Steel rail for high speed and quasi-high speed railways and method of manufacturing the same

a high-speed, quasi-high-speed technology, applied in the direction of furnaces, heat treatment devices, roads, etc., can solve the problems of reducing the service life of the railway, affecting the safety of the running of the train, and affecting the smoothness of the rolling contact, so as to achieve excellent rolling contact fatigue properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

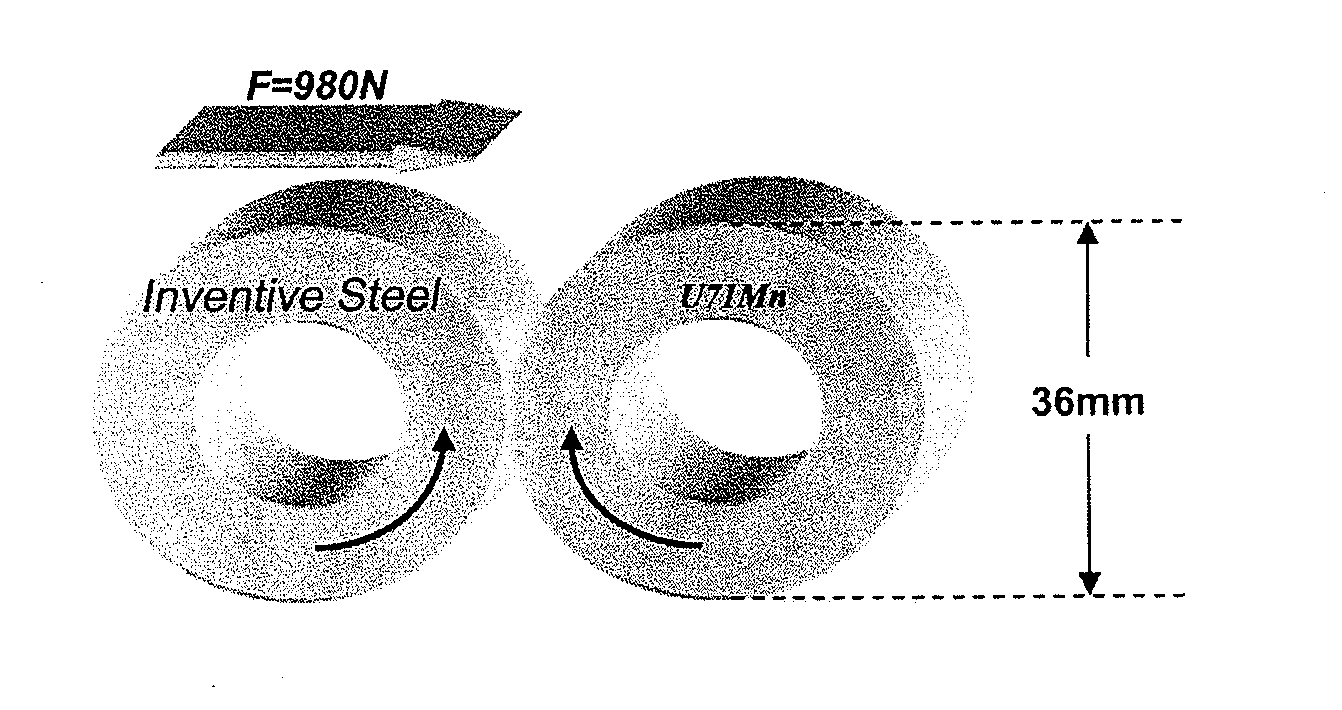

[0055]To obtain a steel rail having a composition as listed in Table 2 below, smelting by a converter, LF refining, vacuum degassing, continuous casting for billet, heating by a billet heating furnace, and rail rolling were sequentially performed, wherein the steel rail was rolled at a finishing rolling temperature of 903° C. and then was placed for 40 seconds; after that, when a temperature of a top surface of a rail head portion decreased to 800° C., compressed air began to be blown so as to uniformly cool the rail head portion at a cooling rate of 3.1° C. / s; and when the temperature of the top surface of the rail head portion reached 520° C., and temperatures of a rail waist and a rail base were respectively greater than 600° C. after blowing, the steel rail was placed in the air to be naturally cooled to a room temperature, thereby obtaining Sample 1.

example 2

[0056]Except for steps of controlled cooling after rolling, a steel rail was manufactured by using the same method as that in Example 1. Specifically, in this example, the steel rail was rolled at a finishing rolling temperature of 910° C. and then was placed for 45 seconds; after that, when a temperature of a top surface of a rail head portion decreased to 780° C., compressed air and a mixture of oil and air began to be blown so as to uniformly cool the rail head portion at a cooling rate of 2.9° C. / s; and when the temperature of the top surface of the rail head portion reached 514° C., and temperatures of a rail waist and a rail base were respectively greater than 600° C. after blowing, the steel rail was placed in the air to be naturally cooled to a room temperature, thereby obtaining Sample 2.

example 3

[0057]Except for steps of controlled cooling after rolling, a steel rail was manufactured by using the same method as that in Example 1. Specifically, in this example, the steel rail was rolled at a finishing rolling temperature of 900° C. and then was placed for 42 seconds; after that, when a temperature of a top surface of a rail head portion decreased to 770° C., a mixture of oil and air began to be blown so as to uniformly cool the rail head portion at a cooling rate of 2.7° C. / s; and when the temperature of the top surface of the rail head portion reached to 530° C., and temperatures of a rail waist and a rail base were respectively greater than 600° C. after blowing, the steel rail was placed in the air to be naturally cooled to a room temperature, thereby obtaining Sample 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com