Casting Apparatus and Method for Using the Same

a technology of casting apparatus and casting rod, which is applied in the field of casting materials, can solve the problems of irritating the skin, heavy weight, and affecting the shape of the body, and achieves the effect of more flexibility in shaping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

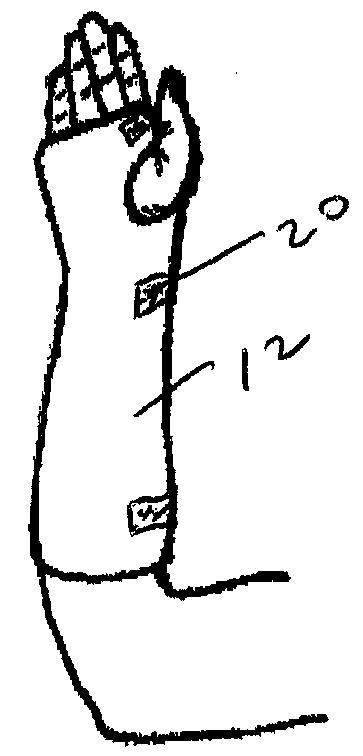

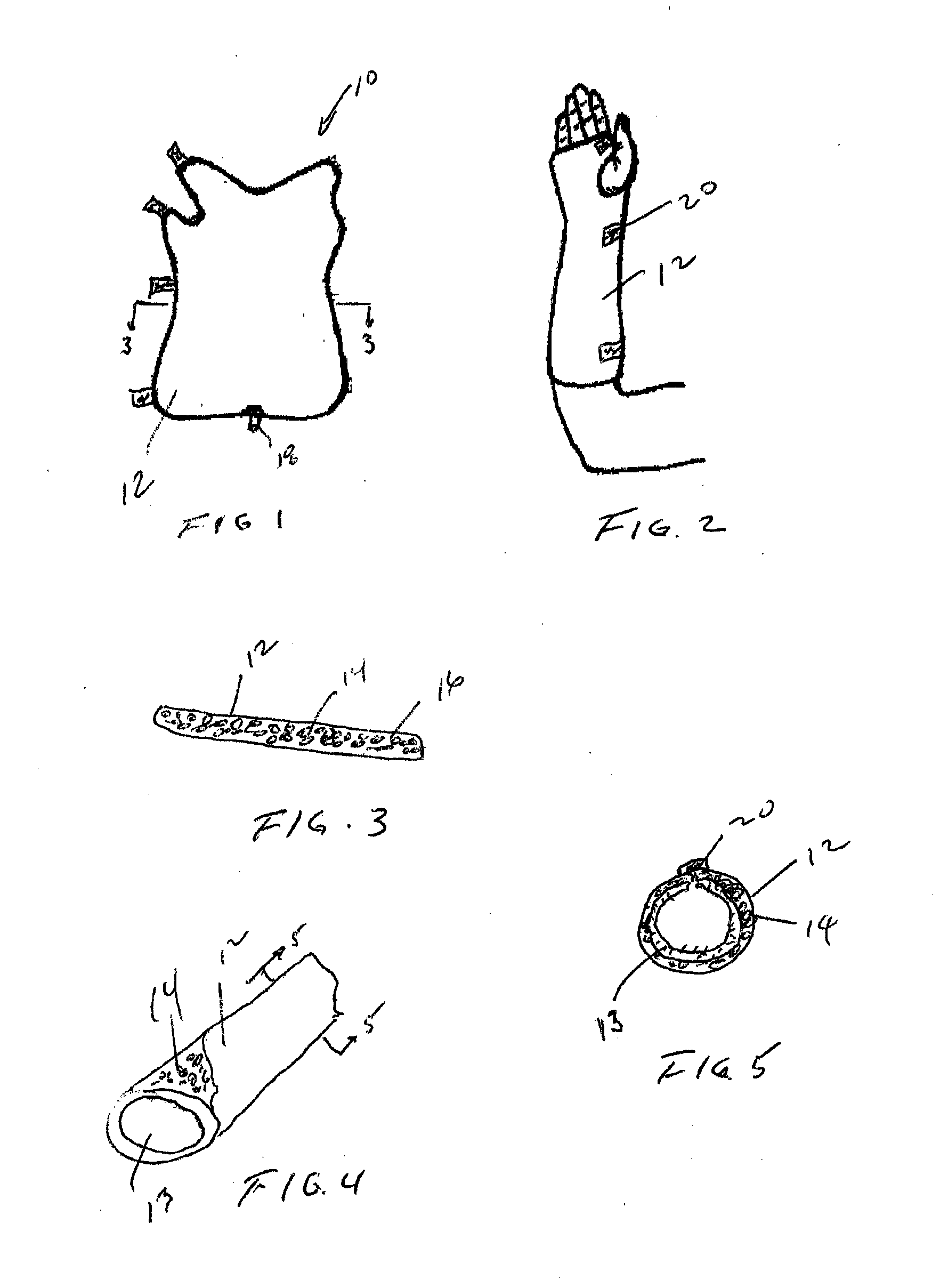

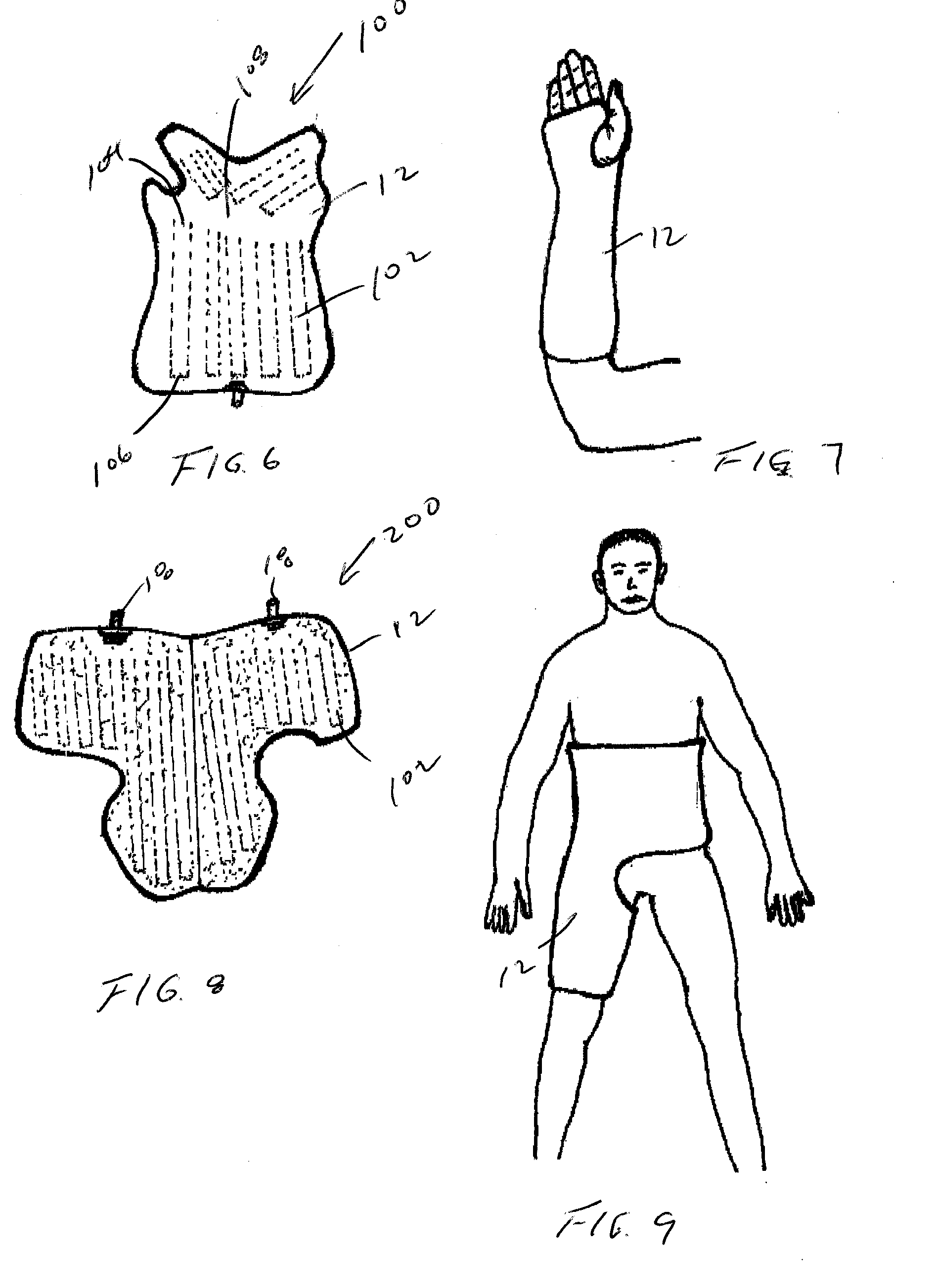

[0025]Referring first to FIG. 1, an embodiment of the invention is generally identified by the reference numeral 10. The casting apparatus 10 defines a casting body 12 adapted for application about the forearm of a patient. The casting body 12 is fabricated of a soft, air-tight plastic or latex material filled with hard spherical plastic granules 14. The granules 14 are about 1-2 mm in diameter and the surface thereof is smooth and slippery.

[0026]Referring now to FIGS. 1 and 3, the casting body 12 comprises a unitary body of plastic material that when laid flat includes substantially planar top and bottom surfaces sealed about the perimeter thereof. The top and bottom surfaces of the casting body 12 are spaced apart to form a relatively narrow longitudinal cavity 16 containing the granules 14. The surface of the casting body 12 that will contact the patient's skin is lined with a layer 13 of felt, cotton material or the like so as not to irritate the patient's skin. The casting body...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| flexible | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com