Patents

Literature

75results about How to "Hardness and" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

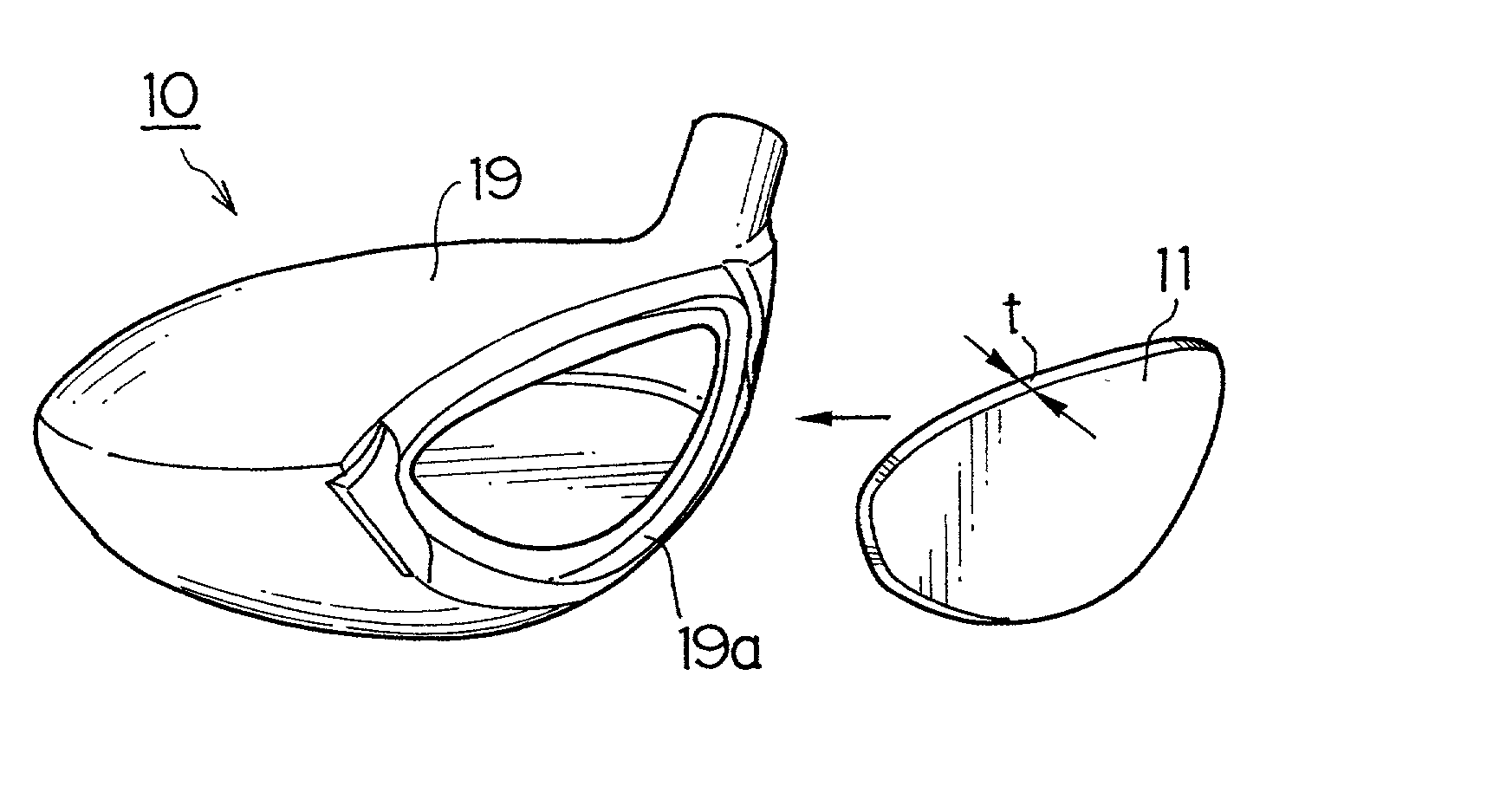

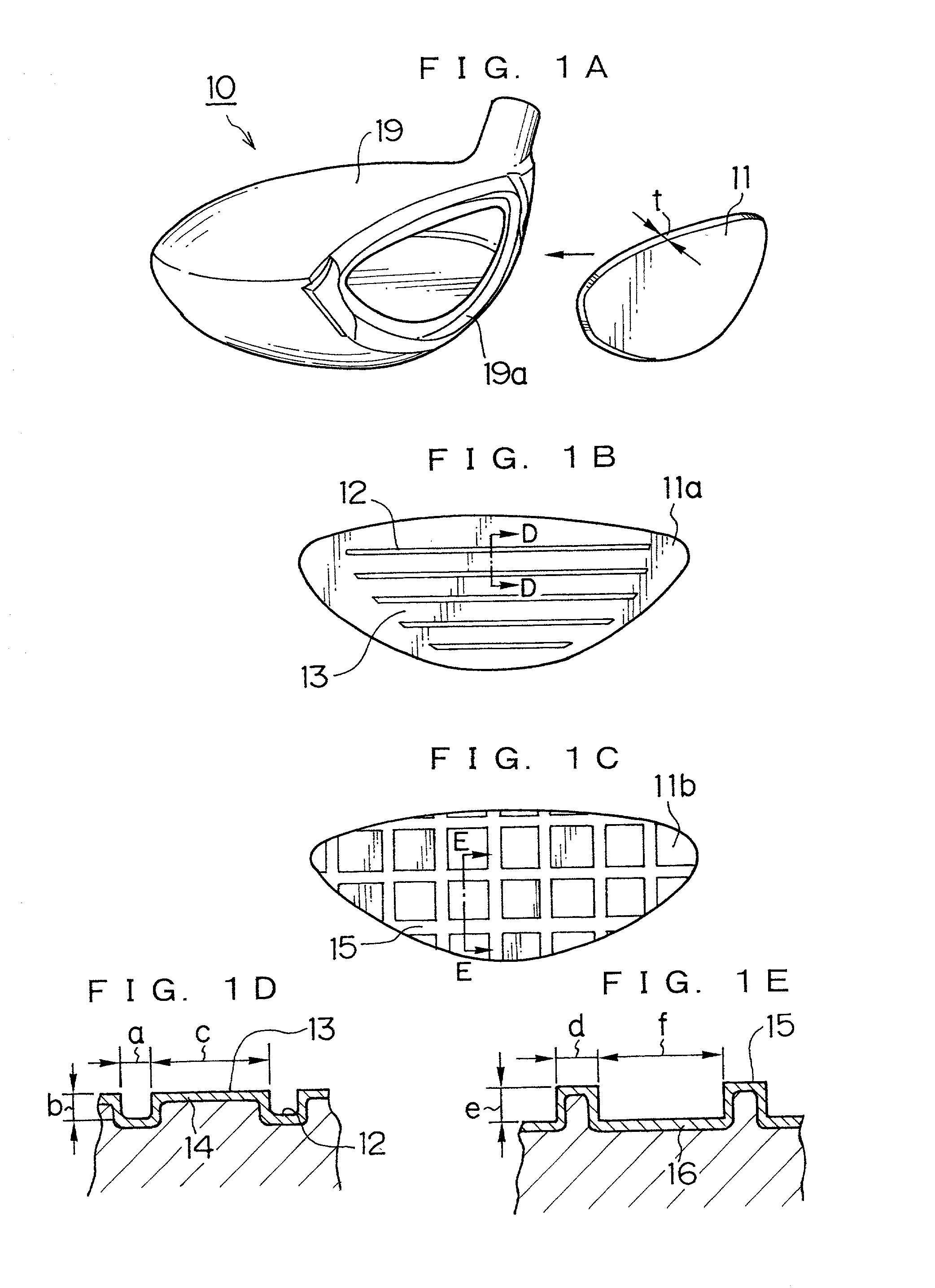

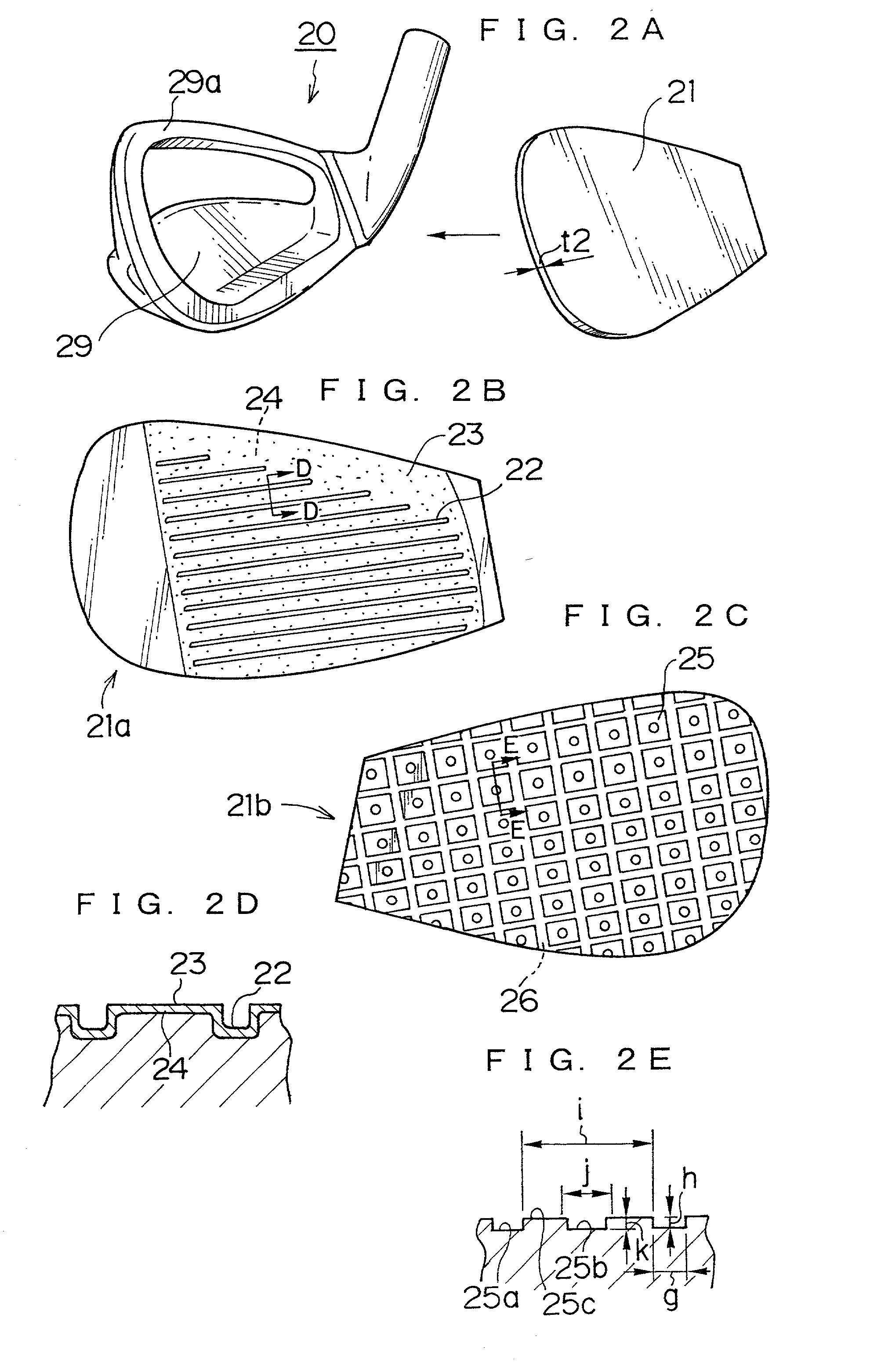

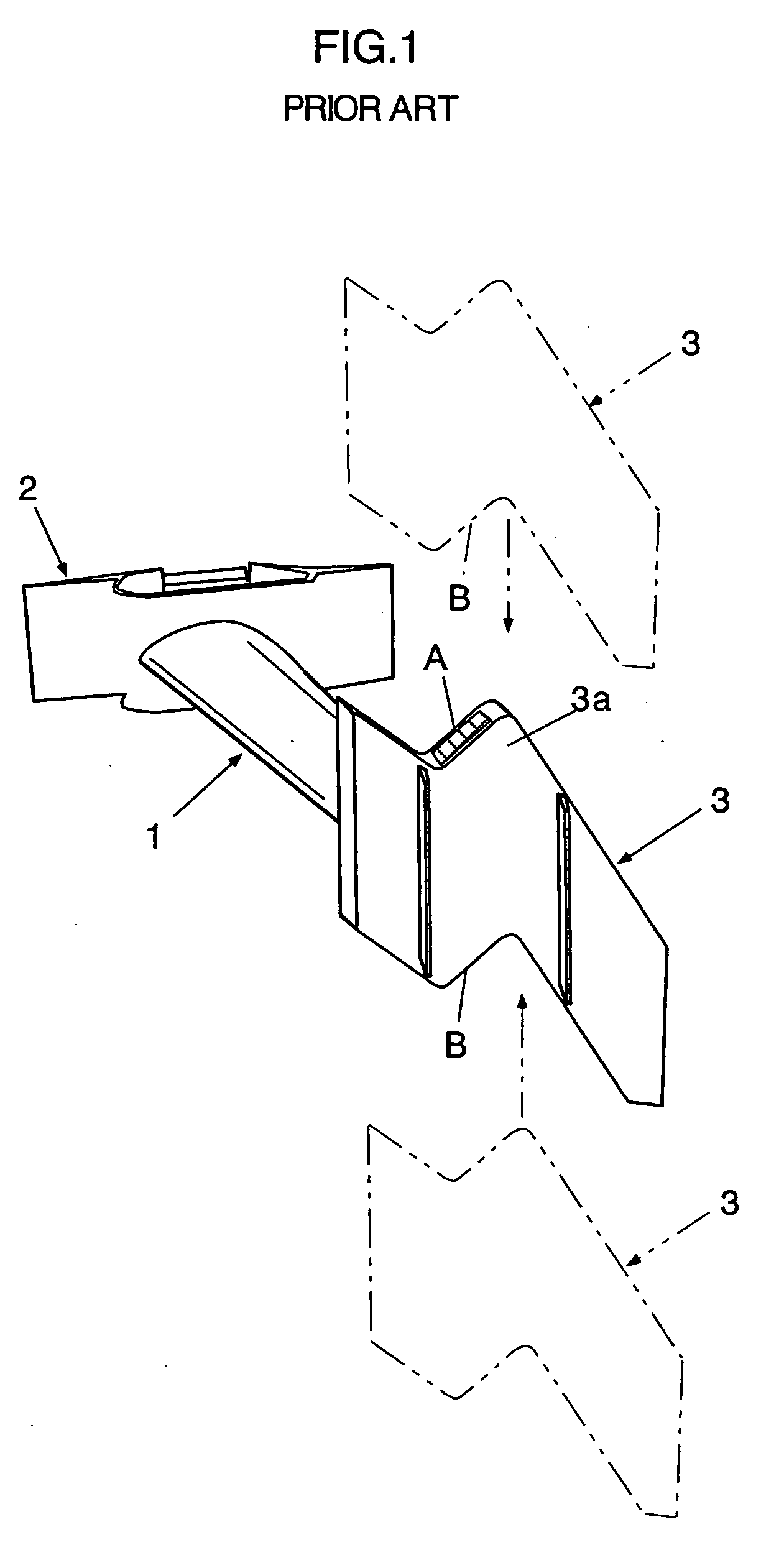

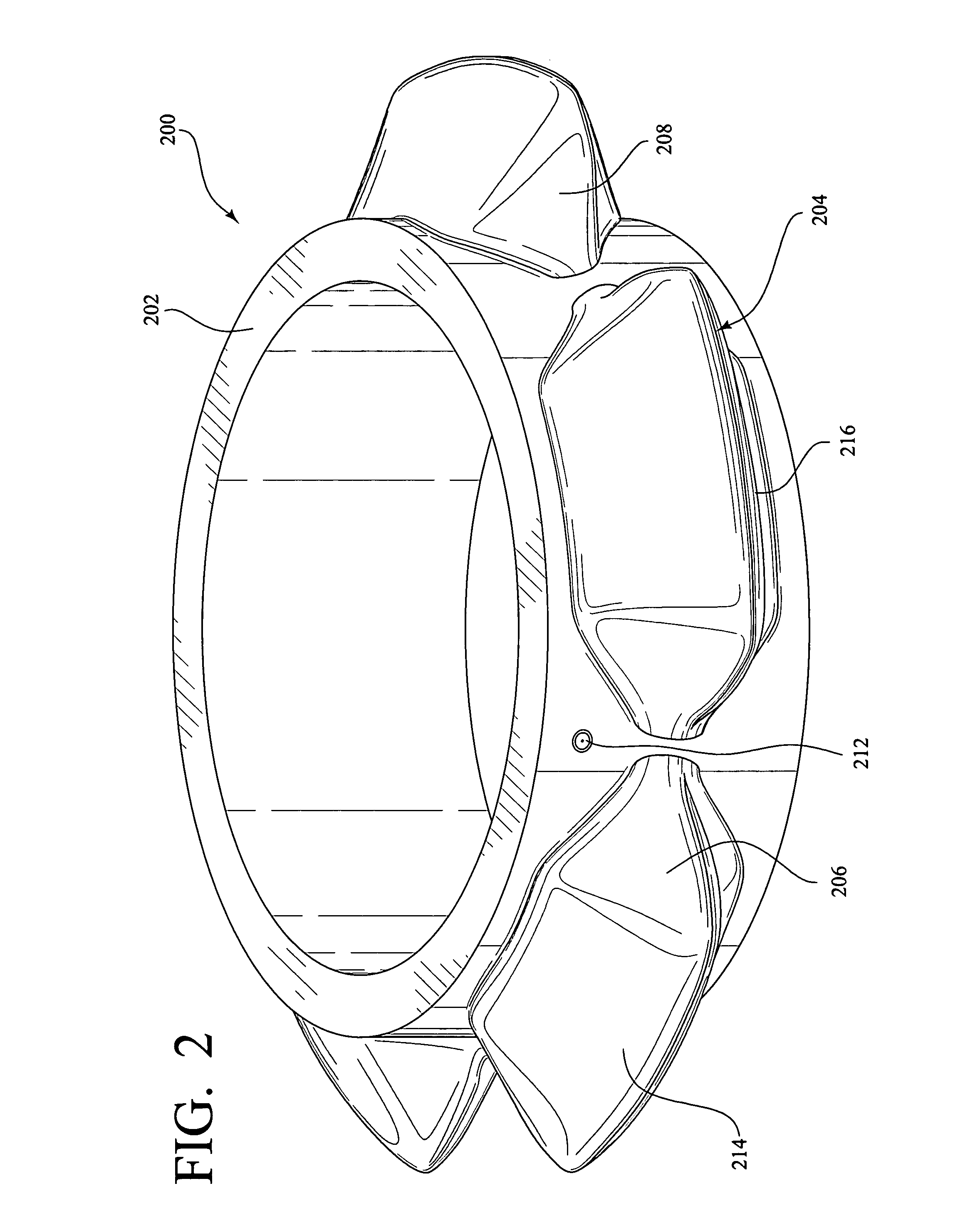

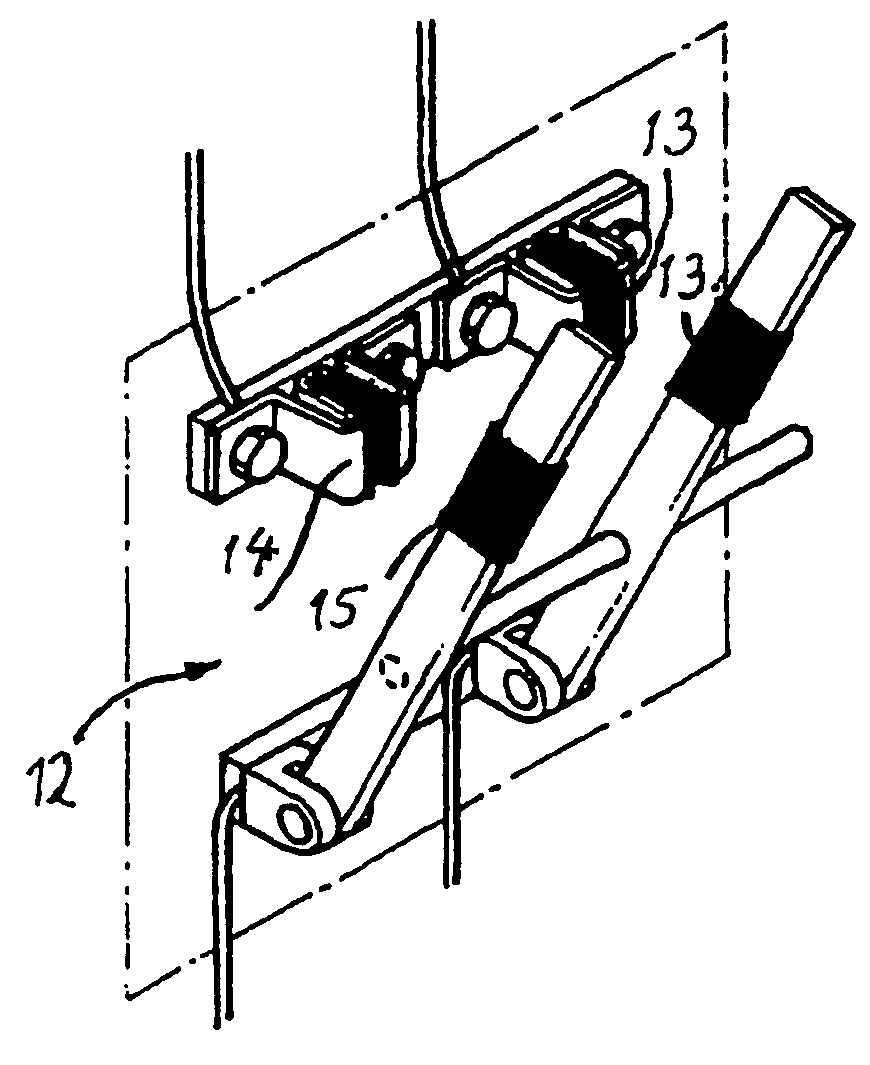

Golf club head and method of manufacturing the same

A face portion 11 of a golf club head 10 is obtained press-forming a metal plate into a predetermined shape. On the front surface 11a of the face portion 11, score lines 12 are formed by means of die sinking of electrical discharge machining, and a mirror finished surface portion 13 is formed by means of finish processing of electrical discharge machining. On the rear surface 11b of the face portion 11, a rib structure 15, and a high hardness layer 16 of an amorphous metal layer are formed. The electrical discharge machining is numerically controlled.

Owner:G P S CO LTD

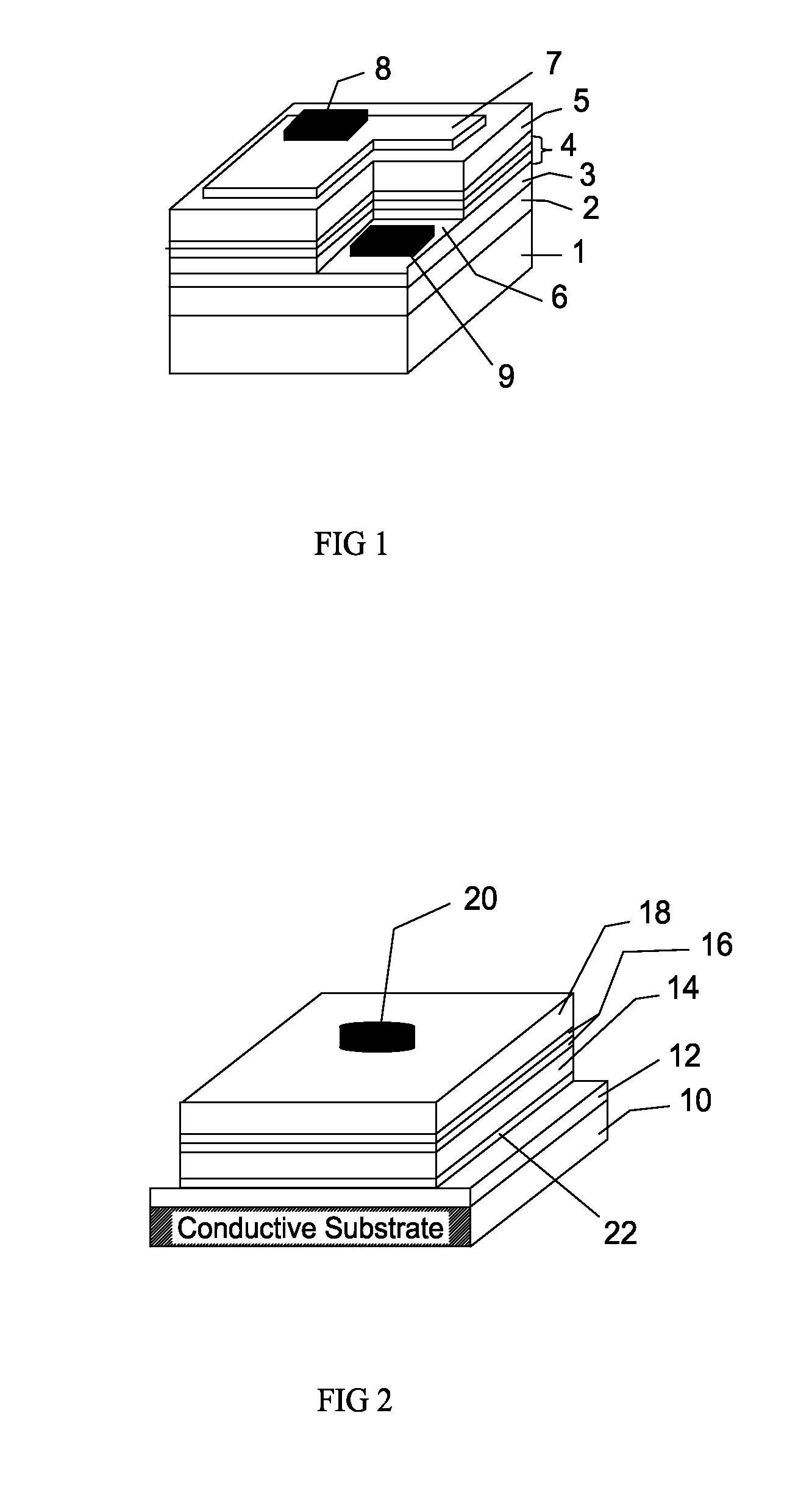

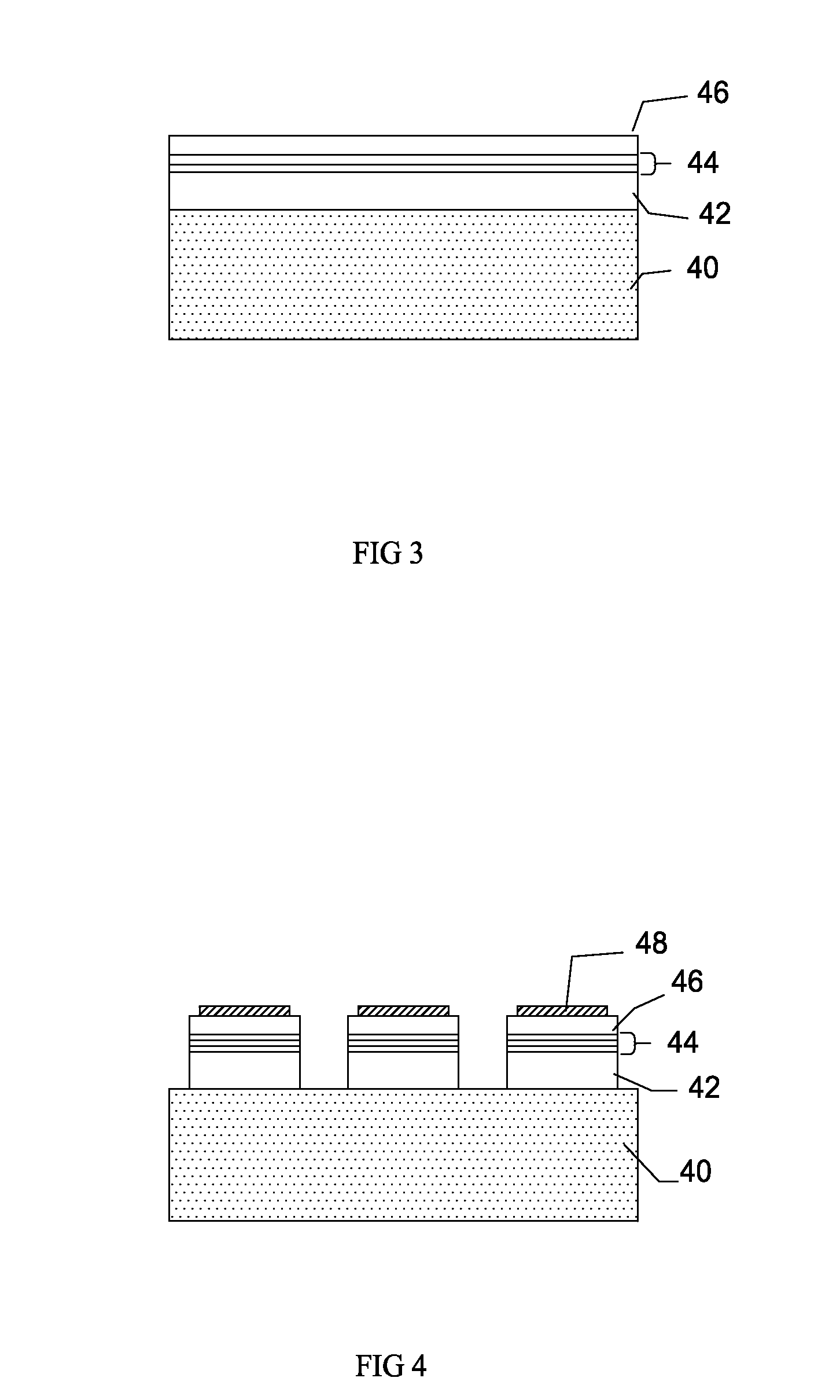

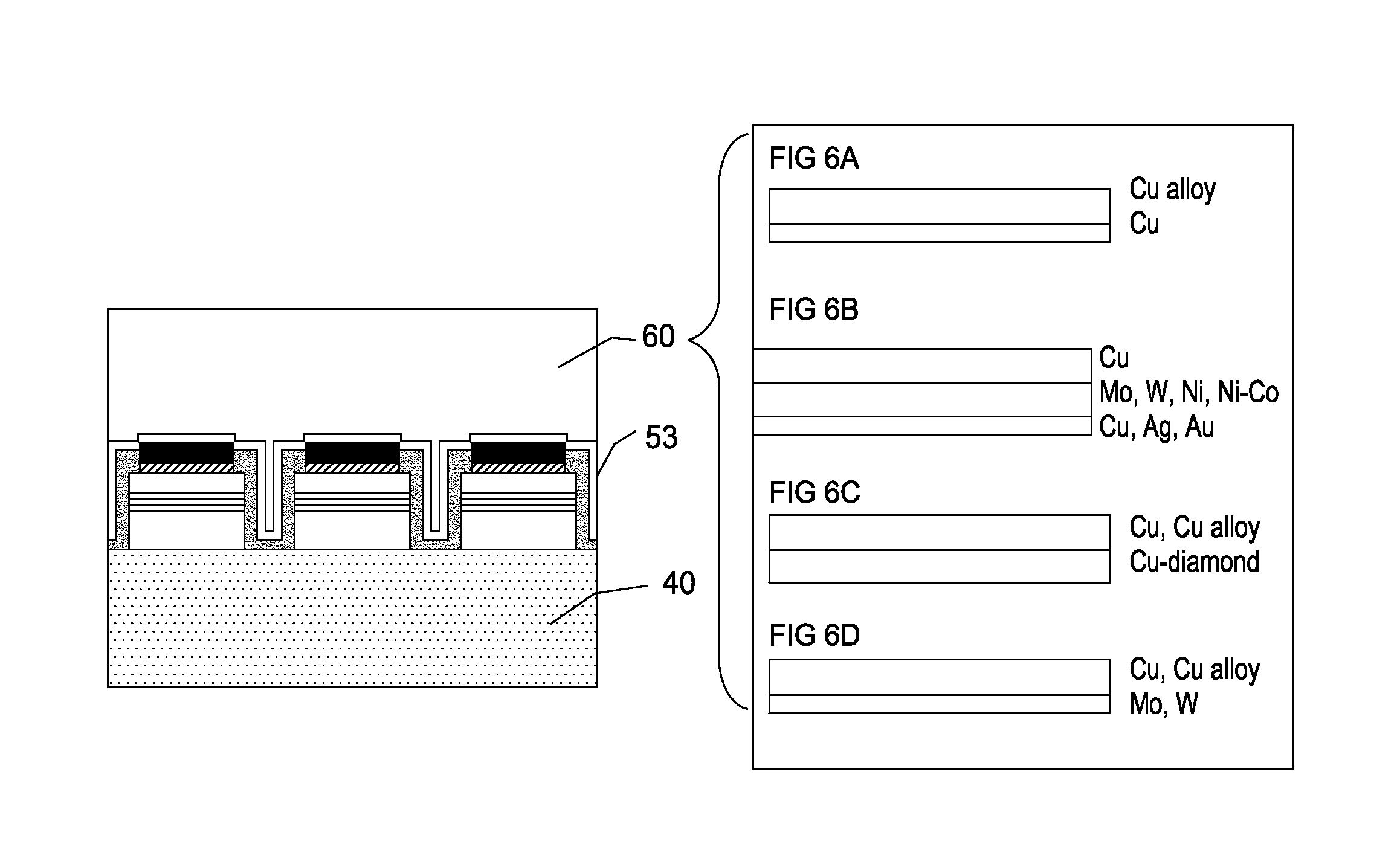

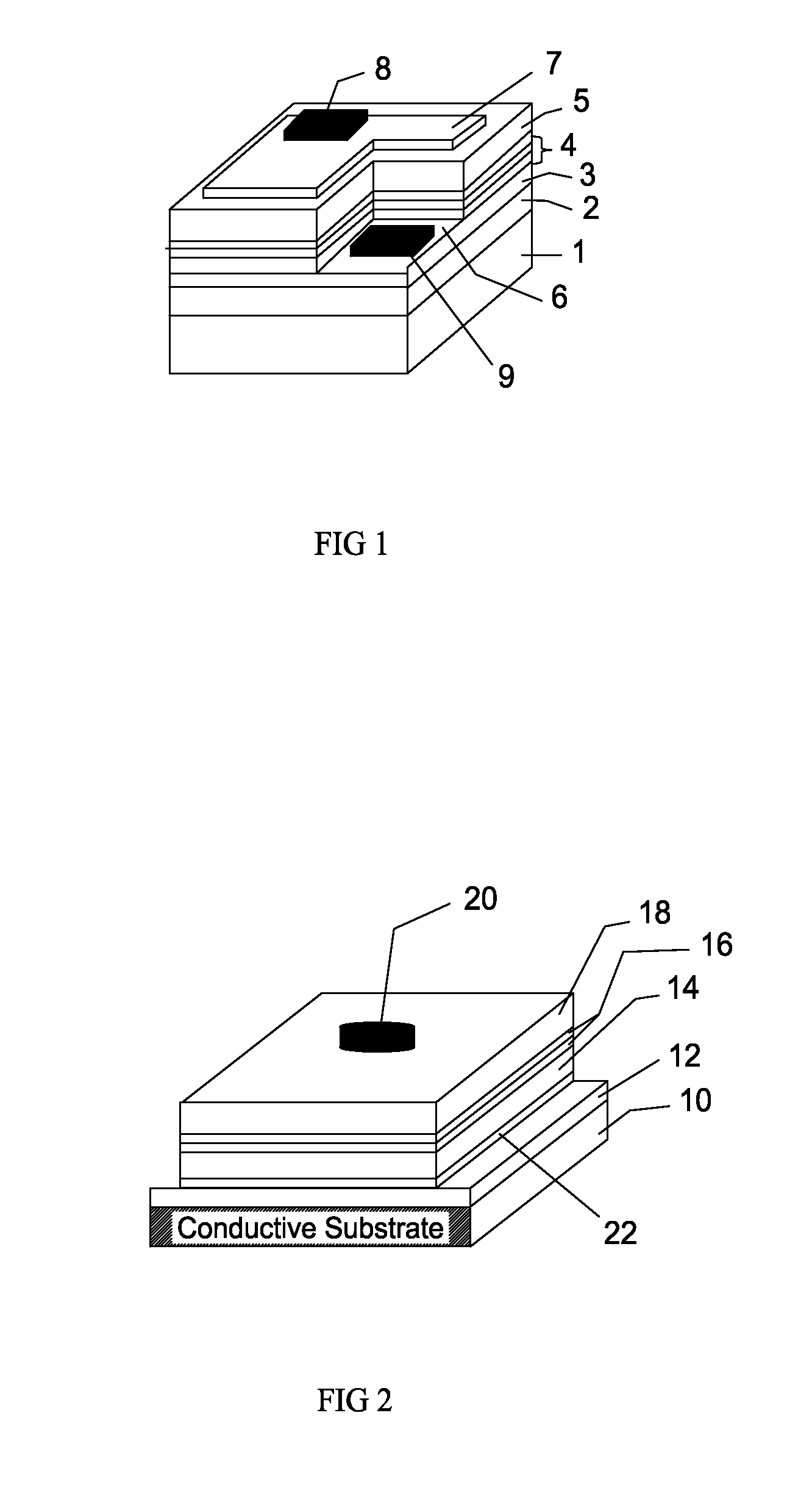

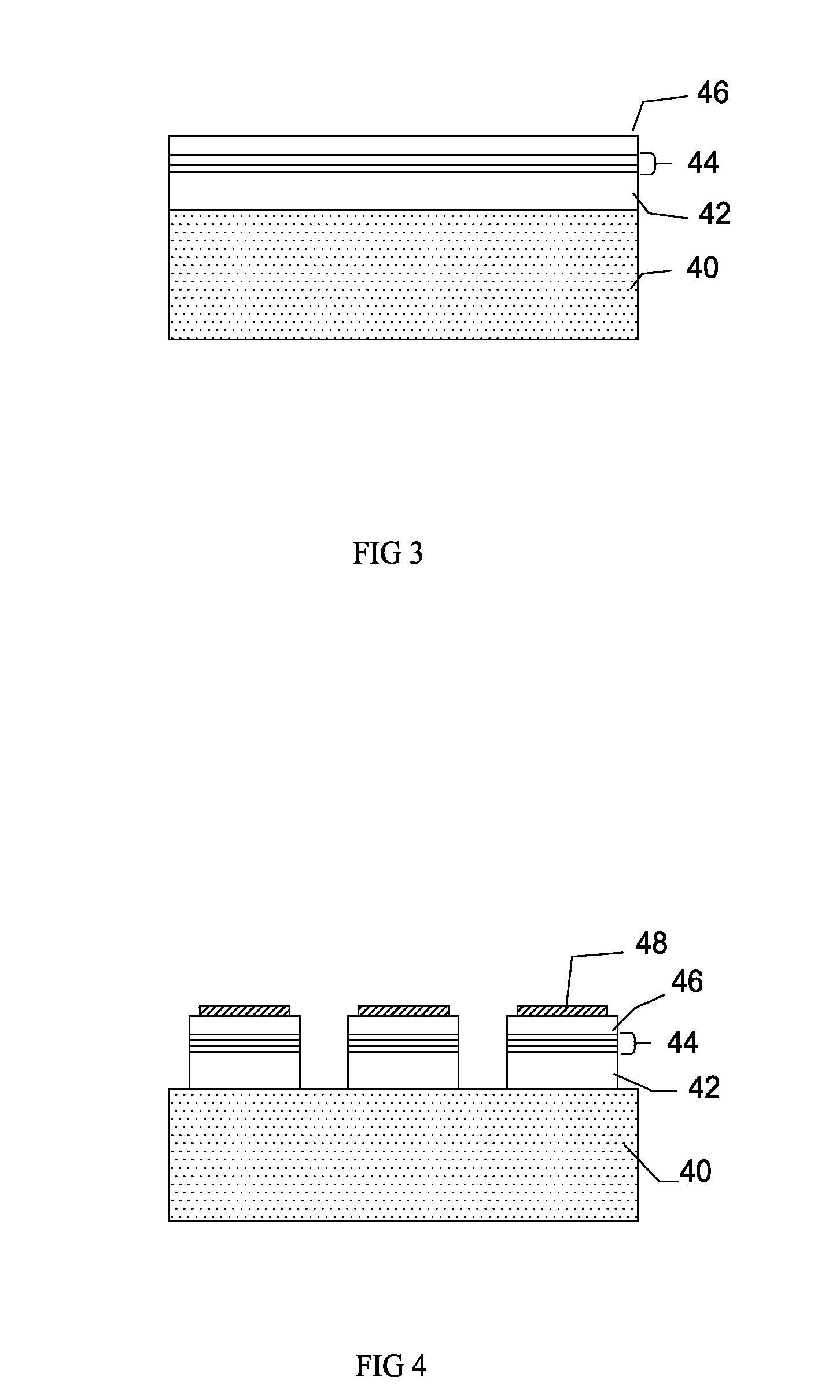

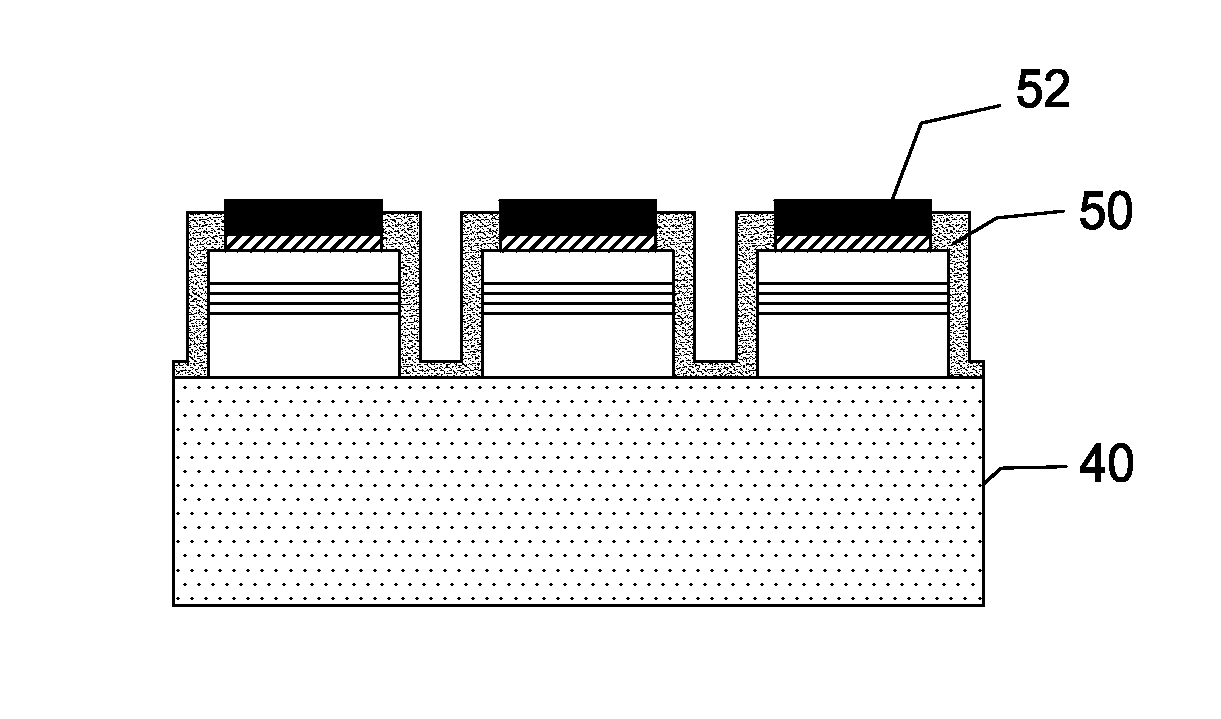

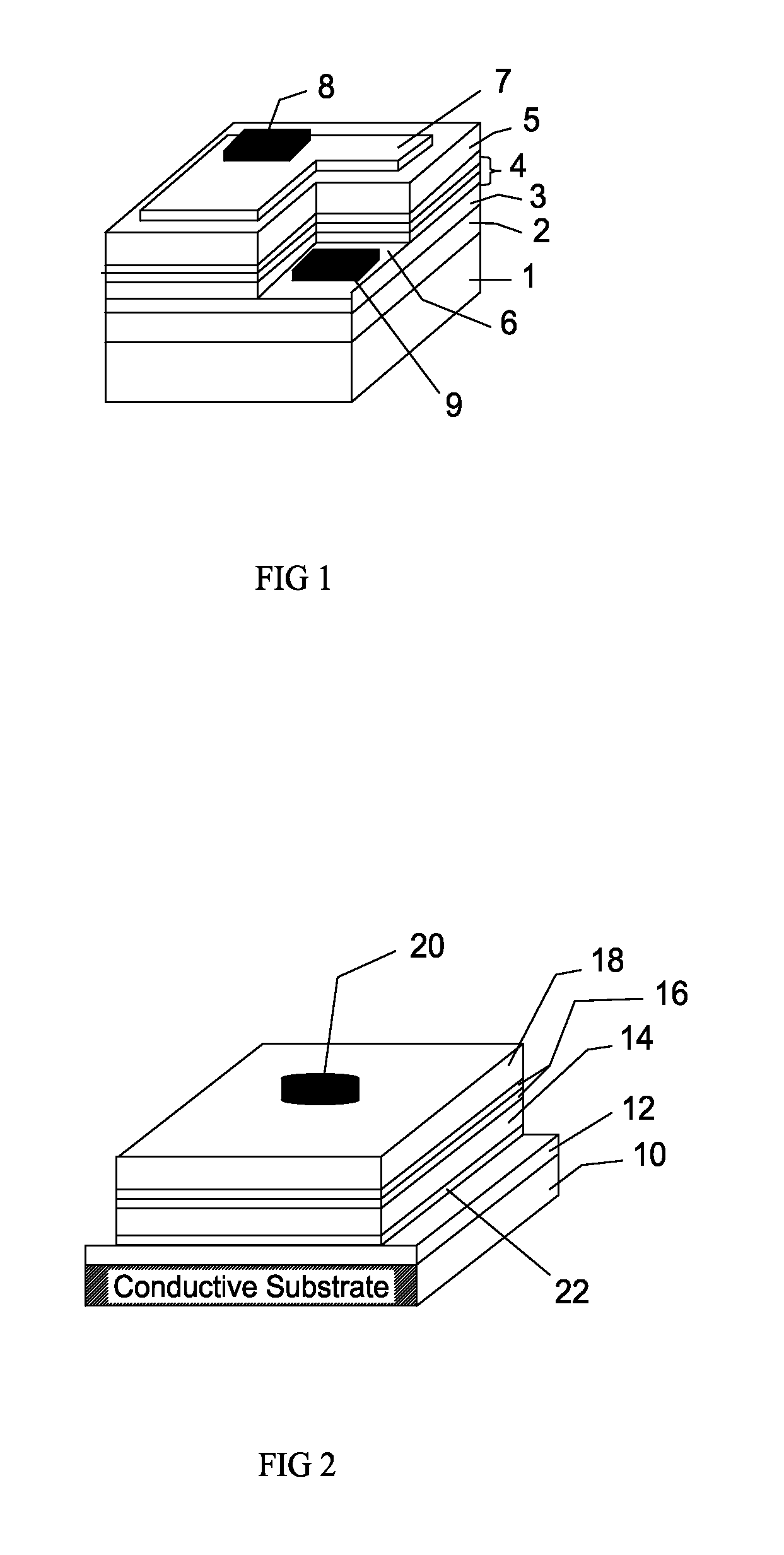

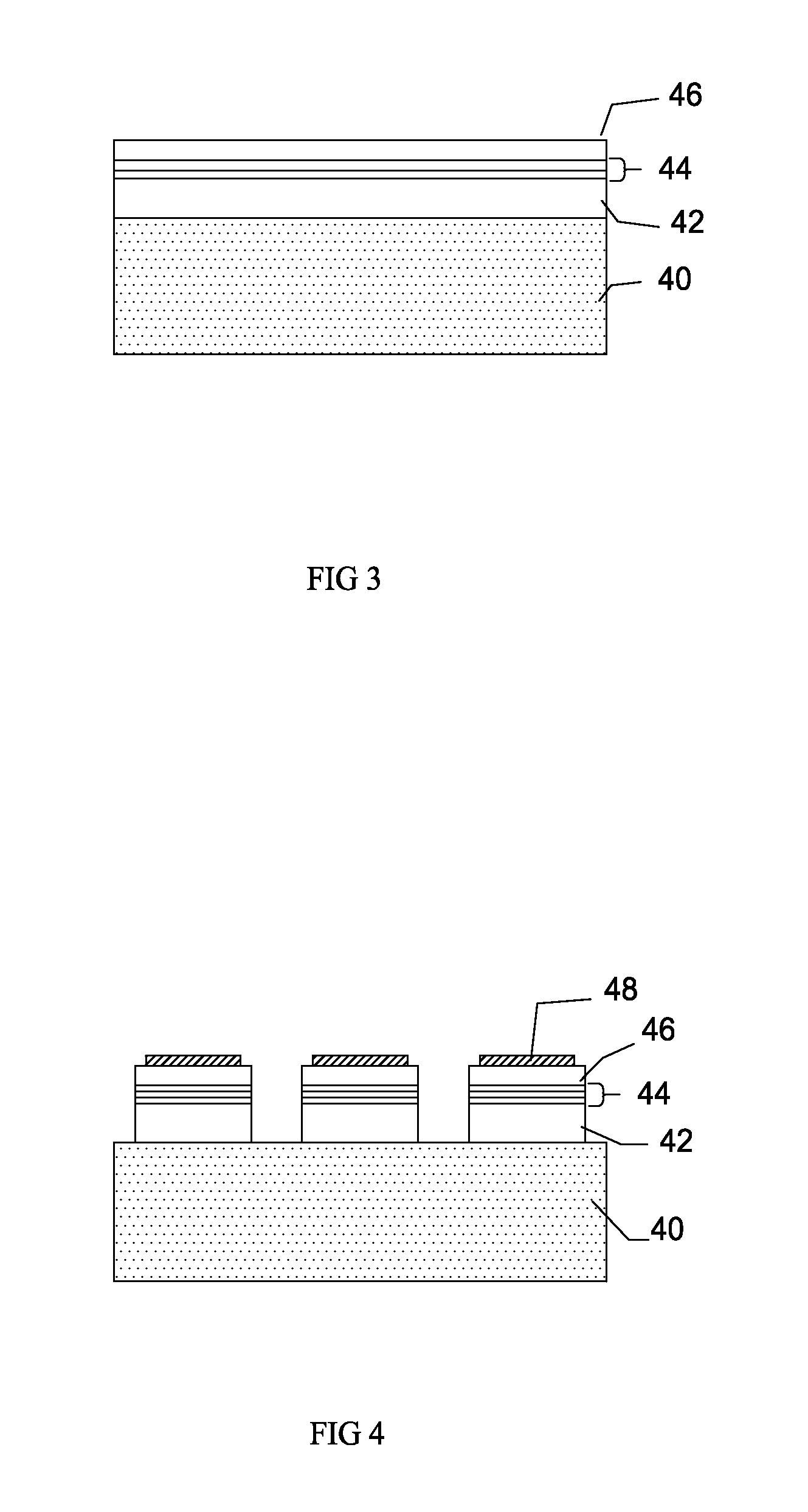

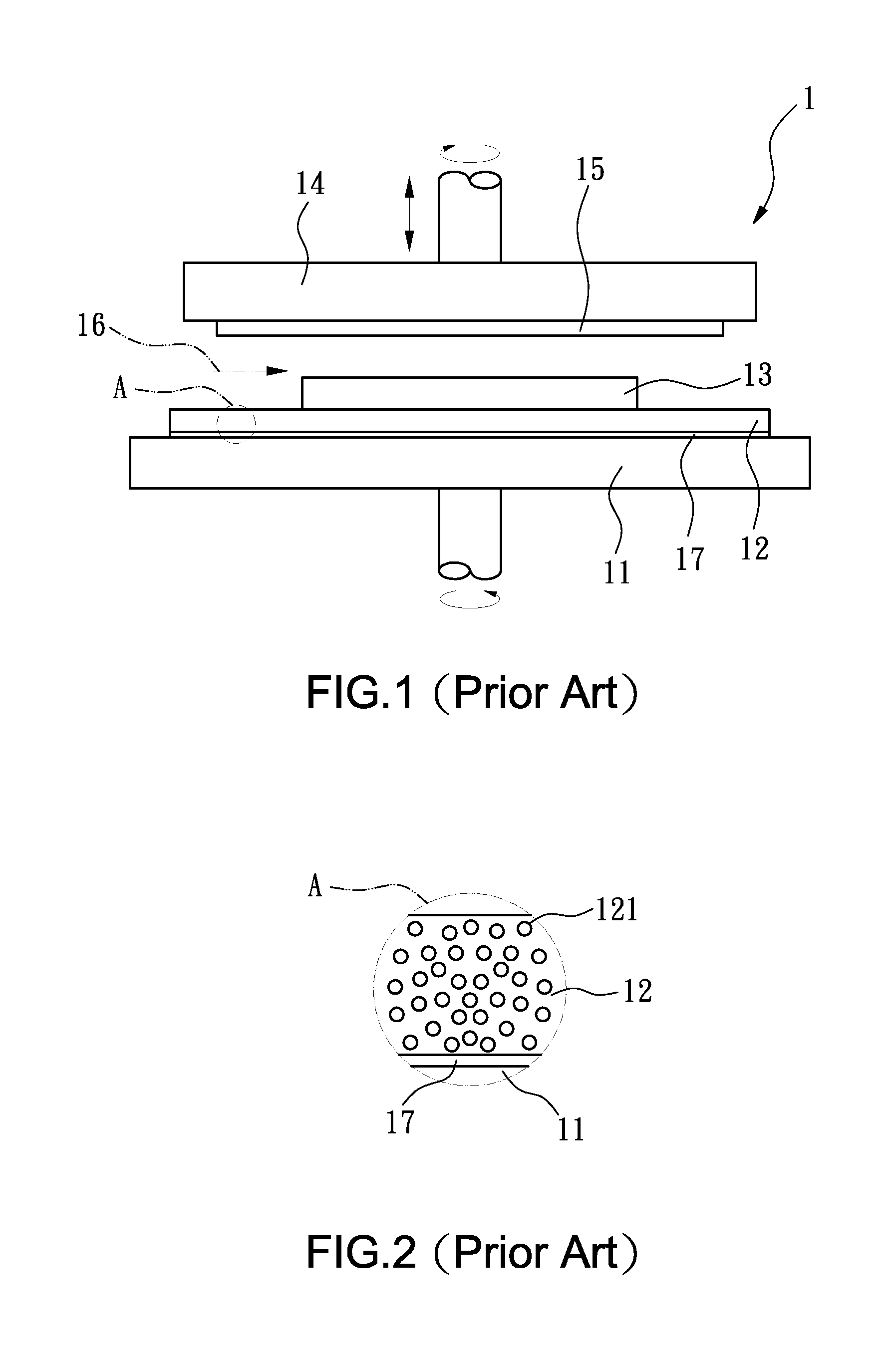

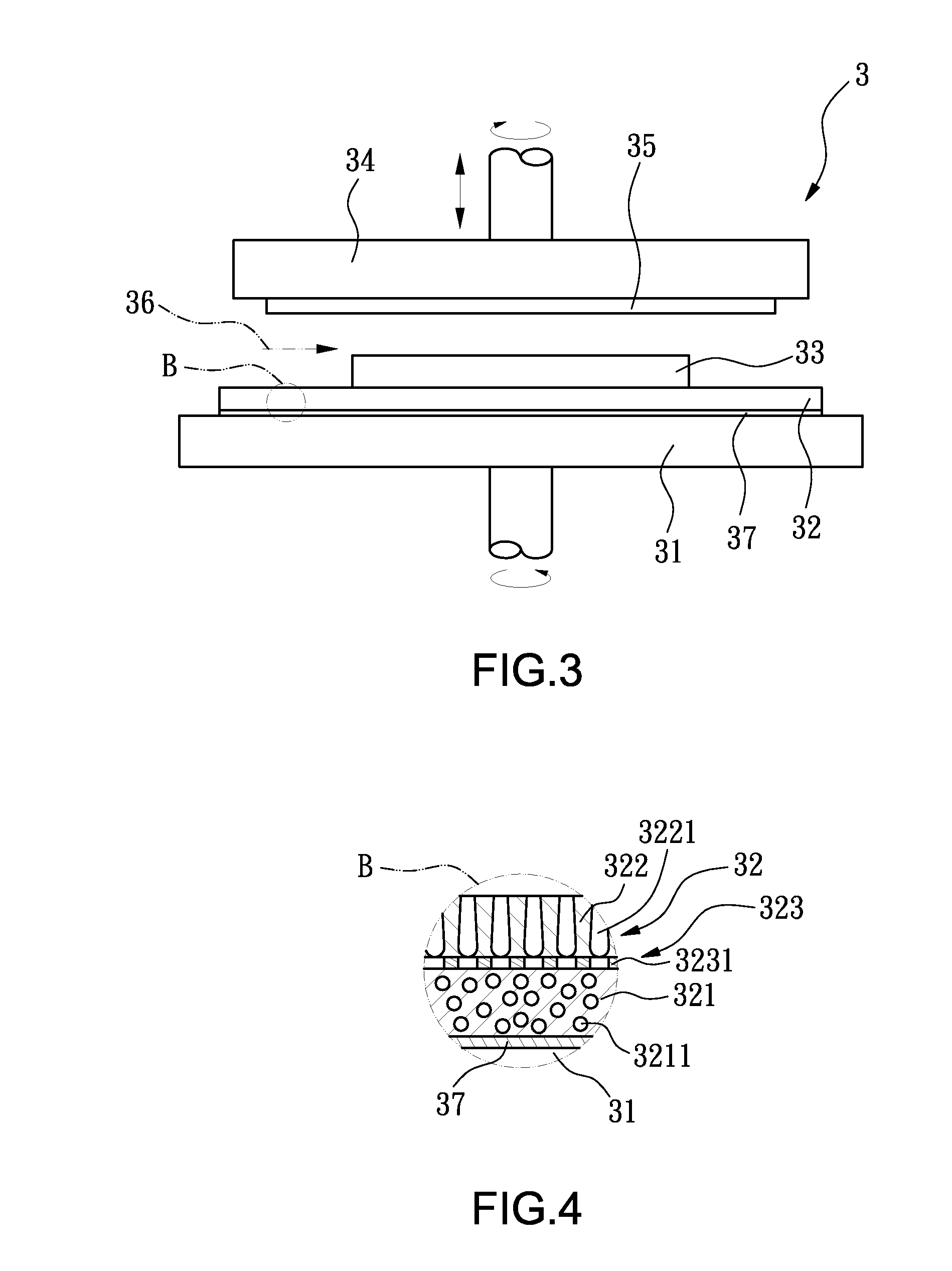

Method for handling a semiconductor wafer assembly

ActiveUS20070231963A1Avoid excessive lightDissipate more heatSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringLight-emitting diode

Systems and methods for fabricating a light emitting diode include forming a multilayer epitaxial structure above a carrier substrate; depositing at least one metal layer above the multilayer epitaxial structure; removing the carrier substrate.

Owner:SEMILEDS OPTOELECTRONICS CO LTD

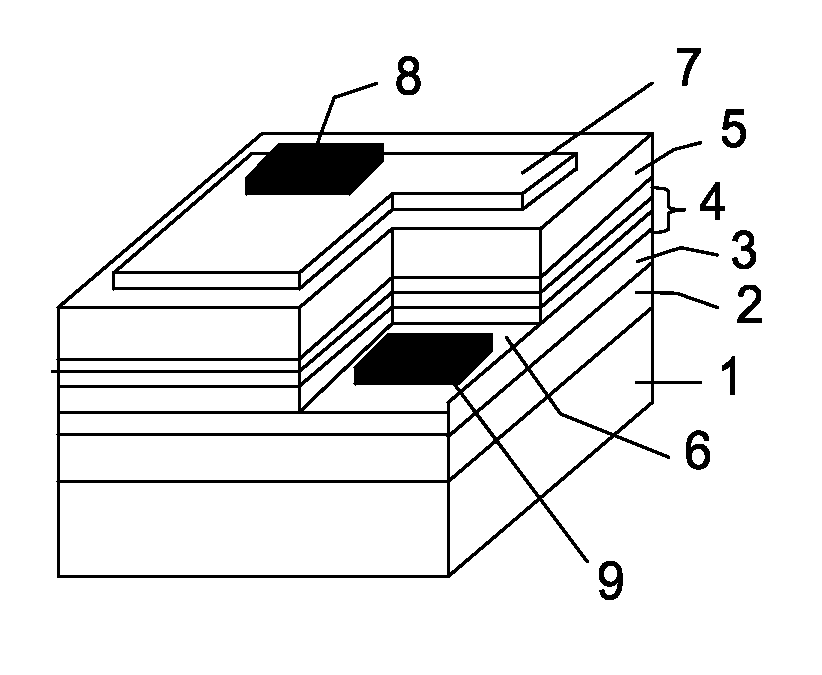

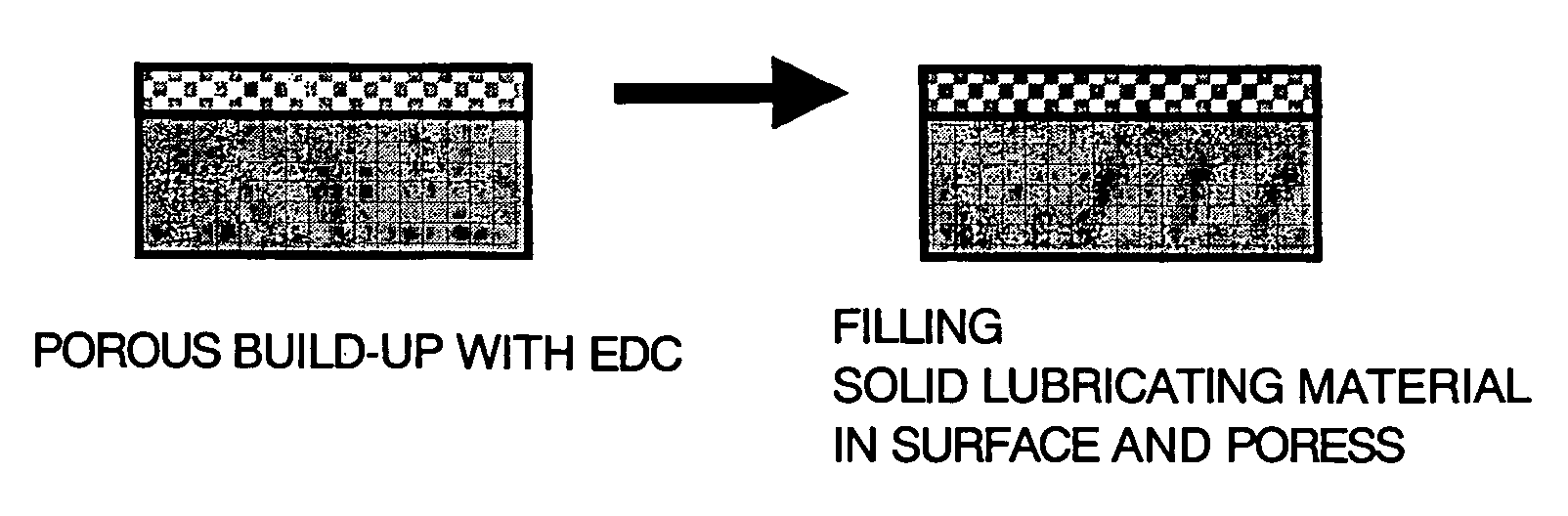

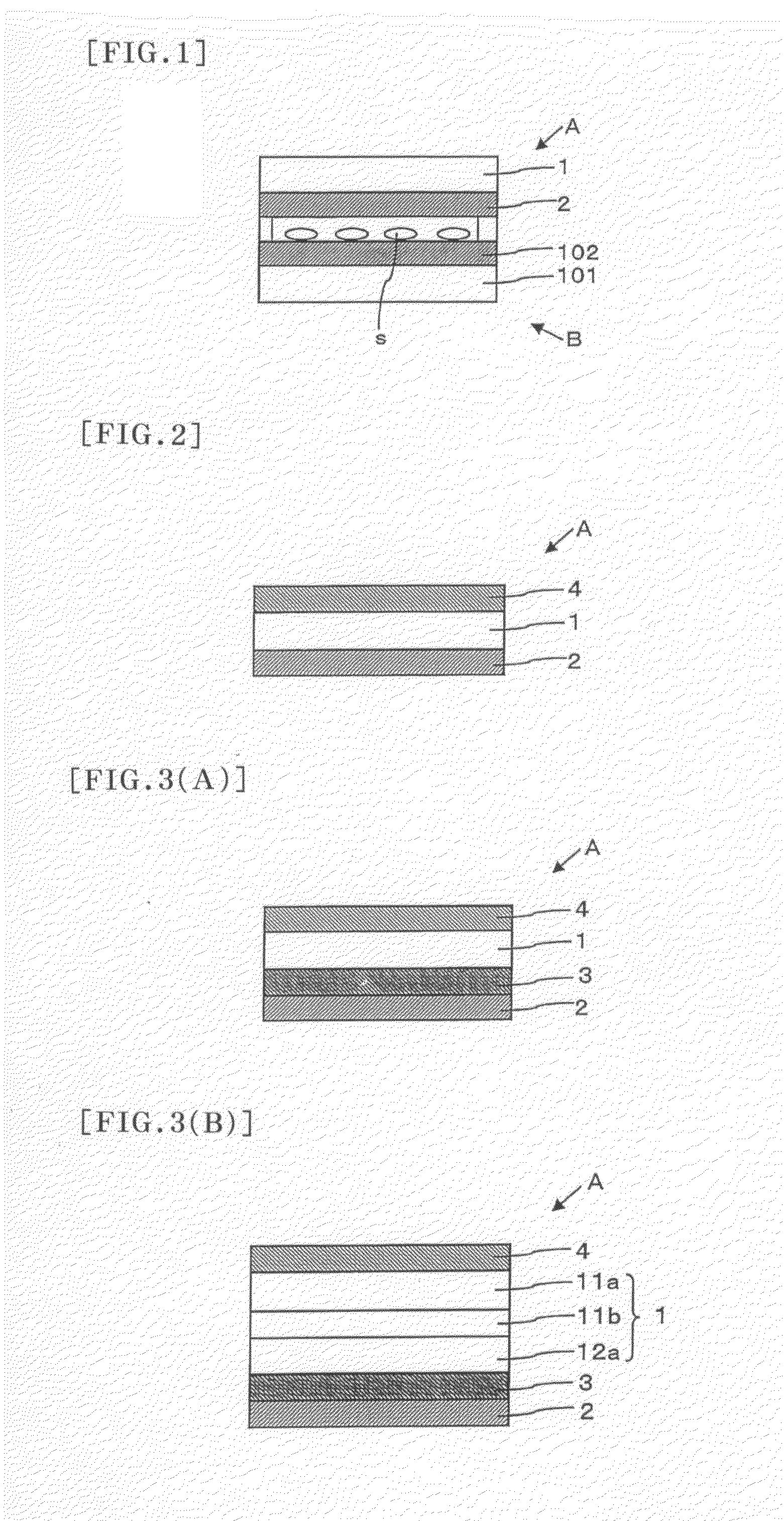

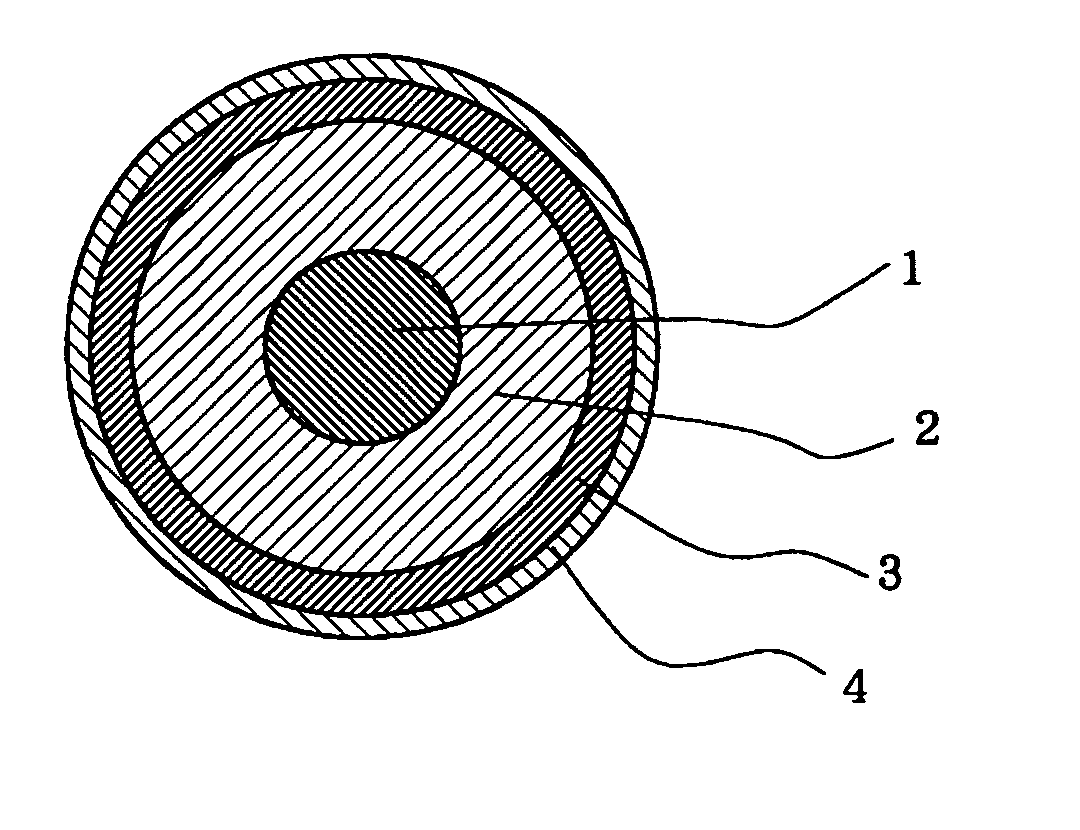

Method for coating sliding surface of high-temperature member, high-temperature member and electrode for electro-discharge surface treatment

ActiveUS20060035068A1Improve adhesionImprove precisionArc welding apparatusEfficient propulsion technologiesCompression moldingNitride

A sliding surface of a high-temperature portion is subjected to an electro-discharge surface treatment with one or both of a high-temperature hard material (4) and a material having a lubricating property at a high temperature (6). The high-temperature hard material (4) is any or a mixture of cBN, TiC, TiN, TiAlN, TiB2, WC, Cr3C2, SiC, ZrC, VC, B4C, Si3N4, ZrO2, and Al2O3. The material having the lubricating property at the high temperature (6) contains chromium and / or chromium oxide (Cr2O3) and / or hexaboron nitride (hBN). An electrode formed by compression molding of the high-temperature-hard material, and the high-temperature lubricating material containing at least one of Cr and hBN and having the lubricating property at the high temperature is used as the electrode for the electro-discharge surface treatment.

Owner:IHI CORP +1

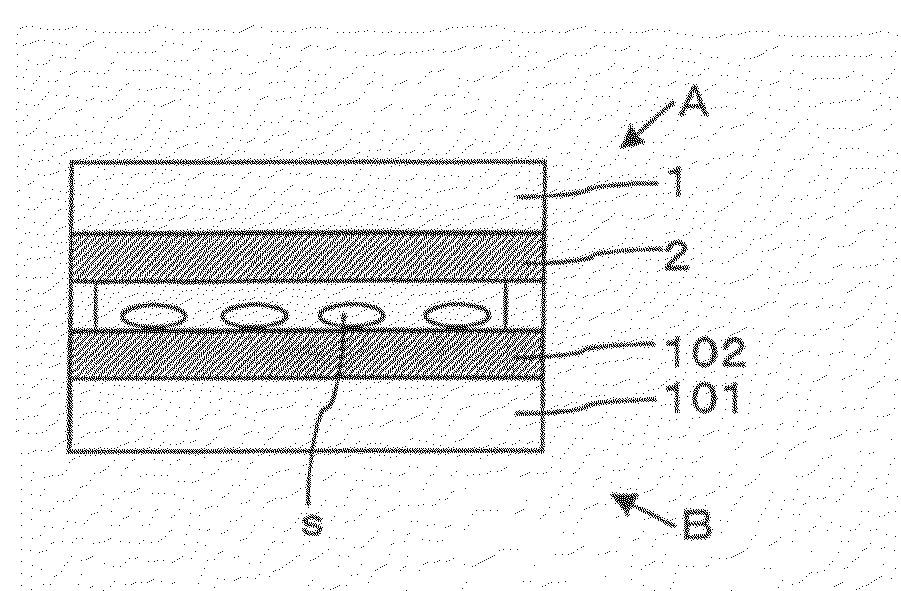

Touch panel

ActiveUS20070252825A1Increased durabilitySolution to short lifeRecord information storageTraffic signalsFilm baseEngineering

A touch panel of the invention comprises a first panel having a first film base with transparency and a first transparent conductive thin film provided on one surface of the first film base; and a second panel having a second film base with transparency and a second transparent conductive thin film provided on one surface of the second film base, wherein the first panel and the second panel are arranged so as to face each other with a spacer therebetween, in such a manner that the first conductive thin film and the second conductive thin film face each other, wherein the surface of the first conductive thin film has a hardness of 1 GPa or more and a modulus of elasticity of 5 GPa or more, the surface of the second conductive thin film has a center line average roughness (Ra) of 0.3 nm to 1.0 nm, and that of the center line average roughness (Ra) of the surface of the second conductive thin film is smaller than that of the surface of the first conductive thin film. The touch panel has good durability.

Owner:NITTO DENKO CORP

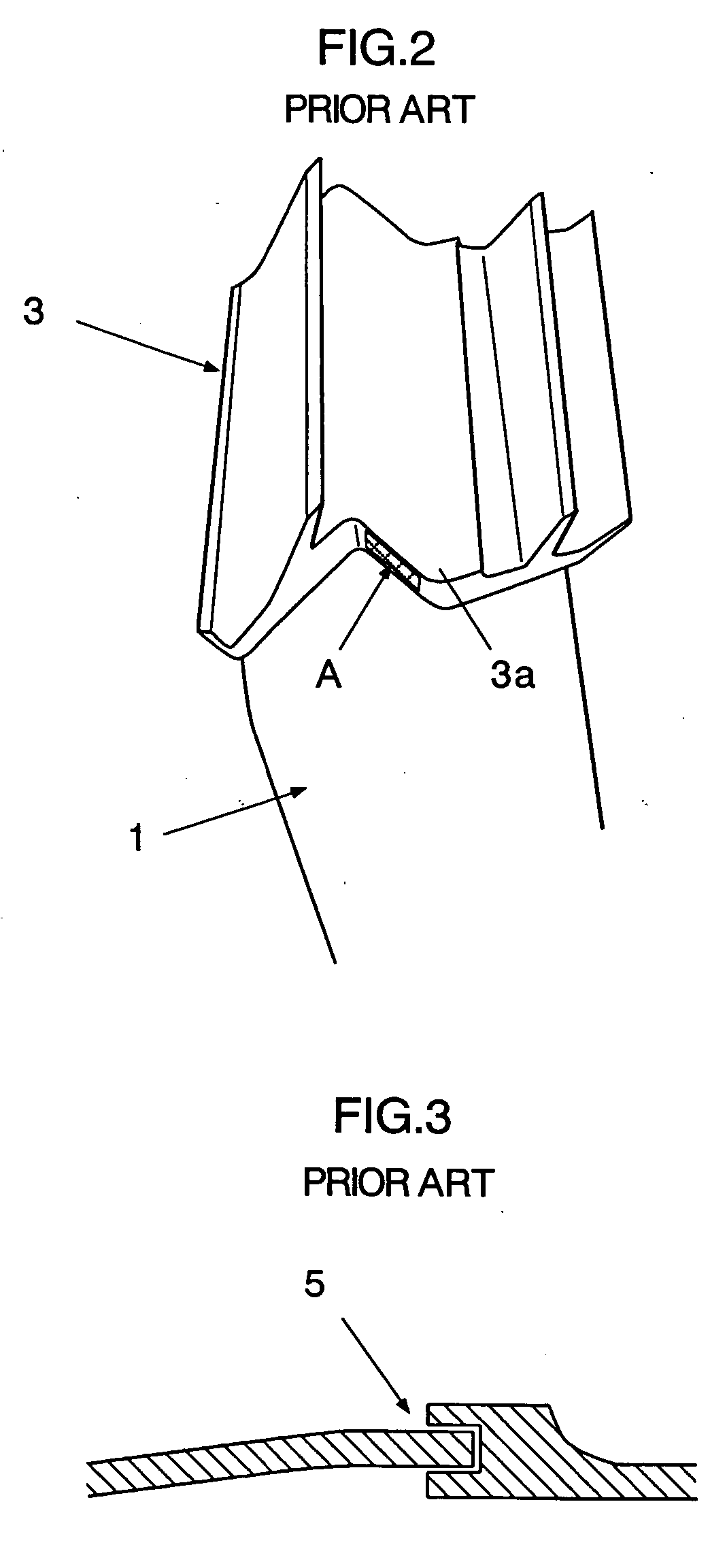

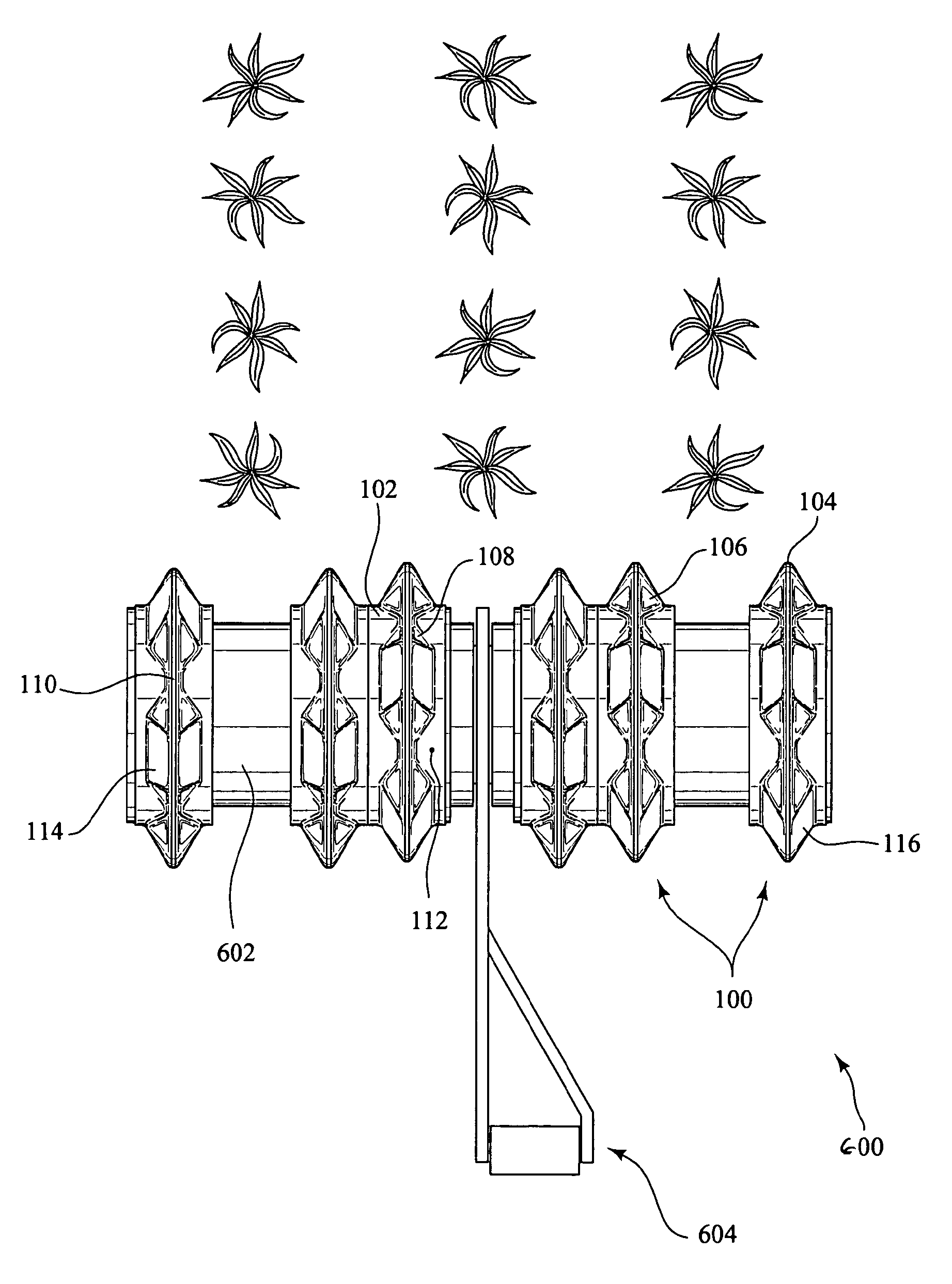

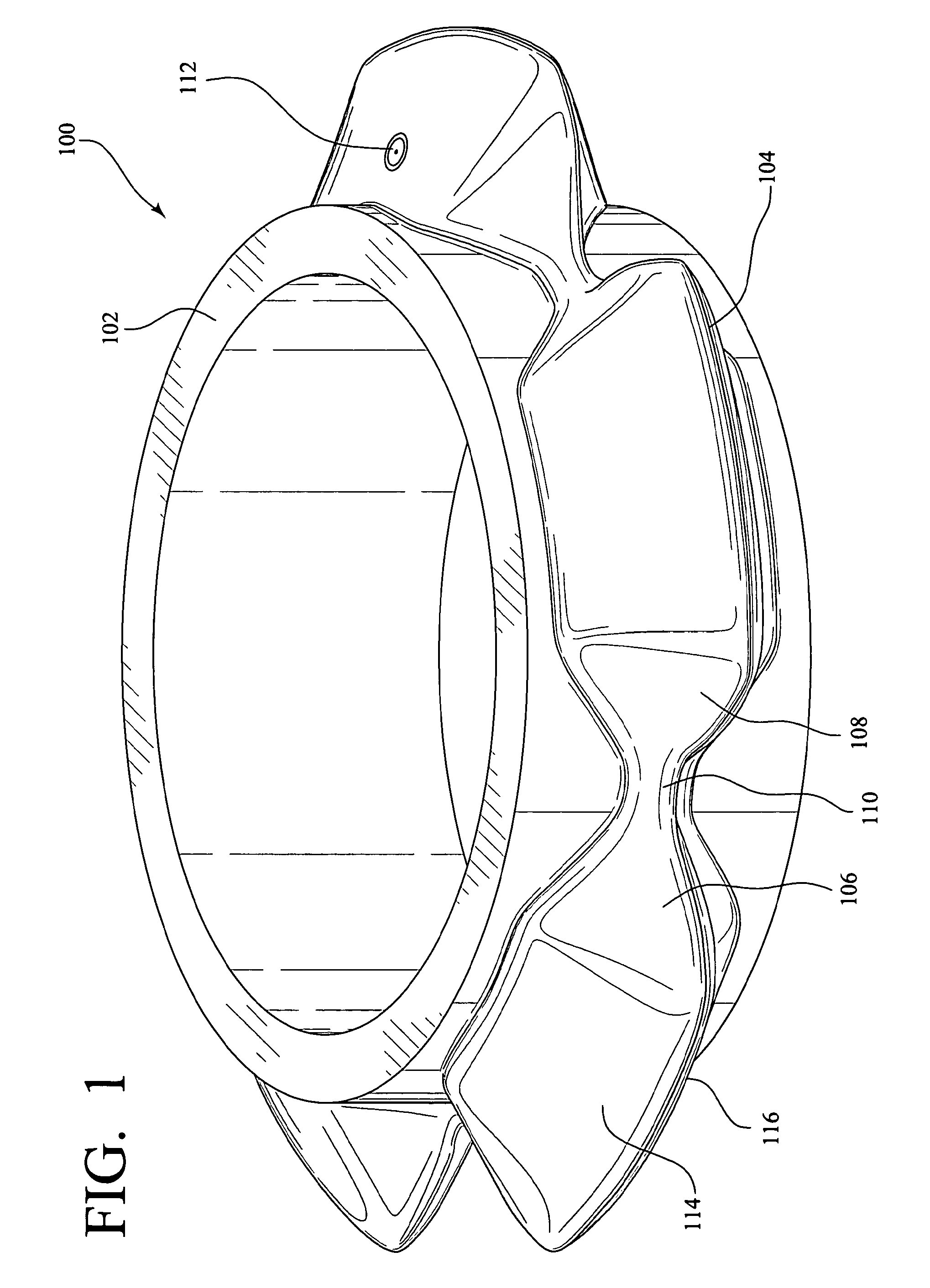

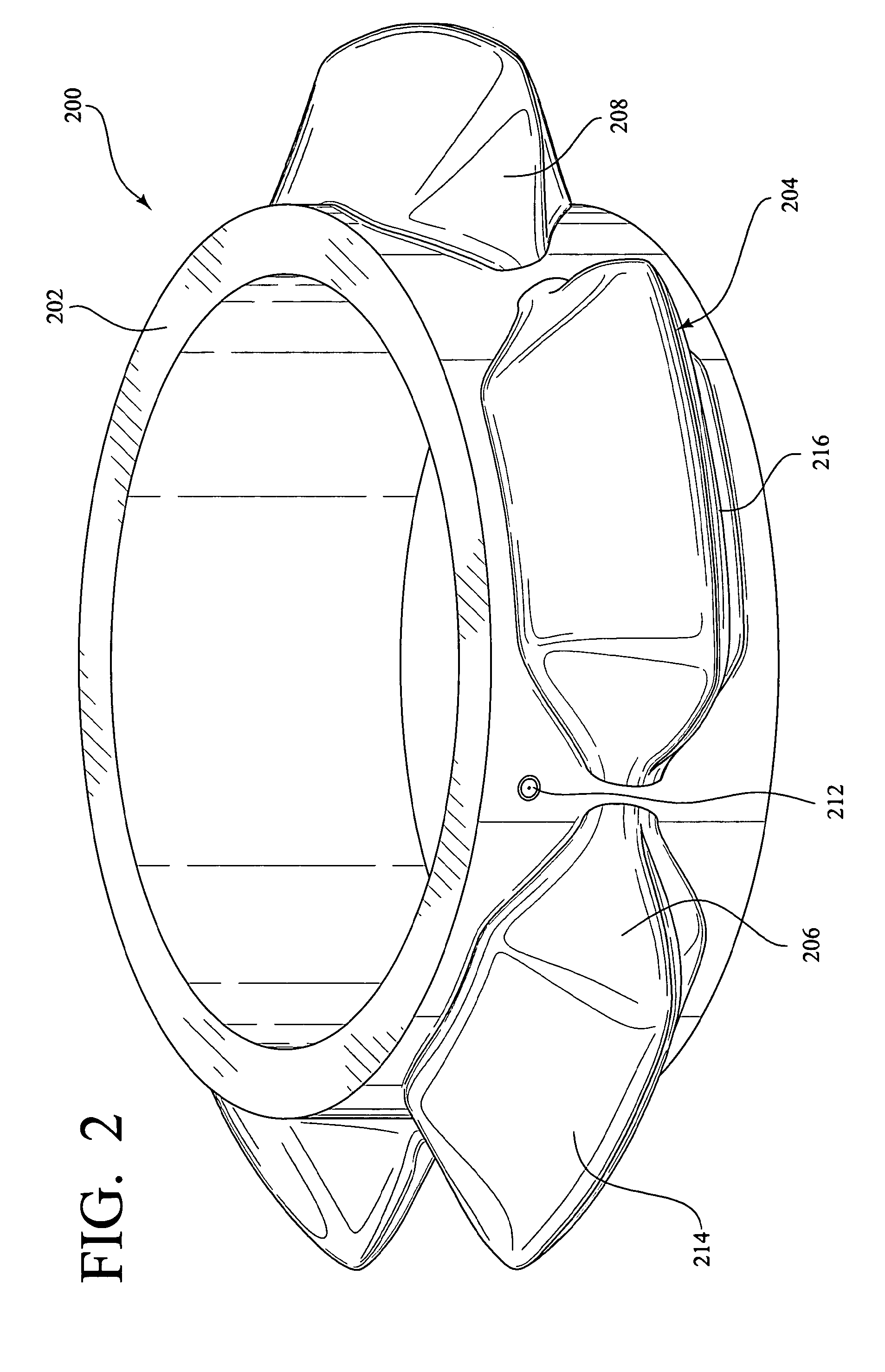

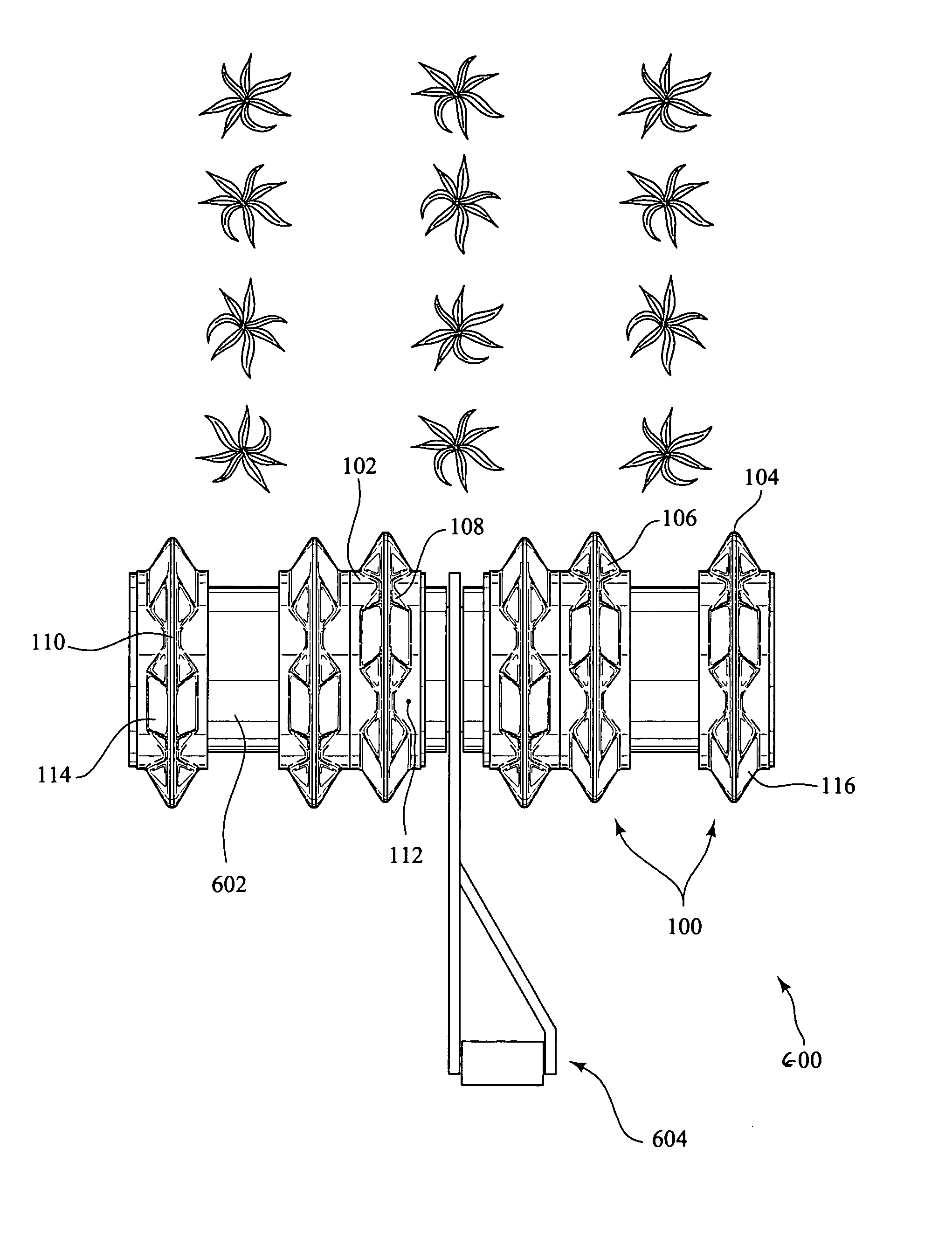

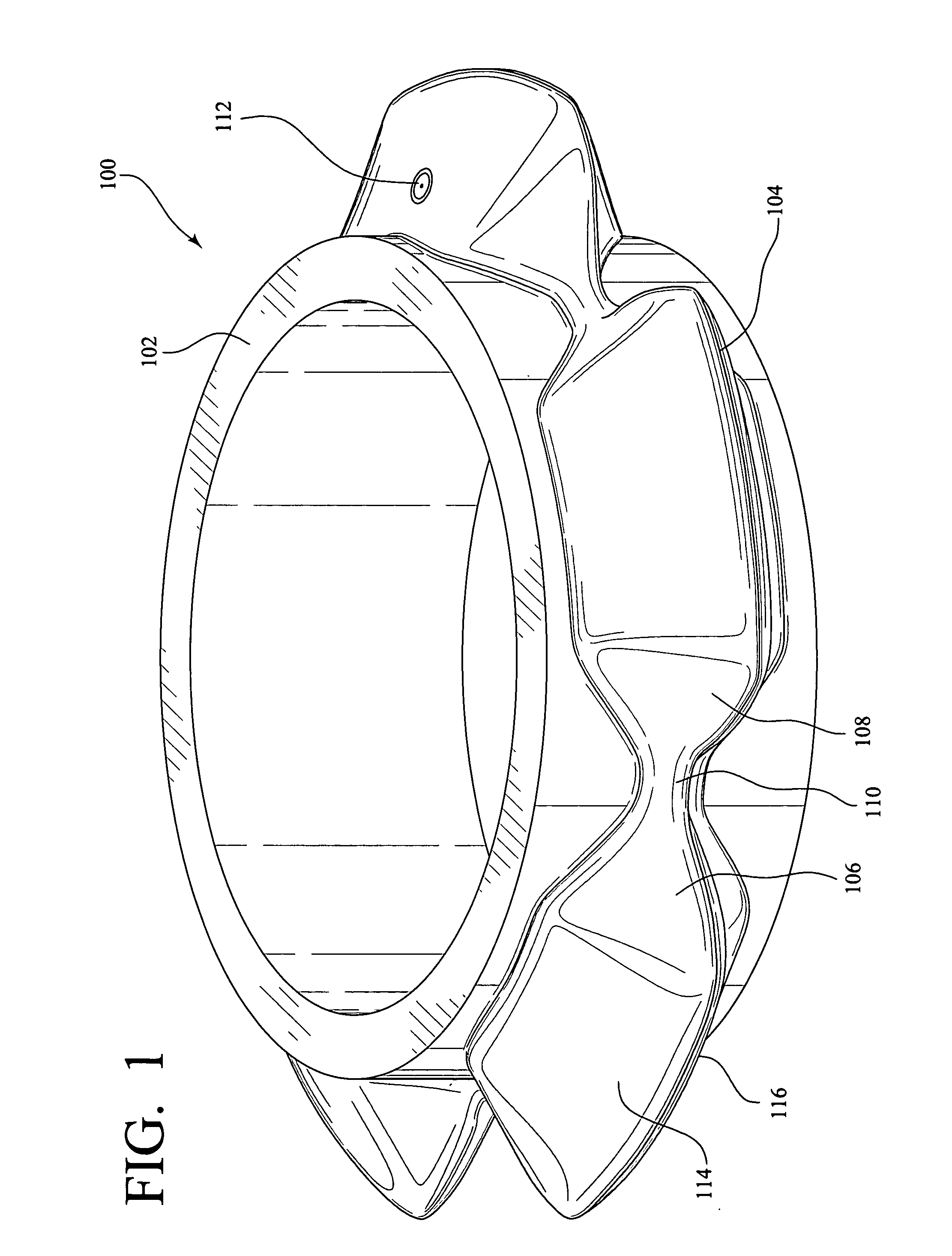

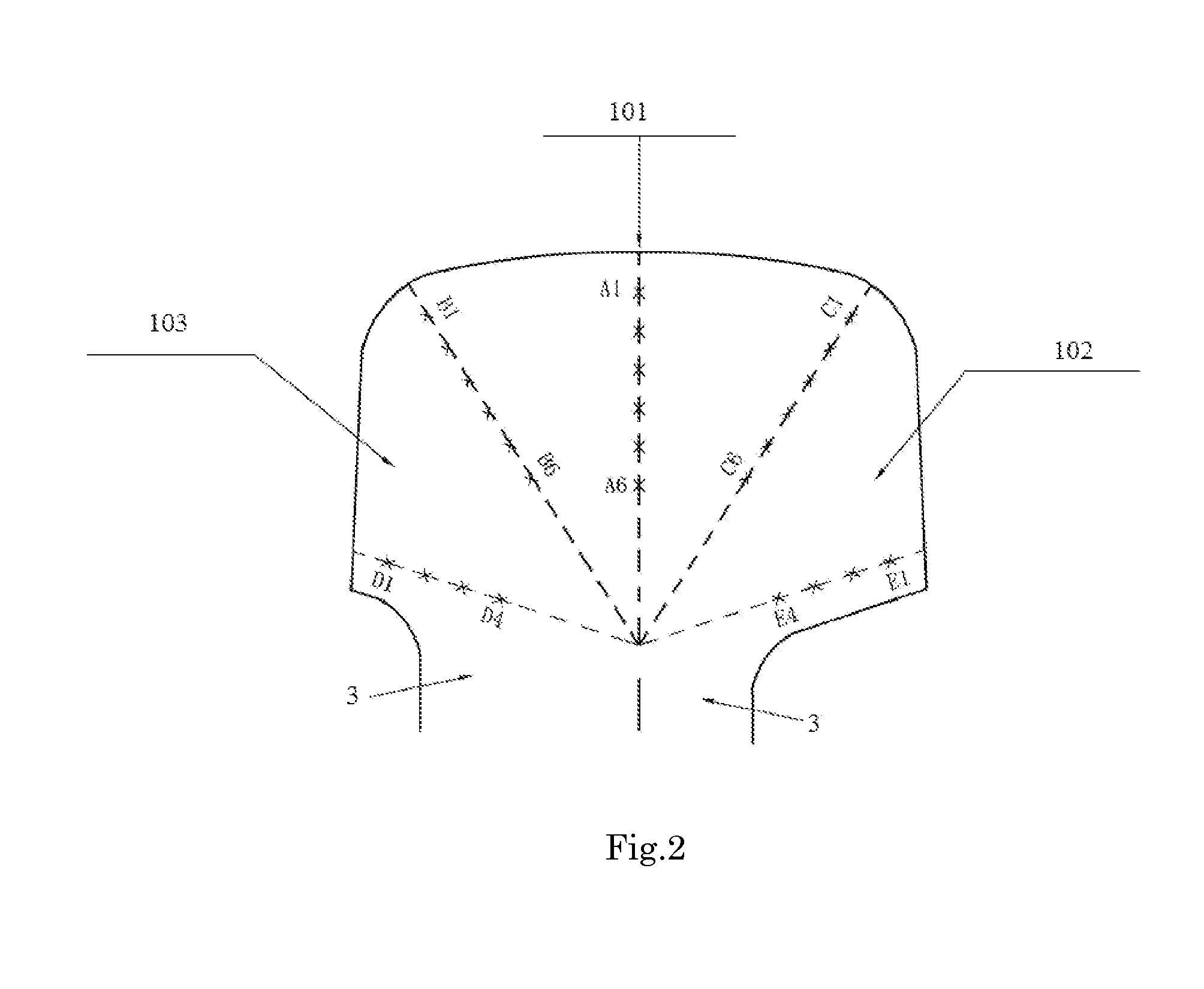

Soil conditioning device

InactiveUS7730961B2Increase aeration and water retention and infiltrationImprove breathabilitySpadesSoil-working equipmentsEngineeringSoil surface

A soil conditioning device having a series of peripheral ridge members having a leading and trailing prow shaped surface circumscribing a disc, wheel or drum. Optionally the prow shaped peripheral ridge members are joined by sub-ridge members forming a single ridge of varying heights circumscribing the disc, wheel or drum. The invention is also of a method for creating a permeable soil surface using the apparatus herein.

Owner:TERRACON TECH LLC

Method for handling a semiconductor wafer assembly

ActiveUS8318519B2Avoid excessive lightDissipate more heatSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringLight-emitting diode

Systems and methods for fabricating a light emitting diode include forming a multilayer epitaxial structure above a carrier substrate; depositing at least one metal layer above the multilayer epitaxial structure; removing the carrier substrate.

Owner:SEMILEDS OPTOELECTRONICS CO LTD

Soil conditioning device

InactiveUS7478684B2Promote infiltrationImprove retentionSoil-working equipmentsHarrowsEngineeringProw

A soil conditioning device having a series of peripheral ridge members having a leading and trailing prow shaped surface circumscribing a disc, wheel or drum and a method of use. Optionally the prow shaped peripheral ridge members are joined by sub-ridge members forming a single ridge of varying heights circumscribing the disc, wheel or drum.

Owner:TERRACON TECH LLC

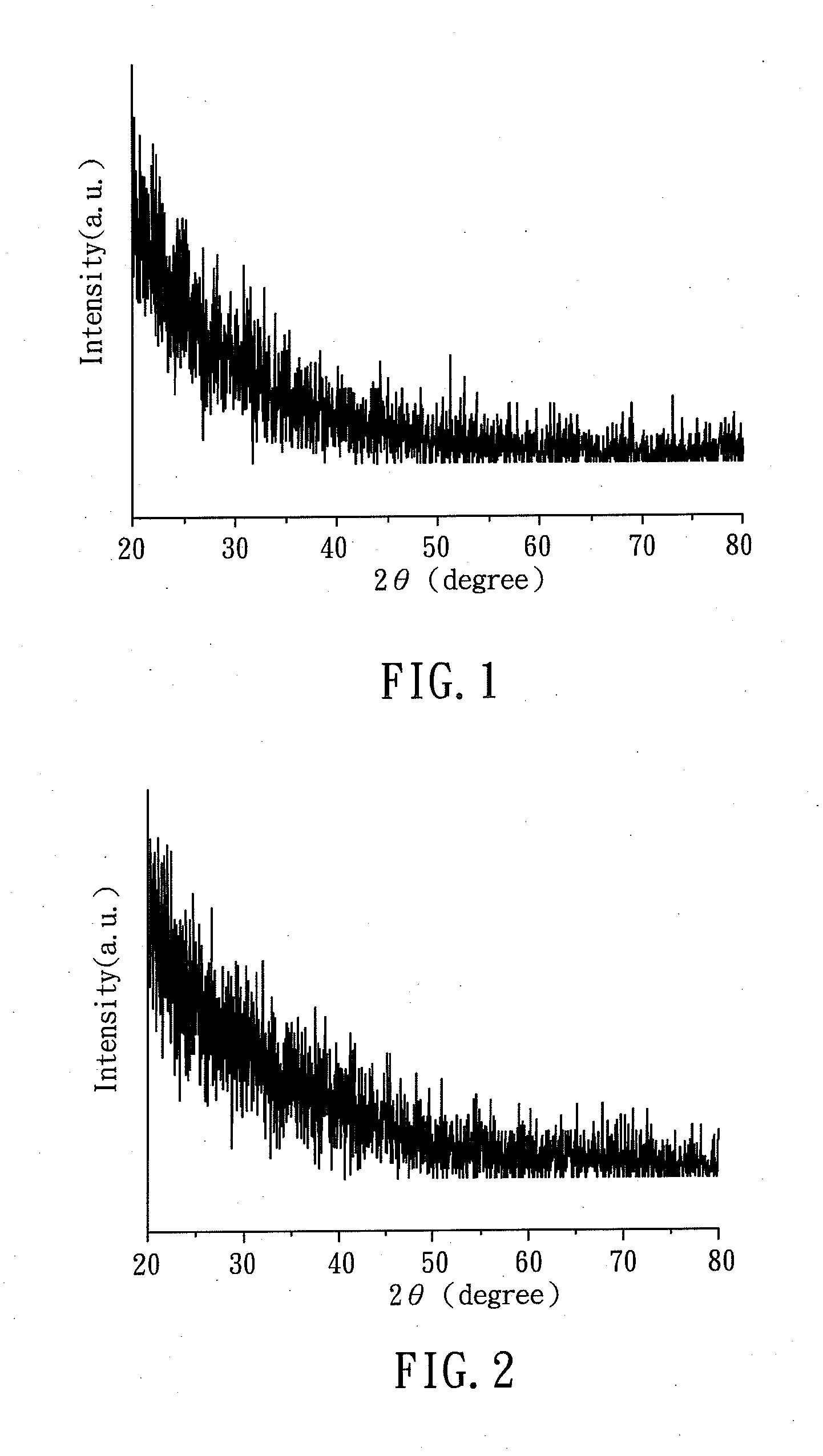

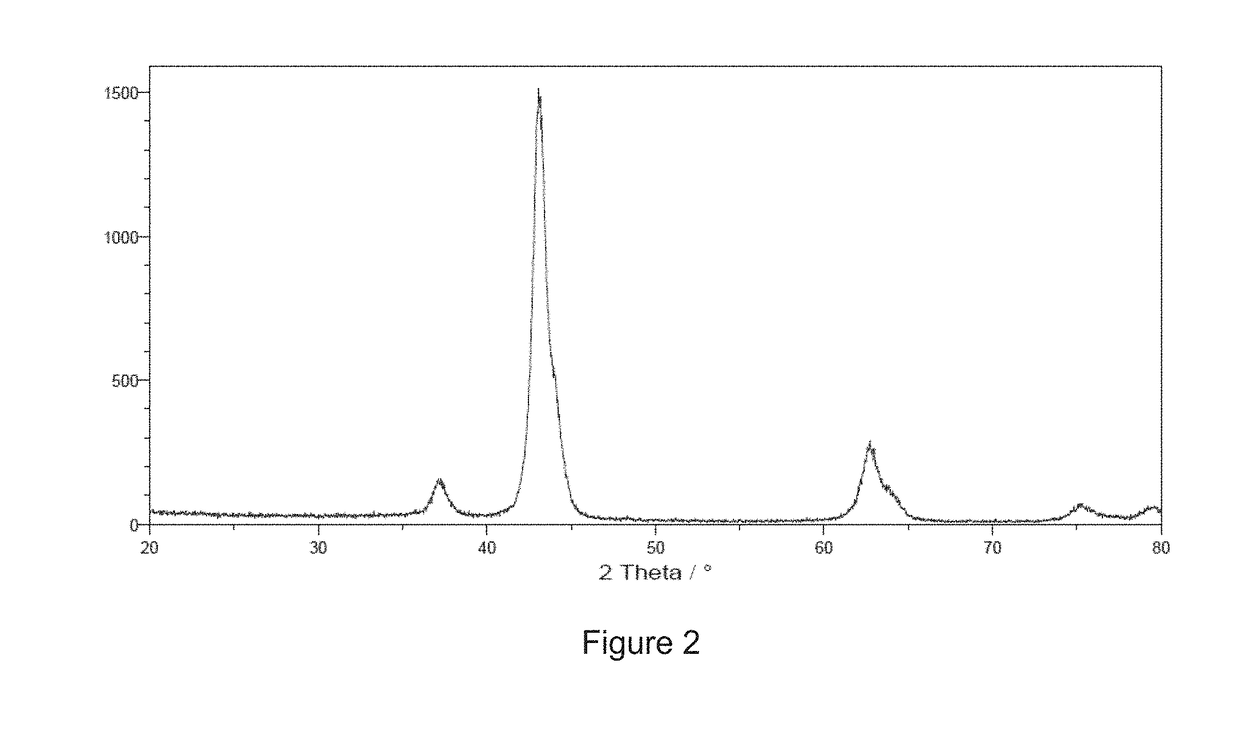

Application of Metallic Glass Coating for Improving Fatigue Resistance of Aluminum Alloys

ActiveUS20130105300A1Improve mechanical propertiesExtend your lifeElectric discharge tubesVacuum evaporation coatingAlloy substrateMetal

A Zr-based or Zr—Cu based metallic glass thin film (MGTF) coated on aluminum alloy substrate and a method of fabricating the metallic glass and MGTF coated on aluminum alloy substrate are disclosed. The Zr-based metallic glass thin film-coated aluminum alloy substrate of the present invention comprises: an aluminum alloy substrate; and a Zr-based metallic glass thin film located on the substrate, in which the Zr-based metallic glass is represented by the following formula 1,(ZraCubNicAld)100-xSix, [formula 1]wherein 45=<a=<75, 25=<b=<35, 5=<c=<15, 5=<d=<15, 0.1=<x=<10.The Zr—Cu-based metallic glass thin film coated substrate of the present invention comprises: an aluminum alloy substrate; a Zr—Cu-based metallic glass thin film located on the aluminum alloy substrate, in which the Zr—Cu-based metallic glass is represented by the following formula 2,(ZreCufAlgAgh)100-ySiy, [formula 2]wherein 35=<e=<55, 35=<f=<55, 5=<g=<15, 5=<h=<15, 0.1=<y=<10.

Owner:NAT CENT UNIV

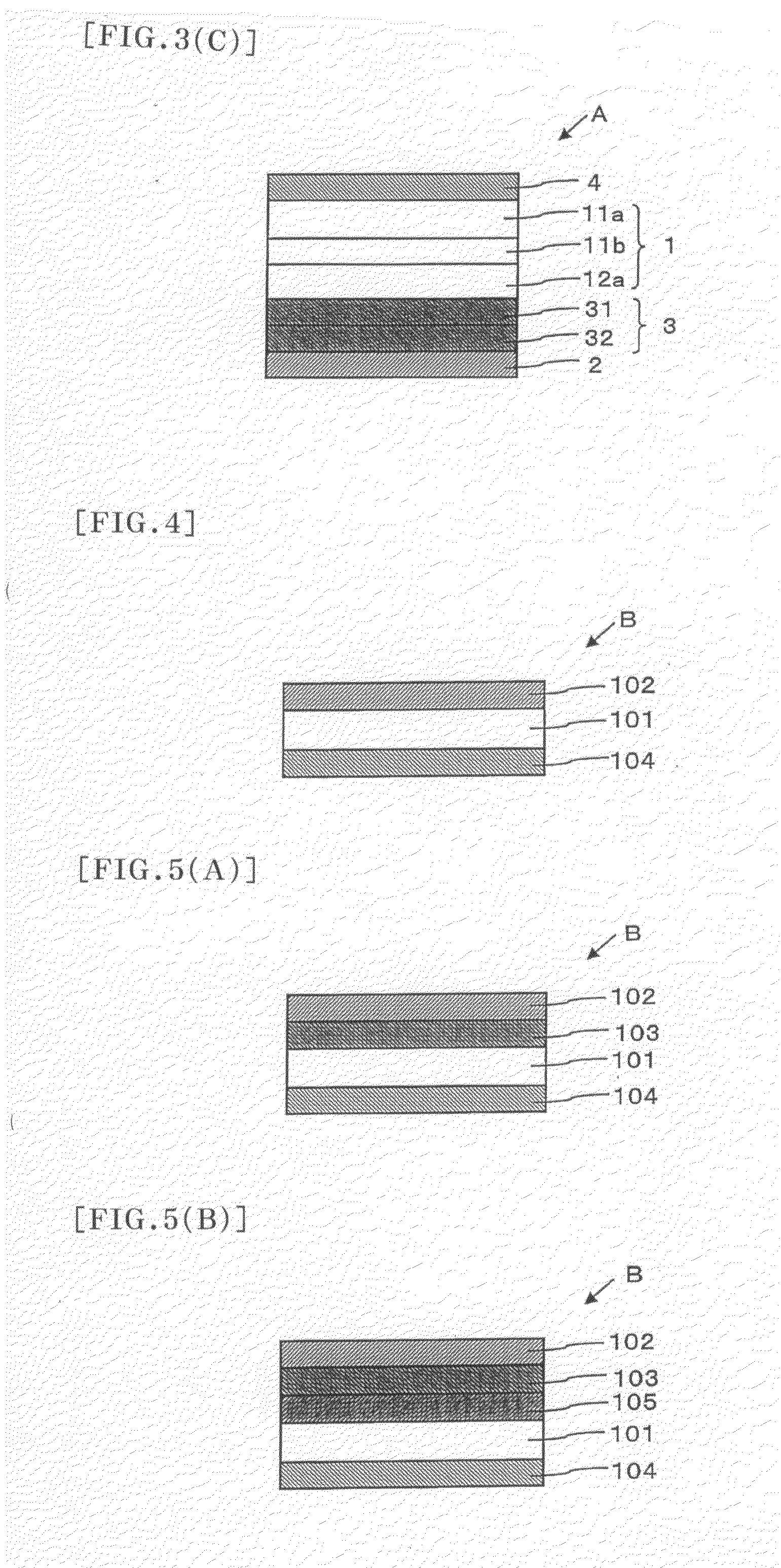

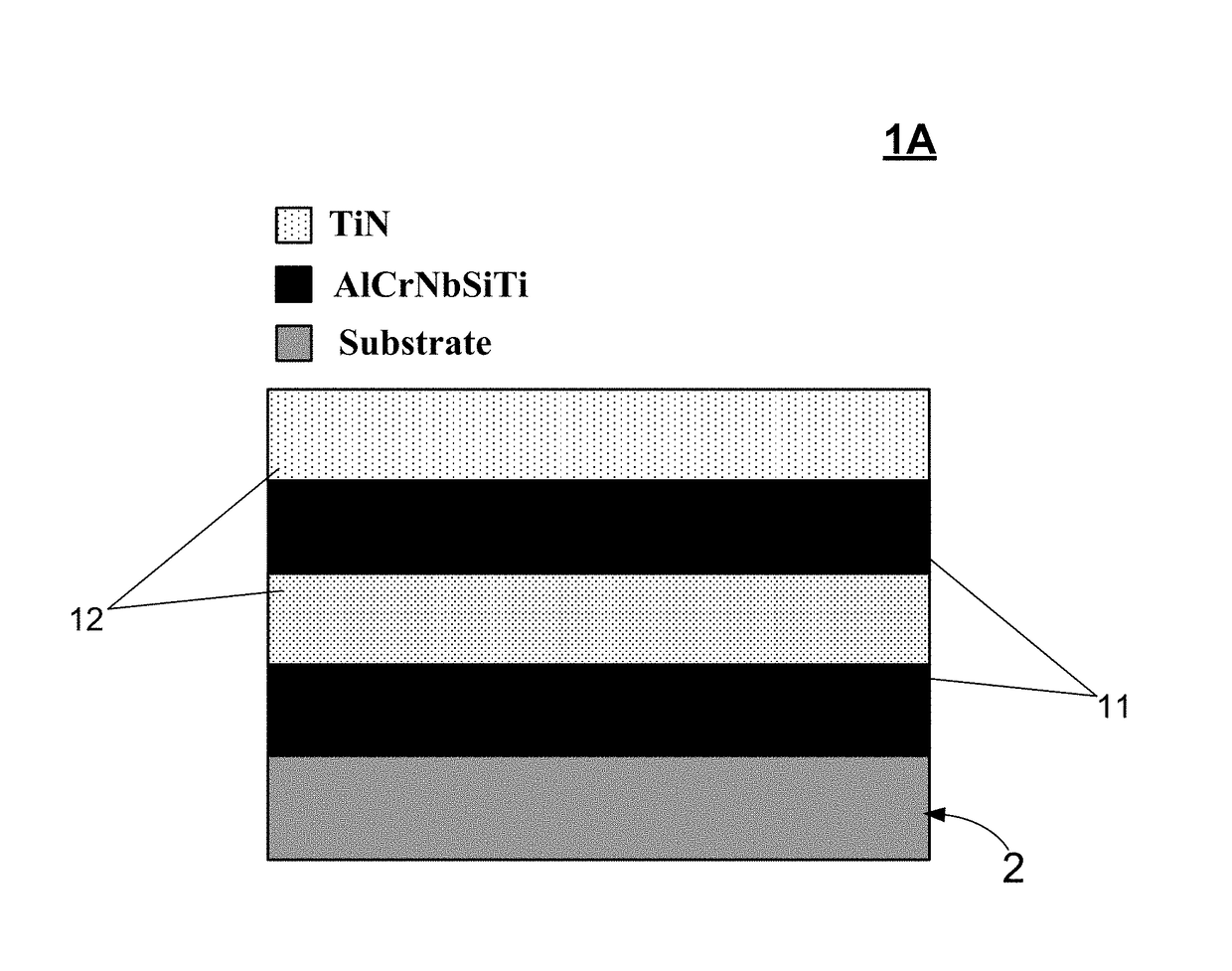

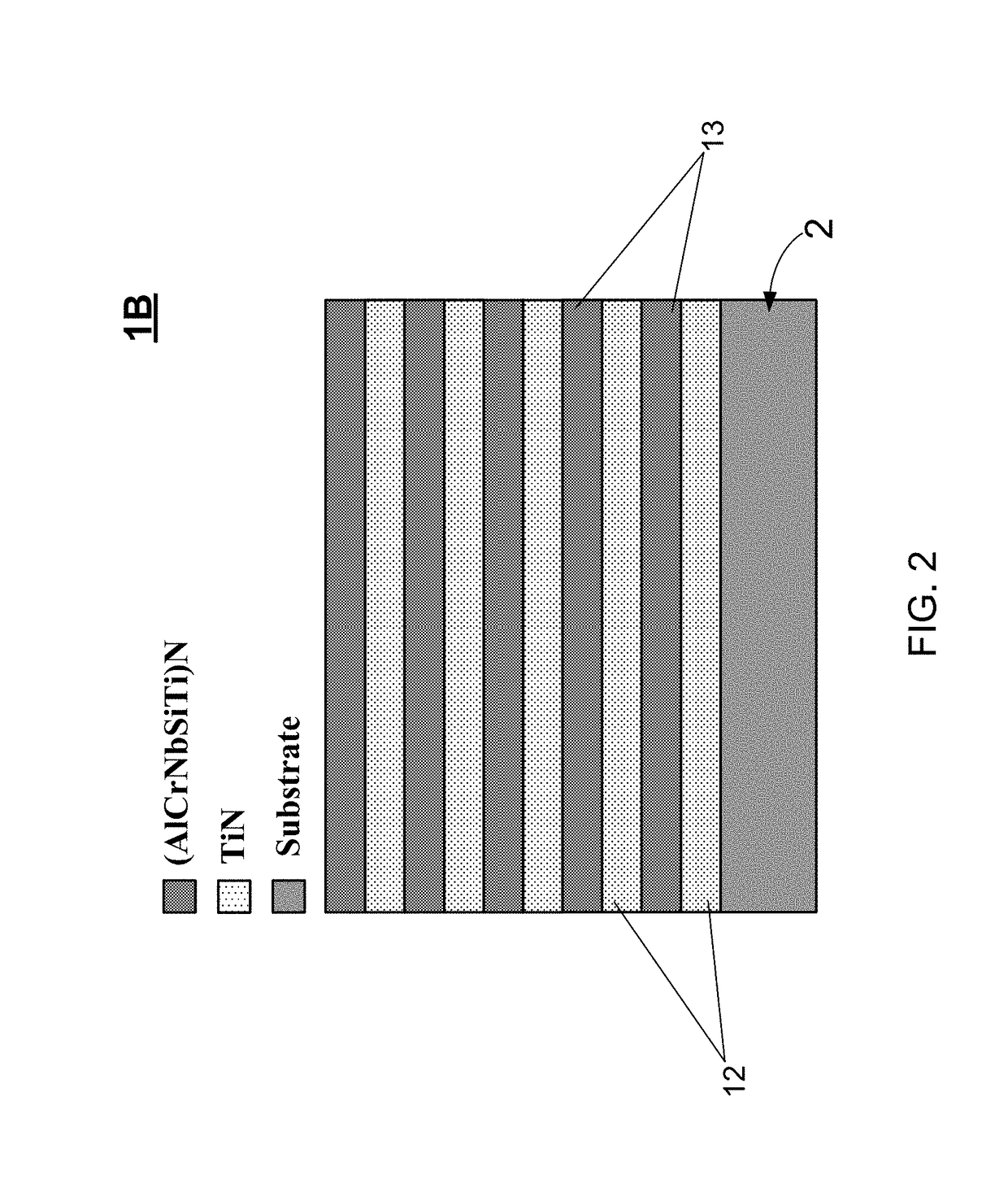

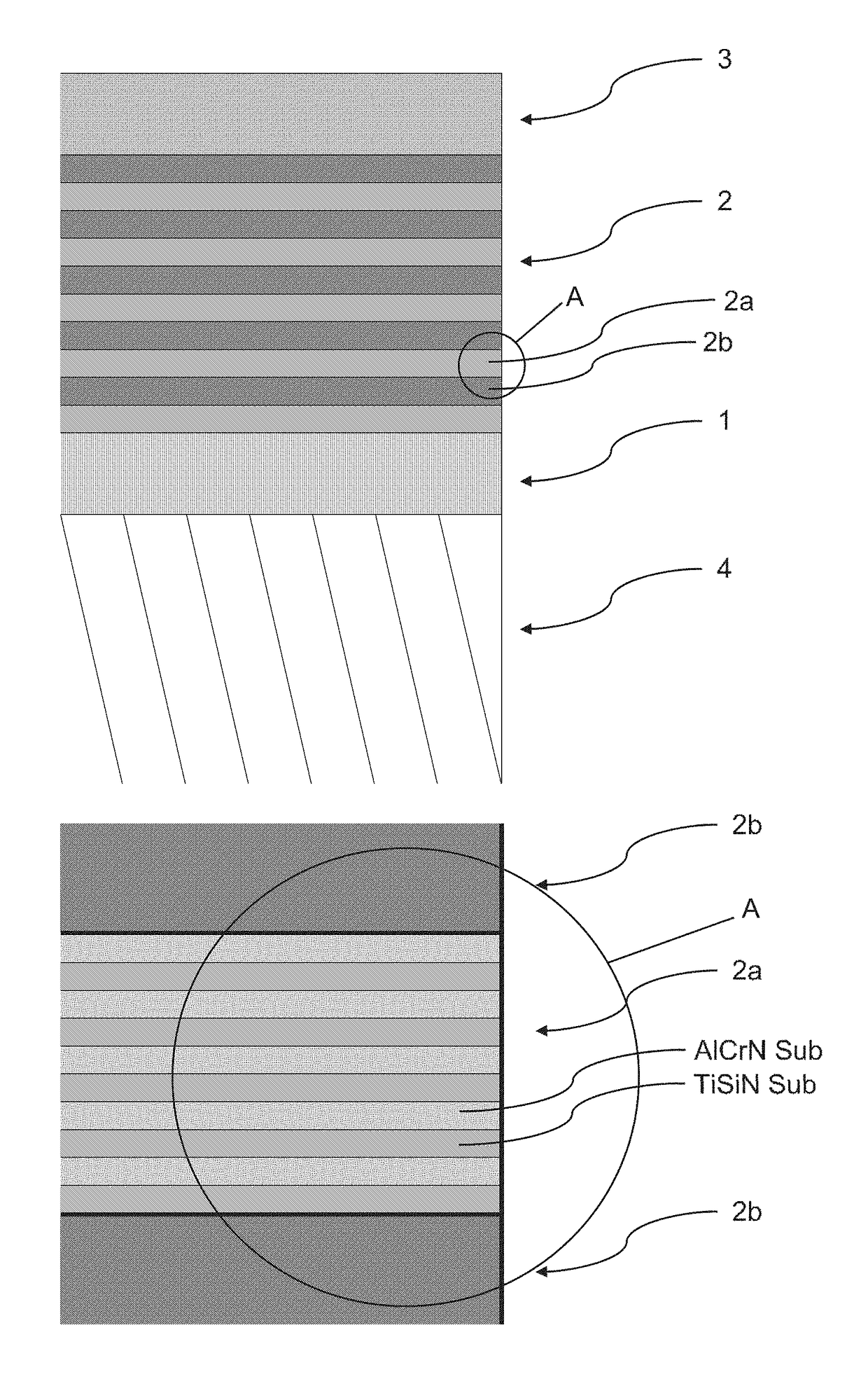

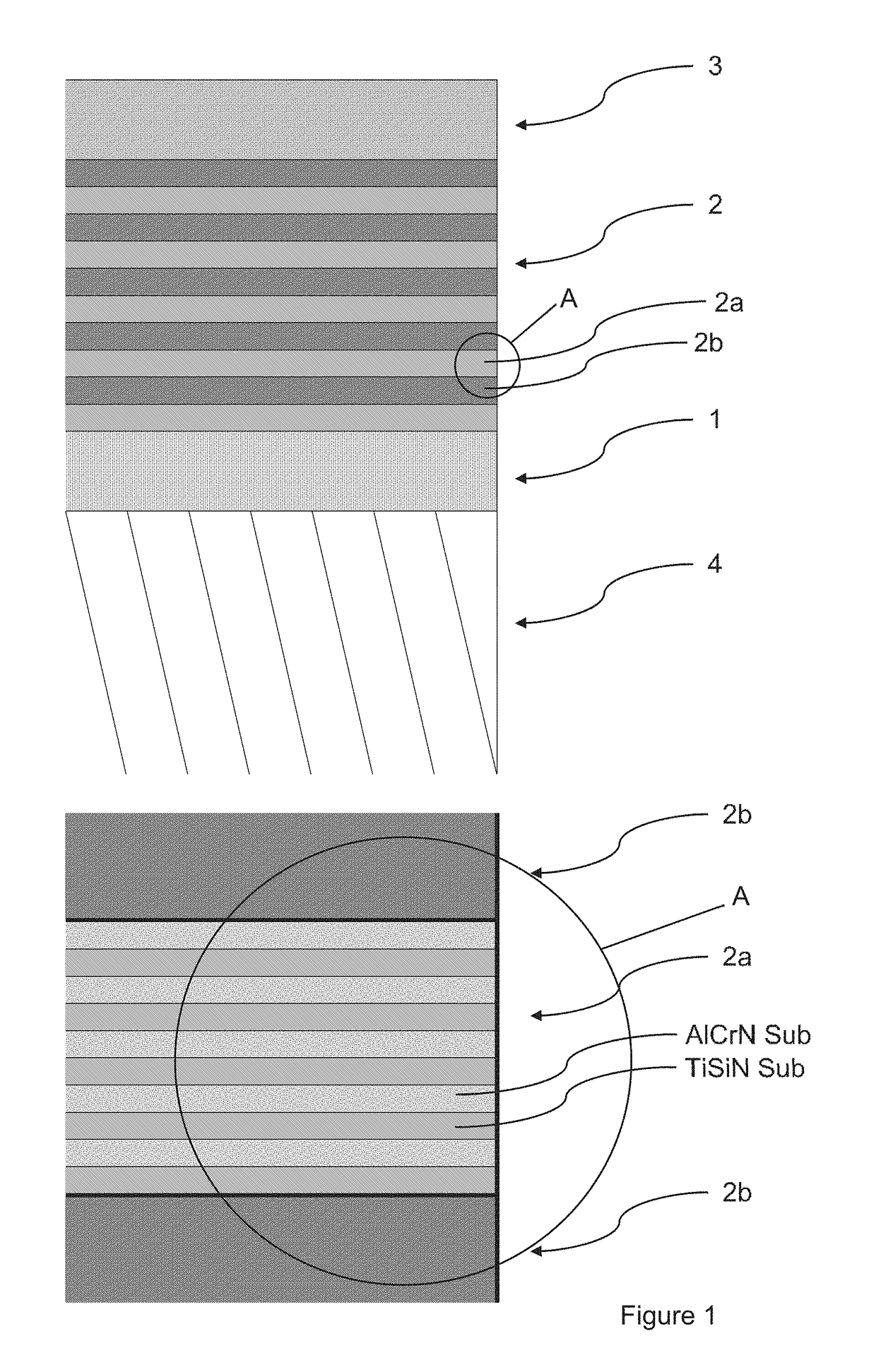

Multi-Film Structure

ActiveUS20180128952A1Reduce plastic deformationGood lookingVacuum evaporation coatingSputtering coatingEngineeringToughness

In the present invention, a multi-film structure being coated on the surface of a workpiece is disclosed. The multi-film structure is formed by making a high-entropy material film of at least two layers and a non-high-entropy material film of at least one layer be stacked on each other. In addition, the multi-film structure can also be formed by making a first high-entropy material film of at least one layer and a second non-high-entropy material film of at least one layer be stacked on each other. This multi-film structure particularly contains interlaminar interfaces to inhibit crack extension and reduce plastic deformation, so that the hardness and toughness of the workpiece coated with this inventive multi-film structure would be obviously enhanced. Moreover, the appearance color of the workpiece can also be changed by the multi-film structure, wherein the color type is dependent on the optical interferences occurring in the multi-film structure.

Owner:HIGH ENTROPY MATERIALS INC

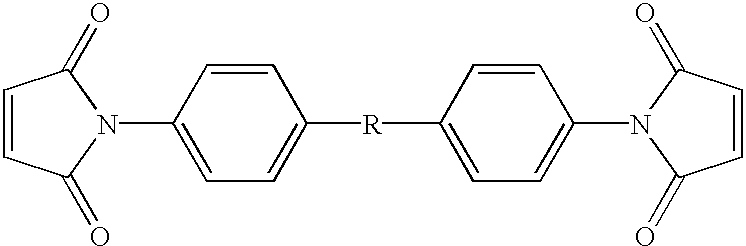

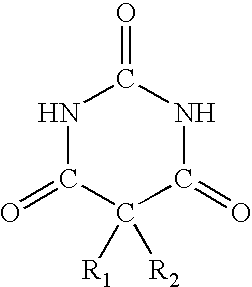

Photosensitive composition

InactiveUS6432613B1Improvement of resolution and adhesionReduce the amount requiredPhotosensitive materialsPhotomechanical apparatusResistAdduct

The present invention discloses a photo-sensitive composition, used as a solder resist or a photosensitive material for insulation layers in the production of printed circuit boards. The photo-sensitive composition comprises a prepolymer containing carboxylic groups and unsaturated vinyl groups; photoinitiator; unsaturated photo-monomer; and the reaction adduct of bismaleimide derivative, barbituric acid derivative and epoxy compounds. The obtained photosensitive composition exhibits high adhesion towards PI substrates, in addition, it can be developed with alkaline water. The photosensitive composition obtained in the invention is very useful in packaging substrates, such as P-BGA, T-BGA and F-CSP due to its high heat resistance and solder resistance.

Owner:IND TECH RES INST

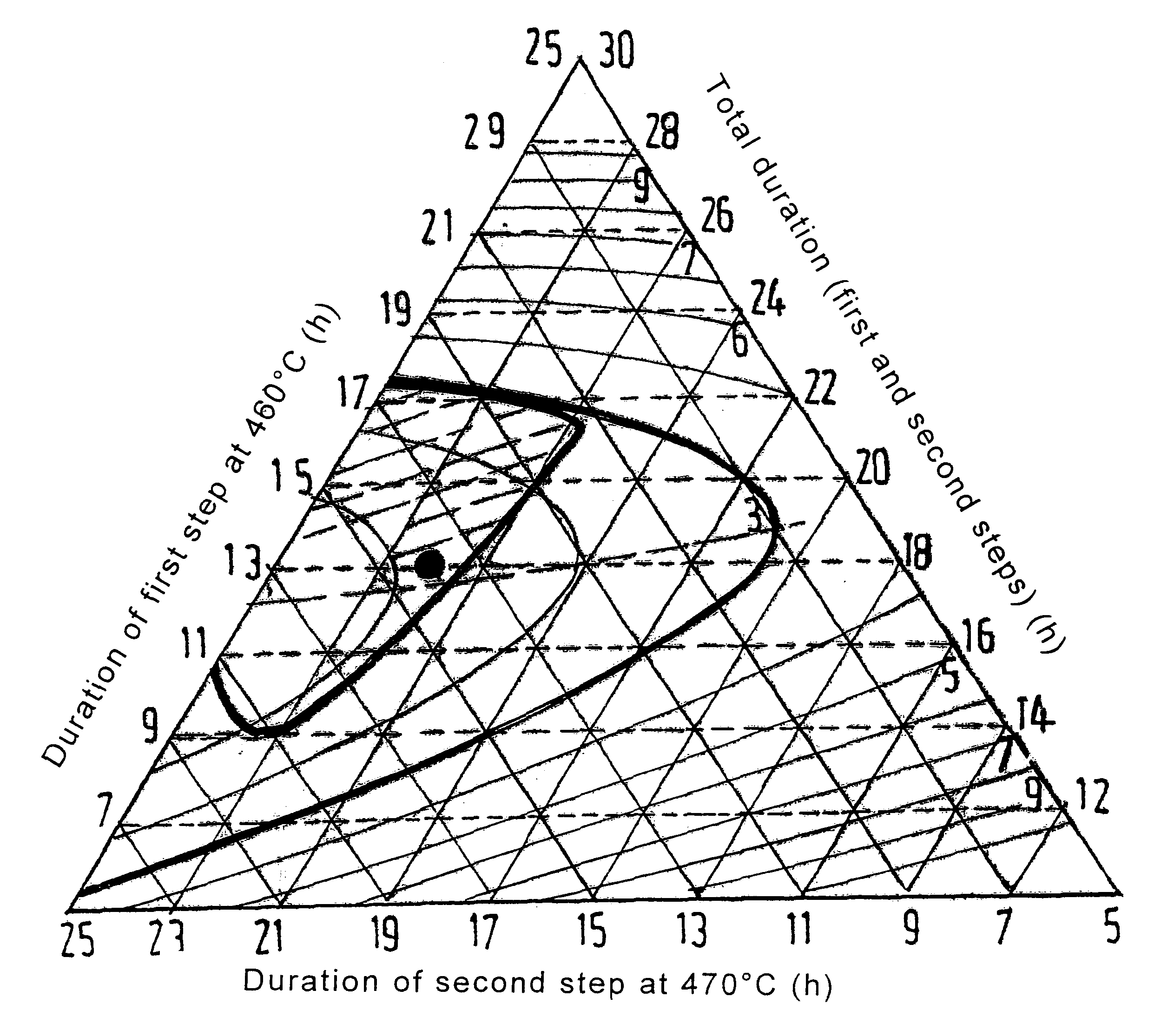

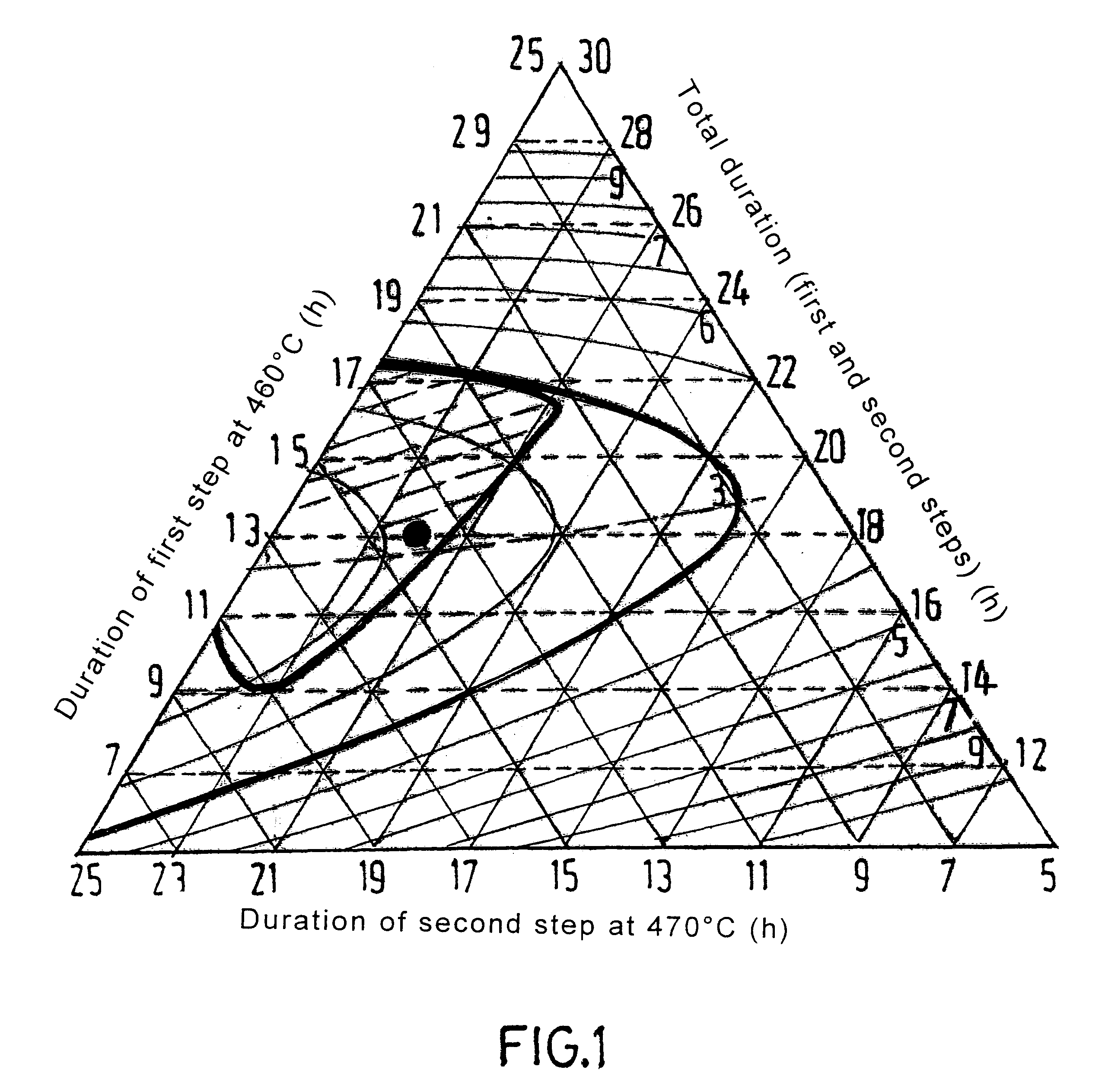

Manufacturing process for a hollow pressure vessel made of AlZnMgCu alloy

InactiveUS6565684B2Solution to short lifeHardness andMetal-working apparatusPressure vesselsSpecific energyHardness

A process for manufacturing a hollow pressure vessel, in which a billet is cast from an alloy with a composition in % by weight, Zn=6.25-8.0, Mg=1.2-2.2, Cu=1.7-2.8, Fe<0.20, Fe+Si<0.40, at least one of the elements selected from the group consisting of Cr, Zr, V, Hf and Sc in an amount of 0.05-0.3, and other elements <0.05 each and <0.15 total. The cast billet is homogenized with a temperature profile such that metal temperature is slightly less than incipient melting temperature at all times, cooled to ambient temperature and softening annealed for a duration of 20 to 40 h between 200 and 400° C. with cooling at a rate of less than 50° C. / h down to a temperature of below 100° C., resulting in a billet hardness <54 HB. A slug is cut out of the softened billet, cold or slightly warm extruded with an extrusion start temperature <300° C., to form a casing which is necked, solution heat treated at a temperature slightly below the incipient melting temperature, for a duration sufficient to obtain an absolute value of specific energy associated with a DTA thermogram signal of less than 3 J / g, quenched in cold water, and aged at between 100 and 200° C. for a duration between 5 and 25 h.

Owner:LUXFER GAS CYLINDERS

Method for handling a semiconductor wafer assembly

ActiveUS20140087499A1Increasing LED performanceDissipate more heatSemiconductor/solid-state device manufacturingNanoopticsEngineeringLight-emitting diode

Systems and methods for fabricating a light emitting diode include forming a multilayer epitaxial structure above a carrier substrate; depositing at least one metal layer above the multilayer epitaxial structure; removing the carrier substrate.

Owner:SEMILEDS OPTOELECTRONICS CO LTD

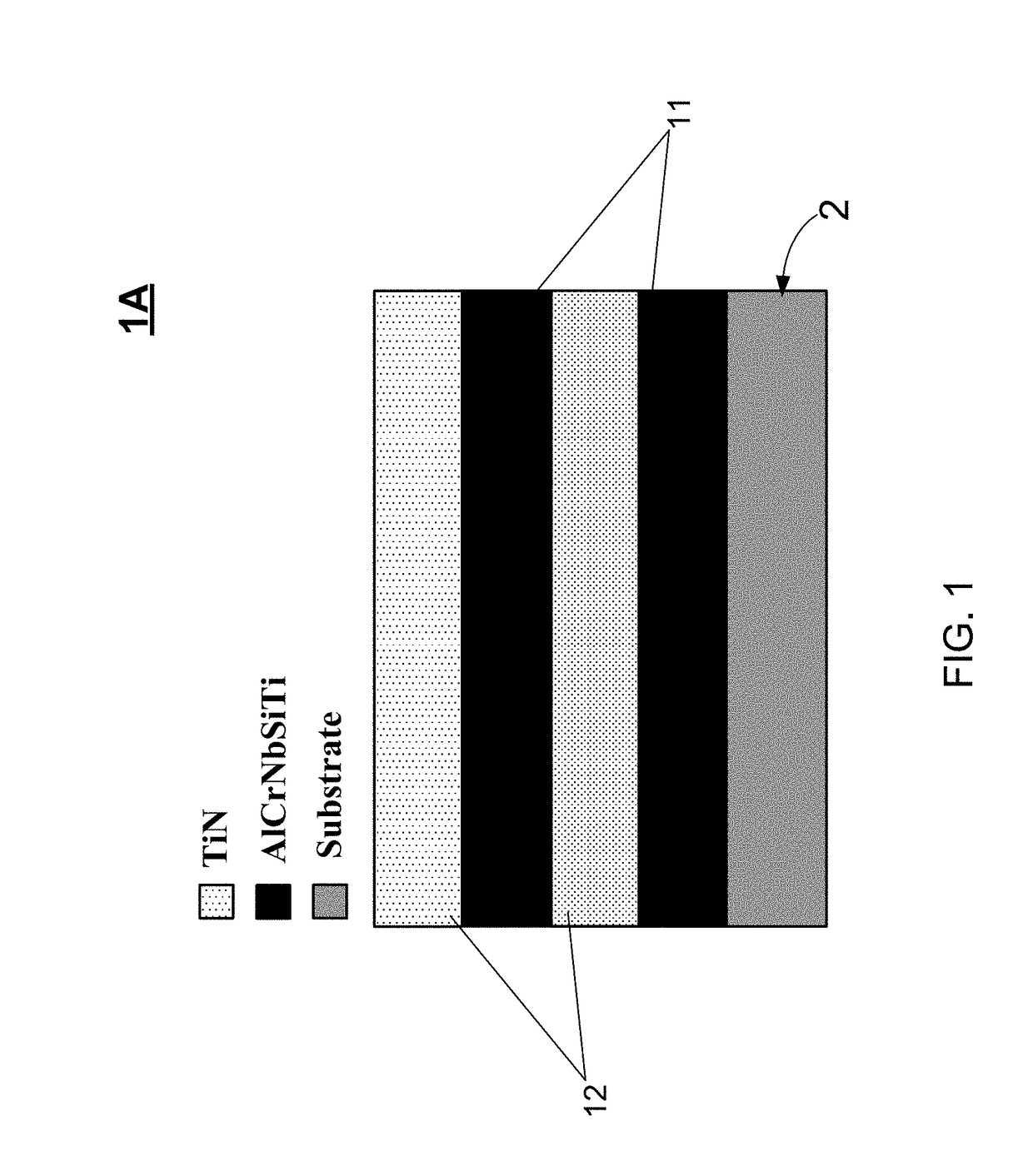

Tool with multi-layer arc pvd coating

ActiveUS20180223415A1Increase coating thicknessDisadvantageous effect on stabilityVacuum evaporation coatingSputtering coatingHard metalNitride

A tool includes a base body of hard metal, cermet, ceramics, steel or high speed steel and a multi-layer wear protection coating deposited thereon by a PVD process. The wear protection coating has a first coat deposited on the base body having a composition of TiaAl(1-a)N, wherein 0.4≤a≤0.6, and a coating thickness of 0.5 μm to 4 μm, and a second coat deposited on the first coat. The second coat includes a sequence of 10 to 80 first and second layers alternatingly arranged one on top of each other. Each of the first and second layers has a thickness of 5 to 100 nm. Each first layer includes nitrides of the elements Ti, Al, Cr and Si, and each second layer has a composition of TixAl(1-x)N, wherein 0.4≤x≤0.6. The first and second coats have up to 10 at-% of further metals, B, C and / or O as impurities in each layer.

Owner:WALTER AG

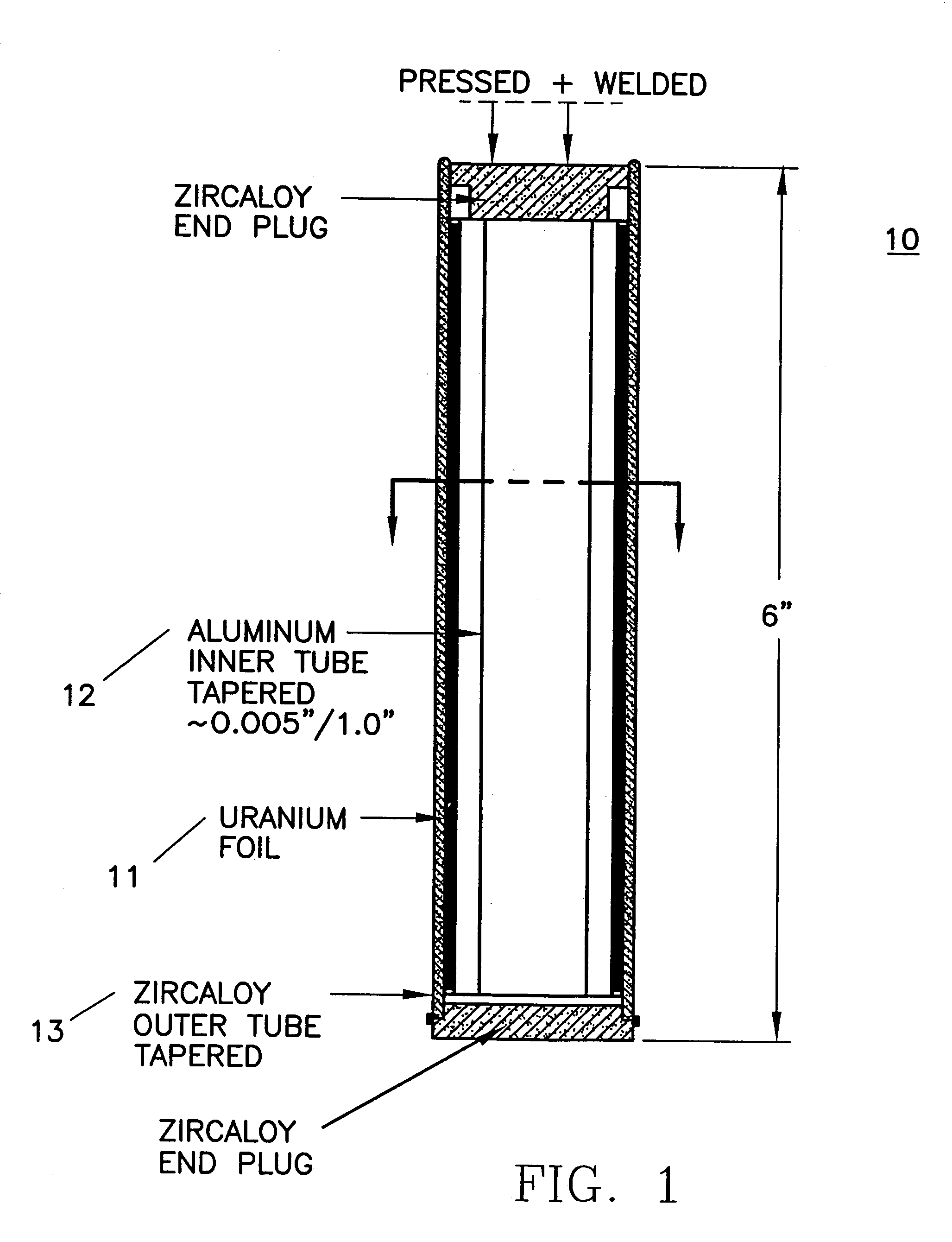

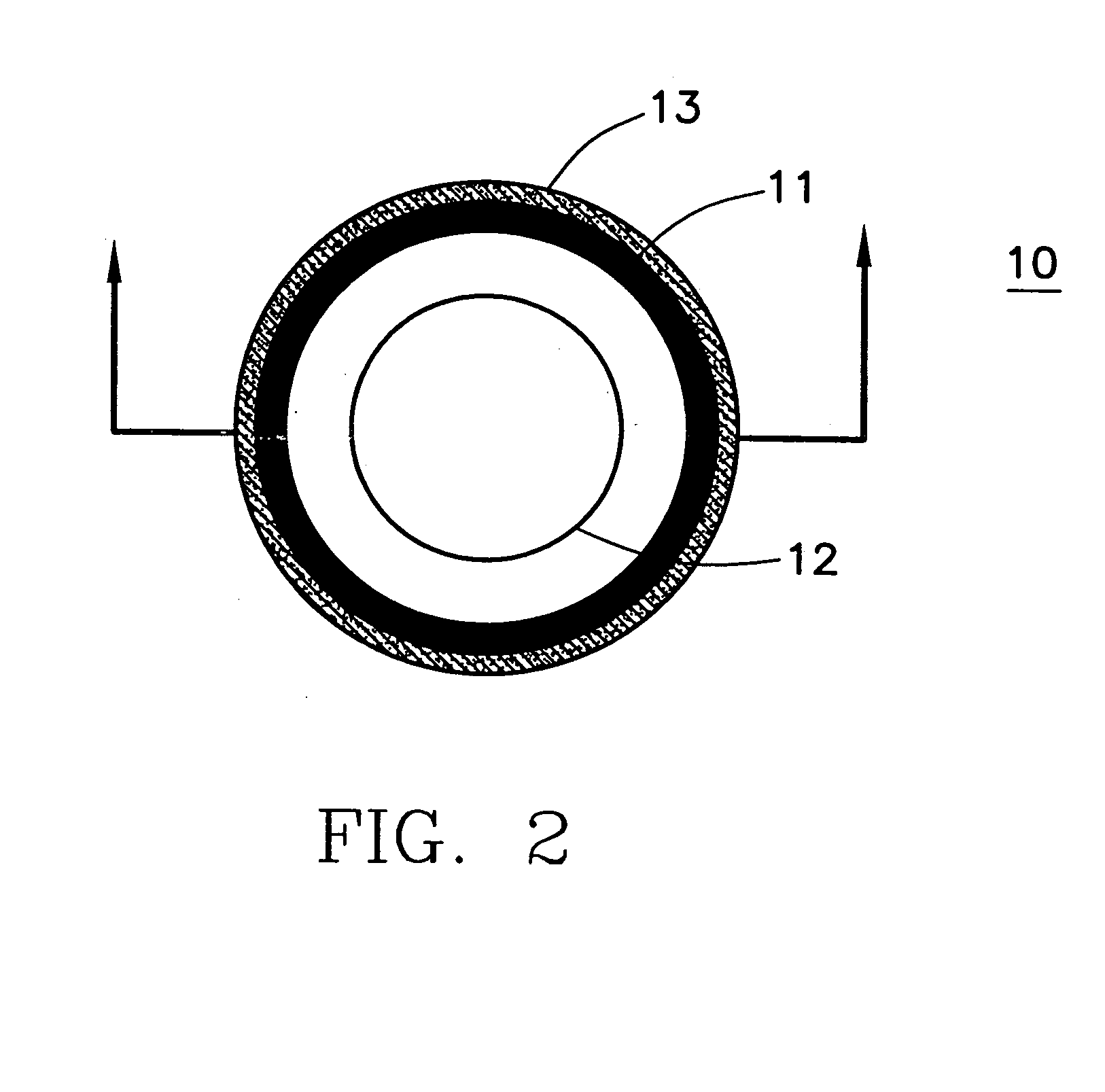

Method for fabricating uranium foils and uranium alloy foils

A method of producing thin foils of uranium or an alloy. The uranium or alloy is cast as a plate or sheet having a thickness less than about 5 mm and thereafter cold rolled in one or more passes at substantially ambient temperatures until the uranium or alloy thereof is in the shape of a foil having a thickness less than about 1.0 mm. The uranium alloy includes one or more of Zr, Nb, Mo, Cr, Fe, Si, Ni, Cu or Al.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

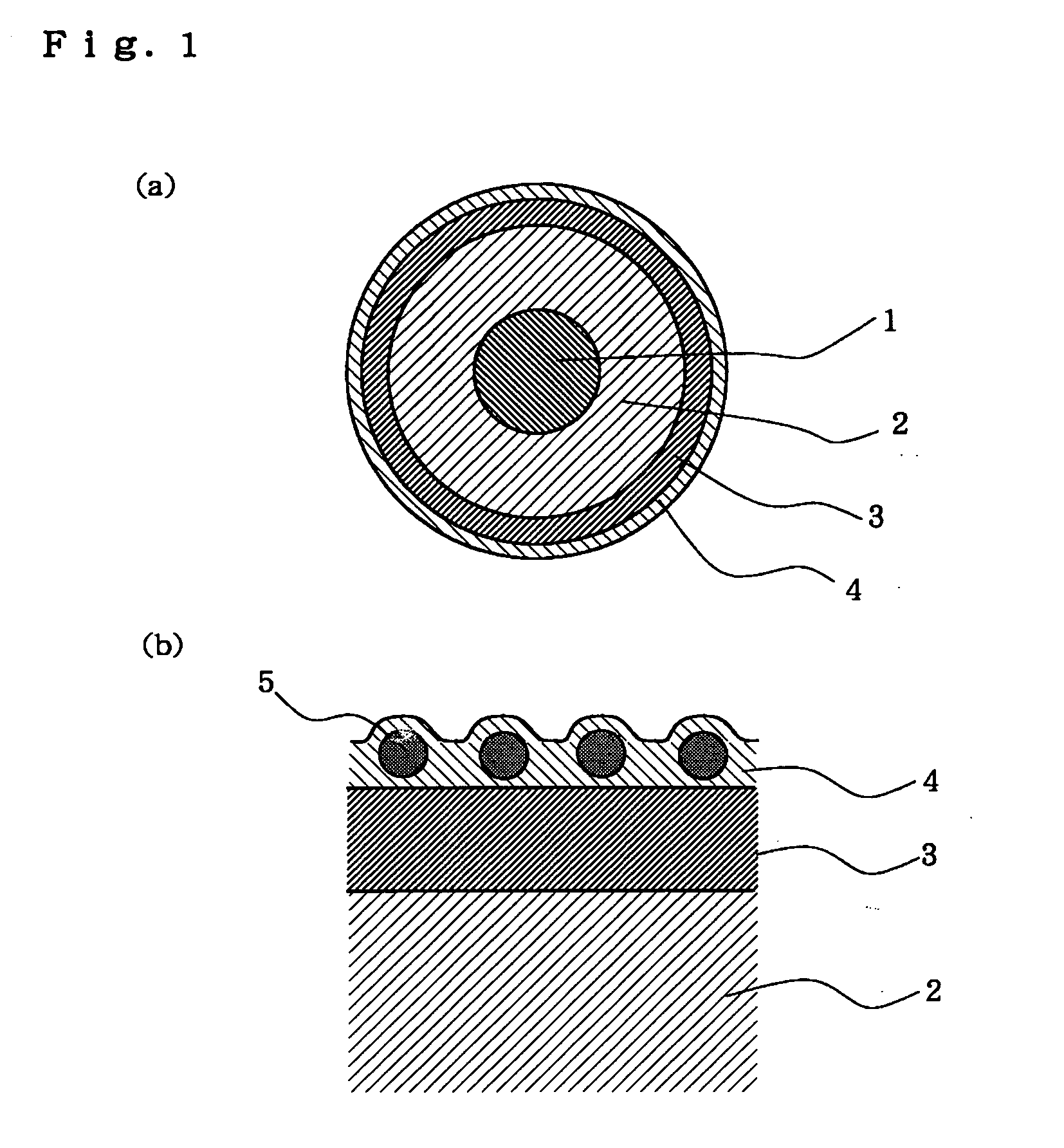

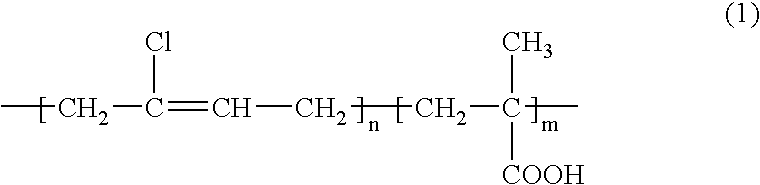

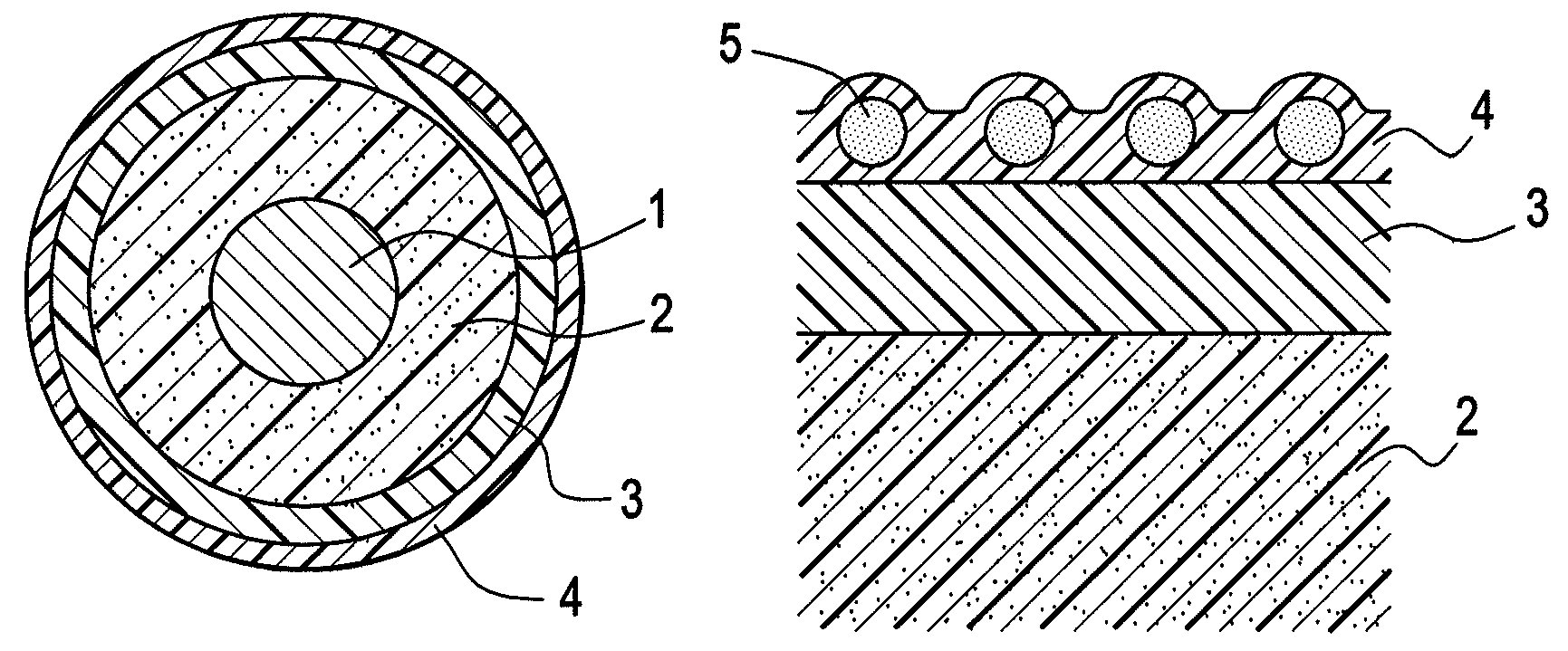

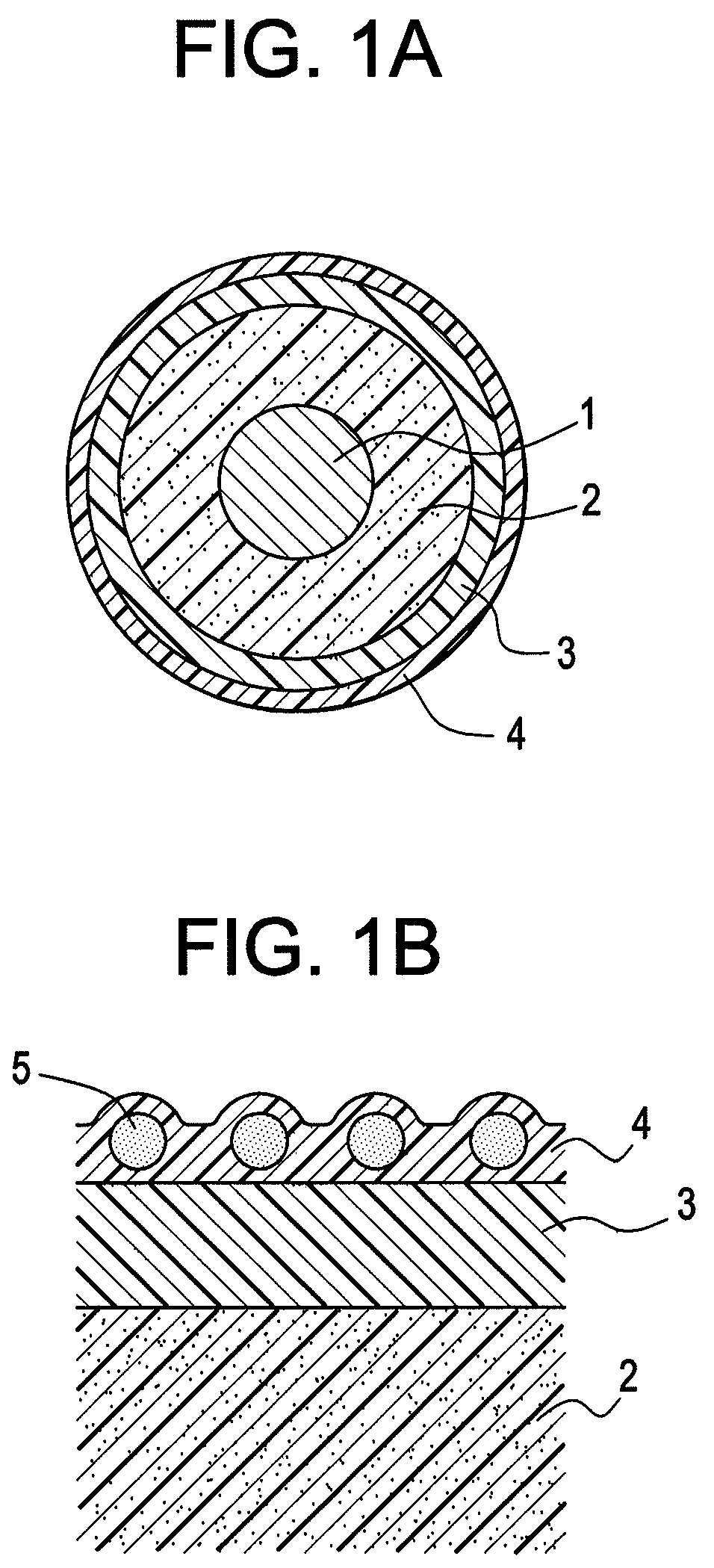

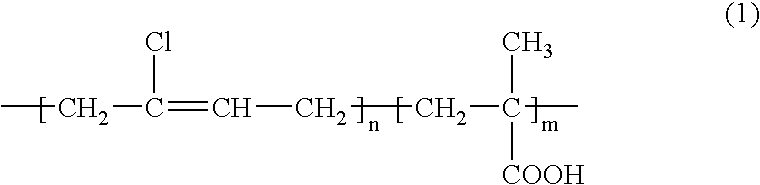

Development roller

InactiveUS20070003331A1Hardness can be ensuredAvoid roughnessLiquid surface applicatorsShaft and bearingsWater basedSurface roughness

A development roller is provided which can ensure a desired surface roughness and roller hardness even when an elastic layer has not sufficient solvent resistance and which can be preferably used for a long period of time without generating any peeling of a coating film during a continuous long operation. In the development roller, an underlying conductive layer having at least one sublayer and a surface resin layer are provided on the elastic layer in that order. The elastic layer is formed of a foam material having a closed cell structure, the underlying conductive layer is formed from a water-based paint containing a conductive agent, and one of the sublayers of the underlying conductive layer that is in contact with the elastic layer is at least primarily composed of a chloroprene-methacrylic acid copolymer.

Owner:BRIDGESTONE CORP

Development roller

InactiveUS7526239B2Hardness andLong-term useLiquid surface applicatorsShaft and bearingsWater basedSurface roughness

A development roller is provided which can ensure a desired surface roughness and roller hardness even when an elastic layer has not sufficient solvent resistance and which can be preferably used for a long period of time without generating any peeling of a coating film during a continuous long operation. In the development roller, an underlying conductive layer having at least one sublayer and a surface resin layer are provided on the elastic layer in that order. The elastic layer is formed of a foam material having a closed cell structure, the underlying conductive layer is formed from a water-based paint containing a conductive agent, and one of the sublayers of the underlying conductive layer that is in contact with the elastic layer is at least primarily composed of a chloroprene-methacrylic acid copolymer.

Owner:BRIDGESTONE CORP

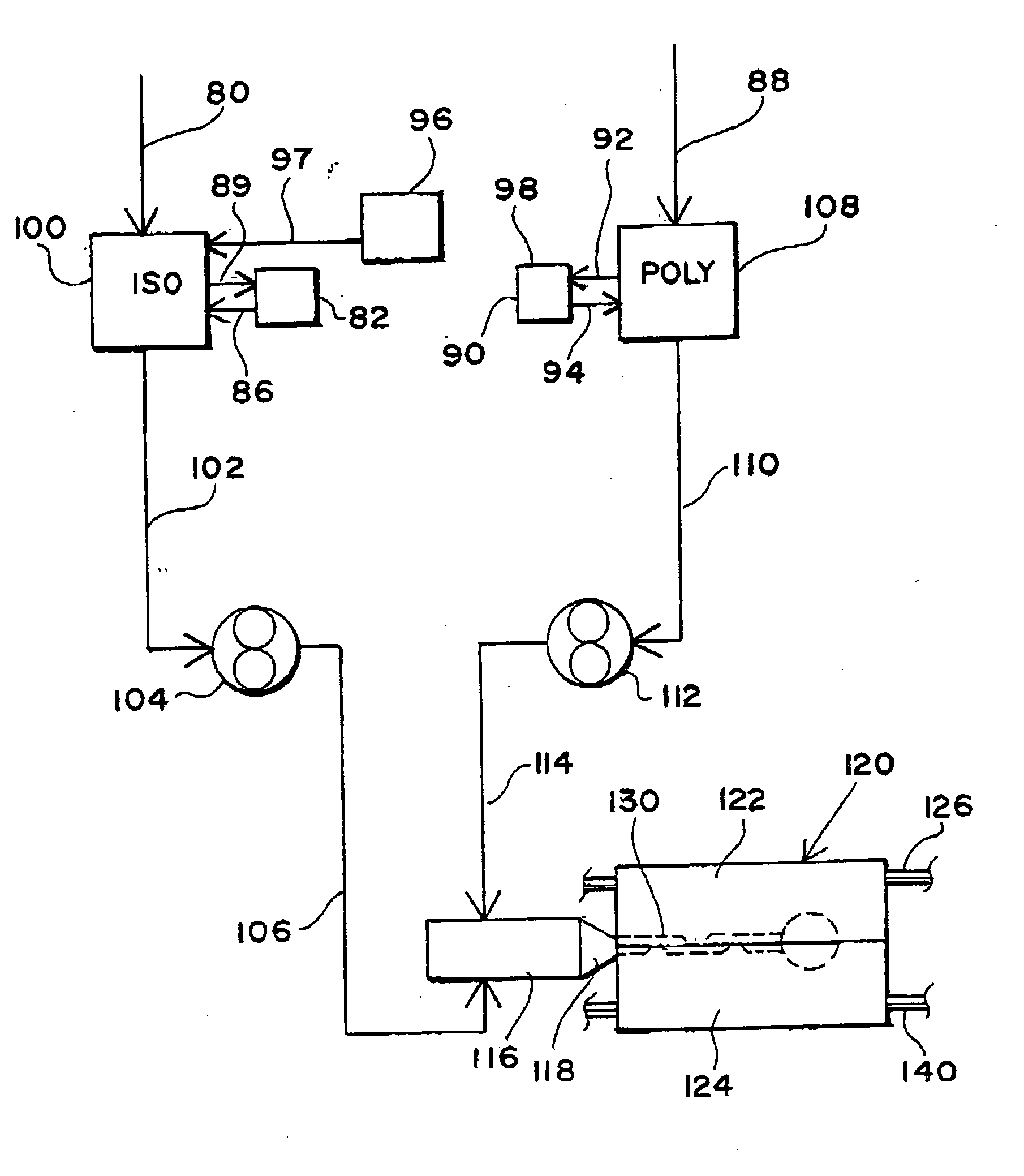

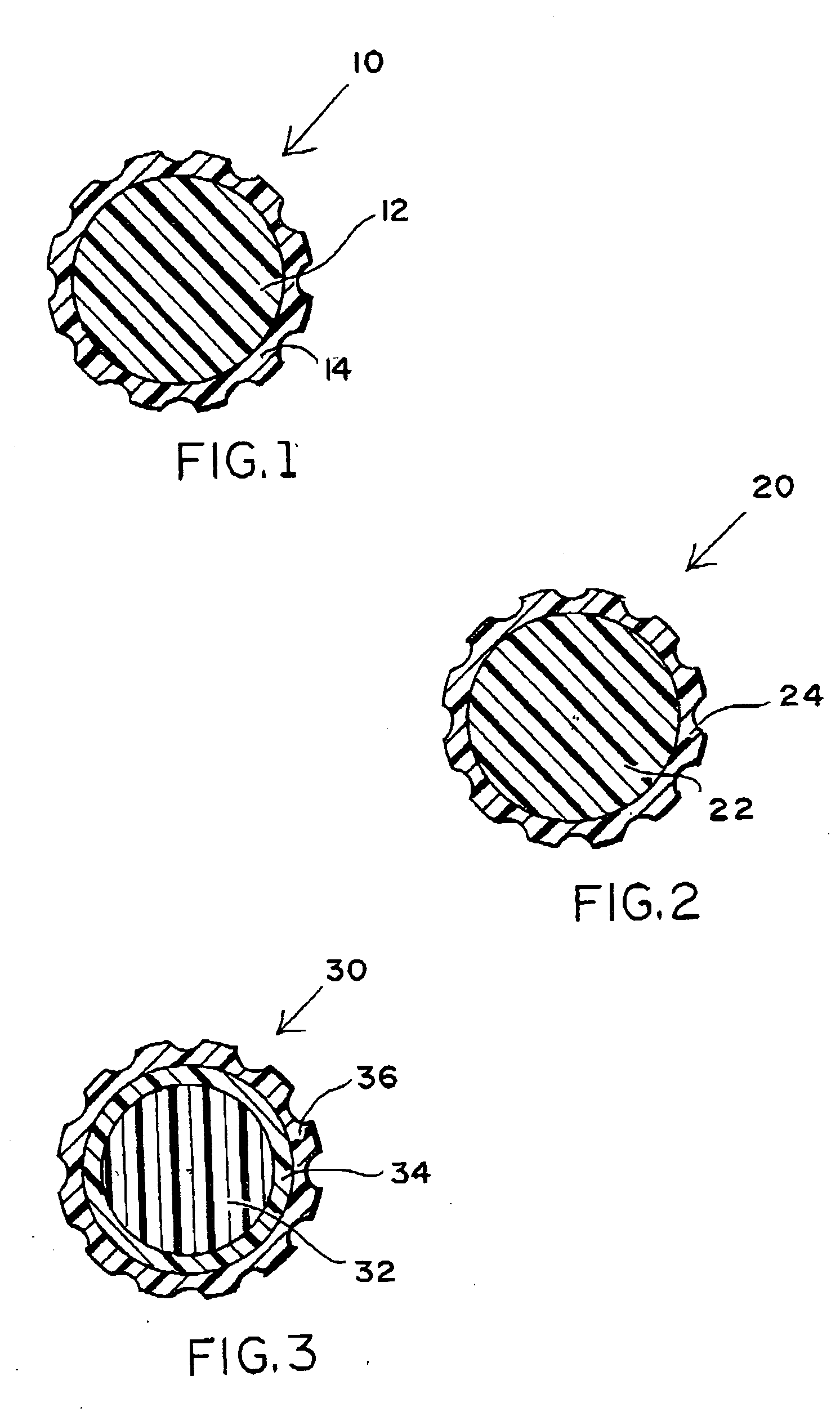

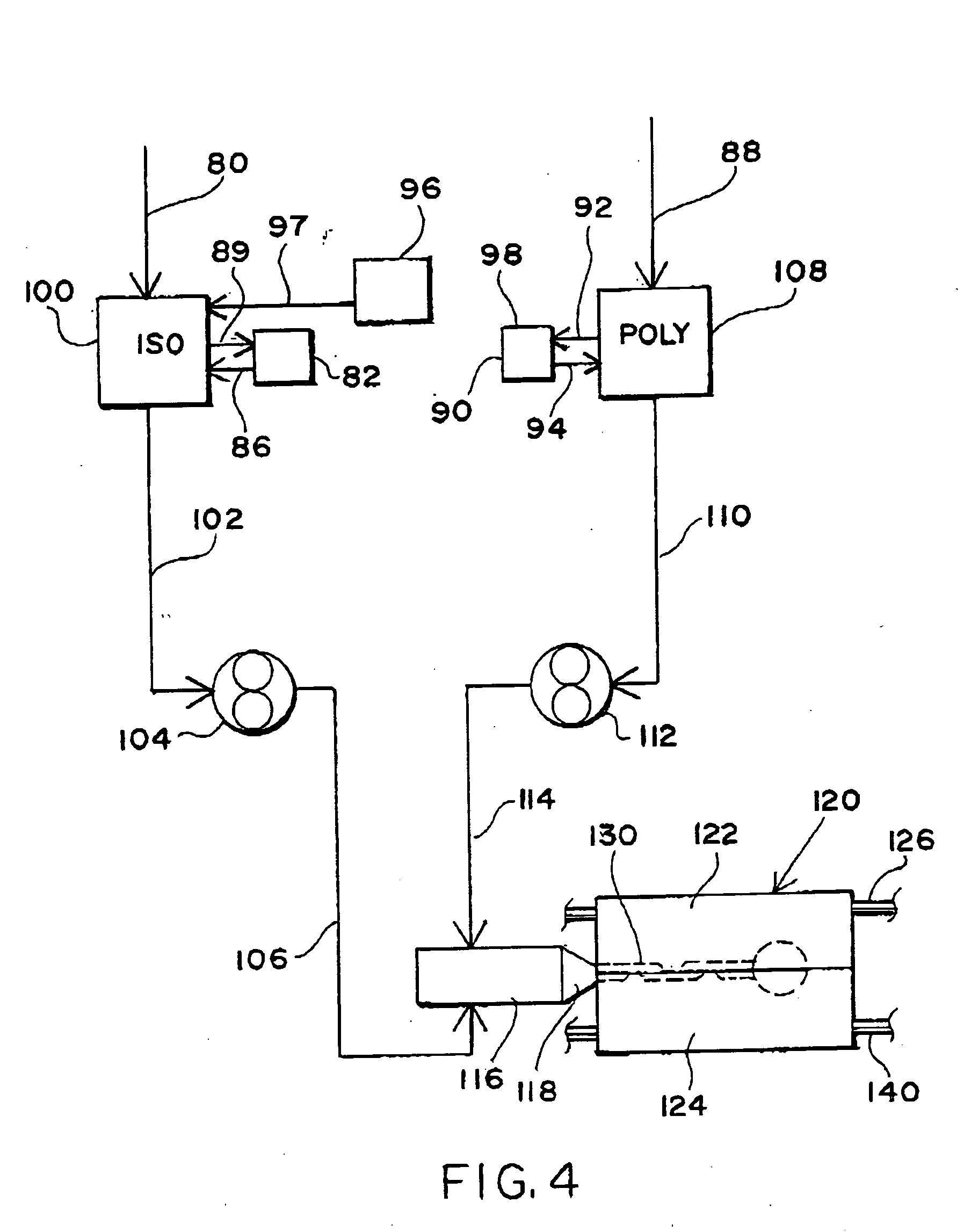

Golf ball which includes fast-chemical-reaction-produced component and method of making same

InactiveUS20050133960A1Maintain good propertiesLow viscosityGolf ballsSolid ballsPolymer scienceChemical reaction

Disclosed herein is a golf ball comprising fast-chemical-reaction-produced component, such as a component which comprises a reaction injection molded polyurethane material. A process of making a golf ball by forming at least one core and / or cover component of the ball by mixing two or more reactants that react and form a reaction product with a flex modulus of 5-310 kpsi in a reaction time of about 5 minutes or less, the component having a thickness of at least 0.01 inches and a demold time of 10 minutes or less is disclosed. In one preferred form of the invention, excess polyurethane from forming golf ball covers is recycled by using it to form golf ball cores.

Owner:KELLER VIKTOR +2

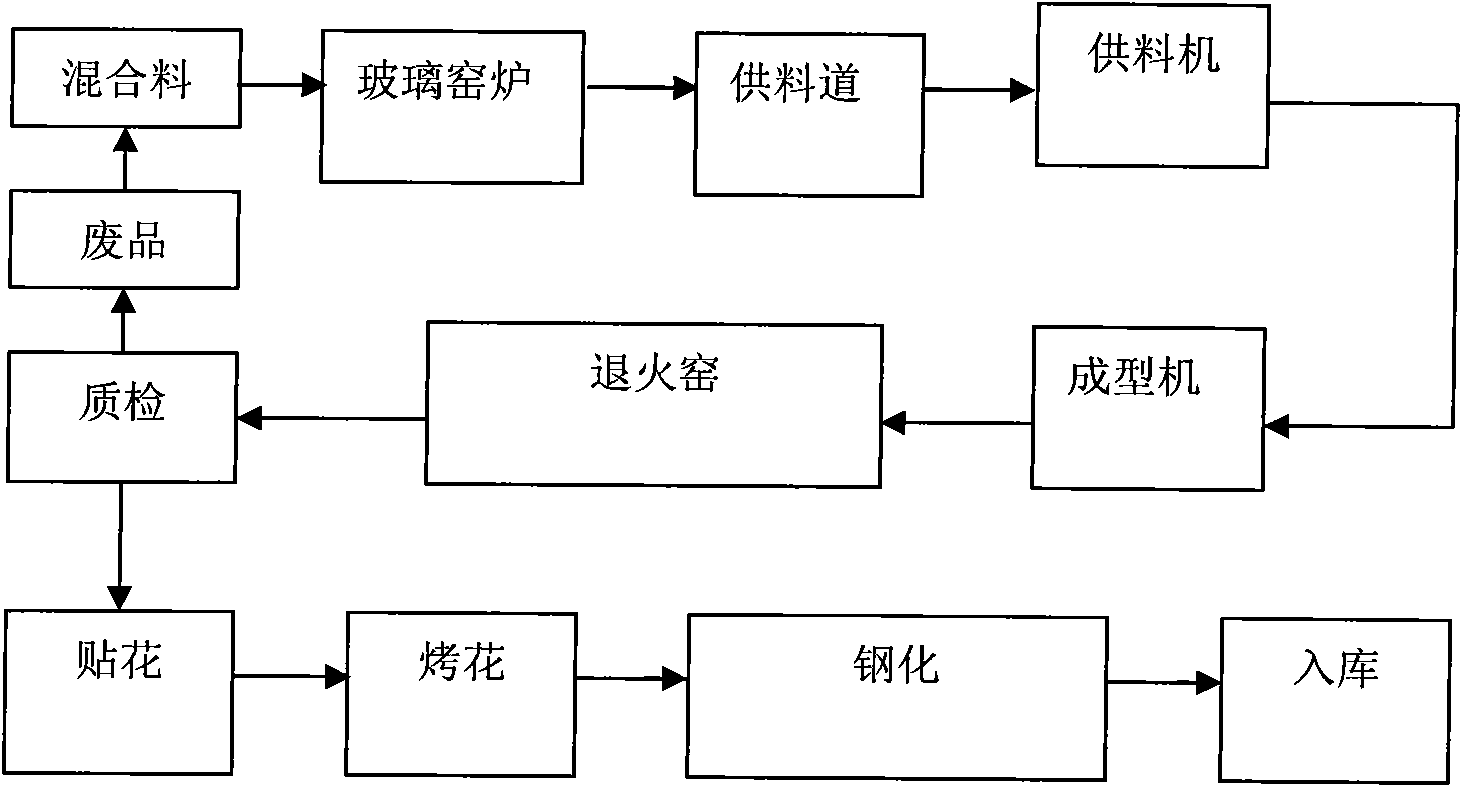

Glass ceramic and preparation method thereof

The invention relates to a glass ceramic and a preparation method thereof, comprising the following raw materials by weight parts: 75-100 weight parts of quartz sands, 10-30 weight parts of lithium feldspar, 30-60 weight parts of feldspar, 25-45 weight parts of sodium carbonate, 2-8 weight parts of sodium nitrate, 2-6 weight parts of barium carbonate, 5-15 weight parts of fluorite powders, 5-10 weight parts of borax, 10-30 weight parts of sodium fluosilicate and 10-20 weight parts of calcite; the method comprises the following steps of: mixing the raw materials and sending the mixture in a glass furnace; melting the mixture as glass melt at the temperature of 1400-1600 DEG C; sending the glass melt into a material supply machine by a material supply passage; sending the glass melt into a forming machine for forming by the material supply machine; sending the formed product into an annealing furnace for annealing; subsequently inspecting the quality of the annealed product; returning the unqualified product to the raw material; and conducting the operations of applique, enamel firing and steeling to the qualified product so as to prepare the finished products. Compared with the prior art, the method has the advantages of low expansion heat-resistance performance, high hardness, being not easy to be scraped or cracked, environmental protection and the like.

Owner:JINGDEZHEN COKING IND GRP CO LTD

Sinter-hardening powder and their sintered compacts

InactiveUS20090142219A1Improve ductilityImprove production yieldTransportation and packagingMetal-working apparatusHigh densityGranularity

A sinter-hardening powder can yield a sintered compact with high strength, high hardness, and high density. A raw powder for sintering includes Fe as its primary component and also comprising 0.1-0.8 wt % C, 5.0-12.0 wt % Ni, 0.1-2.0 wt % Cr, and 0.1-2.0 wt % Mo, wherein the mean particle size of the raw powder for sintering is 20 μm or less. The sintered and tempered compact, without any quenching treatment, has high hardness, high strength, high density, and good ductility.

Owner:TAIWAN POWDER TECH CO LTD

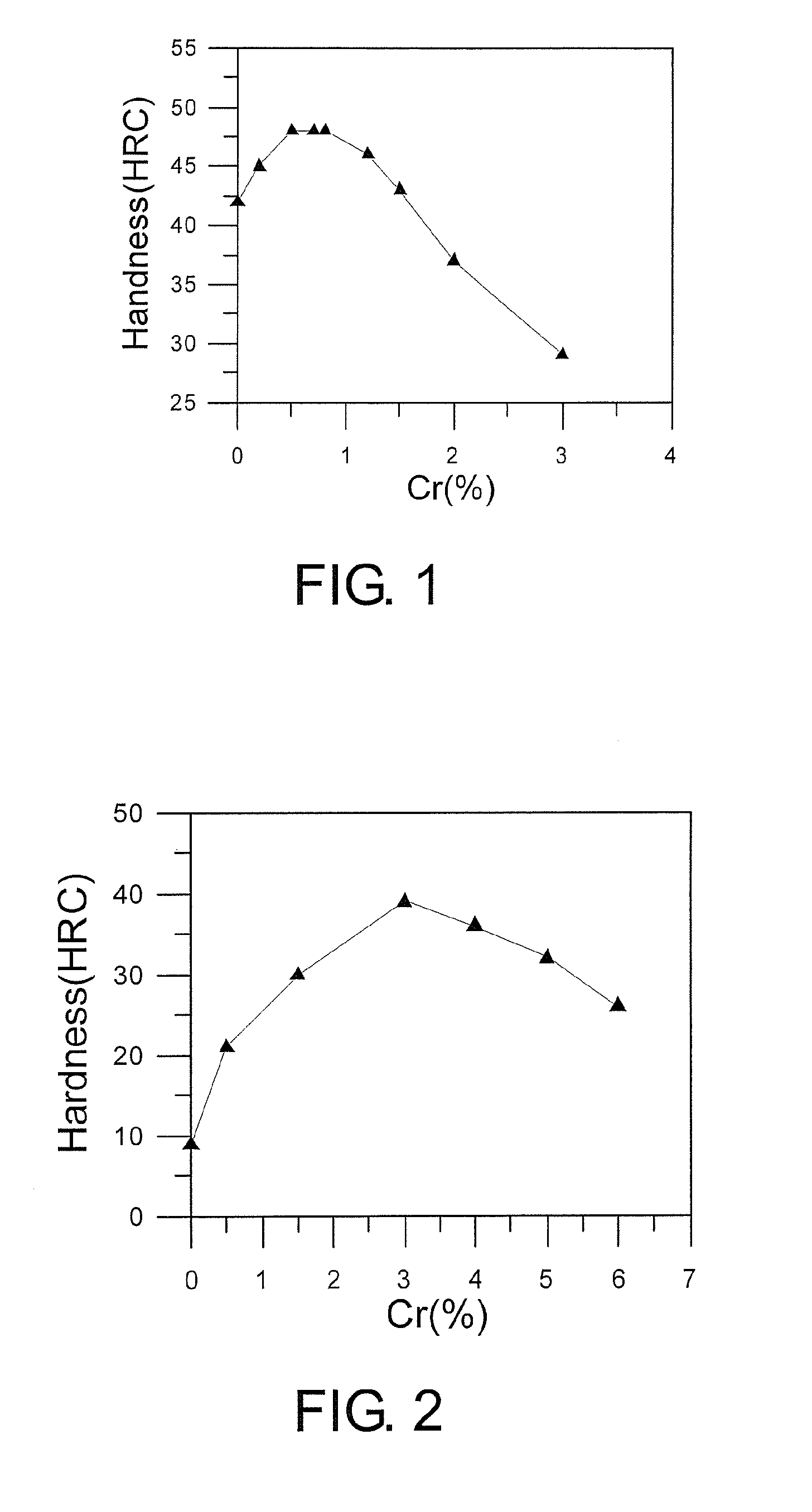

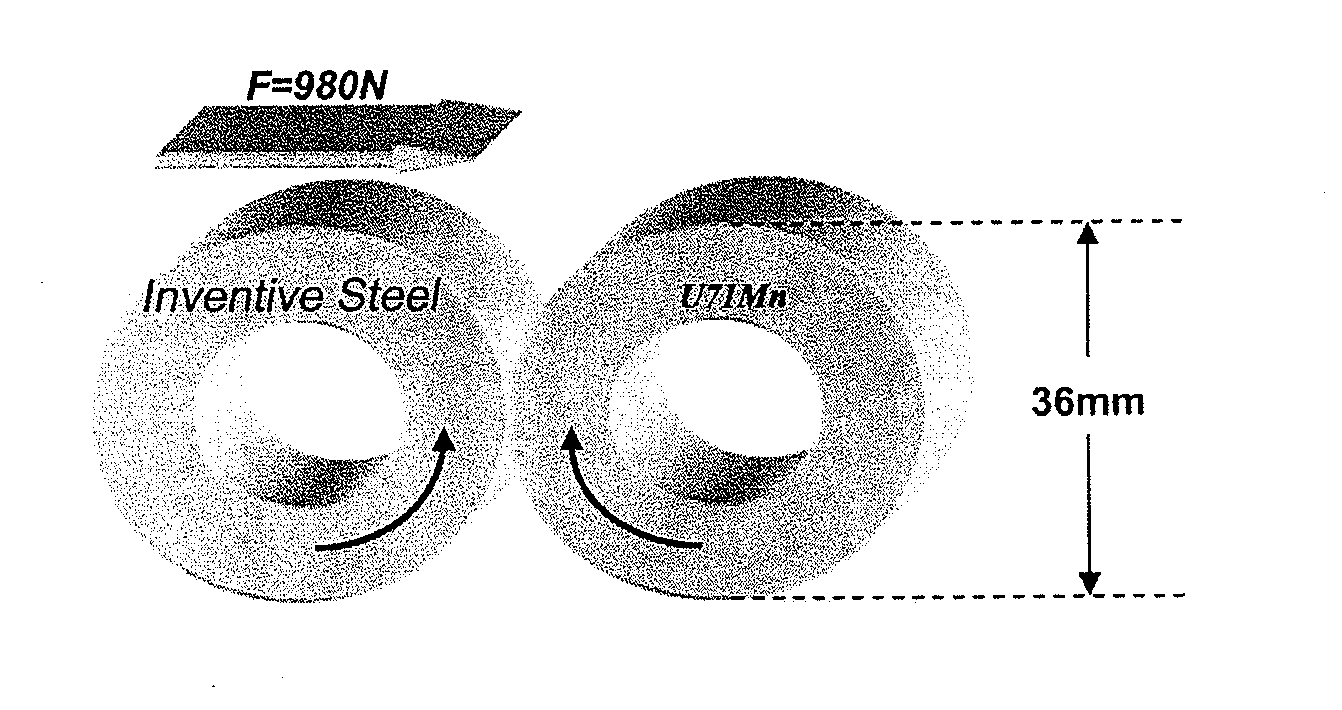

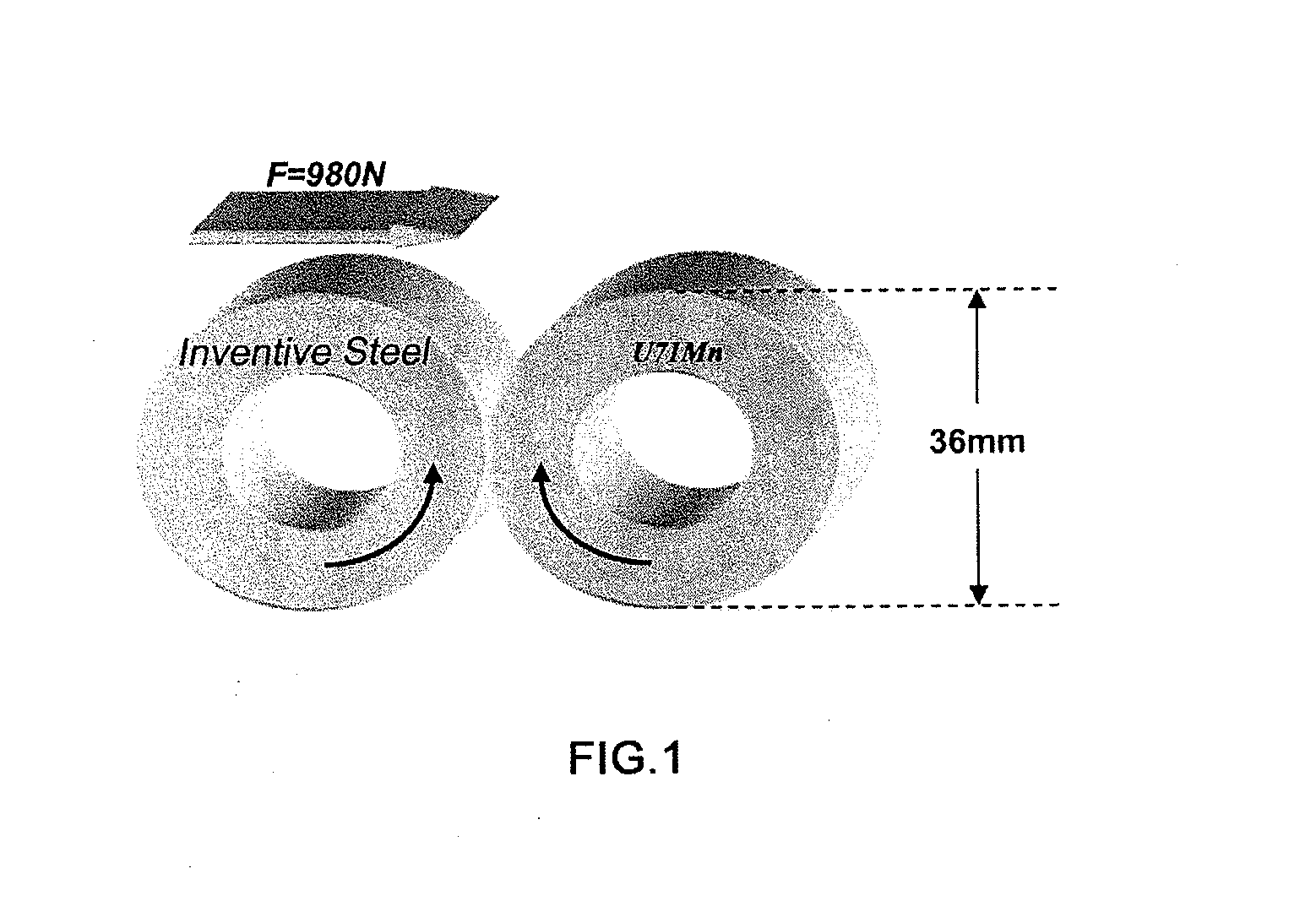

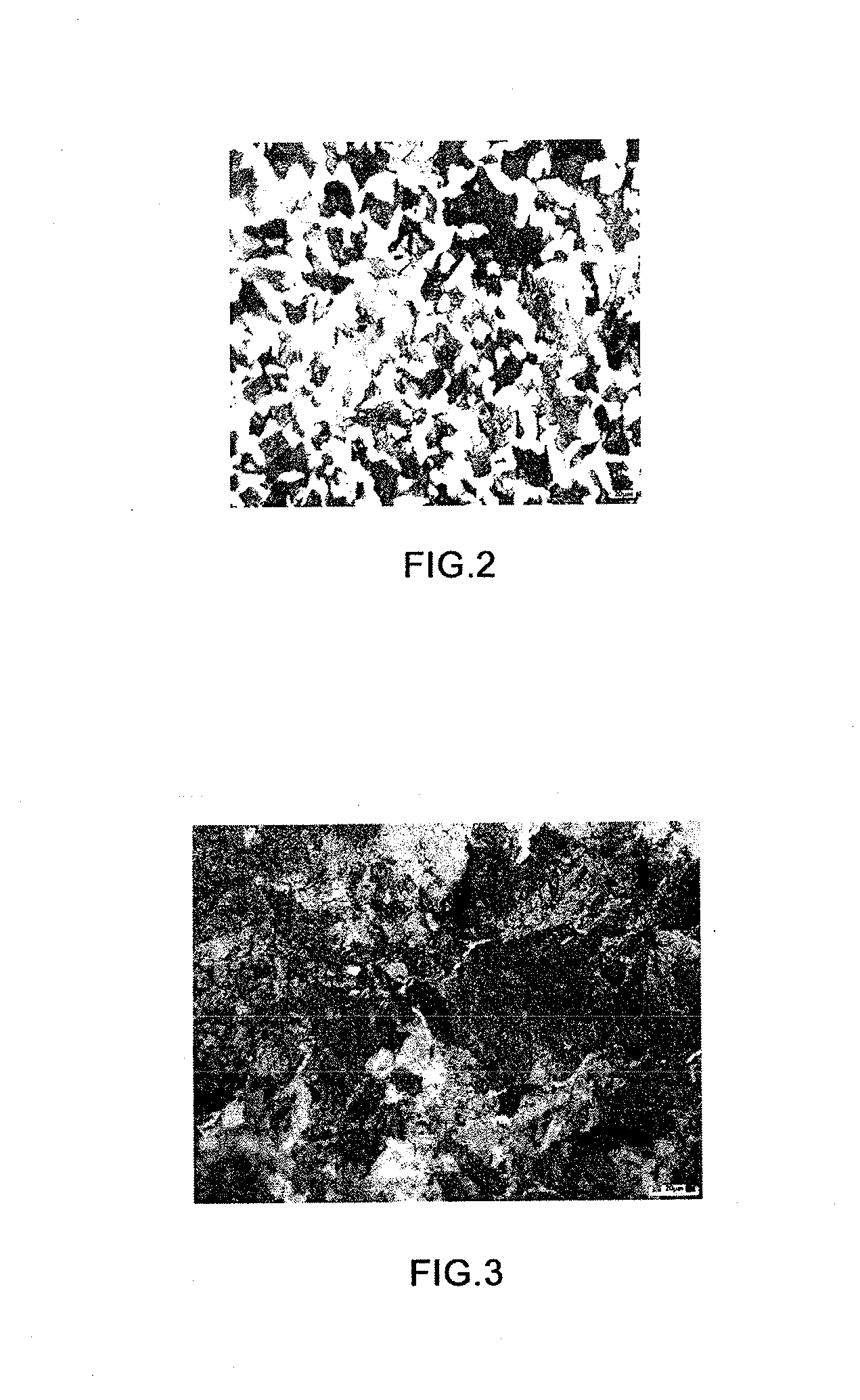

Heat treatment method of turnout track and the turnout track

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

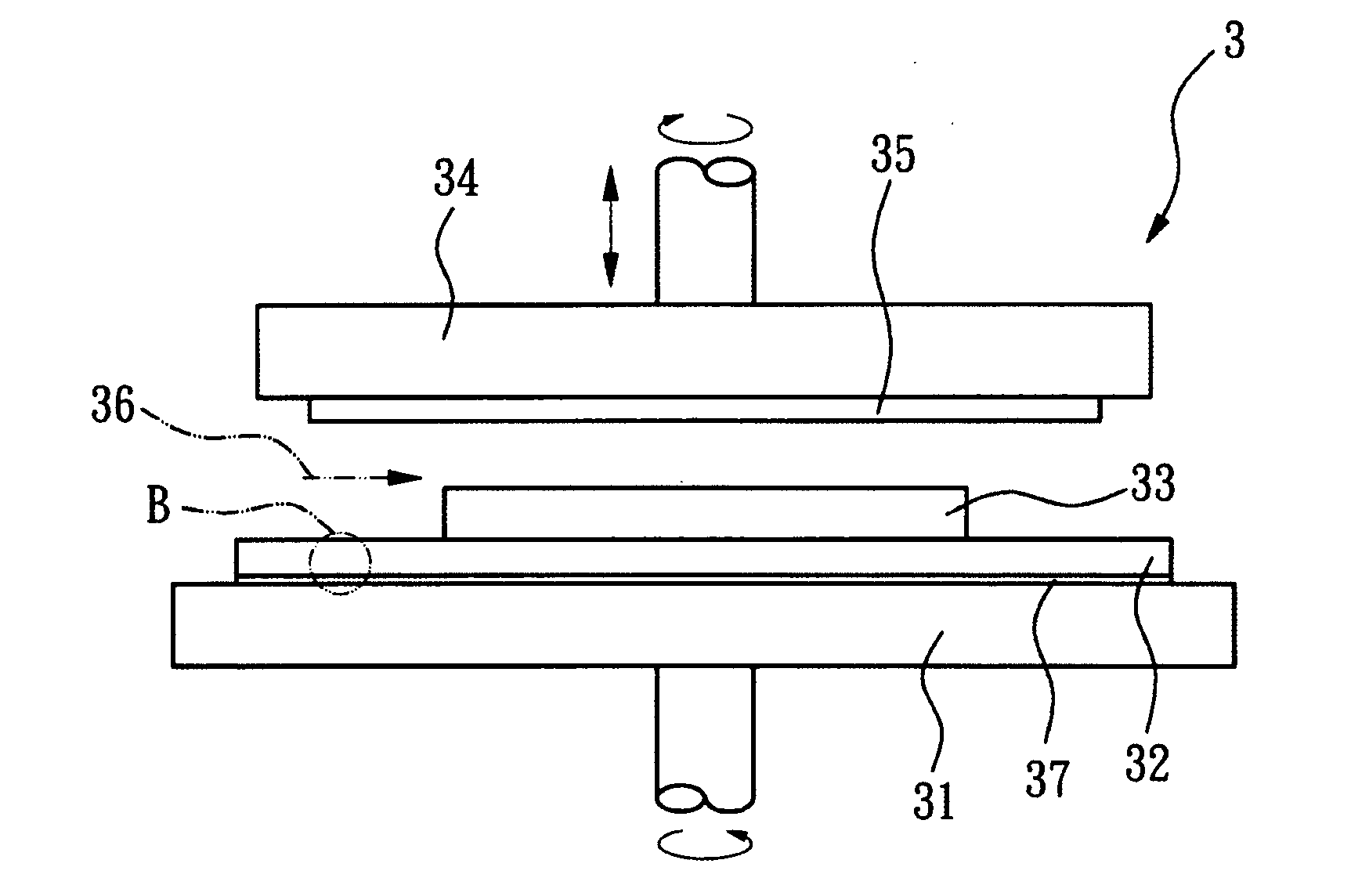

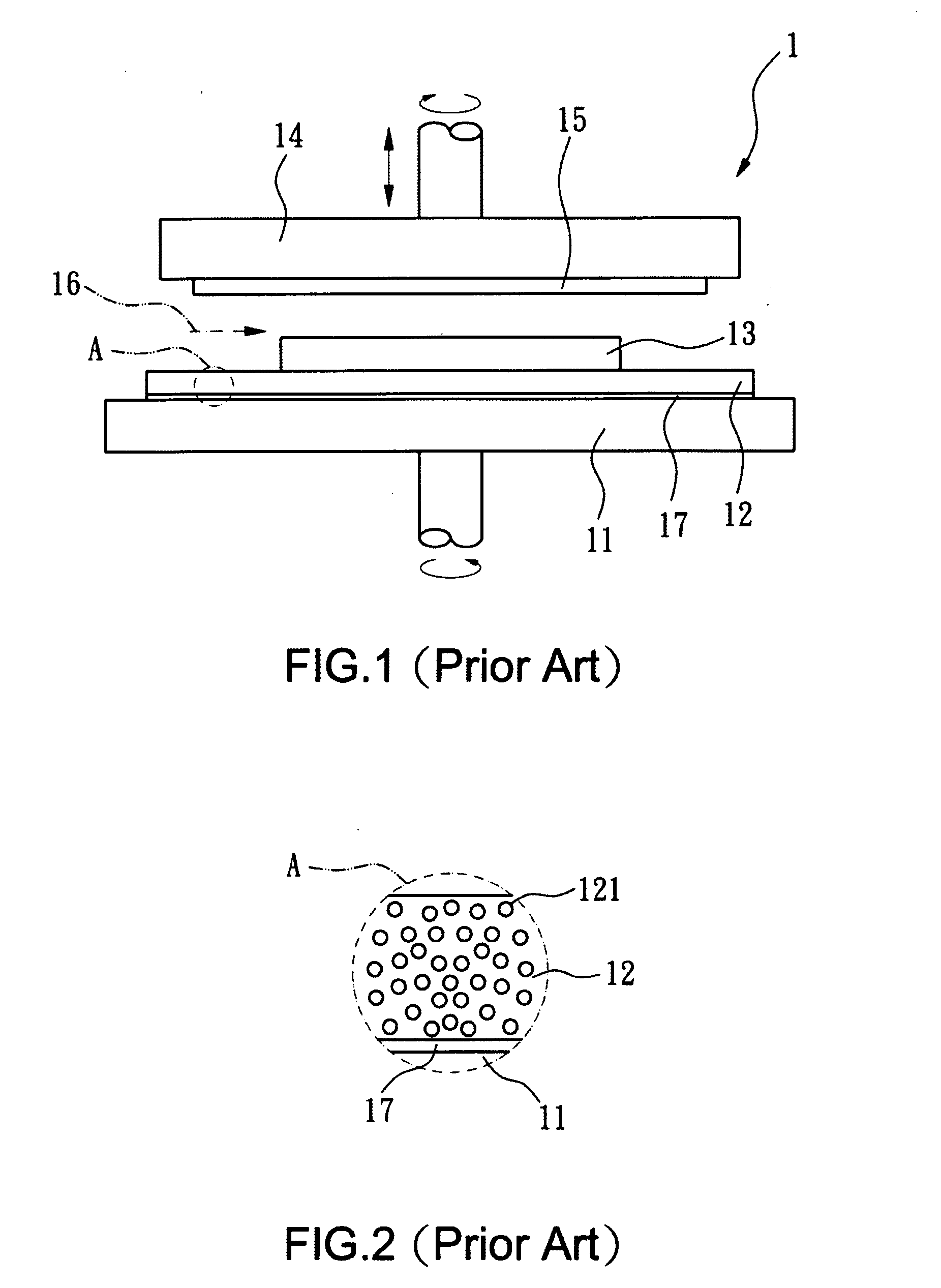

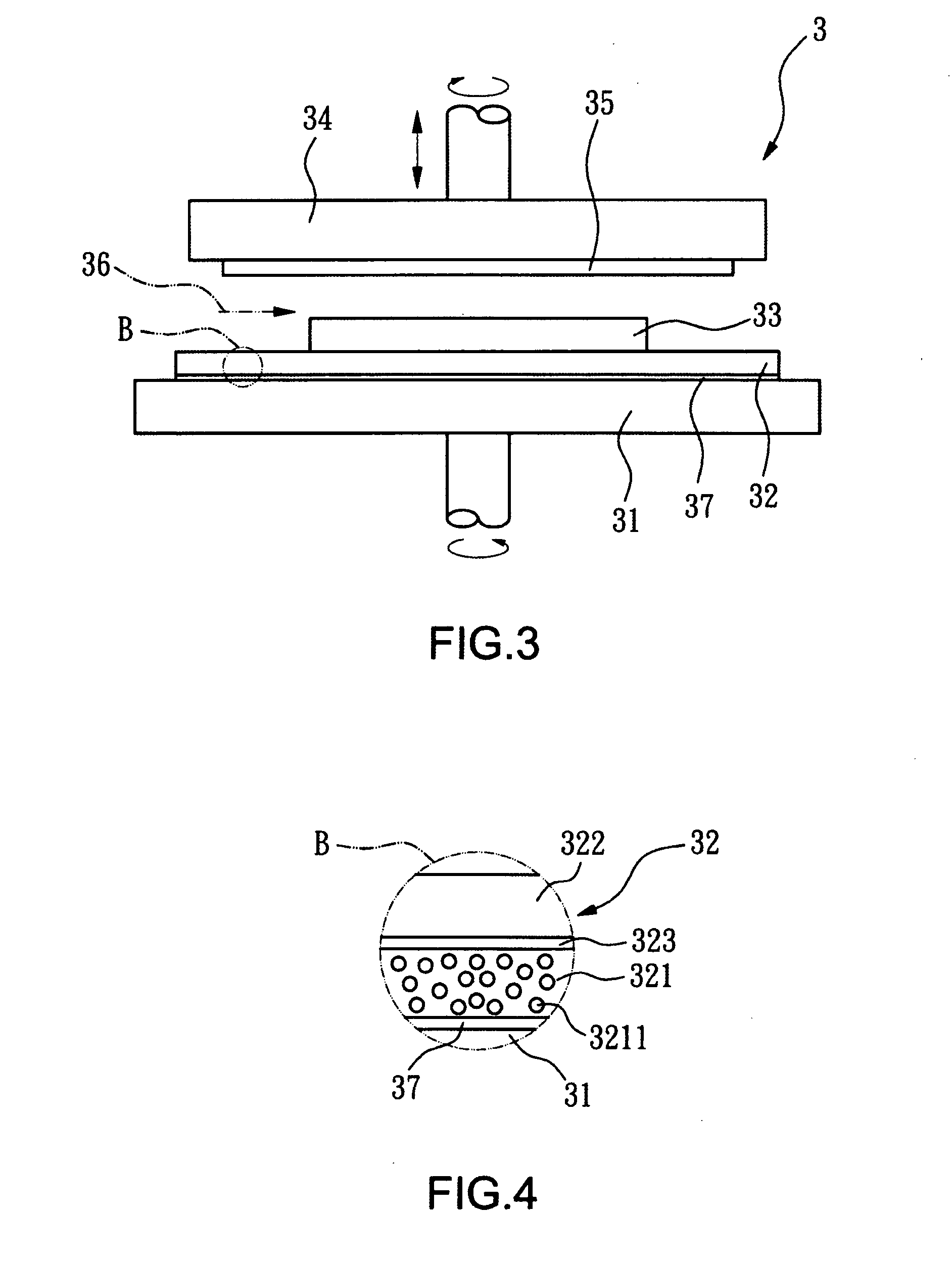

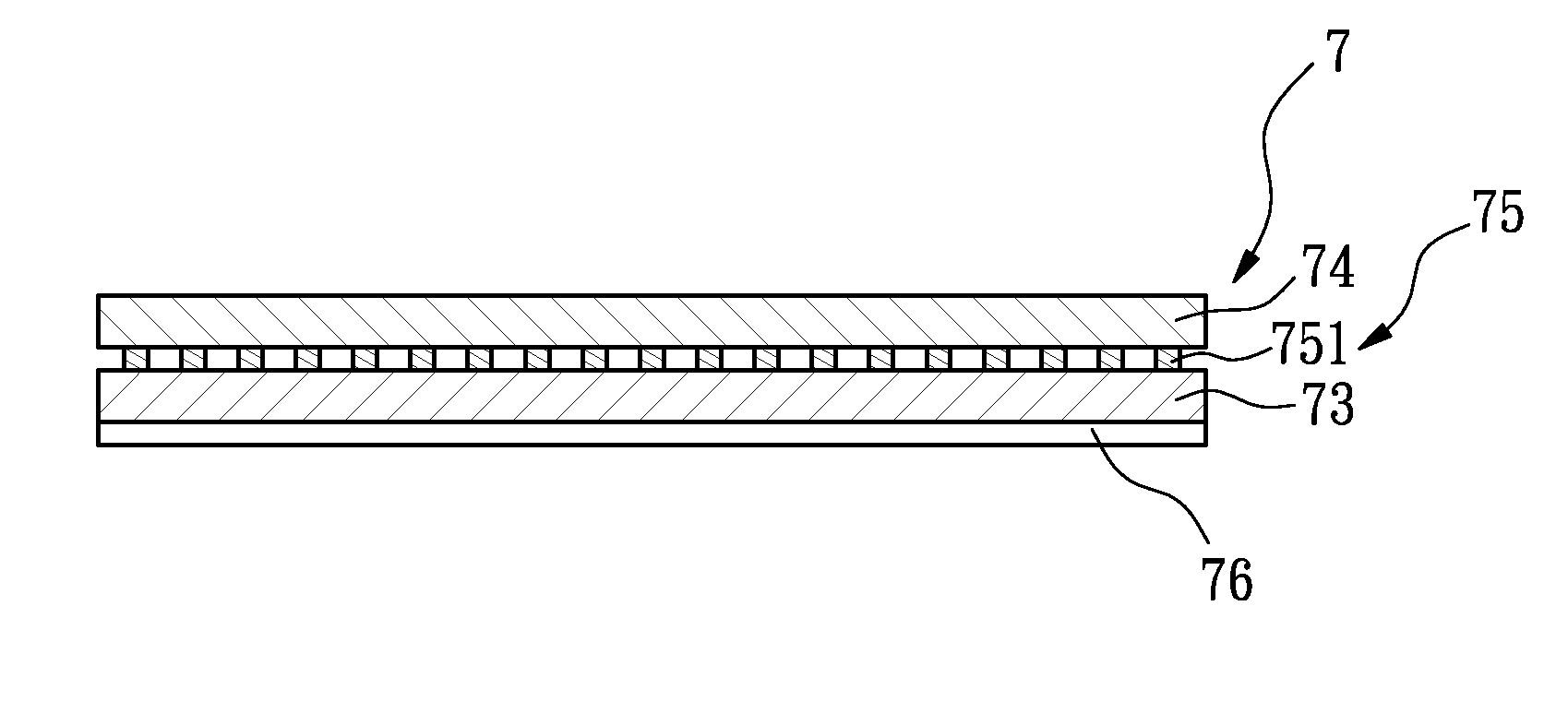

Composite sheet for mounting a workpiece and the method for making the same

InactiveUS20080268223A1Increase the compression ratioEasy to adjustPolishing machinesRevolution surface grinding machinesHardnessEngineering

The present invention relates to a composite sheet for mounting a workpiece and a method for making the same. The composite sheet includes a buffer layer and an adsorption layer. The buffer layer has a plurality of continuous pores. The adsorption layer is located on the buffer layer for adsorbing a workpiece, and the compression ratio of the buffer layer is higher than that of the adsorption layer. Thereby, due to low hardness, good adsorption effect, and high compression ratio, the composite sheet of the present invention has good buffer effect.

Owner:SAN FANG CHEM IND

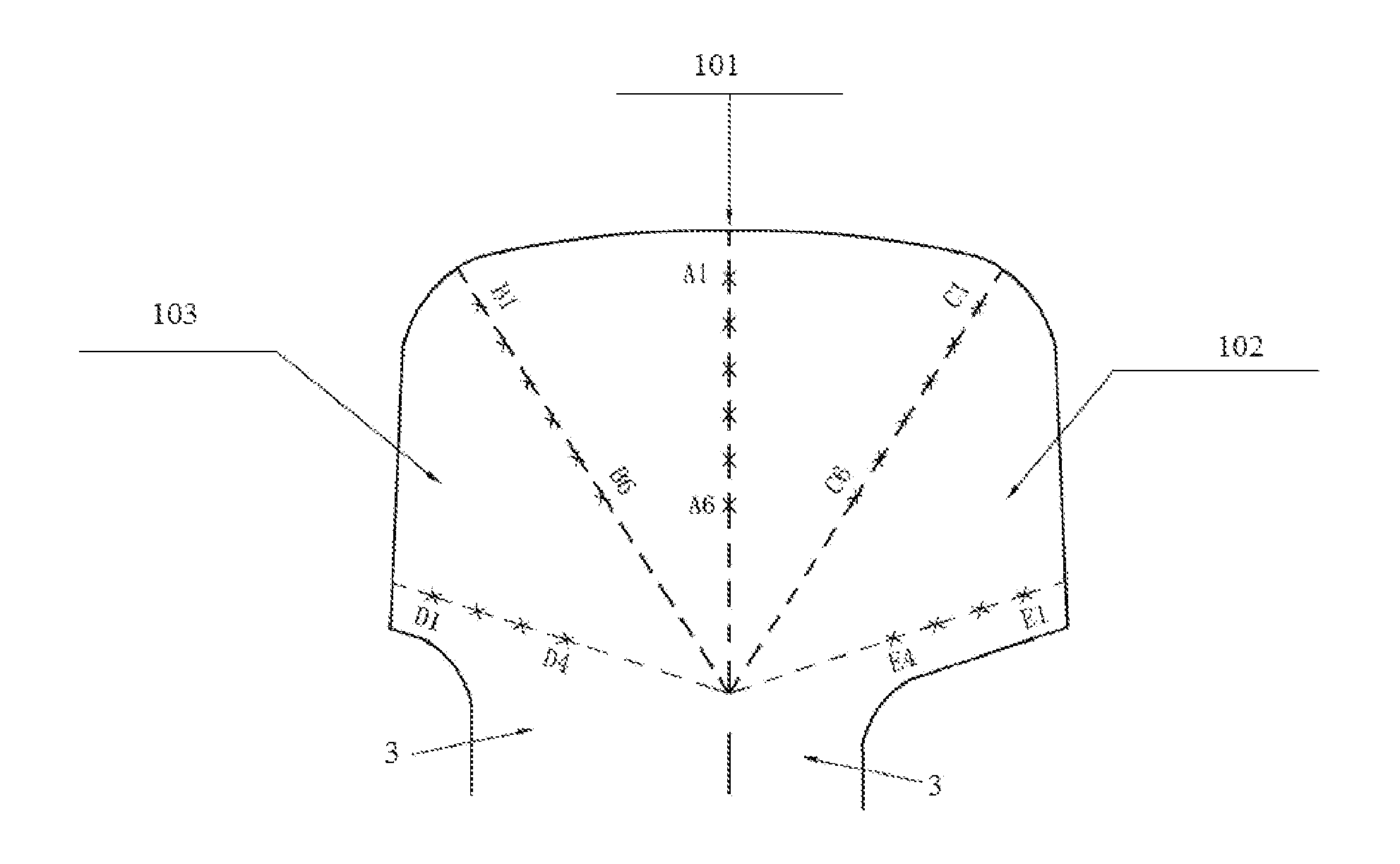

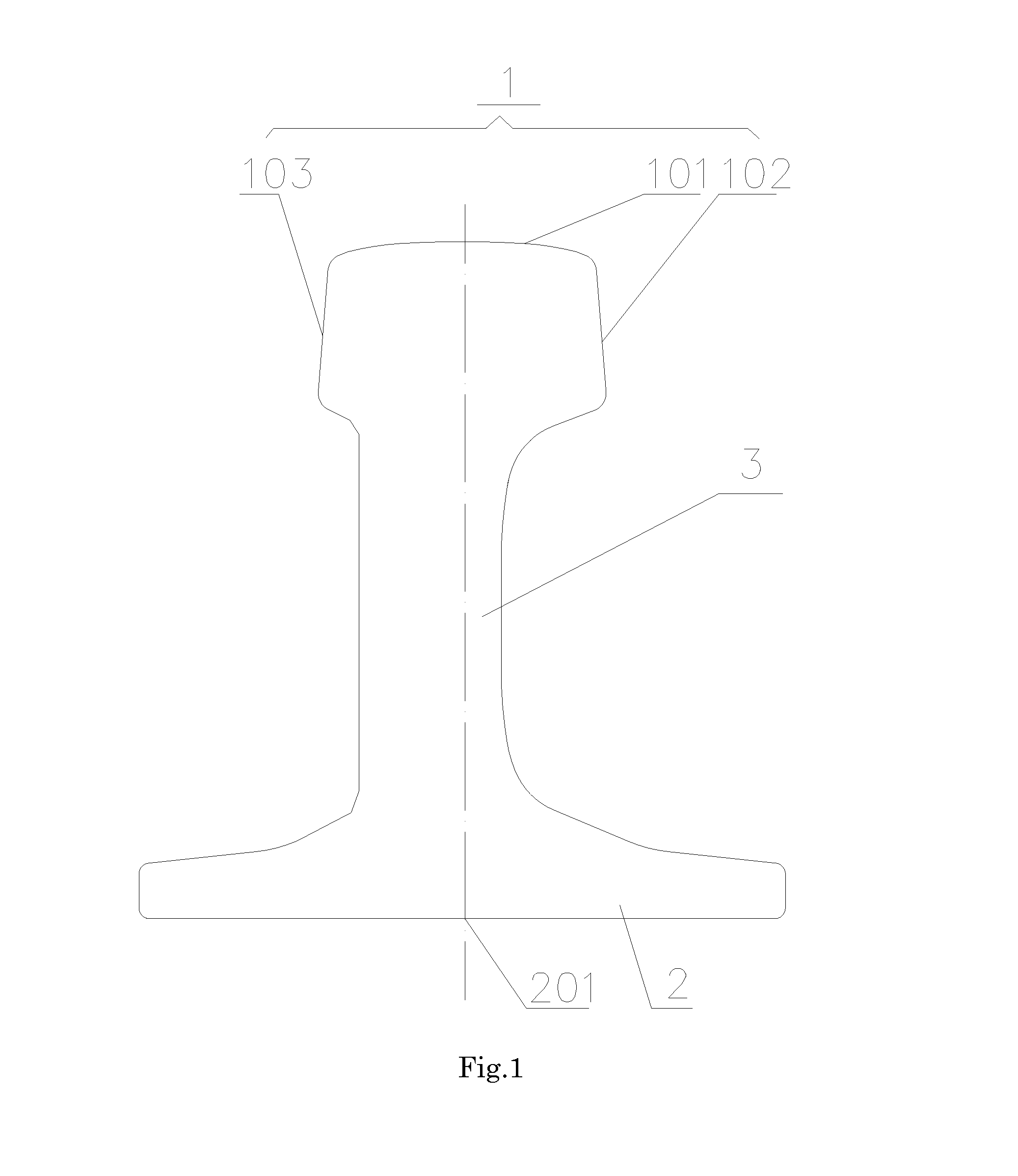

Steel rail for high speed and quasi-high speed railways and method of manufacturing the same

InactiveUS20130193223A1Excellent rolling contact fatigue propertyToughnessRailsMetal rolling stand detailsRare-earth elementRolling contact fatigue

The present discloses a steel rail for high speed and quasi-high speed railways and a manufacturing method thereof. The steel rail having a superior rolling contact fatigue property can be obtained by reducing content of carbon in conjunction with controlled cooling after rolling. The steel rail includes 0.40-0.64% by weight of C, 0.10-1.00% by weight of Si, 0.30-1.50% by weight of Mn, less than or equal to 0.025% by weight of P, less than or equal to 0.025% by weight of S, less than or equal to 0.005% by weight of Al, more than 0 and less than or equal to 0.05% by weight of a rare earth element, more than 0 and less than or equal to 0.20% by weight of at least one of V, Cr, and Ti, and a remainder of Fe and inevitable impurities. The steel rail manufactured according to the method of the present invention maintains the strength and hardness of the existing steel rail for the high speed railways, while enhancing the toughness, plasticity and yield strength, and an energy value required for initiating and expanding microcracks formed at the surface of the steel rail due to fatigue is increased, and thus under the same conditions, the rolling contact fatigue property of the steel rail can be improved, thereby finally improving the service lifetime and the transportation safety of the steel rail.

Owner:PANZHIHUA IRON AND STEEL +1

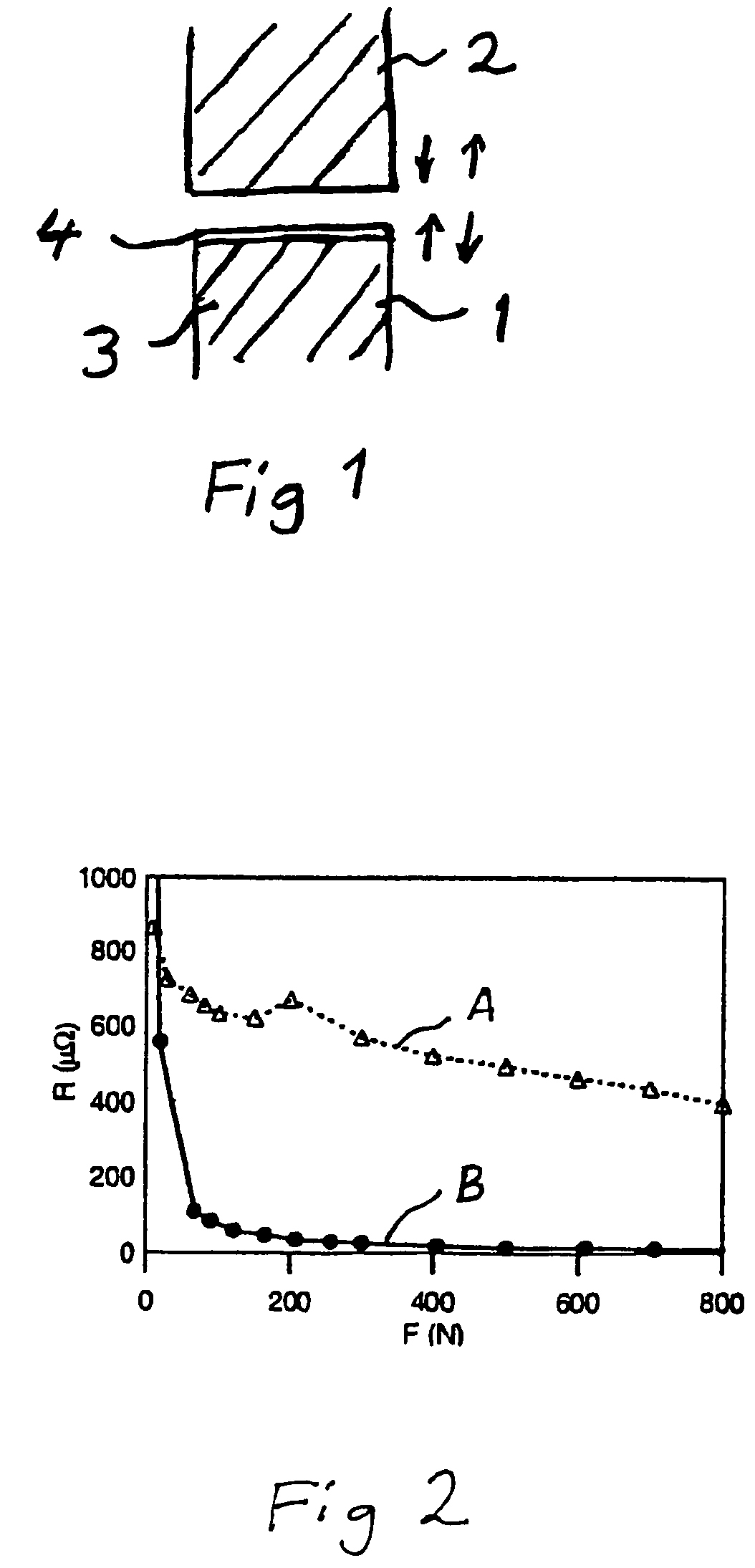

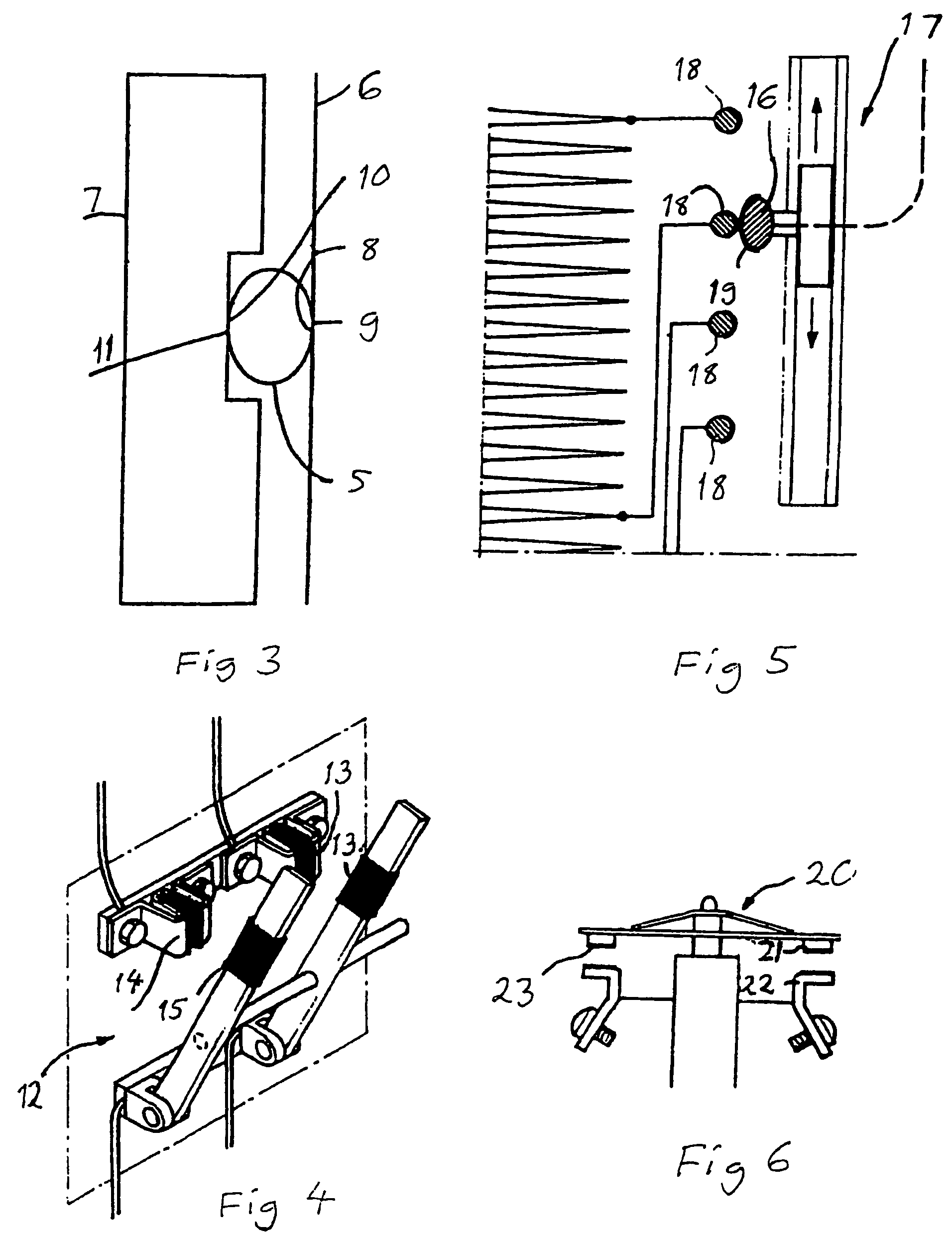

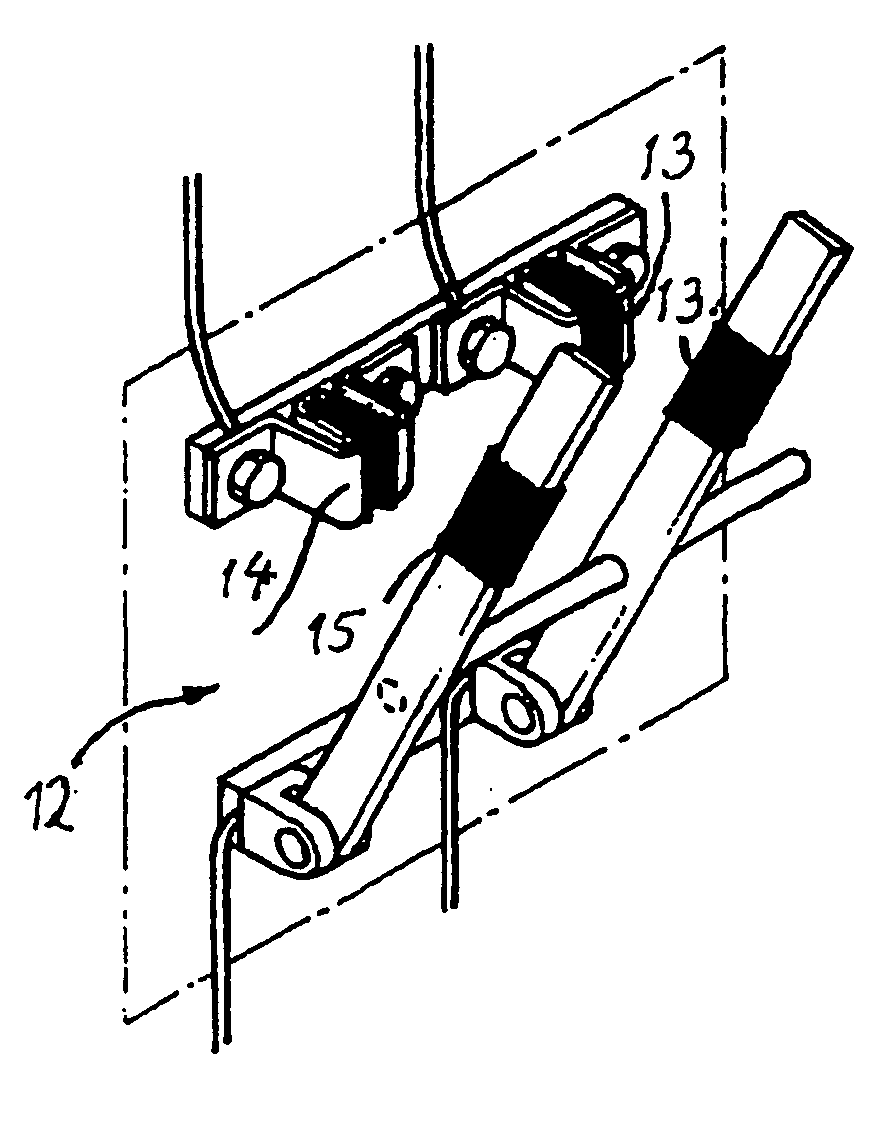

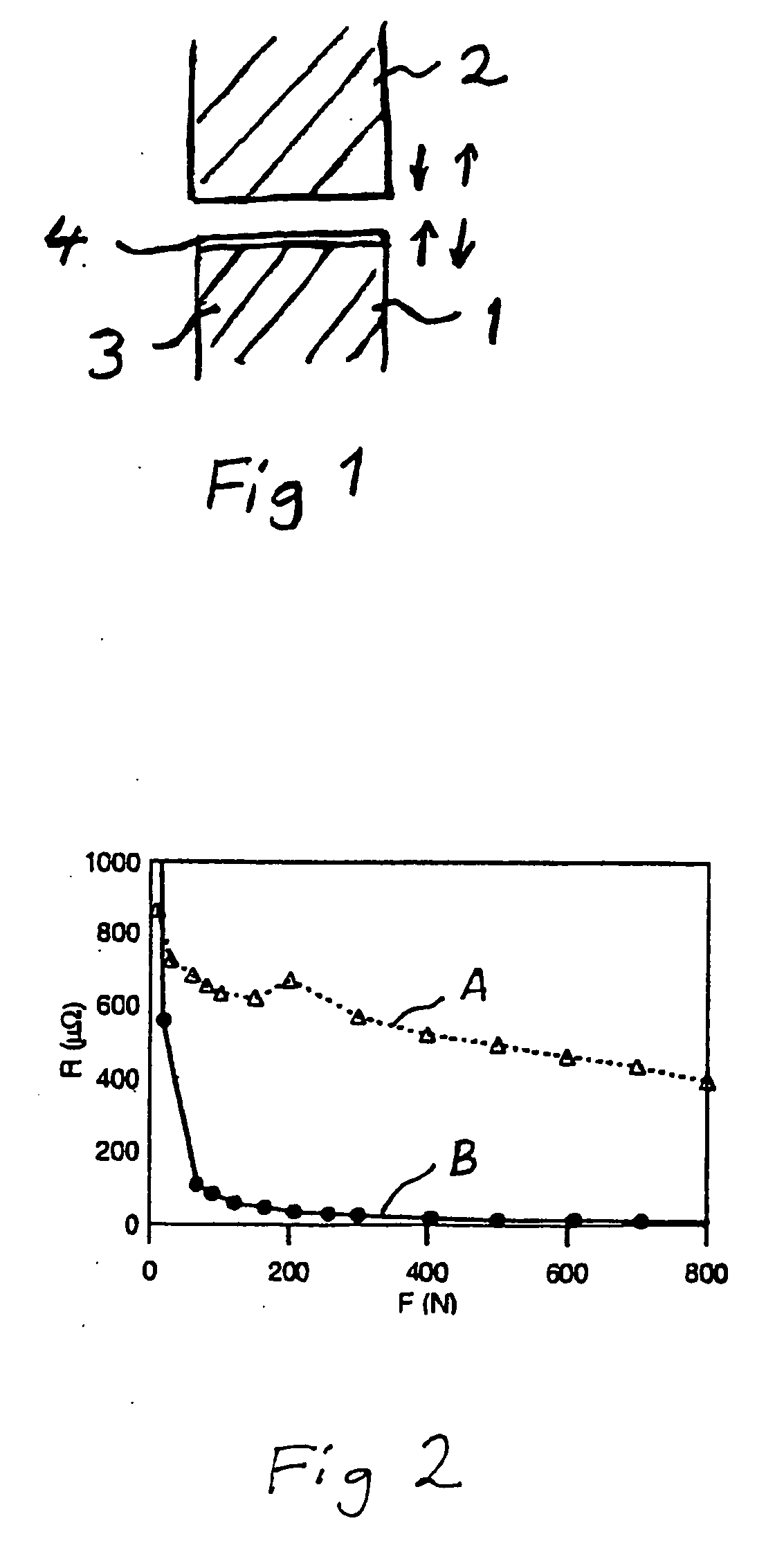

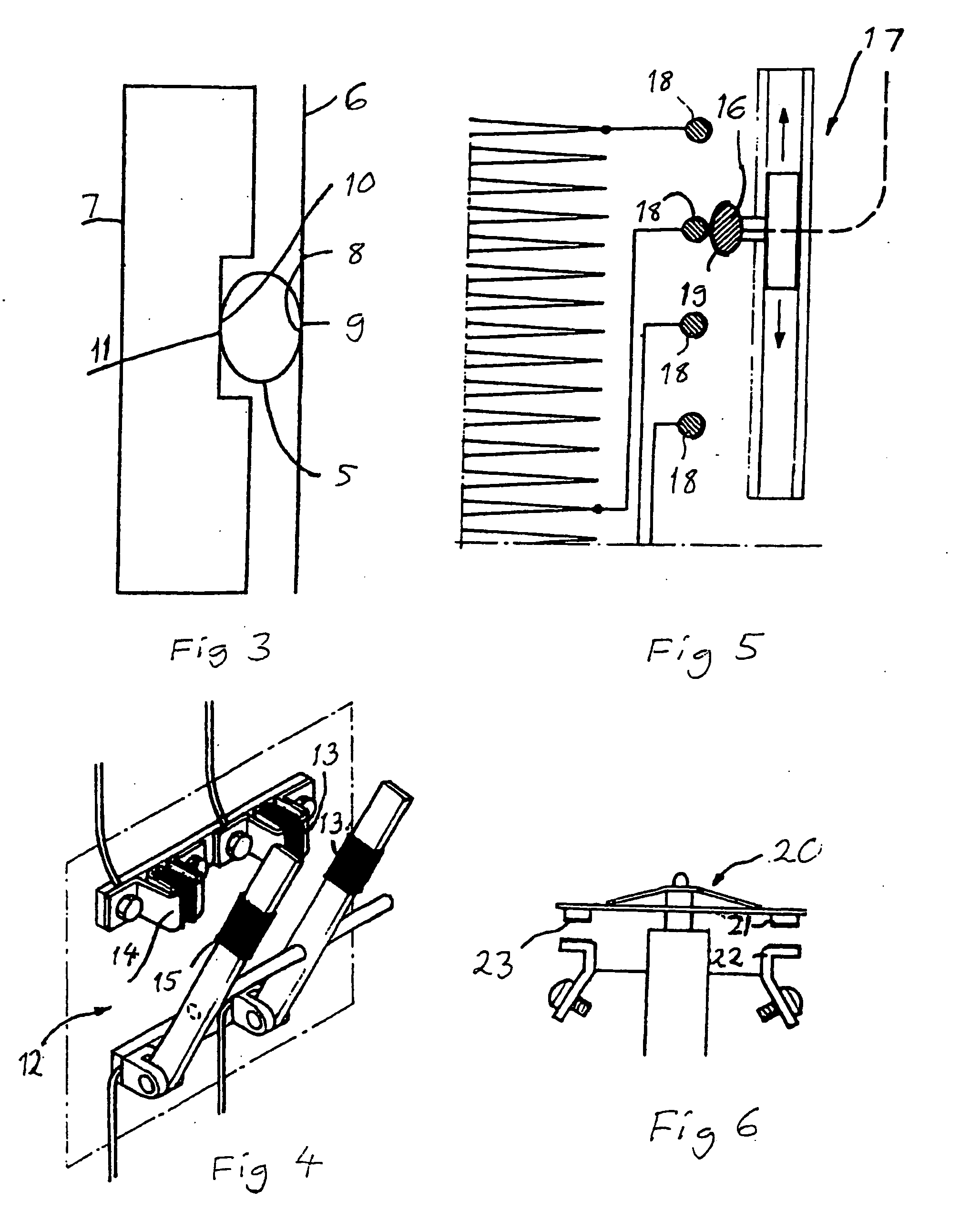

Contact element and a contact arrangement

ActiveUS7709759B2Low resistivityImprove wear resistanceMaterial nanotechnologyContact materialsCarbideContact layer

A contact element for making an electric contact to a contact member for enabling an electric current to flow between the contact element and the contact member includes a body having at least one contact surface thereof coated with a contact layer to be applied against the contact member. The contact layer includes a nanocomposite film having a matrix of amorphous carbon and crystallites of nano-size, i.e. with dimensions in the range of 1-100 nm, of at least one metal carbide embedded therein.

Owner:ABB RES LTD +1

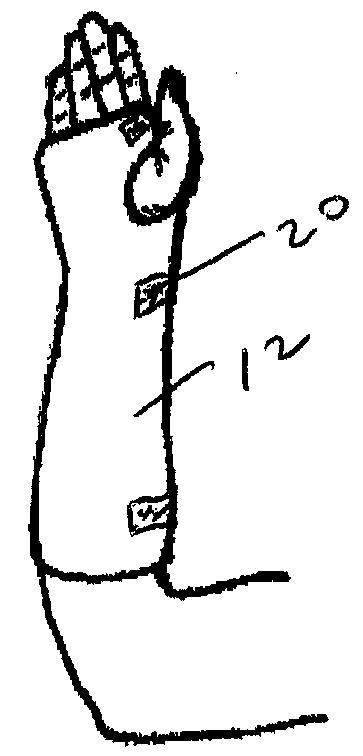

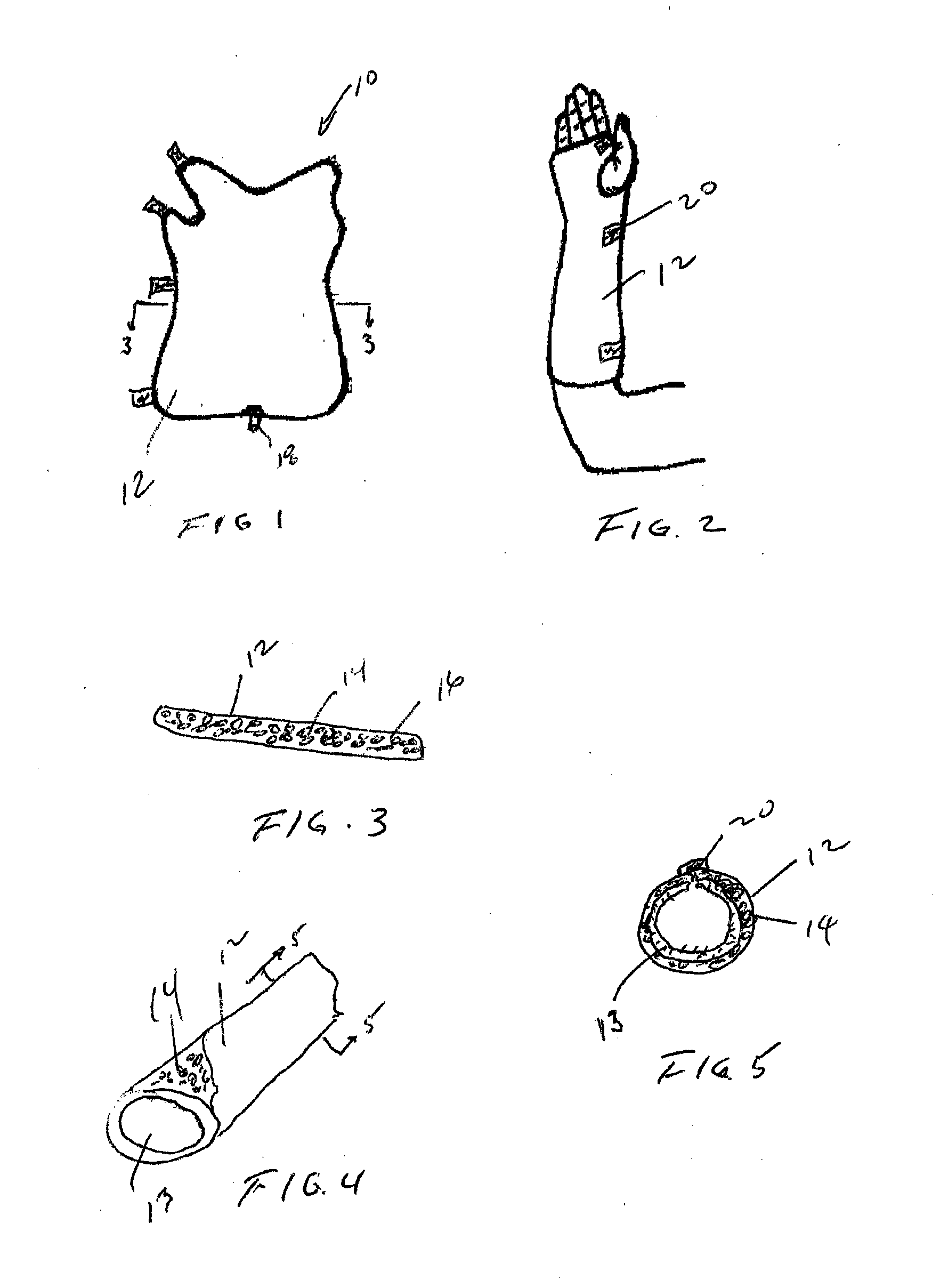

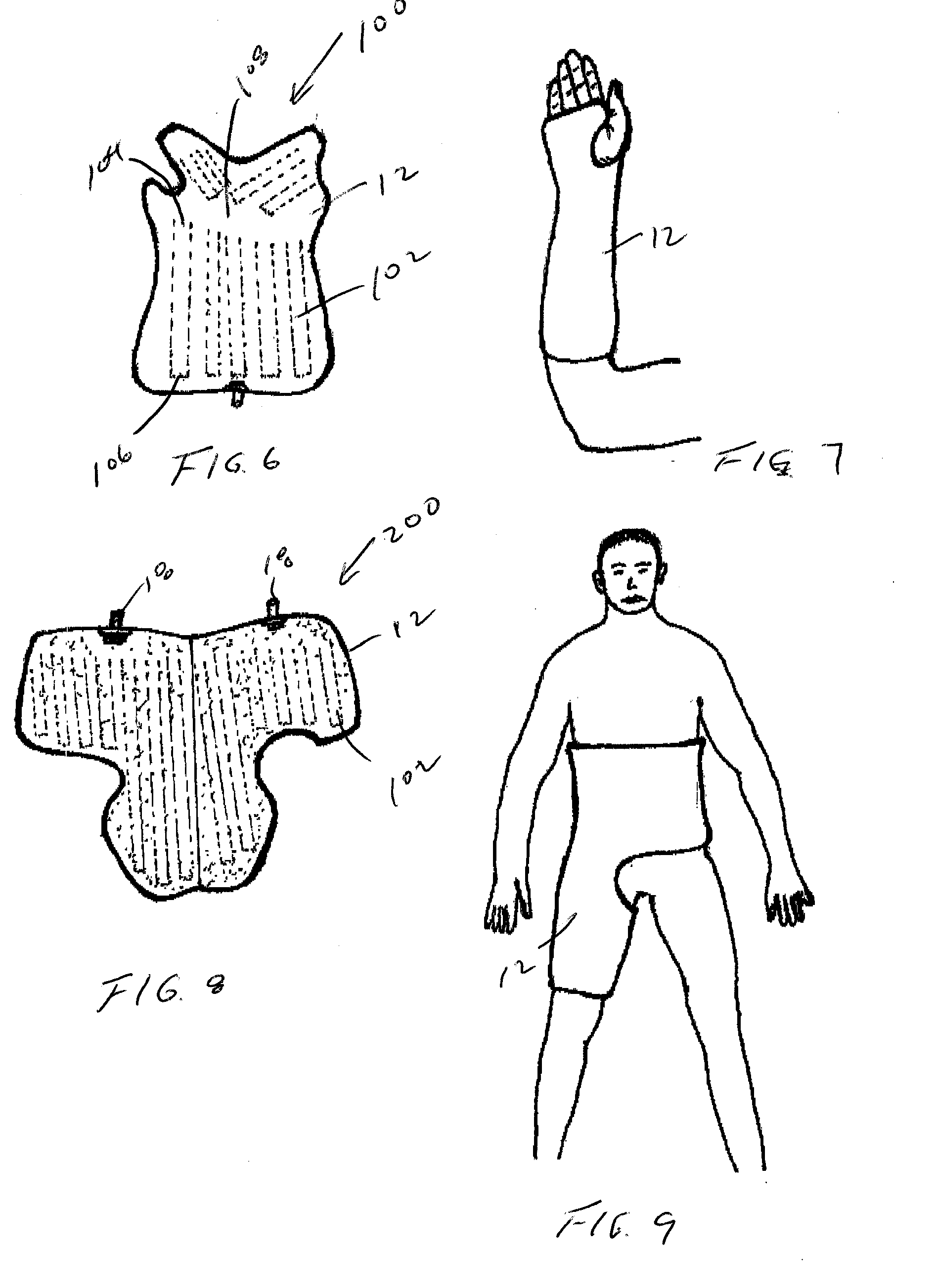

Casting Apparatus and Method for Using the Same

InactiveUS20080269653A1Easy to removeHardness andFinger bandagesPlastersSpherical granuleSpherical form

A casting or splinting device comprises a plastic casting body formed into various configurations for immobilizing a bone fracture or the like. The casting body is filled with small spherical granules having a smooth and slippery surface. The casting body is sealed and provided with an outlet port for aspirating air from within the casting body. Aspiration of air from the casting body results in a rigid casting or splint.

Owner:ZHONG BING TANG

Vinyl formula

The invention discloses a vinyl formula, comprising the following components by weight percent: PVC (polyvinyl chloride) crude powder, PVC baby powder 810, a plasticizer, hard oil TXIB, hard oil 57 degrees, heat-resistant oil ED-S, a stabilizing agent CE-116 and a release agent. The vinyl prepared by the formula disclosed by the invention is good in hardness, smooth in handfeel, strong in plasticity, good in stability, and closer to a real handle of human skin.

Owner:叶青华

Composite sheet for mounting a workpiece and the method for making the same

InactiveUS20090252949A1Reduce hardnessImprove adsorption capacityPolishing machinesRevolution surface grinding machinesHardnessEngineering

The present invention relates to a composite sheet for mounting a workpiece and a method for making the same. The composite sheet includes a buffer layer and an adsorption layer. The buffer layer has a plurality of continuous pores. The adsorption layer is located on the buffer layer for adsorbing a workpiece, and the compression ratio of the buffer layer is higher than that of the adsorption layer. Thereby, due to low hardness, good adsorption effect, and high compression ratio, the composite sheet of the present invention has good buffer effect.

Owner:SAN FANG CHEM IND

Contact Element and a Contact Arrangement

ActiveUS20090178905A1Reduce inconvenienceLow resistivityMaterial nanotechnologyContact materialsCarbideContact layer

A contact element for making an electric contact to a contact member for enabling an electric current to flow between the contact element and the contact member includes a body having at least one contact surface thereof coated with a contact layer to be applied against the contact member. The contact layer includes a nanocomposite film having a matrix of amorphous carbon and crystallites of nano-size, i.e. with dimensions in the range of 1-100 nm, of at least one metal carbide embedded therein.

Owner:ABB RES LTD +1

Polyolefin elastomer composite and foamed elastomer

A polyolefin elastomer composite includes a copolymer, an unsaturated aliphatic polyolefin, an organic peroxide, and an metallic acrylate. The copolymer is an ethylene copolymer, an olefin block copolymer, or a combination thereof. The usage ratio of the unsaturated aliphatic polyolefin and the copolymer is 1:3 to 3:1. Based on the total amount of the unsaturated aliphatic polyolefin and the copolymer as 100 parts by weight, the usage of the organic peroxide is 0.1 to 1 part by weight and the usage of the metallic acrylate is 0.1 to 5 parts by weight. The polyolefin elastomer composite can produce a foamed elastomer having high rebound resilience and low compression set.

Owner:SUNKO INK

Improved natural rubber compositions

InactiveUS20160185934A1Improve anti-aging propertiesImprove securityBridge structural detailsProtective buildings/sheltersPolymer scienceCarbon black

There is herein described improved natural rubber compositions for use in engineered rubber products for use in civil and mechanical engineering applications having nanocarbon and carbon black as reinforcing agents wherein the nanocarbon is uniformly pre-dispersed within the rubber component. In particular there is described rubber compositions comprising a mixture of natural rubber, nanocarbon and carbon black wherein the relative amount in parts per hundred rubber (pphr) of nanocarbon to carbon black is in the range of about 1:40 to about 1:2 and the relative amount in parts per hundred rubber (pphr) of nanocarbon to natural rubber is in the range of about 1:100 to about 10:100 and wherein the nanocarbon component is pre-dispersed within the natural rubber component.

Owner:AMRIL

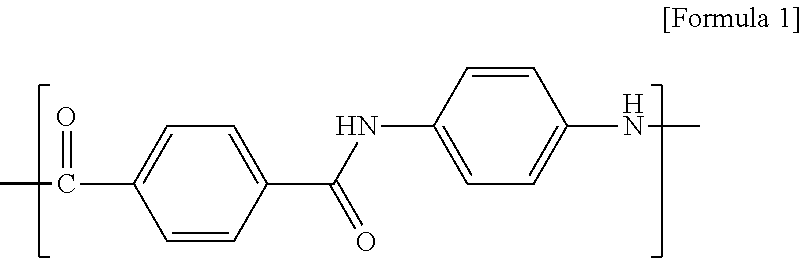

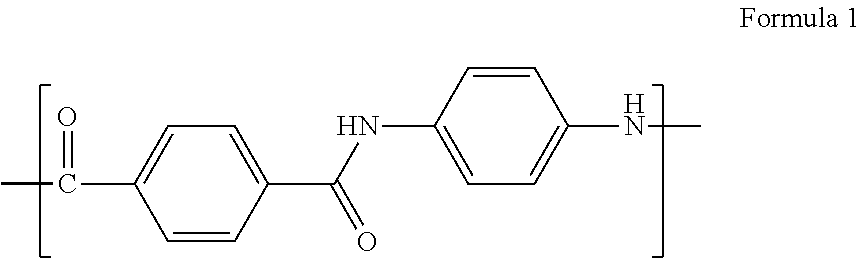

Polyoxymethylene resin composition

ActiveUS20150184110A1Improve friction and wear resistanceImprove thermal stability and tribology propertyWing fastenersAdditivesChemistryThermoplastic polyurethane

A novel polyoxymethylene resin composition is provided, which may be availably used as engineered plastics in various industrial fields and products, such as vehicle parts. The poly resin includes polyoxymethylene, aramide fibers, and thermoplastic polyurethane, thereby providing the novel composition of polyoxymethylene resin and improving various physical properties thereof, such as thermal stability.

Owner:HYUNDAI MOTOR CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com