Aluminum plastic film scouring hole depth measuring device and measuring method thereof

A technology of depth measurement and aluminum-plastic film, which is applied in the direction of mechanical depth measurement, etc., can solve problems such as product abnormality, aluminum-plastic film tearing, battery collapse appearance, etc., to reduce time and strength, avoid axial deviation, avoid The effect of axis offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

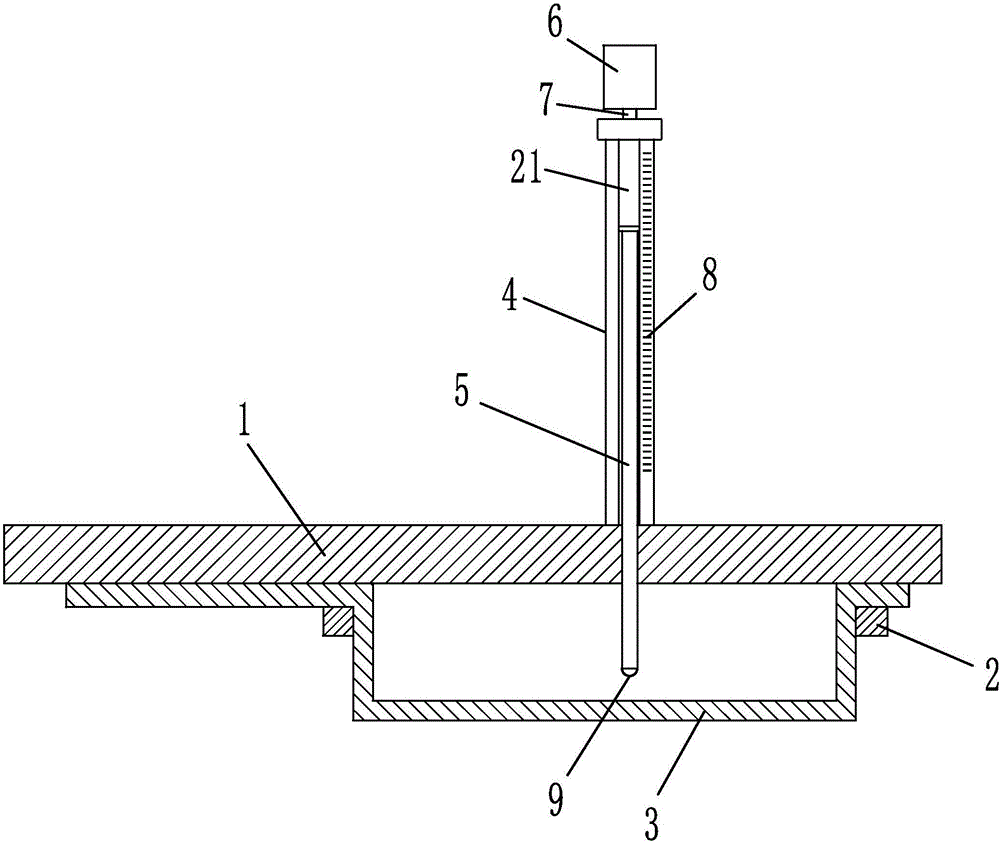

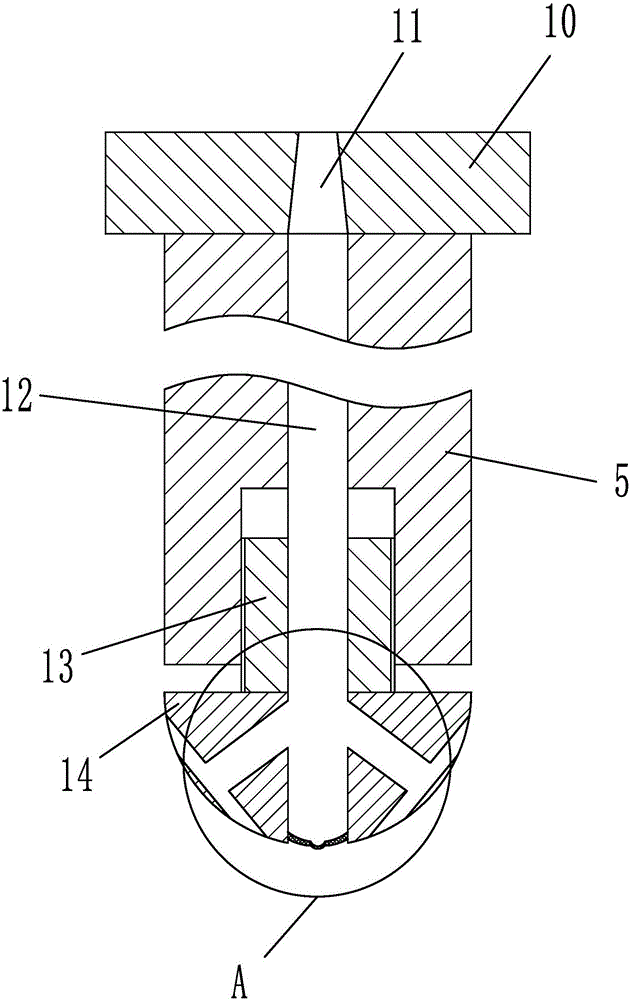

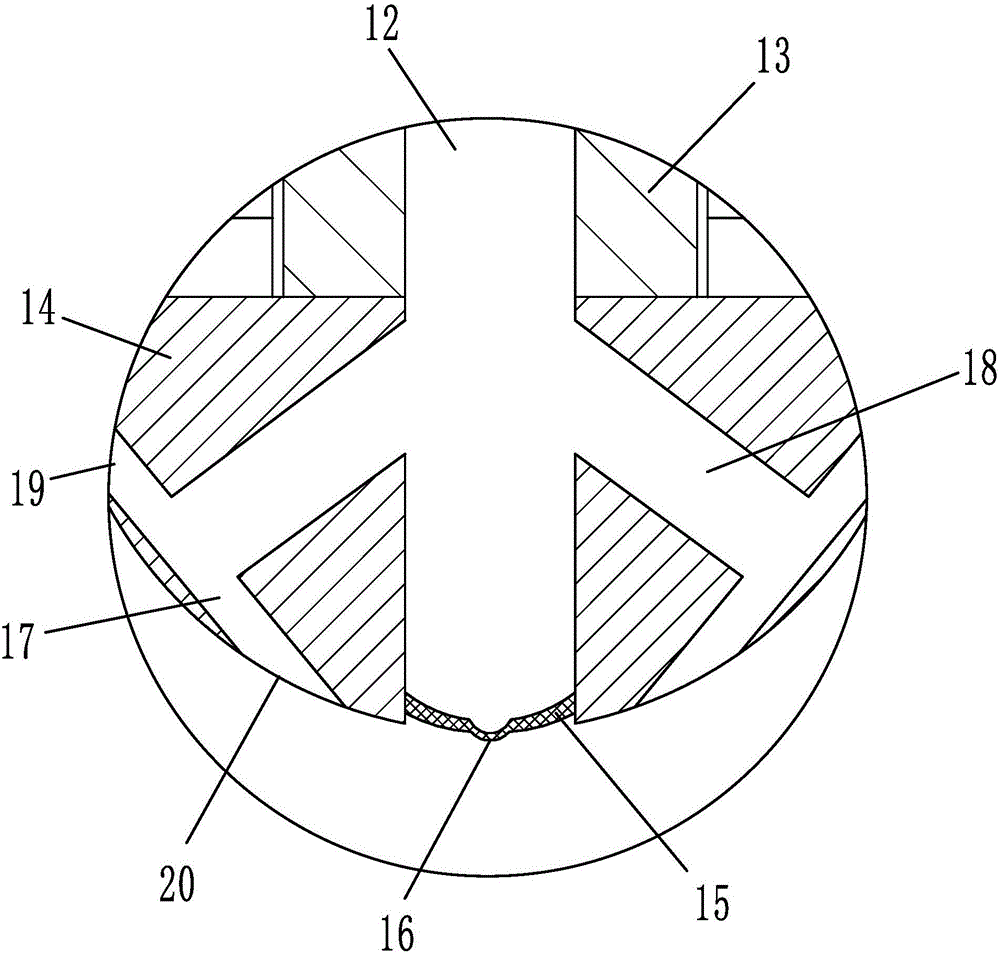

[0023] Embodiment 1: as figure 1 , 2 , shown in 3 and 4, a kind of aluminum-plastic film punching pit depth measuring equipment comprises thickness gauge platform 1 and thickness gauge, and the die hole corresponding to the punching pit of aluminum-plastic film 3 is arranged on the thickness gauge platform, measures The bottom surface of the thickness meter platform is slidingly connected with a positioning ruler 2 for fixing the aluminum-plastic film. The thickness measuring ruler includes a transparent main ruler 4 fixed on the edge of the die hole. The axis of the transparent main ruler is provided with an accommodation cavity 21, and a secondary ruler is slidingly connected in the accommodation cavity. Ruler 5, an air pump 6 is installed on the top of the transparent main ruler, and the air pump communicates with the accommodation chamber through the air pipe 7, and the bottom of the auxiliary ruler is provided with a collision head 9; the axis of the auxiliary ruler and t...

Embodiment 2

[0026] Embodiment 2: The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that, as Figure 5 As shown, several buffer bosses 22 are axially spaced on the inner wall of the connecting column. The thickness of the buffer bosses in the middle is greater than the thickness of the buffer bosses at the upper and lower ends, and the thickness gradually decreases from the middle to the upper and lower ends. A flexible guide sleeve 23 is arranged above the connection between the communication hole and the air passage. The side walls are fixedly connected, and the length of the side walls of the flexible guide sleeve is greater than or equal to the diameter of the communication hole. The inner wall of the connecting column is provided with several buffer bosses at intervals in the axial direction. When the gas inside the subscale enters the connecting column, the buffer bosses can change the diameter of the air passage, and the buffer bosses ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com