Conveying device and control assembly thereof

A technology for controlling components and moving parts, which is applied in the field of medical devices and can solve problems such as affecting blood flow, reducing the blocking effect of covered stents, and insufficient anchoring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

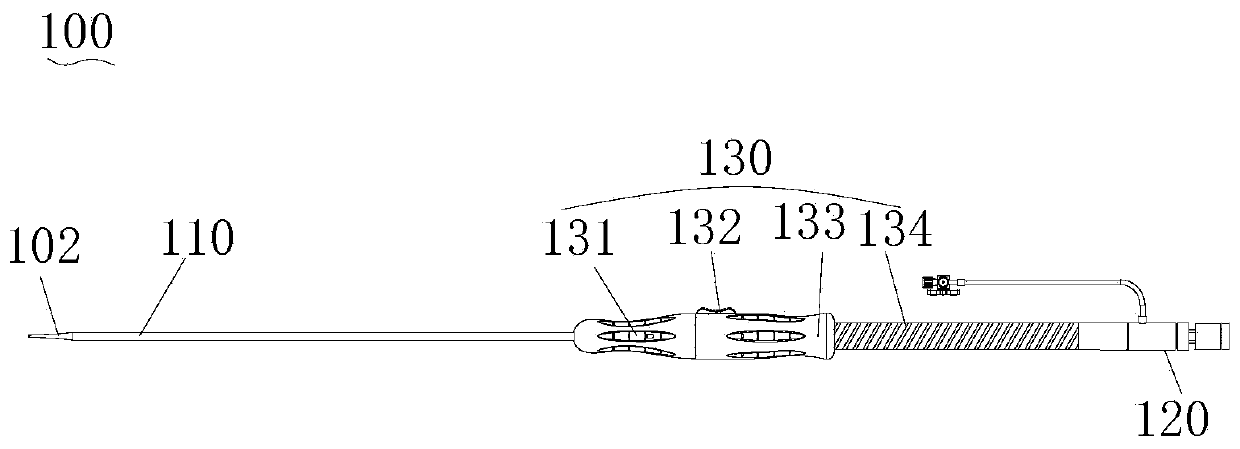

[0044] See figure 1 As shown, the delivery device 100 provided by the present invention includes a delivery sheath 110, an adjustment mechanism 120 and a handle assembly 130.

[0045] The delivery sheath 110 is a hollow tube, and the lumen of the delivery sheath 110 can be loaded with an implant, such as the stent graft 101 (see Figure 4 Shown).

[0046] The distal end of the adjustment mechanism 120 is detachably connected to the stent graft 101 to selectively anchor the stent graft 101 or release the anchor of the stent graft 101.

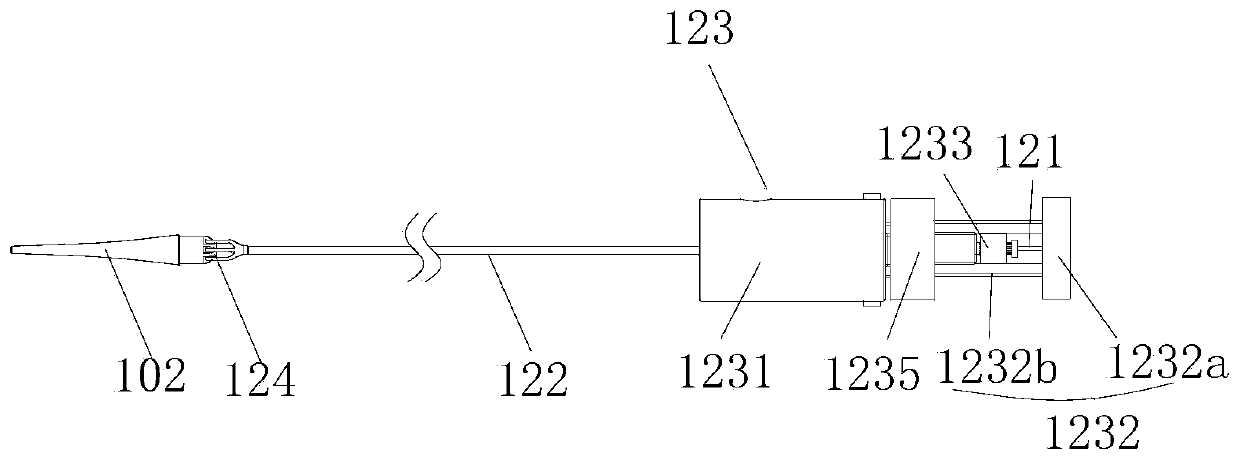

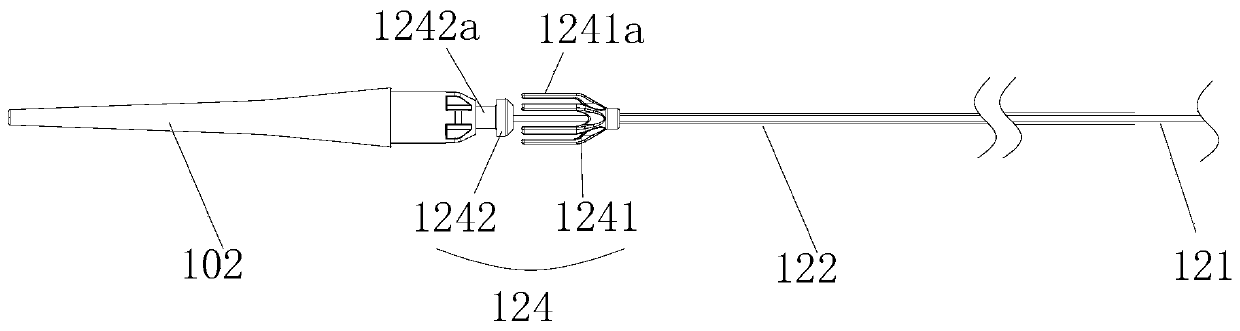

[0047] Combine figure 2 with image 3 As shown, the adjustment mechanism 120 of an embodiment of the present invention includes an inner sheath core tube 121, an outer sheath core tube 122, a control assembly 123, and an anchor assembly 124.

[0048] The outer sheath core tube 122 is sleeved outside the inner sheath core tube 121 and can move axially relative to the inner sheath core tube 121. The control assembly 123 is arranged at the proximal end of...

Embodiment 2

[0110] Combine Figure 15 to Figure 16 As shown, the delivery device 200 of Embodiment 2 also includes a delivery sheath 210, an adjustment mechanism 220, and a handle assembly 230. The structure of the delivery sheath 210 and the handle assembly 230 is similar to that of the first embodiment. The handle assembly 230 includes a front handle 231, a trigger 232, a sliding handle 233 and a screw 234. The mechanism of the handle assembly 230 can be seen in the first embodiment. The handle assembly 130 is not described in detail here.

[0111] The difference between Embodiment 2 and Embodiment 1 is that the structure of the control assembly 223 of the adjustment mechanism 220 is different. Specifically, the first moving part 2232 and the second moving part 2233 of the control assembly 223 have different structural forms relative to the handle body 2231.

[0112] Specifically, combine Figure 17 with Figure 18 As shown, the proximal end of the handle body 2231 is fixedly connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com