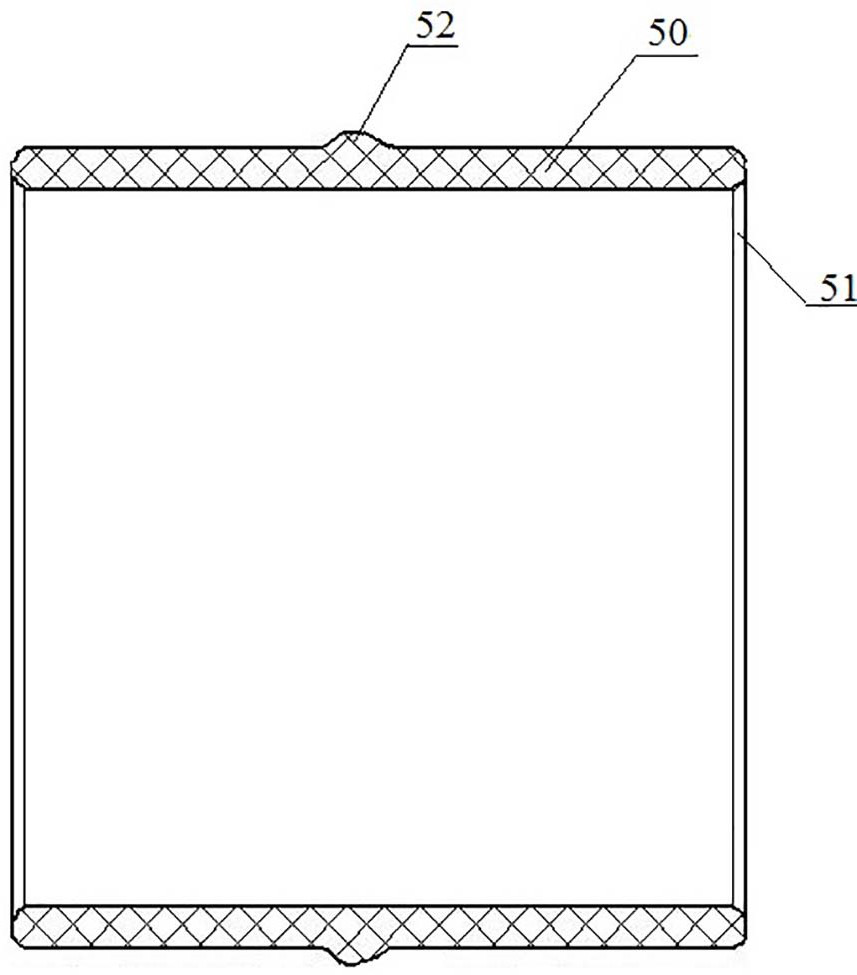

[0061] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, an annular protrusion 52 is provided on the outer peripheral surface of the main shield 50, and a metallized layer is provided on the surface of the annular protrusion 52, while in this embodiment , the outer peripheral surface of the main shielding case 50 is a flat surface, which is directly welded to the metal middle sealing ring 20 .

[0062] Embodiment of the main shielding cover of the vacuum interrupter in the present invention: the embodiment of the main shielding cover of the vacuum interrupter is the main shielding cover 50 recorded in any embodiment of the above-mentioned vacuum interrupter, which is no longer detailed here illustrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com