Glass ceramic and preparation method thereof

A vitreous porcelain and calcite technology, applied in the field of vitreous porcelain and its preparation, can solve the problems of inability to count and large market, and achieve the effects of not sticking dirt, expanding production, and easy production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of vitreous porcelain, this vitreous porcelain is made of quartz sand 85kg, lithium feldspar 20kg, feldspar 44kg, sodium carbonate 33kg, barium carbonate 5kg, sodium nitrate 5kg, fluorite powder 10kg, borax 8.2kg, sodium fluorosilicate 18kg, 14kg of calcite and 0.6kg of clarifying agent are raw materials, and the standards of each raw material are as follows:

[0025] name

Composition %

Graininess

Appearance Quality

color

Special inspection items

stone

Britain

the sand

SiO 2 =98.9

(+0.5, -0.3)

Al 2 o 3 =0.8

(+0.3, -0.35)

Fe 2 o 3 ≤0.05

+20mesh≤

0.1

+100 mesh ≥

80

-150 mesh≤7

No ultra-fine knots

Solid debris

(mud and

stone, etc.)

White

or micro

yellow

≤8

SiO 2 , Al 2 o 3 ,

K 2 O, CaO,

MgO every six months

at least occasionally

1 t...

Embodiment 2

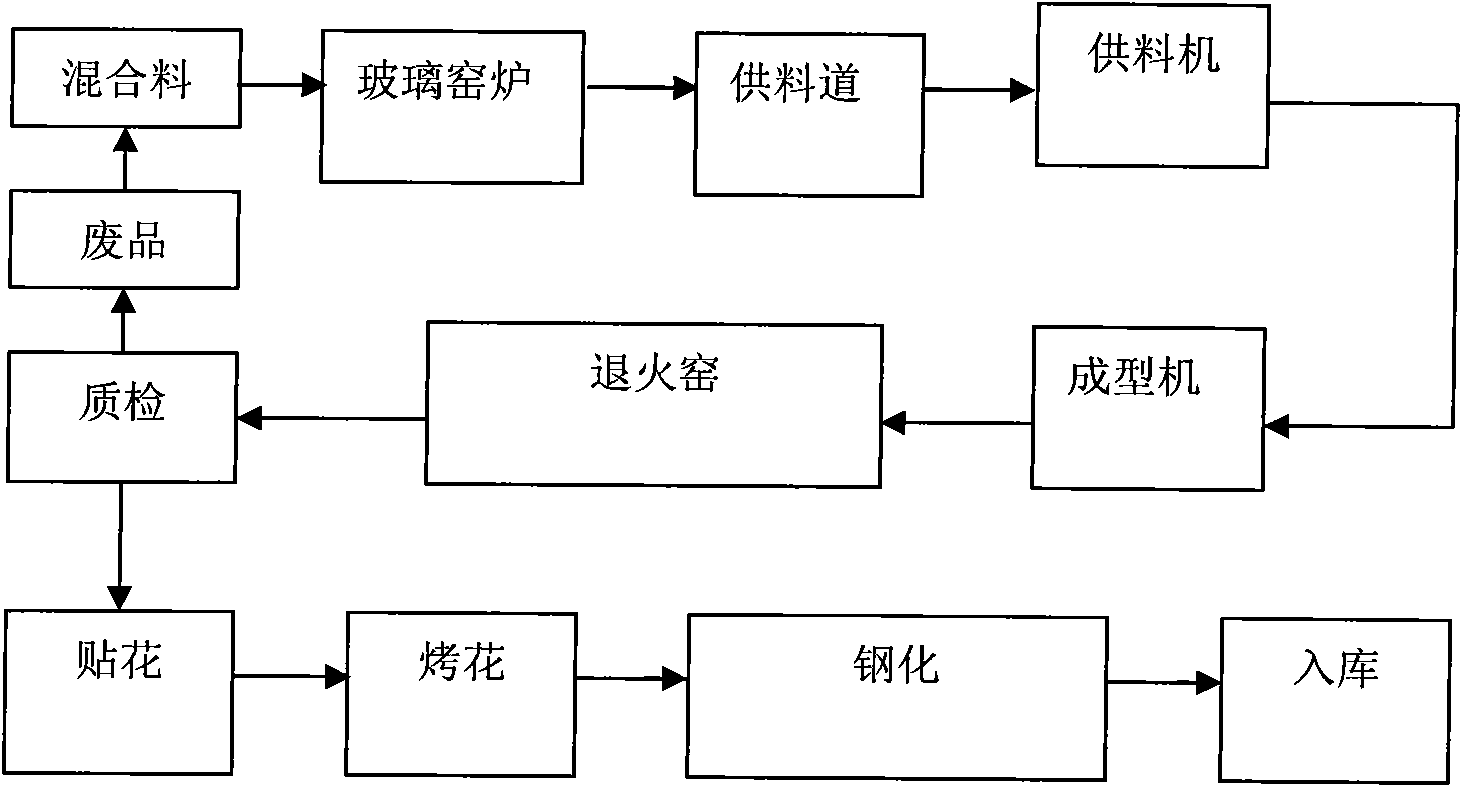

[0097]A kind of vitreous porcelain, the vitreous porcelain is made of 75 parts by weight of quartz sand, 10 parts by weight of lithium feldspar, 30 parts by weight of feldspar, 25 parts by weight of sodium carbonate, 2 parts by weight of sodium nitrate, 2 parts by weight of barium carbonate, fluorite powder 5 parts by weight, 5 parts by weight of borax, 10 parts by weight of sodium fluorosilicate and 10 parts by weight of calcite are used as raw materials. After mixing the raw materials, they are sent into a glass furnace and melted into molten glass at 1400 ° C. The molten glass is passed through the feed The feeding channel is divided into six parts: mixing zone, rear zone A, rear zone B, middle zone, adjustment zone and material pan zone. There is a heater in the feeding channel and a The cooler can adjust the temperature of the feeder channel according to the temperature of the product and the feeder channel. The feeder includes an equalizing part, a punching part, a sheari...

Embodiment 3

[0099] A kind of vitreous porcelain, the vitreous porcelain is made of 100 parts by weight of quartz sand, 30 parts by weight of lithium feldspar, 60 parts by weight of feldspar, 45 parts by weight of sodium carbonate, 8 parts by weight of sodium nitrate, 6 parts by weight of barium carbonate, fluorite powder 15 parts by weight, 10 parts by weight of borax, 30 parts by weight of sodium fluorosilicate and 20 parts by weight of calcite are used as raw materials. After mixing the raw materials, they are sent into a glass furnace, and melted into molten glass at 1600 ° C. The molten glass is passed through the feed The feeding channel is divided into six parts: mixing zone, rear zone A, rear zone B, middle zone, adjustment zone and material pan zone. There is a heater in the feeding channel and a The cooler can adjust the temperature of the feeder channel according to the temperature of the product and the feeder channel. The feeder includes an equalizing part, a punching part, a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com