Washing machine inner barrel

A washing machine and inner tub technology, applied in the field of washing machines, can solve problems such as affecting the washing effect of clothes and cross-infection of laundry, and achieve the effects of eliminating the possibility of water leakage, avoiding cross-infection, and saving washing water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The bucket body and the bottom of the inner bucket described in this embodiment have an integral injection molding structure (not shown in the figure).

Embodiment 2

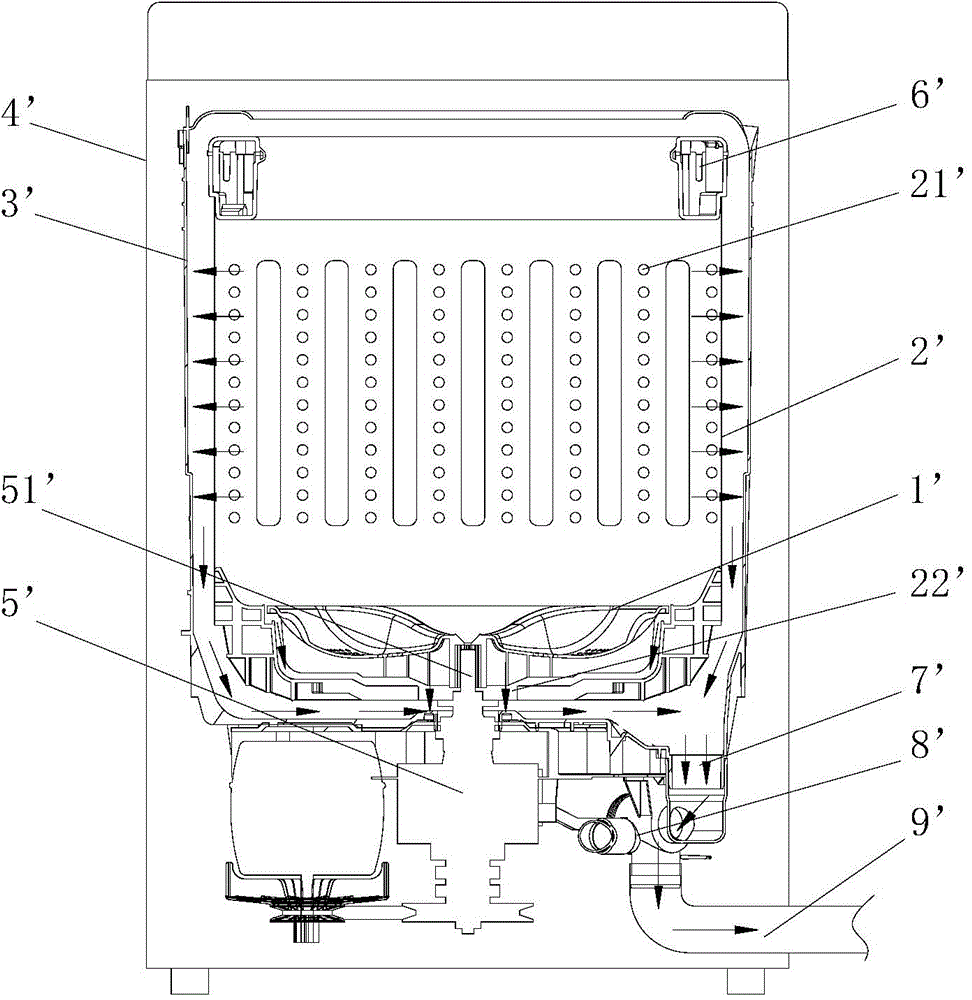

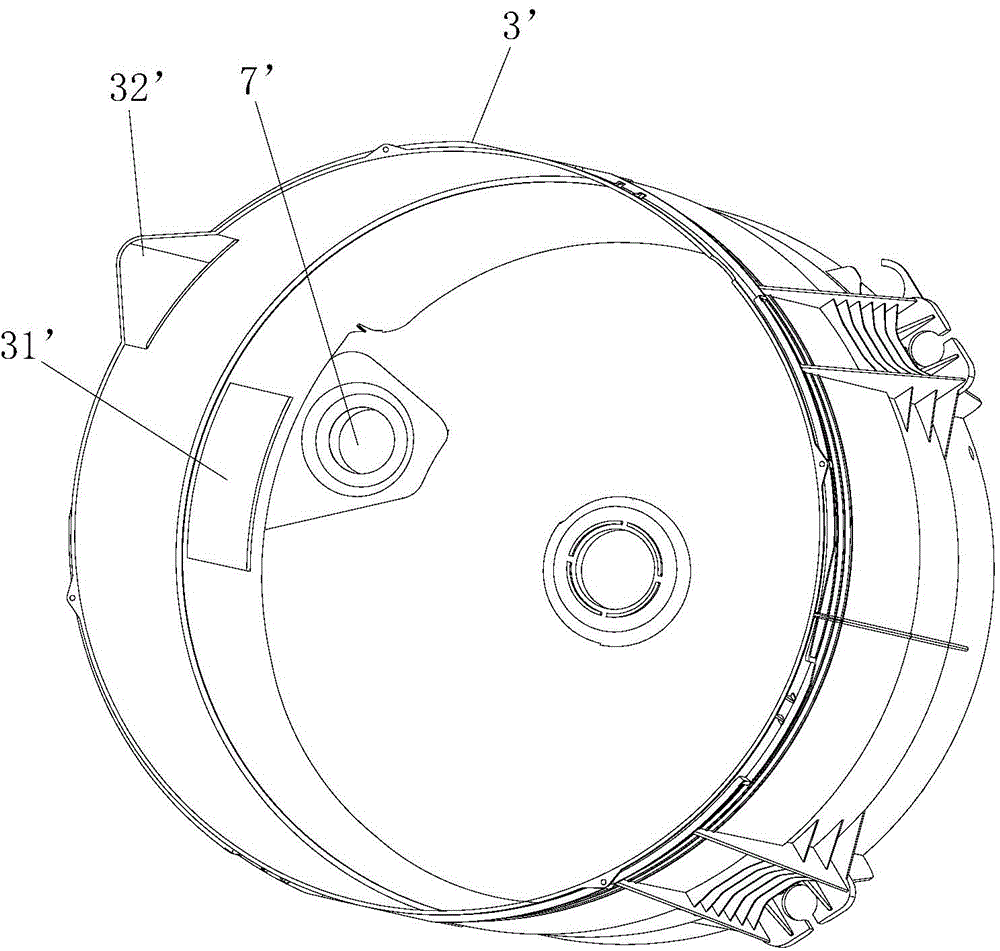

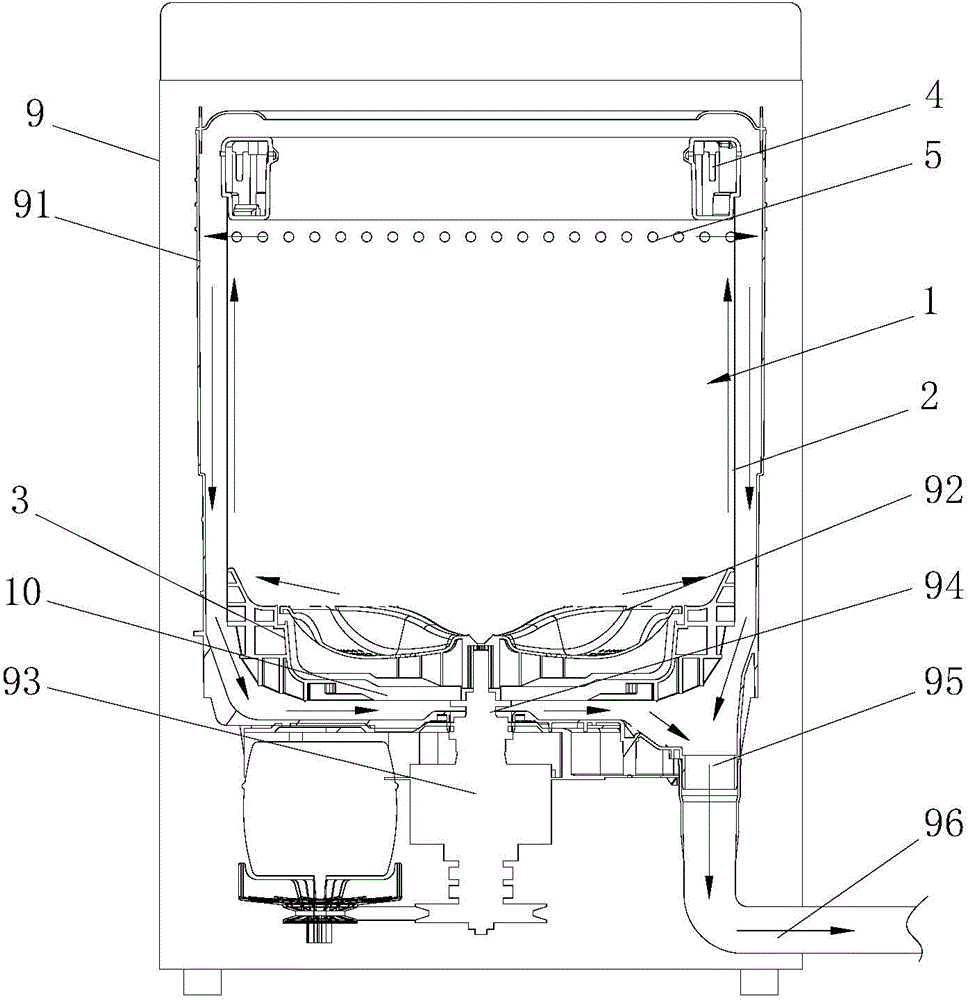

[0046] Such as Figure 5 and Figure 6 As shown, the bucket body 2 described in this embodiment is provided with a circle of pressure profile 21 along the circumference, and the pressure profile 21 cooperates with the upper end surface of the inner barrel bottom peripheral wall 31 to form a blocking support structure, and a sealing ring 6 is arranged between the two to form Face seal.

[0047] Further, the barrel body profile 21 is stamped from outside to inside, forming a circle of protruding barrier ribs 22 on the inner wall of the barrel body 2, and a flange 32 is provided radially outward on the inner barrel bottom peripheral wall 31, The flange 32 is supported under the barrier rib 22 formed by profiling, and the sealing ring 6 is sandwiched between them.

[0048] Preferably, the contact surface formed between the barrier rib 22 and the flange 32 forms a horizontal plane structure or a downwardly inclined plane structure outward from the center, and this structure facil...

Embodiment 3

[0050] Such as Figure 6 and Figure 7 As shown, the present embodiment is a further improvement on the basis of the second embodiment: the upper surface of the flange 32 is provided with an annular groove 33, and the sealing ring 6 is positioned through the annular groove 33, and the lower surface of the barrier rib 22 and the protrusion The upper surface of the edge 32 presses the sealing ring 6 to form an end face seal. This structure further prevents the sealing ring from falling off and has a longer service life.

[0051] Preferably, the sealing ring 6 is an annular flat body structure, the lower surface is provided with an annular rib 61, and the annular rib 61 is correspondingly installed in the annular groove 33 provided on the upper surface of the flange 32 (see Figure 7 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com