Elevator motor structure

A technology of motor structure and lifter, which is applied in the direction of manual mechanism, power control mechanism, wing leaf control mechanism, etc., which can solve the problems of easy misalignment, affecting the effect, and large axial force of the worm, so as to prevent axial deviation. Move, improve the service life, improve the effect of self-locking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

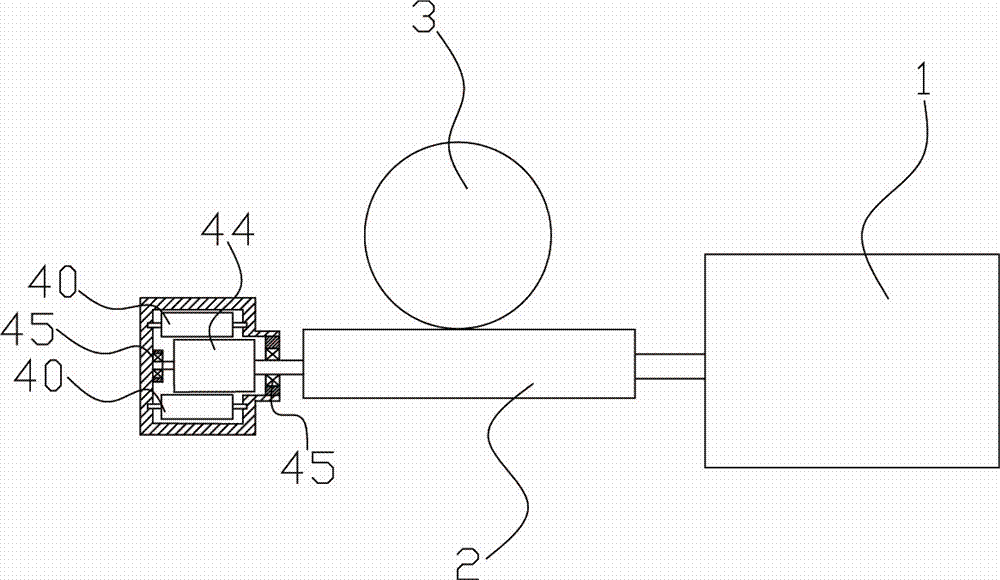

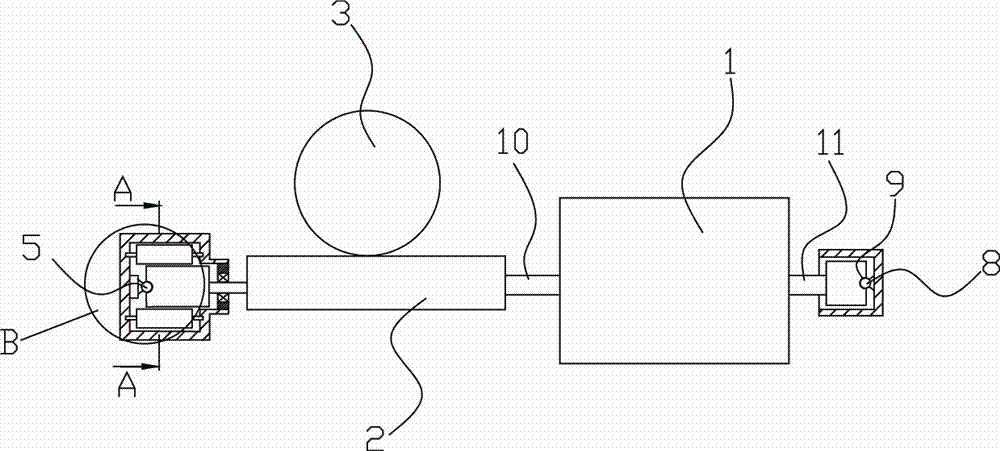

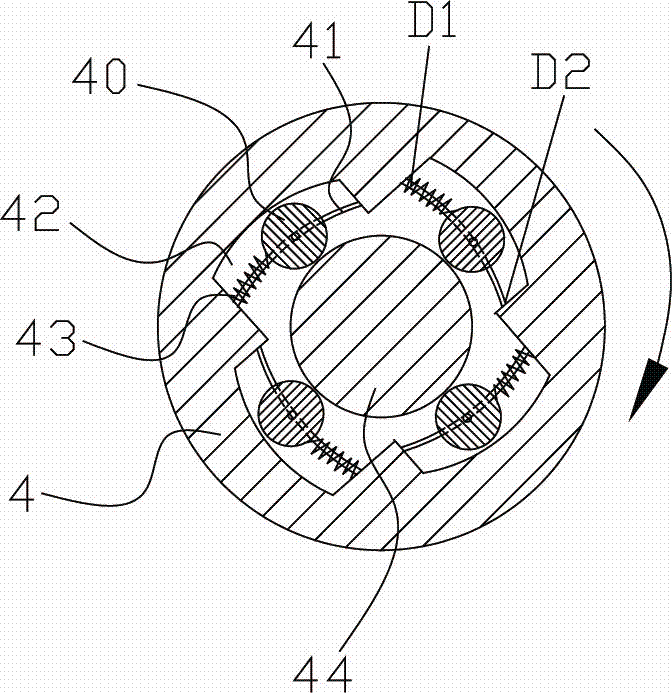

[0014] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1 to Figure 2 , the elevator motor structure, including a motor 1, the two ends of the motor 1 are respectively drawn with a first output shaft 10 and a second output shaft 11, the first output shaft 10 is connected with a worm 2, and also includes a 2 meshed turbine 3, a rotating roller 44 is provided at one end of the worm 2, and a sleeve 4 is also included, and the rotating roller 44 is located in the sleeve 4, and at least one set of The extruding element 40, the extruding element 40 abuts against the rotating roller 44, a groove 42 for accommodating the extruding element 40 is arranged on the sleeve 4, and a sliding rail 41 is arranged in the groove 42, The extruding element 40 is slidably arranged on the slide rail 41 , and the elastic member 43 is arranged on the slide rail 41 against the extruding element 40 , and the slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com