Mode of realizing high performance of electric connector with tail end wire welding

An electrical connector and wire bonding technology, which is applied in the direction of conductive connection, parts of connecting devices, and connection, etc., can solve the problems of unguaranteed, short circuit at the tail end of the electrical connector, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

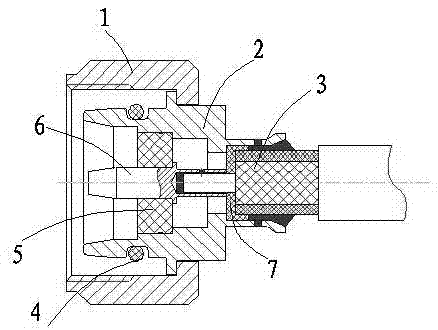

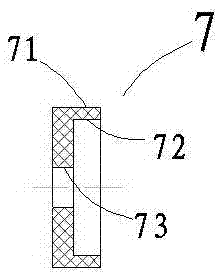

[0029] Such as figure 1 Shown is a structural schematic diagram of a high-performance method for realizing a tail-end welding electrical connector according to the present invention. The tail end of the electrical connector includes an outer conductor (2), a cable (3), a support body (7), and an inner conductor (6), the supporting body (7) plays the role of preventing axial deviation and fixing the solder flow range at the same time.

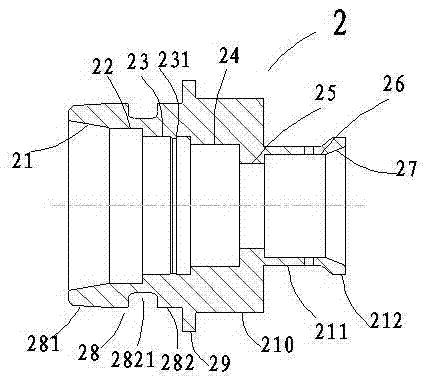

[0030] Such as figure 2 As shown, the outer conductor (2) is sequentially provided with the first inner cavity (21), the second inner cavity (22), the third inner cavity (23), the fourth inner cavity (24), and the fifth inner hole Cavity (25), the sixth inner hole cavity (26); the third inner hole cavity (23) is provided with a barb structure (231), and the third inner hole cavity (23) is used to assemble the dielectric body (5); the outer conductor ( 2) Set the first outer cylindrical surface (28), the second outer cylindrical surface (29), ...

Embodiment 2

[0039] Support body (7) also can not use, as Figure 9 In the figure above, the stripping structure of the cable design adopts this structure.

[0040] Such as Figure 8 As shown, an interference fit is set between the outer diameter of the fifth inner cavity (25) of the outer conductor and the outer diameter of the cable dielectric body (32), and the outer diameter of the sixth inner cavity (26) of the outer conductor and the outer diameter of the cable shielding layer (33) Clearance fit or interference fit.

[0041] Such as Figure 9 As shown, the cable (3) is first welded to the inner conductor (6) and then pressed Figure 8 Attached to the outer conductor for final tail soldering.

[0042] Both of the above two solutions are based on the same inventive concept, and both can achieve the same purpose, that is, to prevent the axial displacement, and at the same time fix the flow range of the solder to prevent the solder from short-circuiting the tail end of the electrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com