Current conduction nozzle

The technology of contact tip and body is applied in the field of contact tip, which can solve the problems of difficult processing of the inner hole of the contact tip and low matching accuracy of the inner hole of the contact tip, and achieve the effects of simple structure, easy processing and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

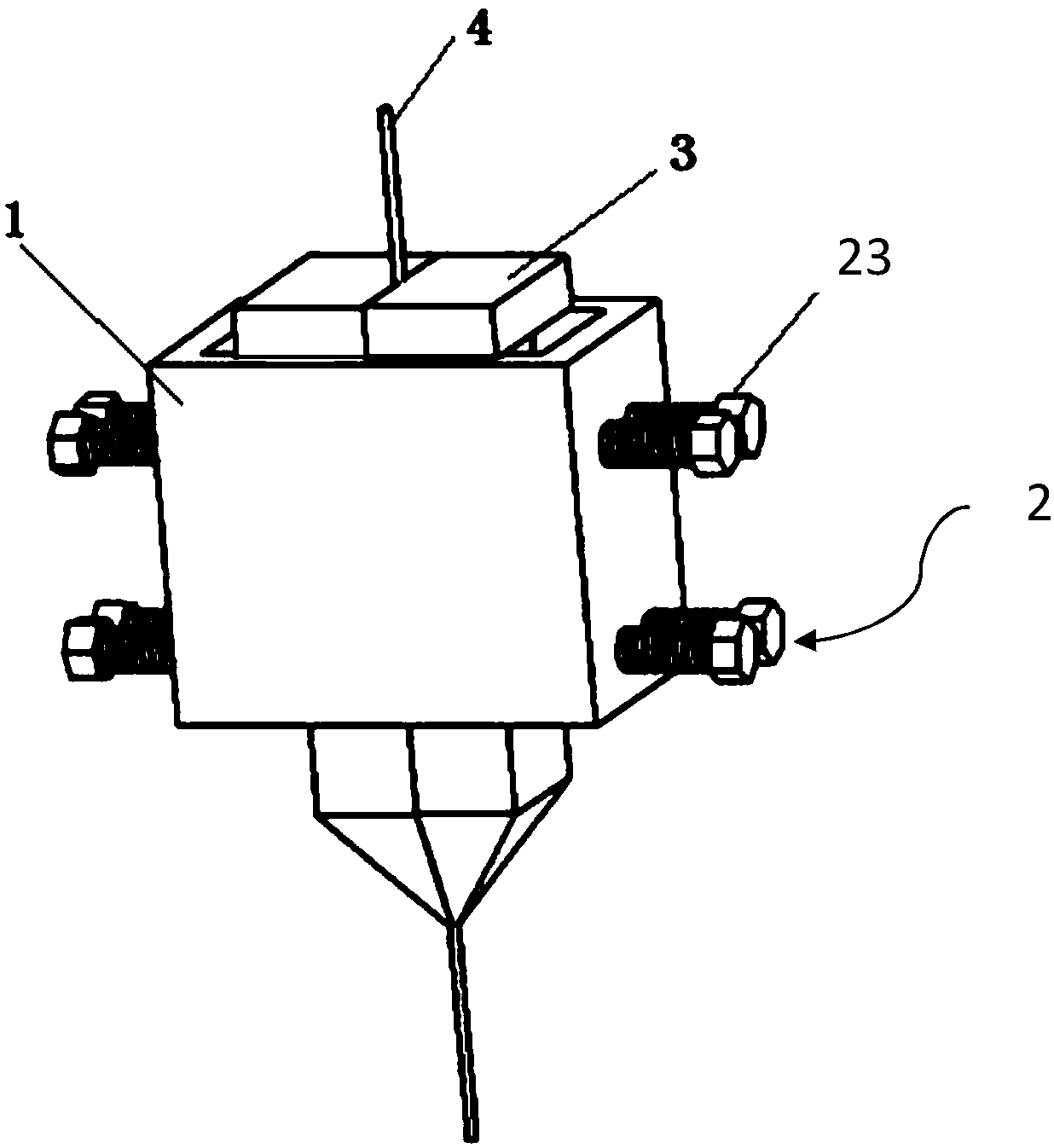

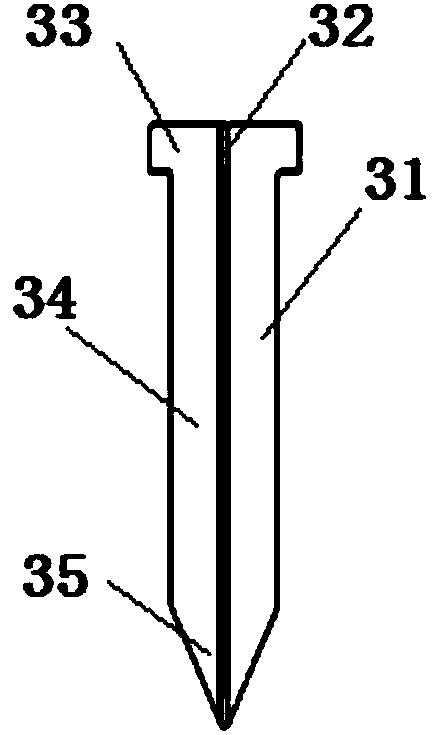

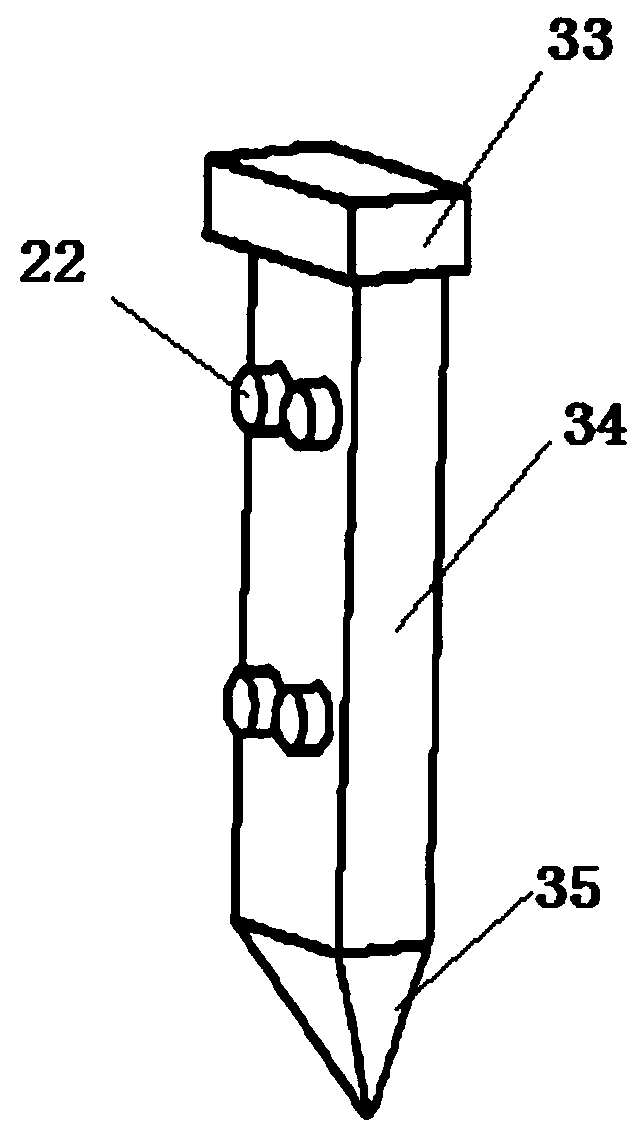

[0027] like Figure 1-5 As shown, the contact tip of the present invention includes a contact tip body 3, a housing 1 and a spring adjustment device 2; the housing 1 is provided with a contact tip body mounting hole 11, and the wall of the housing 1 is provided with two sets of threaded mounting holes 12, The two sets of threaded mounting holes 12 are located at two different heights in the axial direction of the housing 1 . Each set of threaded holes includes four threaded holes, and the four threaded holes are symmetrically arranged on two opposite side walls of the housing 1 . The spring adjusting device 2 includes a spring 21 corresponding to the threaded mounting hole 12, a boss 22 and a bolt; the contact tip body 3 is composed of two mating bodies 31, and the mating surfaces of the two mating bodies 31 are respectively provided with a half groove. Two half gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com